19

d. It is recommended that a water meter be installed on the

system fresh water intake to monitor the system for any

leaks by monitoring make-up water usage. Untreated

fresh water sources will introduce oxygen, minerals and

contaminants into the system.

e. Correct any system leaks prior to placing the boiler in operation.

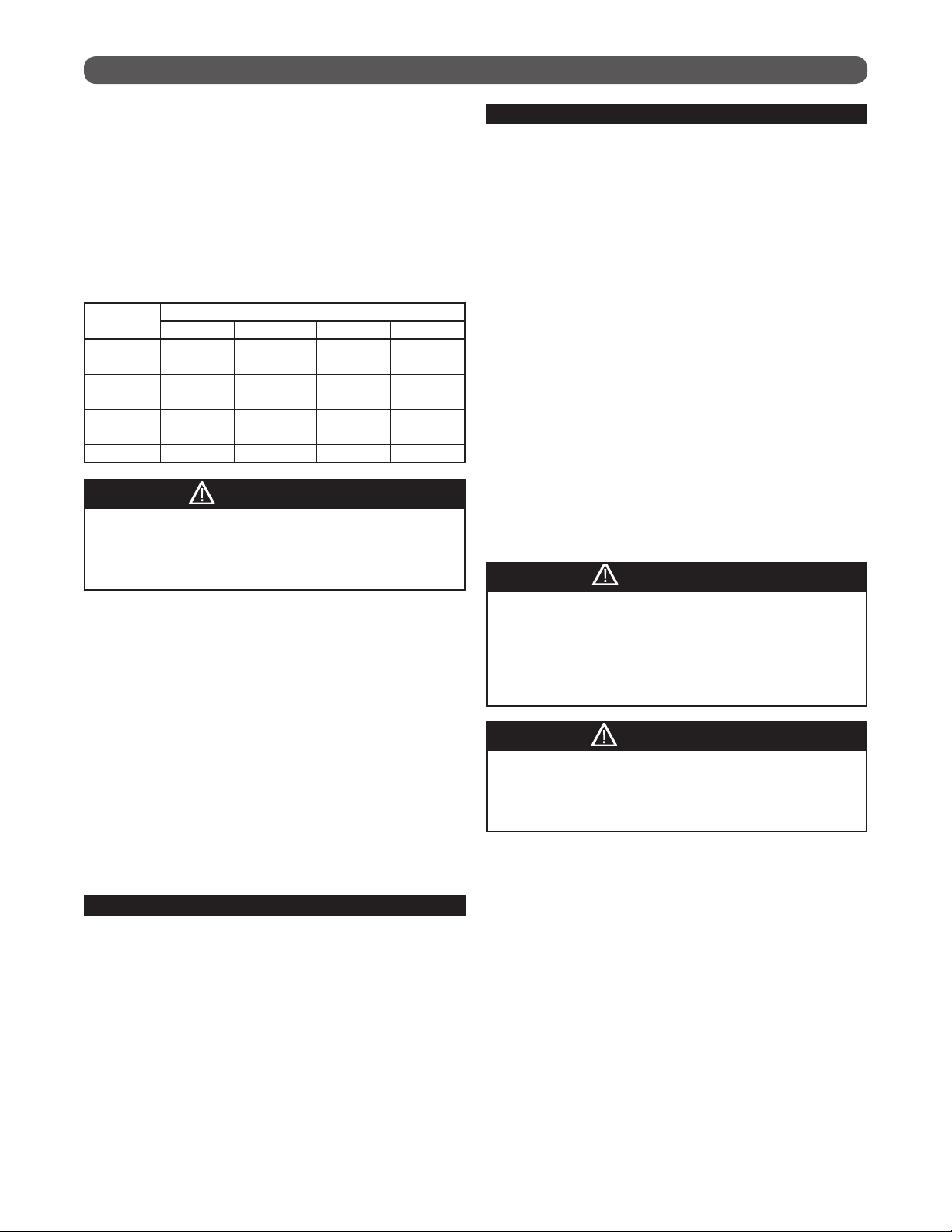

