ELSAN Elektrik San VEMS 80-2-77 Troubleshooting guide

CONTENTS

CONTENTS…………………………………………………………..…. 1

1. GENERAL INFORMATION

1.1. Working Conditions ……………………………………………. 2

1.2. Transportation…………………………………………………….. 2

1.3. Storage………………………………………………………………… 3

1.4. Safety ……………………………………………….………………… 3

2. SETUP AND OPERATION

2.1. Setup ……………………………………………….…………………. 4

2.2. Insulation Resistance

…………………..……………………. 4

2.3. Vibration Generation Methods ………….………………. 5

2.3.1. Circular Method ……………………………………… 5

2.3.2. Single Direction Method ……...……………….. 5

2.4. Setting the Centrifugal Force…….……………….……. 5-6

2.5. First Start and Running…………….……………………….. 7

2.6. Rotation Direction ……………………………………………… 7-8

2.7. Final Check ………………………………………………………… 8

3. MAINTENANCE

3.1. Cleaning ……………………………………………………………… 9

3.2. Bearings ……………………..……………………………………… 9

3.2.1. Lubrication of Bearings ……….………….……… 9

3.2.2. Bearing Replacement

…….…………..……….... 11

3.3. Sealing Component ……………………...…………………… 11

4. FAULTS, REASONS, AND SOLVINGS

4.1. Tables of Troubleshooting .…………..…………………. 12-14

5. IDENTIFICATION AND MARKING

5.1. Vibration Motor Identification Plate ………………….. 15

5.2. Description of the sections on the plate …………… 15

6. COMPONENT OF VIBRATOR

6.1. Part Mapping With Section View .…………………..… 16

6.2. Bill of Material of Vibration Motor………………………… 17

7. OTHER INFORMATIONS

7.1. List of the Related Standards ………………………… 18

7.2. Figure – Table Indexes.……………………………………. 19

7.3. Authorized Services List …………………………..………. Back

cover

2

1. GENERAL INFORMATION

This operation and maintenance instruction includes low voltage, totally enclosed, cage rotor

asynchronous vibration motors manufactured in accordance with TS / EN norms.

This operation and maintenance instruction may not contain specific information about specific

applications and areas. In this case, the user must make appropriate protection arrangements during the

installation.

The following points should be considered for the matters not mentioned in this instruction,

1. Technical data given in the catalog and on the name plate

2. Information about the facility to use the vibration motor

3. Protective measures according to where the vibration motor will be used

Our vibration motors are 2 (TWO) YEAR WARRANTY. But; vibration motors not operated under

the conditions specified in this instruction, catalog, and name plate or not having the necessary

protection schemes in accordance with TS 10316 - EN 60204-1 are excluded from the warranty.

The structural changes to be made on the parts and repair and maintenance operations by

unauthorized personnel shall cause the vibration motor to be excluded from the warranty.

Bearings used in vibration motors are not guaranteed by the bearing manufacturer.

1.1. OPERATING CONDITIONS

Standard vibration motors, designed to operate at rated voltage and frequency (380 V, 50 Hz), -15 ÷

+40 °C ambient temperature and at sea level up to 1000 m.

Standard vibration motors within the scope of this operation and maintenance instruction are totally

enclosed, non-ventilated, and IP55 protection class. Measures should be taken for the vibration motors which

operating outdoors to protect against rain, snow, dust etc.

1.2. TRANSPORTING

80 and 90 frame motors have a lifting eye and bigger frames have lifting holes.

3

If the vibration motor has to be lifted together with additional loads, such as the chassis or the

driven machine; the additional loads must be lifted by their own system.

Vibration motors should never be placed on the fan covers and they should not be transported

and stored in this way.

1.3. STORAGE

The vibration motor must be checked visually if it is damaged or not during transportation. If the vibration

motor is to be stored for a long time, it must be kept a place which is clean, free of moisture and vibration.

1.4. SAFETY

Vibrating motors are connected to the power supply network and are rotated by magnetic induction. When

they transported, installed, used and maintained according to this operation and maintenance instruction, it

does not endanger any life

Vibration motors are industrial products. In this regard, the installation process must be carried

out by experienced and qualified personnel. Vibration motors are manufactured by taking

precautions against earth leakage and / or static electricity.

1. GENERAL INFORMATION

4

2. SETUP AND OPERATION_______________________

2.1. SETUP

During the stage of setting up the vibration motor, it should be taken into consideration that the

vibration motor can be easily reached during maintenance and repair times.

Vibration motors to work outside; The sun's rays should not come directly into the vibration

motor.

During normal operation, the vibration motor body may become too hot to touch. Therefore, the

vibration motor must not be touched.

2.2. INSULATION RESISTANCE

In case of vibration motors to be used after a long storage or waiting period, the insulation resistance

of the windings must be measured before commissioning. In the insulation resistance measurement process,

DC 500V is applied to the windings with insulation resistance measuring device (megaohmmeter) and the

resistance is read at the end of one minute.

