EMB WALLENSTEIN WE230 Installation guide

TRAILER WOODSPLITTER

MODEL WE230

ASSEMBLY INSTRUCTION MANUAL

EMB MANUFACTURING INC.

4144 BOOMER LINE

ST. CLEMENTS, ON

N0B 2M0 CANADA

PH: (519) 699-9283

FAX: (519) 699-4146

PRINTED IN CANADA

Rev 191011 PART NUMBER: Z97502

Please review and understand the

operators manual before attempting

to operate this machinery.

2

1.0 ASSEMBLY SAFETY

1. Read and understand the Assembly Manual and all safety signs before starting.

2. Follow good safety practices:

- Keep service area clean and dry.

- Be sure electrical outlets and tools are properly grounded.

- Use adequate light for the job at hand.

3. Use properly sized tools, stands, jacks and hoists at all times.

4. Use two men to handle heavy and/or bulky components.

5. Position in a large open area to allow access from all sides during assembly.

6. Keep the assembly area neat and clean to prevent slipping or tripping.

7. Place safety stands or large blocks under the machine or components before going underneath

the component for assembly.

8. Stay away from overhead power lines and obstructions when lifting the machine during as-

sembly. Contact with power lines can cause electrocution. Contact with obstructions can

damage components or cause them to fail.

9. Tighten all fasteners to their specied torque before using the machine.

ENGLISH TORQUE SPECIFICATIONS

SAE 2

(N.m) (lb-ft)

Bolt Torque*

Bolt

Diameter

"A"

SAE 5

(N.m) (lb-ft)

SAE 8

(N.m) (lb-ft)

1/4"

5/16"

3/8"

7/16"

1/2"

9/16"

5/8"

3/4"

7/8"

1"

8

13

27

41

61

95

128

225

230

345

6

10

20

30

45

60

95

165

170

225

12

25

45

72

110

155

215

390

570

850

9

19

33

53

80

115

160

290

420

630

17

36

63

100

155

220

305

540

880

1320

12

27

45

75

115

165

220

400

650

970

Torque gures indicated above are valid for non-greased or non-oiled threads and heads unless oth-

erwise specied. Therefore, do not grease or oil bolts or caps crews unless otherwise specied in this

manual. When using locking elements, increase torque values by 5%.

* Torque value for bolts and capscrews are identied by their head markings.

2.0 BOLT TORQUE

3

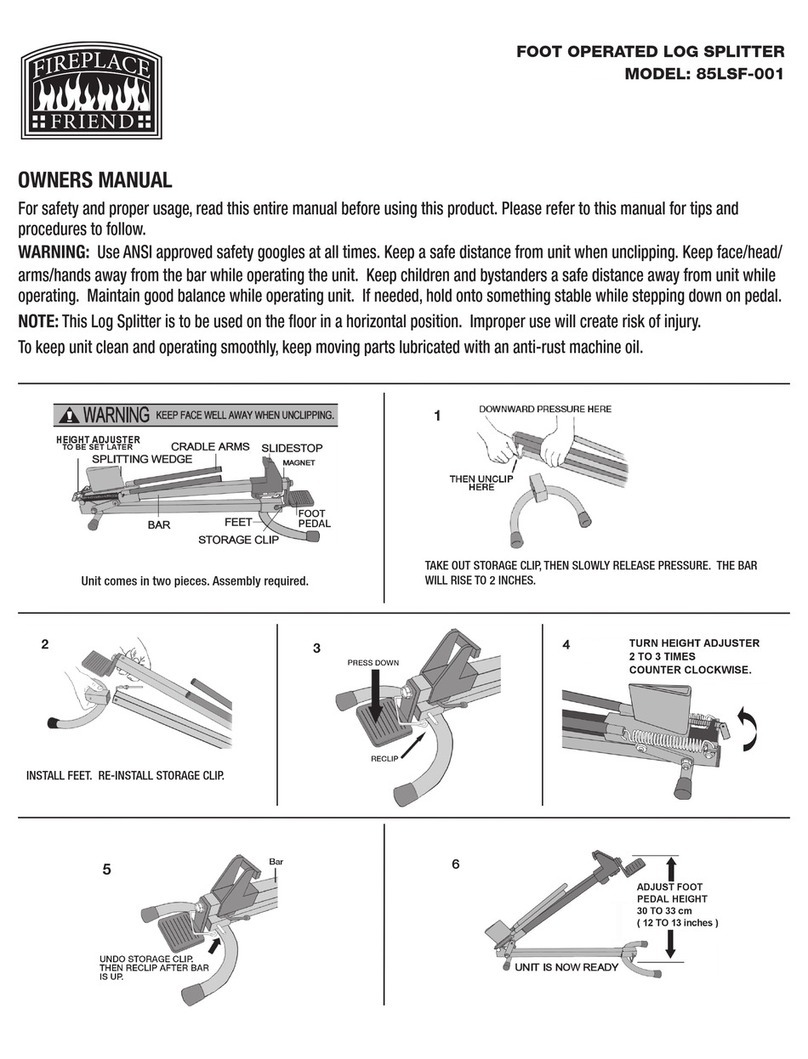

3.0 ASSEMBLY

The machine is shipped from the factory in a partially disassembled conguration and

attached to a pallet that provides easy moving and handling. Always use tools, equip-

ment and fork lifts of appropriate size and capacity for the job.