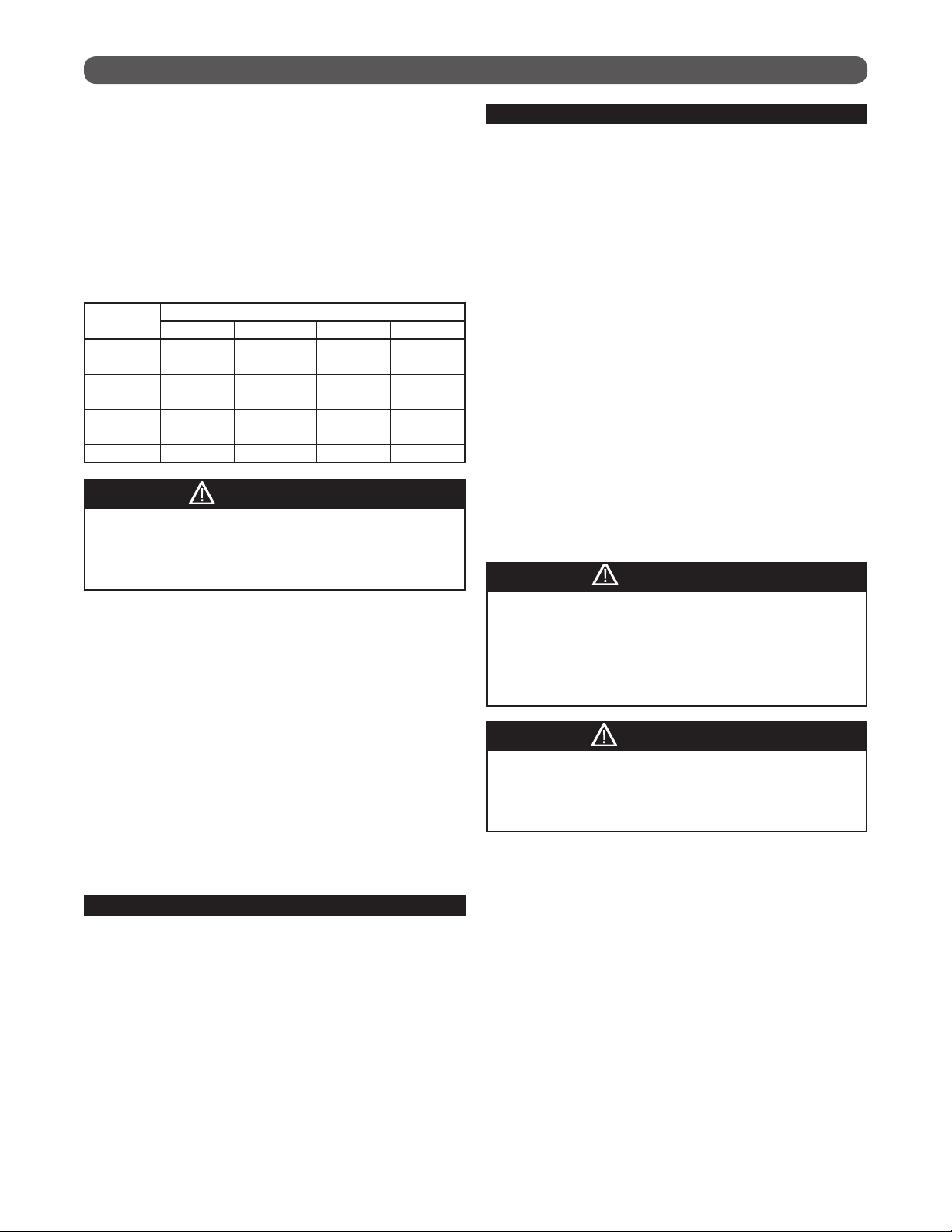

Table 4.1: Recommended Water Treatment Products

for use in Stainless Steel Condensing

Boiler Applications

Domestic Heat System:

The Peak boilers use a high efficiency flat plate heat exchanger

to quickly heat cold domestic water. This plate heat exchanger

has small passageways that can become clogged with sediment

and scale of steps are not taken to protect it.