Insulation resistance value measured at 25 ° C; 10 MΩ’ in a new vibration motor and 1 MΩ in a vibration

motor that has worked for a period of time.

If the measured insulation resistance value is below the limit values; winding must be cleaned and dried.

If the insulation resistance value is still low, the windings must be dried. Drying can be done in an oven or

with a heat gun. (heat gun temperature is 80 ° C)

Using DC voltage with the help of a transformer, drying can be achieved by applying a current not

exceeding 10% of the rated voltage and 20% of the rated current to the terminals U1 and V1 of the winding.

The insulation resistance must be checked again after the vibration motor has cooled down.

Do not touch the terminals during and after the measurement due to high voltage. After

measurement, the windings must be discharged immediately.

5

2. SETUP AND OPERATION

2.3. VIBRATION GENERATION METHOD

There are basically two vibration generation methods

2.3.1. Circular Method

In this method, vibration force is obtained in a circular direction in 360 ° clockwise and counterclockwise

using a vibration motor.

(Figure-1.a).

2.3.2. Single Direction Method

In this method, vibration forces are obtained in only one direction and sine curve by using two vibration

motors.(Figure-1.b).

a. Circular Method

b. Single Direction Method

Figure-1. Vibration generation methods

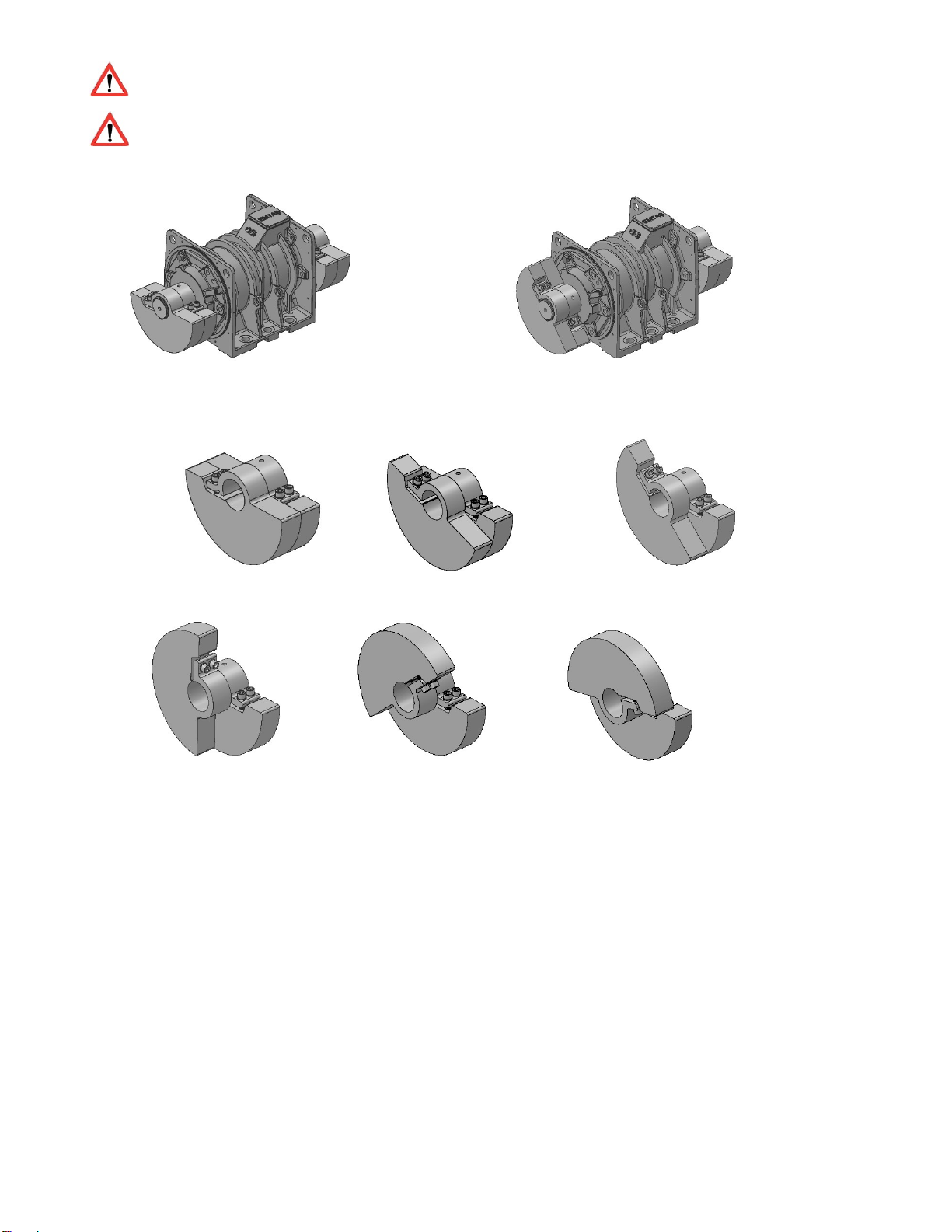

2.4. SETTING THE CENTRIFUGAL FORCE

Vibration motors are vibrated with eccentric hammers on both sides of the motor. A total of four eccentric

hammers are available in a vibration motor with two fixed and two adjustable.

