Endress+Hauser

Liquistation CSF48

Table of contents

1 Maintenance. . . . . . . . . . . . . . . 4

1.1 Recommended maintenance . . . . . . . . . . . 4

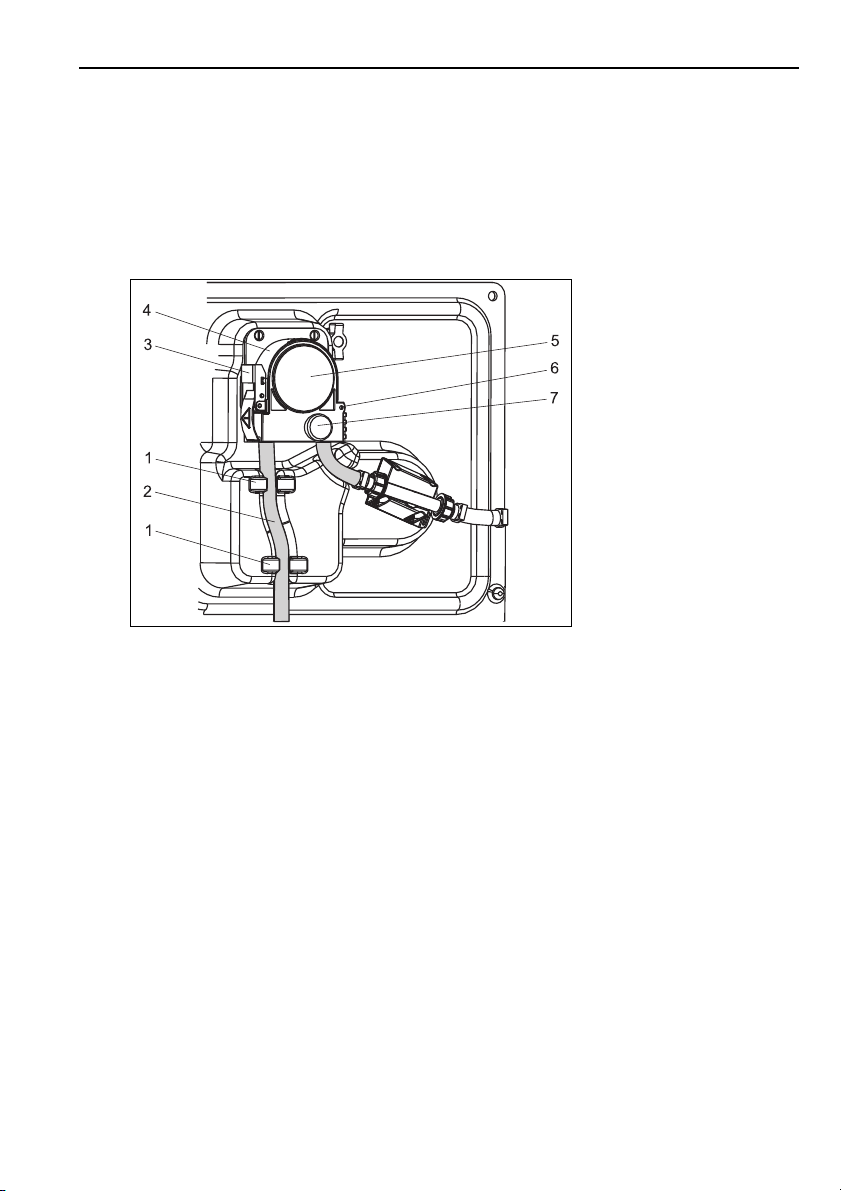

1.2 Replacing the pump tube . . . . . . . . . . . . . . 5

1.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Calibration . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Replacing the storage batteries . . . . . . . . . 13

2 Diagnostics menu . . . . . . . . . . 14

2.1 Diagnostics list . . . . . . . . . . . . . . . . . . . . . 14

2.2 Logbooks . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 System information . . . . . . . . . . . . . . . . . 18

2.4 Status of inputs/outputs . . . . . . . . . . . . . . 20

2.5 Systemtest/Reset . . . . . . . . . . . . . . . . . . . 20

2.6 Sensor change (for version with sensors with

the Memosens protocol) . . . . . . . . . . . . . . 23

2.7 Manual hold (for version with sensors with the

Memosens protocol) . . . . . . . . . . . . . . . . . 24

2.8 Term information . . . . . . . . . . . . . . . . . . . 24

2.9 Simulation . . . . . . . . . . . . . . . . . . . . . . . . 24

2.10 Sensor information (for version with sensors

with the Memosens protocol) . . . . . . . . . . 25

3 Troubleshooting . . . . . . . . . . . 26

3.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . 26

3.2 System error messages . . . . . . . . . . . . . . . 26

3.3 Device-specific errors . . . . . . . . . . . . . . . . 46

3.4 Process errors without messages . . . . . . . . 47

3.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.7 Software history . . . . . . . . . . . . . . . . . . . . 53