1. Water hardness is to be maintained between 50 ppm

CaCO3 (3gr/gal and 150 ppm CaCO3 (9 gr/gal).

2. A sediment filter is provided with the flow restrictor in the

unit. This filter should be checked annually. An additional

filter or y-strainer can also be installed prior to the unit.

3. Annual cleaning of the plate heat exchanger is also

recommended to prevent scaling.

C. OPERATING PARAMETERS

1. The Peak boiler is designed to operate in a closed loop

hydronic system under forced circulation. This requires the

system to be completely filled with water and requires a

minimum water flow through the boiler to operate effectively.

2. The minimum system pressure is 11.6 psig (80 kPa). The

maximum allowable pressure is 40 psig (275 kPa).

3. The recommended minimum system pressure for optimal

operation at higher temperature is 14.5 psi (100kPa).

4. The internal pump is sized appropriately to allow for the

minimum flow rate required through the heat exchanger.

Ensure that the piping up to the boiler is capable of handling

a minimum flow rate of 5.0 GPM to allow for proper flow

rates when the boiler is in CH mode.

WATER PIPING AND CONTROLS

Supplier

Fernox Sentinel Sotin ADEY

Universal

Cleaner

Restorer F3

or F5 X300 – –

Sludge

Remover

Cleaner F3

or F5 X400 Sotin 212 –

Inhibitors Protector

F1/Alphi 11 X100, X500 Sotin 212 M C 1+

Antifreeze Alphi 11 X500 – –

WARNING

Do not use petroleum based cleaners when cleaning

the boiler system. Damage to the gaskets found in

typical system components can occur resulting in

signicant property damage.

D. SYSTEM COMPONENTS

Figure 4.1 shows the symbol key for piping diagrams in this section.

The following are brief descriptions of system components.

1. Pressure/Temperature Gauge: A combination pressure/

temperature gauge is provided with each Peak boiler to be

mounted in the piping from the boiler supply to the system as

shown in Figures 4.2 & 4.3. Most local codes require this gauge.

2. Air Elimination: Closed loop hydronic systems require air

elimination devices. As the system water is heated, dissolved

oxygen and other gases will separate from the liquid. An air

elimination device (such as a TACO Vortech®Air Separator)

is required to remove the dissolved gases preventing

corrosion in the piping system and eliminating noise.

3. Expansion Tank: An expansion tank (such as a Bell &

Gossett Series HFT) is required to provide room for

expansion of the heating medium (water or glycol solution).

Consult the expansion tank manufacturer's instructions for

specific information regarding installation. The expansion

tank is to be sized for the required system volume and

capacity. In addition, be sure that the expansion tank is

sized based on the proper heating medium. Glycol solutions

may expand more than water for a similar temperature rise.

4. Y-Type Strainer or Filter Ball®Valve: Embassy recommends the

use of a strainer device in the system to prevent dirt or sediment

from clogging the heat exchanger. A 20 mesh stainless steel

screen is adequate to protect the heat exchanger. The strainer

should be cleaned often in the first several months of operation.

The Filter Ball®Valve from Jomar International incorporates a

strainer into a ball valve which allows the technician to isolate

the water circuit while cleaning the strainer.

5. Flow Control Valve: Flow control valves such as the TACO

Flo-Chek or Bell & Gossett Flo-Control™ are used to

prevent gravity circulation by incorporating a check valve

with a weighted disc.

6. Pressure Reducing Valve: A pressure reducing valve, such

as the Bell & Gossett B-38 or a TACO #329, is used in a

hydronic system to automatically feed water to the system

whenever pressure in the system drops below the pressure

setting of the valve. These valves should not be used on

glycol systems unless close supervision of the glycol solution

is practiced.

WARNING

CAUTION

Use only inhibited propylene glycol solutions which

are specically formulated for hydronic systems.

Ethylene glycol is toxic and may cause an

environmental hazard if a leak or spill occurs.

Use only inhibited propylene glycol solutions which

are specically formulated for hydronic systems.

Unlike automotive antifreeze, solutions for hydronic

applications contain corrosion inhibitors that will

protect system components from premature failure

due to corrosion.