Our vibration motors are shipped with the eccentric hammers set to step 3 (85%).

The vibration force is increased or decreased by changing the positions of the tuned hammers. As the

angle between the fixed and tuned hammers increases, the vibration force decreases.

To adjust the vibration force:

Remove the safety cover on both sides of the vibration motor.

Loosen the bolts on the adjustable (outside) hammers.

Rotate the adjustable hammers over the shaft to set them to the appropriate setting for your system.

Tighten the bolts on the adjustable hammers.

Install the safety cover on both sides of the vibration motor by checking that the sealing piece (oring)

between the vibration motor cover and the safety cover is properly installed.

6

2. SETUP AND OPERATION

The vibration motors must not be operated when the safety cover on both sides of the motor is

not installed.

The position of the hammers on both sides of the vibration motor, must be the same (parallel).

If the adjustment is made in a different direction, the position of the hammers on both sides is

not the same (parallel), the vibration motor shaft, the vibration motor mounting bolts and / or

the chassis to which the vibration motor is connected are damaged.

True False

Şekil-2. Setting the centrifugal force

1. Level (% 100) 2. Level (% 95) 3. Level (% 85)

4. Level (% 70)

5. Level (% 50)

6. Level (% 30)

Figure-3. Setting level of centrifugal force

7

2. SETUP AND OPERATION

2.5. FIRST START AND RUNNING

Our vibration motors are manufactured as standard only for direct starting. For this reason, our

vibration motors have 3 pole outputs in the terminal boxes.

The suitability of the network that will feed the vibration motor to the vibration motor plate

information must be checked and the supply cables should be selected according to these values. If the voltage

difference is greater than ± 5%, the vibration motor windings may be damaged.

Check the tightness of the nuts at the terminals. Loosely nuts cause the vibration motor to

malfunction.

The user has the responsibility to protect the vibration motor against overload. The vibration

motor must be connected to the mains via a thermal-magnetic switch which is capable of

protection against overcurrents. The current setting of the switch must not be more than 1.05

times the rated current of the vibration motor. Otherwise, the vibration motor is not covered by

the warranty.

Overload protection will only be possible by sensing excessive heat caused by overload and other

reasons (two phases, excessive ambient temperature or altitude, excessive starting stop, etc.). Install a

thermistor in the winding and to connect the terminals coming from the thermistor to the thermistor relay is

necessary for overload protection.

PTC thermistors are mounted as standard on 132, 160, 180 and 200 types of vibration motors and

Phase Protection Relay is given as free of charge. On request, our smaller vibration motors are supplied with

a thermistor and are supplied with a relay.

Vibration motors of type 132, 160, 180 and 200 should be used with thermistors. Otherwise, the

warranty terms will be invalid.

2.6. ROTATION DIRECTION

Our vibration motors are designed to operate in both directions. The rotation direction of the vibration

motor can be changed by replacing any two of the mains phases in the connection diagram L1, L2 and L3.

8

2. SETUP AND OPERATION

Şekil-4. Running Diagram

2.7. FINAL CHECK

If the mechanical and electrical connections of the vibration motor are technically

appropriate, it shall be appropriate to start the operation after the following checks.

1. The operating conditions must be compatible with the vibration motor plate. (3~380V %5, 50Hz

%2)

2. If the vibration motors are not used for a long time, the insulation resistance values must be sufficient.

3. All mechanical and electrical connections must be tight.

4. The moving and energized parts must be fully protected against touching.

5. The position of the hammers on both sides of the vibration motor must be the same (parallel).

When the vibration motor is being serviced, the vibration motor must not be connected to the

mains power (no power) and must be de-energized in the auxiliary circuits (heater etc.).

9

3. MAINTENANCE

3.1. CLEANING

Before and after work, dust accumulated on the body should be cleaned.

3.2. BEARINGS

Vibration motors are equipped with long-life bearings that can carry axial, radial and combined loads without

problems.

3.2.1. Lubrication of bearings

Vibration motors are equipped with lubricating nipples and oil drain channels. The grease type and lubrication

range are indicated on the vibration motor plate.

In order not to deteriorate the chemical and physical properties of the greases, different types

of greases should never be mixed. When lubricating, be sure to use the type of grease indicated

on the vibration motor plate.

