CG Drives & Automation, 01-7318-01r1 3

Contents

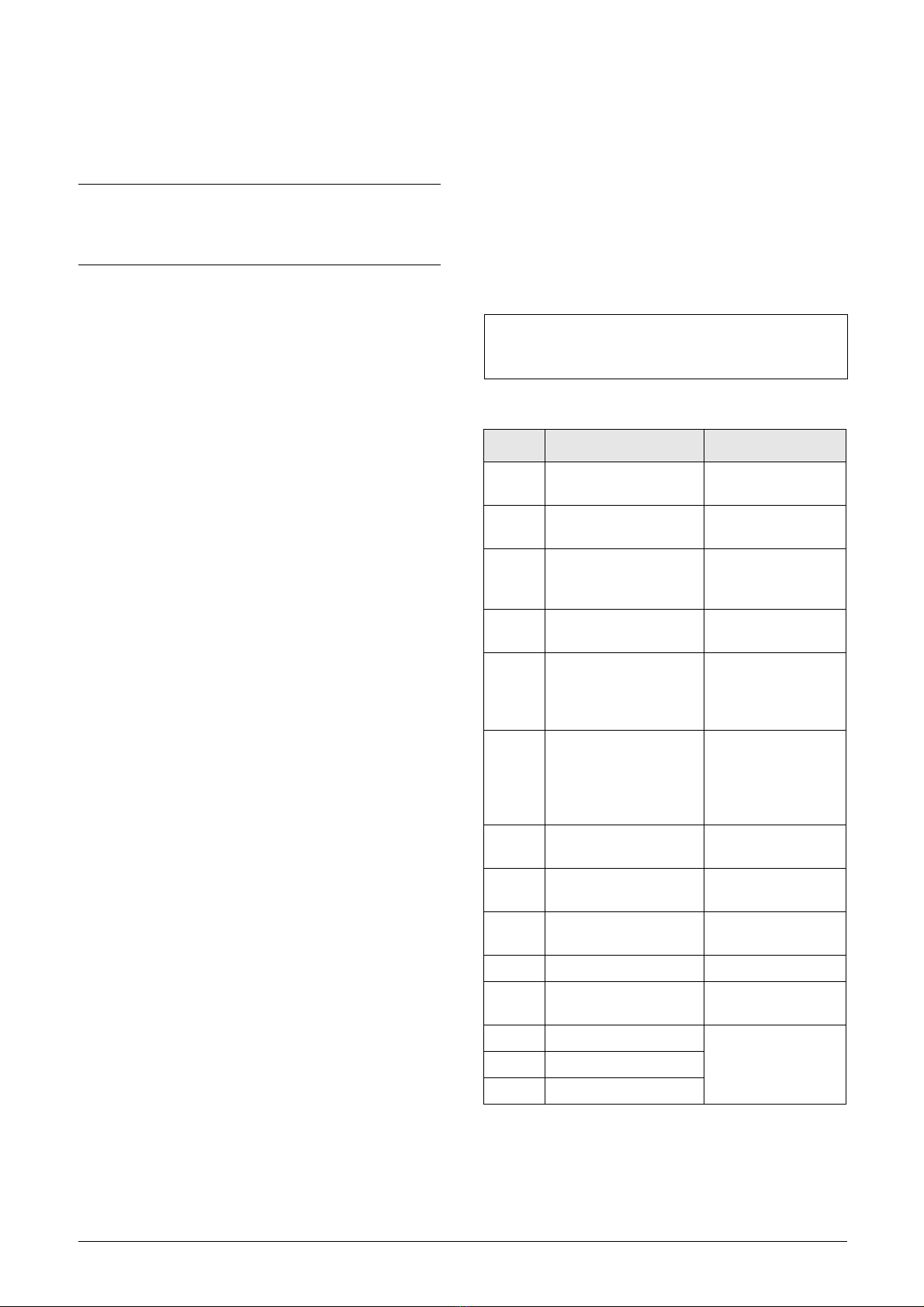

Safety Instructions ......................................... 1

Contents.......................................................... 3

1. Introduction..................................................... 5

1.1 Delivery and unpacking ............................................ 5

1.2 Using of the instruction manual............................... 5

1.3 Type code number..................................................... 5

1.4 Standards .................................................................. 6

1.5 Dismantling and scrapping....................................... 8

1.6 Glossary ..................................................................... 8

2. General description ..................................... 11

2.1 AC drive types .......................................................... 12

2.2 Emotron single drive cabinet concept ................... 14

2.3 Emotron AFR/AFG concept..................................... 15

3. Mounting ...................................................... 17

3.1 Lifting instructions................................................... 17

3.2 Cabinet mounting.................................................... 18

3.3 Mounting AFR/AFG/VSI power modules

(inside the cabinet) ................................................. 20

4. Installation ................................................... 21

4.1 Before installation................................................... 21

4.2 Connect motor and mains ...................................... 21

4.3 Cable specifications ................................................ 22

5. Control connections .................................... 23

5.1 Control board........................................................... 23

5.2 Terminal connections for AFR/AFG........................ 24

5.3 Inputs configuration with the switches.................. 25

5.4 Control connections for Emotron

FDUL/VFXR/FDUG/VFXG ........................................ 26

5.5 Connecting the control signals............................... 29

5.6 Connecting options ................................................. 30

6. Getting Started ............................................ 31

6.1 Connect the mains and motor cables.................... 31

6.2 Using the function keys .......................................... 31

6.3 Remote control........................................................ 32

7. FDUL/VFXR/FDUG/VFXG/AFR/AFG

Main features 35

7.1 Autoreset at trip ...................................................... 35

7.2 Power-up and DC-link charging .............................. 35

7.3 Automatic power supply parameter detection...... 36

7.4 Power supply synchronisation................................ 36

7.5 Start command........................................................ 36

7.6 Start on regeneration demand............................... 36

7.7 Under voltage ride through for AFR/FDUL/VFXR ....... 36

7.8 PWM modulation..................................................... 37

7.9 Active power (Energy) control ................................. 37

7.10 Limit the regeneration capability of AFR/AFG....... 37

7.11 Reactive power

(Q or cos φ) control (normally not used)................ 37

7.12 Frequency (f) control ............................................... 37

7.13 Energy actual value signals .................................... 37

7.14 Power factor calculations ....................................... 37

7.15 Fault signals ............................................................ 38