4 Accessories. . . . . . . . . . . . . . . 54

4.1 Accessories for Liquistation CSF48 . . . . . . 54

4.2 Measuring cable . . . . . . . . . . . . . . . . . . . . 55

4.3 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5 Spare parts . . . . . . . . . . . . . . . 58

5.1 Peristaltic pump . . . . . . . . . . . . . . . . . . . . 58

5.2 Vacuum pump . . . . . . . . . . . . . . . . . . . . . 59

5.3 Climate control module . . . . . . . . . . . . . . 61

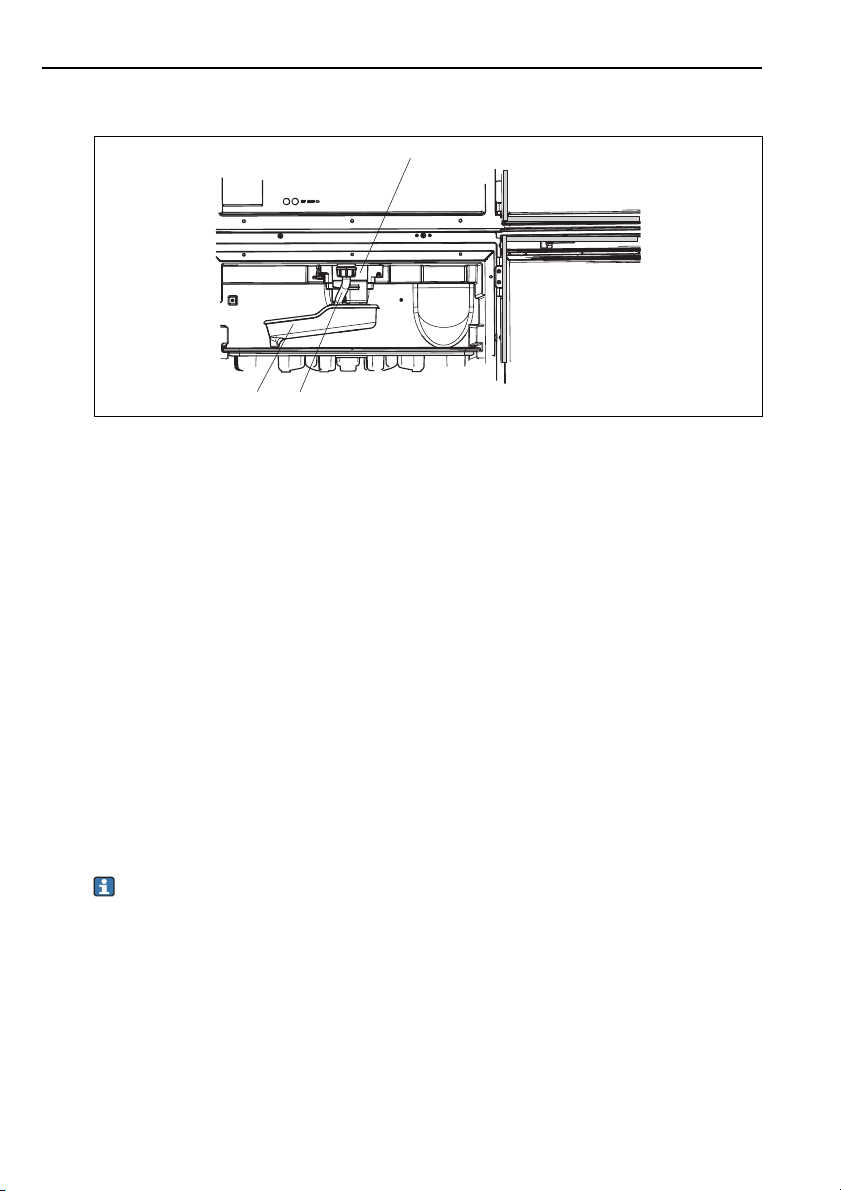

5.4 Sample compartment . . . . . . . . . . . . . . . . 62

Index . . . . . . . . . . . . . . . . . . . 63