In the case of initial lubrication, no grease should be expected from the discharge duct. After

several lubrication, dirty grease will appear in the discharge duct.

For re-lubricating bearings;

Remove the grease drain plug

Clean the dirty grease on the drain and make sure the drain is open.

Clean the grease nipple and the tip of the grease gun.

Pump up to half the grease of the quantity indicated in the table on page -11.

Operate the vibration motor at full speed for several minutes.

When the vibration motor stops, pump the remaining grease into the bearing.

Install the grease drain plug.

Lubrication hours (operating hours) and grease quantities (gr) for vibration motors with lubricating

nipples are given in Table-1.

10

3. MAINTENANCE

VIBRATION MOTOR / BALL- ROLLER (63/64 SERIES - NJ TYPE)

BEARINGS

VIBRATION MOTOR

TYPE 2 Pole 4 Pole 6 Pole 10 Pole

VEMS 80-2-77 0,7 kW 2.000 4 - - -

VEMS 80-4-47 0,37 kW - 3.300 5 - -

VEMS 90-2-116 1,7 kW 1.750 7 - - -

VEMS 90-4-117 0,55 kW - 2.800 10

- -

VEMS 90-4-159 0,75 kW - - -

VEMS 90-4-181 1,1 kW - 2.700 12

- -

VEMS 90-6-108 1,1 kW - - 3.500

10

-

VEMS 100-4-242

1,5 kW - 2.250 18

- -

VEMS 100-4-282

2,0 kW - - -

VEMS 100-10-80

0,2 kW - - - 5.000 1

0

VEMS 112-2-210

2 kW 1.150 15

- - -

VEMS 112-4-327

2,2 kW - 2.250 15

- -

VEMS 112-4-413

2,4 kW - 2.100 26

- -

VEMS 112-4-456

3,2 kW - - -

VEMS 112-6-145

1,5 kW - - 2.900

15

-

VEMS 112-6-202

2 kW - - -

VEMS 132-2-530

4 kW 900 22

- - -

VEMS 132-4-551

3,5 kW - 2.000 34

- -

VEMS 132-6-416

3,2 kW - - 2.800

23

-

VEMS 160-4-736

5,8 kW - 1.700 44

- -

VEMS 160-6-583

4 kW - - 2.500

38 -

VEMS 160-6-705

4,5 kW - - -

VEMS 160-6-881

7,5 kW - - 2.400

54

-

VEMS 160-6-981

8,0 kW - - -

VEMS 180-6-130

9,2 kW - - 2.300

78

-

VEMS 180-6-136

11 kW - - -

VEMS 200-6-137

11,2 kW - - 2.300

78

-

VEMS 200-6-153

12,5 kW - - 2.100

96

-

VEMS 200-6-181

15 kW - - -

Table-1. Lubrication Interval of Bearings

[Operating Hours] and Grease Amounts [gr]

The values in the table are calculated for the bearing temperature of 100 ° C.

11

3. MAINTENANCE

Refer to the vibration motor plate for current bearing and lubrication information.

3.2.2. Bearing Replacement

Dismantling of bearings:

Roller bearings: The inner ring must be heated with flame and removed by means of a puller. If not,

the inner ring should be turned and refuted.

Ball Bearings: After the inner ring has been heated slightly, it should be removed by using puller.

Never use hammer.

Mounting of bearings:

The inner rings of the ball bearings and roller bearings must be heated to an average temperature of

80 ° C in the induction heater or in the oil bath (open bearings only). The heated bearing can be easily

installed on the shaft.

When the bearings are mounted on the shaft, impacts from the outer ring must not be applied. Instead,

light impacts can be applied to the ring-type tools and the bearing inner ring made of the shaft diameter.

When attaching the vibration motor bearing covers, suitable tools should be used with the cover

diameter.

To replace the bearings, the rotor and shaft assembly must be removed. During this time, the

stator windings must be observed and the windings must be protected.

A bearing must not be unpacked until it is installed. They must be protected from dirty and dusty

environments.

3.3. SEALING COMPONENTS

The sealing components (eg oring) between the vibration motor cover and the housing must be

correctly seated in the housing. Damage must be prevented when adjusting the vibration force.

Oil seals with 112 and 132 types and 160 types of vibration motors (excluding 7,5 kW - 1000 1 /

min) must be fitted with suitable tools.

The sealing components can be lubricated with machine oil before assembly. The sealing components

must be installed in the correct axis to the mounting locations. When they are not fitted on the right axis, they

cause excessive friction.