7.16 Supply voltage measurement board (SVMB)

(synchronizing/bypass option) ............................... 38

7.17 Grid code functionality............................................ 40

7.18 Brake resistor overload protection ........................ 49

7.19 Detection of open circuit ........................................ 49

7.20 Remote control functions ....................................... 49

8. EMC and Machine Directive........................ 51

8.1 EMC standards........................................................ 51

8.2 Stop categories and emergency stop .................... 51

9. Operation via the Control Panel.................. 53

9.1 Control panels ......................................................... 53

9.2 General .................................................................... 53

9.3 Control panel with 2-line display ............................ 54

9.4 Control panel with 4-line display ............................ 58

9.5 The menu structure ................................................ 62

9.6 Programming during operation .............................. 63

9.7 Editing values in a menu ........................................ 63

9.8 Copy current parameter to all sets ........................ 63

9.9 Programming example............................................ 64

10. Serial communication.................................. 65

10.1 Modbus RTU ............................................................ 65

10.2 Start and stop commands ...................................... 65

10.3 Reference signal ..................................................... 65

10.4 Description of the EInt formats .............................. 66

11. Functional description................................. 69

11.1 2-line LCD display.................................................... 69

11.2 4-line LCD display.................................................... 70

11.3 Menus ...................................................................... 71

11.4 Main Setup [200].................................................... 72

11.5 Process and Application Parameters [300] .......... 81

11.6 I/Os and Virtual Connections [500]....................... 83

11.7 Logical Functions and Timers [600] ...................... 97

11.8 View Operation/Status [700] ............................... 113

11.9 View Trip Log [800] ............................................... 119

11.10 System Data [900]................................................ 120

11.11 AFE Option [O00]................................................... 122

11.12 Grid Code Functions [G00]................................... 127

12. Troubleshooting, Diagnoses and

Maintenance ..............................................147

12.1 Trips, warnings and limits..................................... 147

12.2 Trip conditions, causes and remedial action ...... 148

12.3 Maintenance ......................................................... 153

13. Options........................................................ 155

13.1 Supply voltage measurement board (SVMB) ...... 155

13.2 Liquid cooling ........................................................ 155

13.3 I/O Board ............................................................... 155

13.4 Brake chopper....................................................... 155

13.5 EmoSoftCom.......................................................... 156

13.6 Control panel ......................................................... 156

13.7 External control panel kits (4-line) ....................... 157