When the machine is shipped, follow this assembly procedure:

1. Clear the area of bystanders, especially small children.

2. Be sure you have all the required tools before you start.

3. Move the shipping package into an area where it is accessible from all sides.

4. Remove the 4 screws holding the lid to the ship-

ping pallet. (2 on each end)

5. Remove the lid and set to one side.

6. Remove the screw securing the hitch beam \

support leg ass'y to the skid.

4

7. Remove the screws securing the front and rear

shipping brackets to the skid, but do not remove

the brackets from the splitter beam. Carefully

move the tires from the skid to a safe place.

Shipping Brackets (splitter beam)

8. Open manual tube (located on the axle ass'y),

and remove the bag of hardware.

9. Carefully rotate the splitter beam ass'y to 90° at

the tongue channel ass'y, so that the beam rests

on top of the pivot assembly and the tongue

channel.

5

10. Fasten the splitter beam to the pivot ass'y by

inserting the 3/8 x 4 1/2" bolt through the bolt

hole as shown.

11. Assemble 3/8 hex locknut and tighten as speci-

ed on the torque chart (pg 2)

12. Once the splitter beam ass'y is fastened to the

pivot, remove the two shipping brackets from

the splitter beam ass'y as shown

6

13. Carefully pull back the cylinder ass'y into

position

14. Ensure the cylinder ass'y is back as far as it will

go, so that the collar of the cylinder is tight up

against the cylinder mount as shown.

15. Locate the cylinder saddle, fastened to the

wheel hub, remove the lug nut, carefully remove

the saddle from the hub, keep the lug nut.

7

16. Place the saddle on top of the cylinder collar

mount as shown, align the bolt holes and insert

the 1/2 x 1 1/2 bolt through the saddle (one on

each side)

Assemble 1/2" hex locknut on each bolt and

tighten as specied on the torque chart (pg 2)

17. Insert the 1/2 x 3" bolt (one on each side)

through the gland clamp and through the saddle

and cylinder mount, assemble 1/2" hex locknut

on each bolt and tighten as specied on the

torque chart

(Pg 2)

Gland Clamp

18. Remove the pivot lock bolt, to allow the latch

handle to lock into place

8

19. Ensure latch handle has locked into place to

keep the splitter assembly beam in position.

20. Remove the screws securing the tongue chan-

nel shipping bracket to the skid, but do not

remove the shipping bracket from the tongue

channel.

21. The tongue ass'y is attached to the axle ass'y

by one bolt, carefully pivot the tongue ass'y on

the bolt clockwise, so that the anges on both

ass'y's line up.

9

22. Once the anges are lined up, rest the entire

ass'y on the oor, supported by the tongue

channel shipping bracket.

23. Insert the 3/8 x 1-1/4" carriage bolts through the

3 remaining holes on the anges, assemble 3/8"

hex locknut on each bolt and tighten all 4 nuts

as specied on the torque chart

(Pg 2)

24. Assemble any loose hose into hose clamps (al-

ready attached to the unit). Do not overtighten

the clamps or hose damage will result.

line up

anges shipping

bracket

10

25. Remove the snapper pin and lower the sup-

port leg, assemble the hitch beam ass'y to the

tongue channel, along with a 3/8 washer insert

the 3/8 x 3" bolts through the 2 holes on the

tongue channel, assemble 3/8" hex locknut on

each bolt and tighten hex nuts as specied on

the torque chart (pg 2)

26. Align the support leg with the lower holes in

the hitch beam, and install the snapper pin and

latch it, to secure the support leg in the lowered

position. Allow the splitter to rest on the support

leg.

27. When the support leg is secured, then carefully

remove the tongue channel shipping bracket.

remove 2 nuts

and bolts

11

28. On the right side, remove the screws securing

the axle shipping brackets to the skid, and unbolt

the brackets form the axle ass'y.

29. Carefully tilt the splitter high enough to install

the tire, assemble 1/2" lug nut on each lug and

tighten the lug nuts as specied on the torque

chart (pg 2)

30. Repeat for the step 28 and 29 for the left side.

12

31. Finally the hydraulic control handle must be

installed. Using a pair of needle nose pliers,

remove the cotter pin that secures the handle

pivot pin to the valve. Remove the pivot pin.

Once the pivot pin is removed, then the handle

will come free.

32. Fit the slotted end of the handle into the lower

pivot, position the handle so that the hole in the

handle lines up with the pivot hole. Carefully

insert the pivot pin.

33. Using needle nose pliers, secure the pivot pin

by re-inserting the cotter pin. Test the function

of the handle to ensure everything is assembled

properly.

Congratulations on

successfully completing assembly of

the

WE230 Woodsplitter

Table of contents

Popular Log Splitter manuals by other brands

Scheppach

Scheppach HL750ST Translation of original instruction manual

Central Machinery

Central Machinery 67090 Owner's manual & safety instructions

SpeeCo

SpeeCo LS401213 owner's manual

Kohler

Kohler DK2 POWER OPS240 Assembly guide

Maxim

Maxim LSM75BVG, LSM55H, LSM80H Operator's manual

Northern Industrial Tools

Northern Industrial Tools M1107C owner's manual

Farmi Forest

Farmi Forest 380 HF Expert OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Scheppach

Scheppach HL810 Translation of the original instruction manual

MTD

MTD 24BF572B729 Operator's manual

Wen

Wen 4225 user manual

Super Handy

Super Handy GUO084 Operator's manual

SpeeCo

SpeeCo Splitmaster 401628BB owner's manual