12

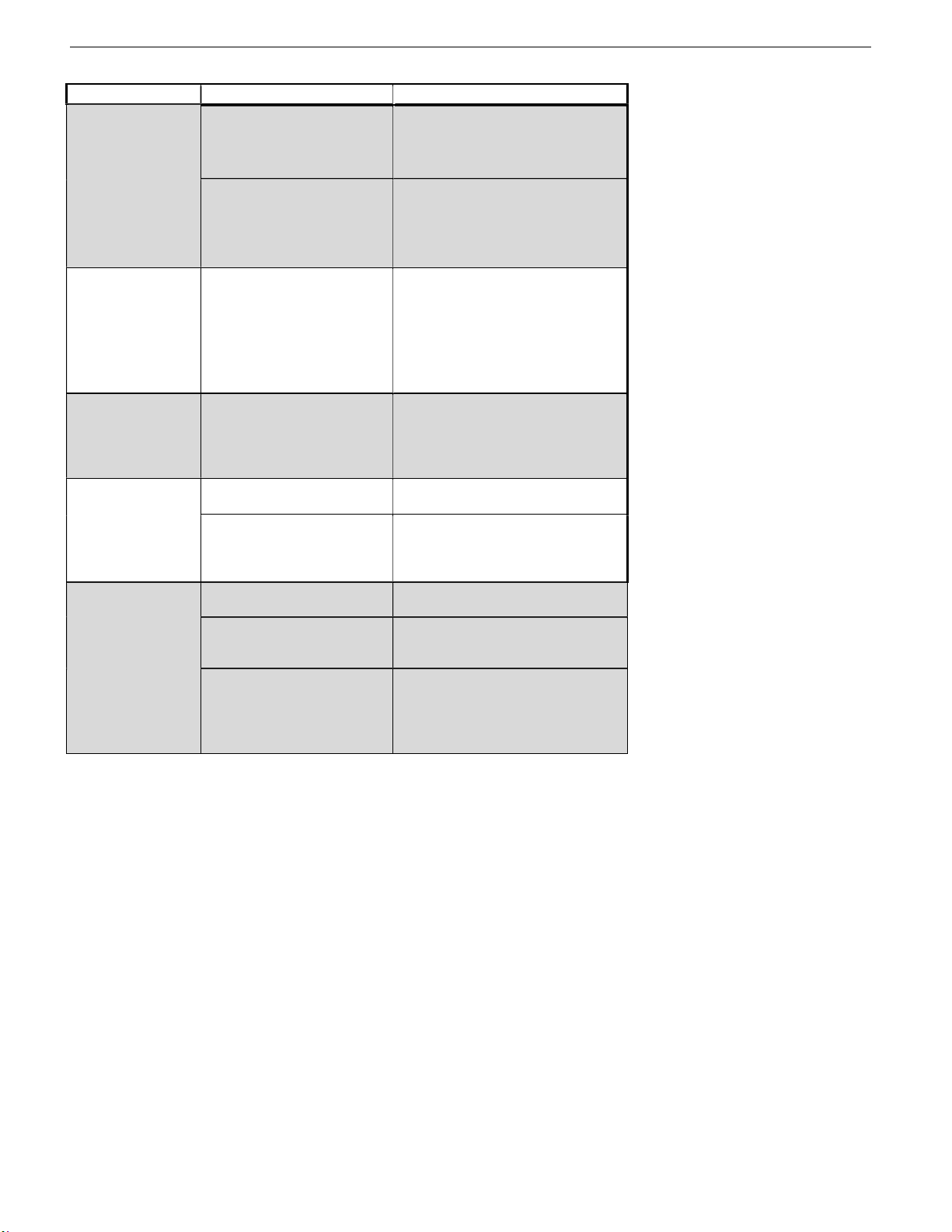

4. TROUBLESHOOTING

4.1. MALFUNCTION OF VIBRATION MOTOR

FAULTS

REASONS SOLVINGS

The vibration motor

does not rotate

under voltage,

there is no sound

from the vibration

motor.

Fault in control circuit

(panel).

Check terminal ends, if there

is no power, check the board

for faults.

There is no energy in at

least two phases. In the

control with the test

light, energy is seen.

However, there is no

value in the voltmeter.

Check fuses, cables, and the

relevant screws and

terminals (Deactivate the

vibration motor during

replacement of defective

fuses).

The thermal relay or

thermistor phase

protection relay has

deactivated the

vibration motor.

Check the thermic relay,

thermistor and thermistor

relay

The ground mounting

bolts are loose.

Tighten the bolts.

The vibration motor

does not rotate

under voltage and

has excessive

magnetic sound.

There is no energy in

one of the phases.

Find the non-energized

phase, replace the relevant

fuse.

The counter torque is

too big.

Check and rearrange the

system, run the vibration

motor with no load.

The vibration motor

is not working

under load. But the

magnetic sound is

normal.

The mains voltage is

low.

Measure the voltage.

The vibration motor

is

overheating when

running without

load.

Mains voltage is high.

Measure the mains voltage

and the no load current.

Table-2 - Troubleshooting

13

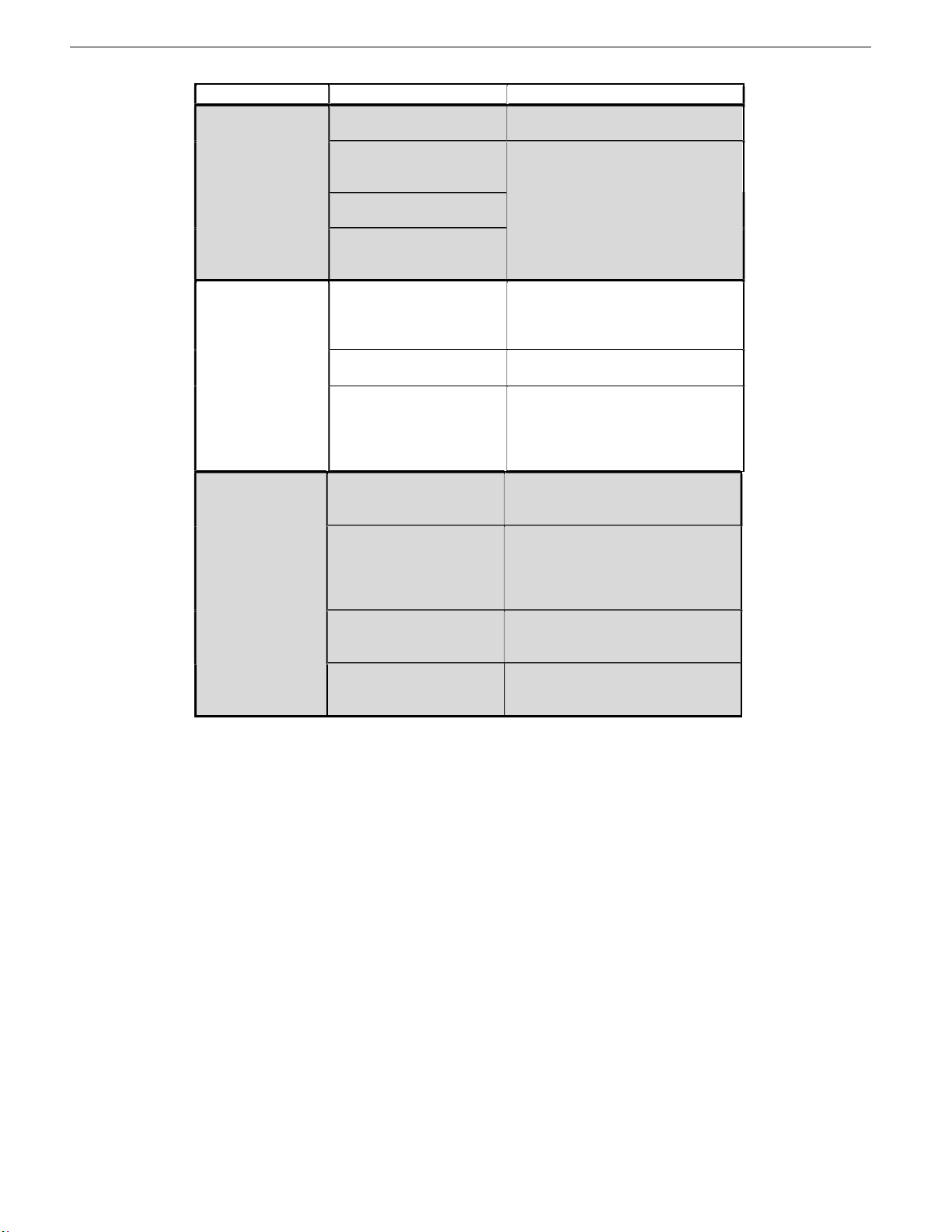

4. TROUBLESHOOTING

4.1. MALFUNCTION OF VIBRATION MOTOR

FAULTS

REASONS SOLVINGS

The vibration

motor works fine

while unloaded.

The speed of the

vibration motor is

extremely low

under load.

One of the phases is die

after the vibration motor

has started running.

Control the voltage on each

phase

Rotor short-circuit bars

are broken, ampermeter

reads irregular currents.

Contact an authorized service

center.

The current and

temperature

values exceed

the normal

values when the

vibration motor is

running.

Vibration motor

overloaded.

Check the current.

The vibration

motor is warm

when it is

running without

load.

Mains voltage is

high.

Measure the mains voltage

and the no-load current.

The vibration

motor stops for

a certain

period of time.

Vibration motor

overloaded.

Do not overload the motor.

The thermic relay is

not correctly set or

thermistor device

active

Correct the thermic relay

setting.

The vibration

motor is

running

extremely loud.

The chassis mounting

bolts are loose. Tighten the bolts.

The welded assembly

of the machine are

broken.

Repair the assembly

connections.

The eccentric hammer

adjustment of the

vibration motor is

distorted.

Adjust the eccentric

hammers of the vibration

motor so that they are at

the same angle on both

sides.

Table-2 - Troubleshooting

14

4. TROUBLESHOOTING

4.1. MALFUNCTION OF VIBRATION MOTOR

FAULTS

REASONS SOLVINGS

The phase

currents are

extremely

different.

Phase voltages are

different. Check the voltage.

The mains voltage or

the windings are

disconnected. Check mains voltage and

windings.

Stator winding

touches the ground.

There is a short

circuit in the

stator windings.

The bearing is

deteriorating

very quickly.

Bearing overloading.

Check the system.

Eliminate excessive radial

and axial forces, if any.

Lubrication problem.

Take care to lubricate.

The eccentric hammer

adjustment of the

vibration motor is

distorted.

Adjust the eccentric hammers of

the vibration motor so that they

are at the same angle on both

sides.

The bearings

have

overheated

after a long

period of

operation.

Grease

lubricated

bearings have

a whistling

sound

.

No oil in the

bearing.

Lubricate the bearing,

replace if necessary.

Sealing of the

bearing covers (such

as seals and seals)

is damaged.

Replace the bearing,

contact service if

necessary.

Bearing is running

dry

.

Take care to lubricate.

Error in the bearing

cage.

Replace the bearing.

Table-2 - Troubleshooting

15

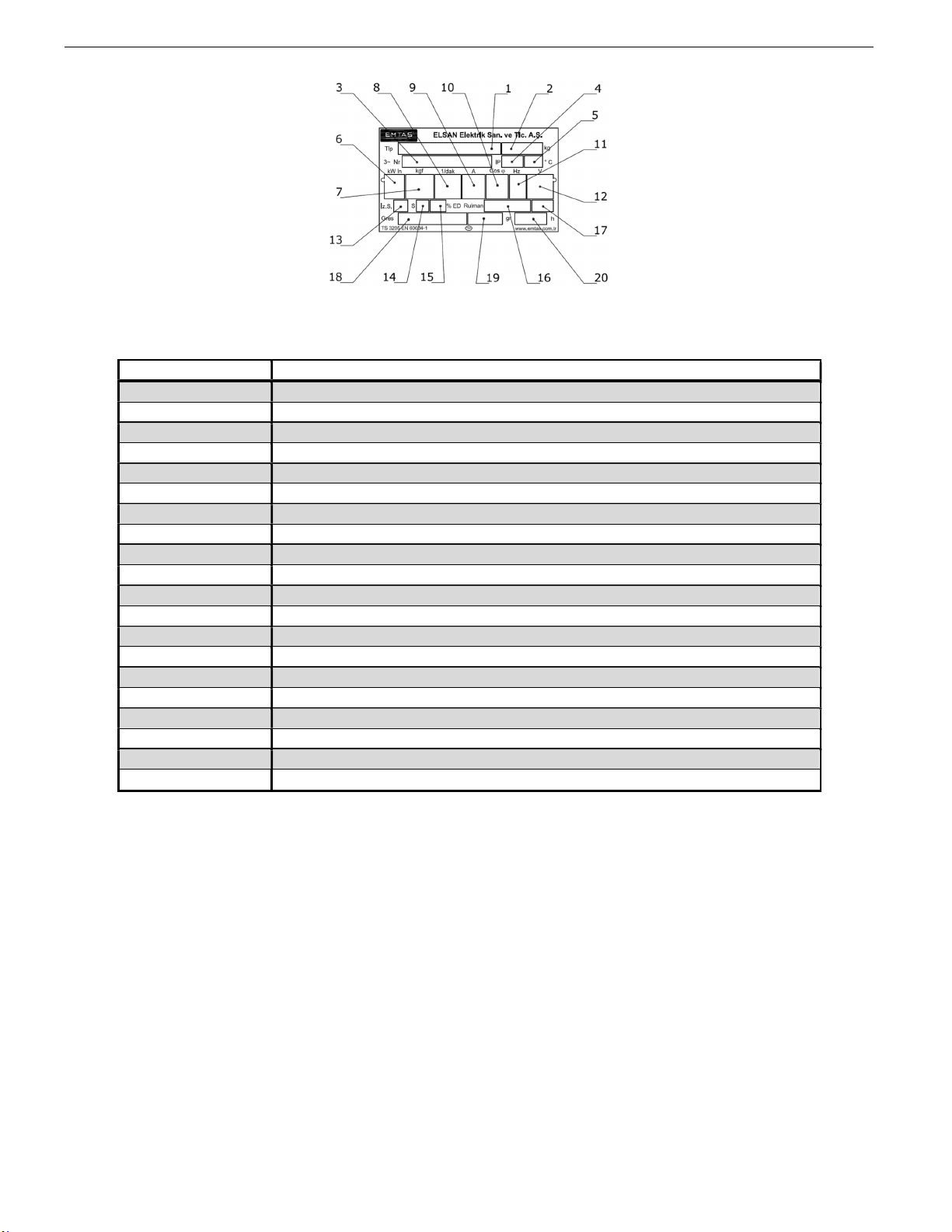

5. IDENTIFICATION AND MARKING

5.1. IDENTIFICATION AND MARKING

Figure 5- Vibration Motor Name Plate

5.2. DESCRIPTIONS OF THE SECTIONS ON THE NAME PLATE

Number Definition

1 Vibration Motor Type

2 Vibration Motor Weight, [kg]

3 Serial Number

4 Ingress Progress Class

5 Operating Environment Temperature [°C]

6 Input Power, [kW]

7 Centrifugal Force, [kgf]

8 Rated Speed, [1/dak]

9 Rated Current, [A]

10 Power Factor, Cos φ

11 Frequency, [Hz]

12 Voltage, [V]

13 Winding Insulation Class

14 Duty

15 Power Factor, [%]

16 Bearing Data

17 Bearing Data

18 Type of Grease

19 Grease Quantity for Relubrication , [gr]

20 Interval of Lubrication [running time (h)]

Table-3. Name Plate Descriptions of Vibration Motor

16

6.COMPONENT OF VIBRATOR______________________________________________________

6.1. PART MAPING WITH SECTION VIEW

Figure

-

6

.

Part mapping of vibration motor

17

6.COMPONENT OF VIBRATOR______________________________________________________

6.2. PART LIST OF VIBRATION MOTOR

PART NUMBER PART NAME

1 FRAME

2 STATOR PACK

3 STATOR WINDING

4 SHAFT

5 ROTOR PACK

6 SOLID SHAFT RING FOR BEARING

7 BEARING

8 SHIELD

9 OUTER BEARING CAP*

10 SETSCREW BOLT**

11 PERMANENT HAMMER

12 SETTING HAMMER

13 HAMMER CLAMPING BOLT

14 SHAFT RING FOR HAMMER

15 LUBRICATION FITTING

16 O-RING (SEALING COMPONENT)

17 SAFETY COVER

18 TERMINAL BOARD

19 TERMINAL BOX COVER

20 CABLE GLAND

Table-4. Part list of vibration motor

* Outer ball cap (except 7.5 kW - 1000 1 / min) for 160 types of vibration motors with 112/2 and 132 types;

There are 100,112 and 160 types and 180 and 200 types of vibration motors with inner ball cap.

** Setscrew mounting should use a removable screw adhesive. (Example: Loctite 243)

18

7. OTHER INFORMATION

7.1. LIST OF RELATED STANDARDS

DOCUMENT NAME OF DOCUMENT

TS EN 60034-1 Rated values and performance

TS EN 60034-2-1 Measurement methods of efficiency and loss

TS 3209

EN 60034-5 Ingress Progress Classification (IP Classification)

TS 3210

EN 60034-6 Cooling Method (IC Classification)

TS 3211

EN 60034-7

Construction and assembly arrangements

(IM Classification)

TS EN 60034-8 Markings of the terminals and direction of rotation

TS EN 60034-9 Noise level limits

TS 6848

EN 60034-12 Starting Performance

TS EN 60034-14 Vibration limits and measurement

TS EN 60034-15 Voltage resistance in AC machines

TS EN 60034-18-1 Insulation and thermal classification

TS EN 50347 Identification of Induction Motor

Table-5. List of related standarts

7.

OTHER INFORMATION

7.2. INDEX OF FIGURE AND TABLE

FIGURE NAME OF FIGURE SECTION PAGE

1 Vibration generation methods 2.3 6

2 Setting the centrifugal force 2.4 6

3 Setting level of centrifugal force 2.4 7

4 Running Diagram 2.6 9

5 Name Plate of Vibration Motor 5.1 18

6 Part Maping of Vibration Motor 6.1 19

Table.6. Index of Figure

TABLE NAME OF TABLE SECTION PAGE

1 Lubrication Interval of Bearing 3.2.1 10

2 Troubleshooting 4.1 12-14

3 Name Plate Descriptions of Vibration Motor 5.2 15

4 Part list of Vibration Motor 6.2 17

5 Related Standarts 7.1 18

6 Index of Figure 7.2 19

7 Index of Table 7.2 19

8 List of Authorized Services 7.3 Back Cover

Table.7. Index of Table

This manual suits for next models

28

Table of contents

Popular Engine manuals by other brands

MVVS

MVVS 175 NP 3012 operating instructions

Doosan

Doosan DE12T Operation & maintenance manual

Mitsubishi

Mitsubishi 4G93-SOHC Workshop manual

BRP

BRP Rotax 4-TEC 150 Operator's manual

Toshiba

Toshiba Low Voltage Motors VR Series Brochure & specs

Stobag

Stobag MOVENO DWIR-E Installation and use instructions and warnings