Venting System

A chimney connector and chimney make up the venting system. Inside, chimney temperatures may

exceed 2000 degrees F. To protect against a chimney fire, the connector and chimney must be

properly installed and maintained. When a connection is made through a combustible wall to the

chimney, a thimble must be used. A chimney support package must be used when a connection is

made through the ceiling to a prefabricated chimney. These accessories are of primary importance to

provide safe clearances to combustible wall and ceiling materials.

The unit may be connected to either a code approved masonry chimney with a flue liner or a

prefabricated listed high temperature (tested to 2100 degrees F) residential and building type heating

appliance chimney per UL 103 or ULC S629. The chimney size should not be less than or more than

three times greater than the cross-sectional area of the flue collar. Do not connect it to a chimney

serving another appliance.

Proper draft must be provided for your Energy King unit. Draft is the force that moves air from the

stove up through the chimney. The amount of draft in your chimney depends on the length of the

chimney, local geography, nearby obstructions, and other factors. Too much draft may cause

excessive temperatures in the stove and may damage the catalytic combustor. Inadequate draft may

cause backpuffing into the room and plugging of the chimney or catalyst.

Chimney Connector

Your chimney connector should be 6-inch diameter, minimum 24

MSG black or 25 MSG blued steel. Aluminum and galvanized steel

should not be used, since they cannot withstand the high temperatures

a wood fire produces. Never use chimney connector pipe as a chimney.

You must connect your stove to a chimney like those illustrated in this

manual. DO NOT PASS CHIMNEY CONNECTOR THROUGH

COMBUSTIBLE WALL OR CEILING.

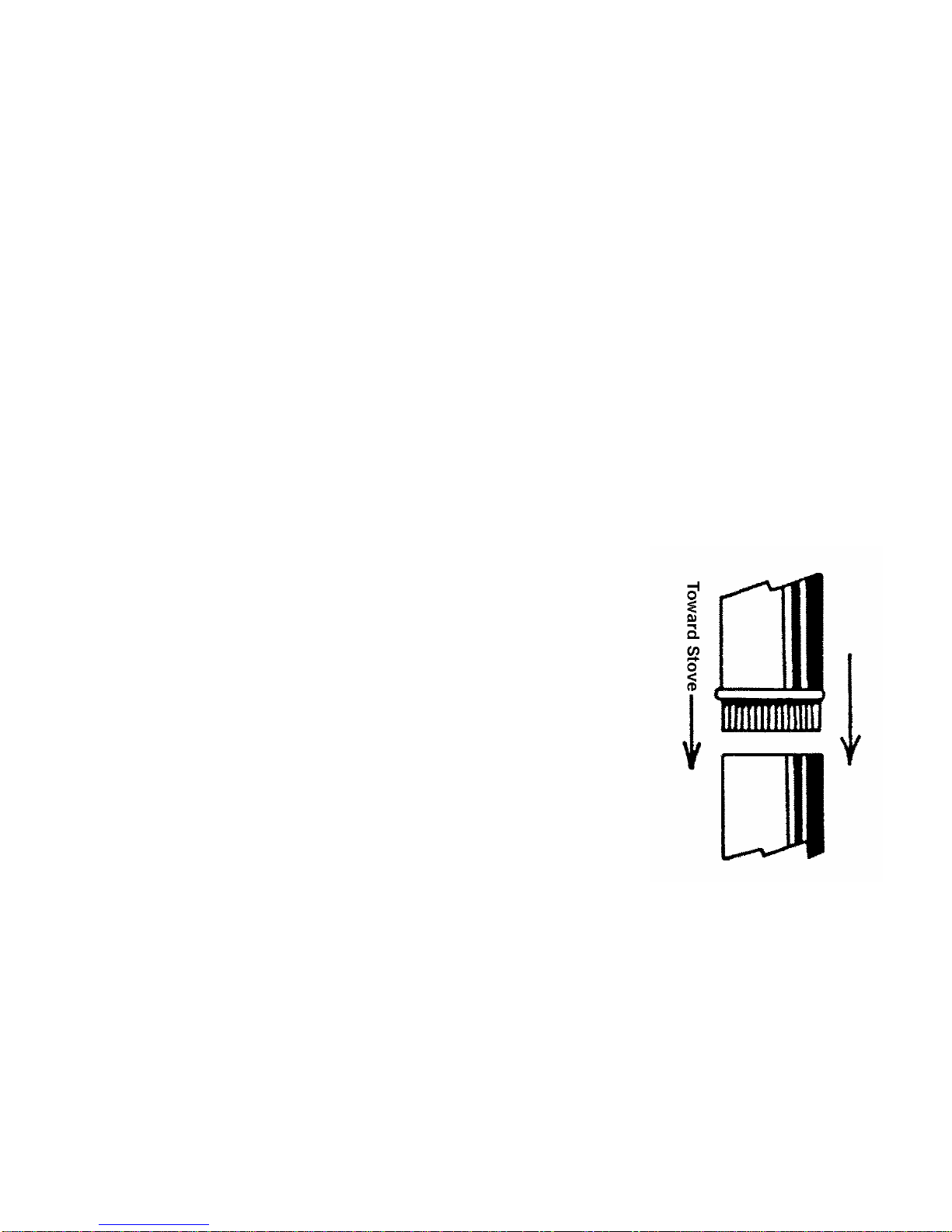

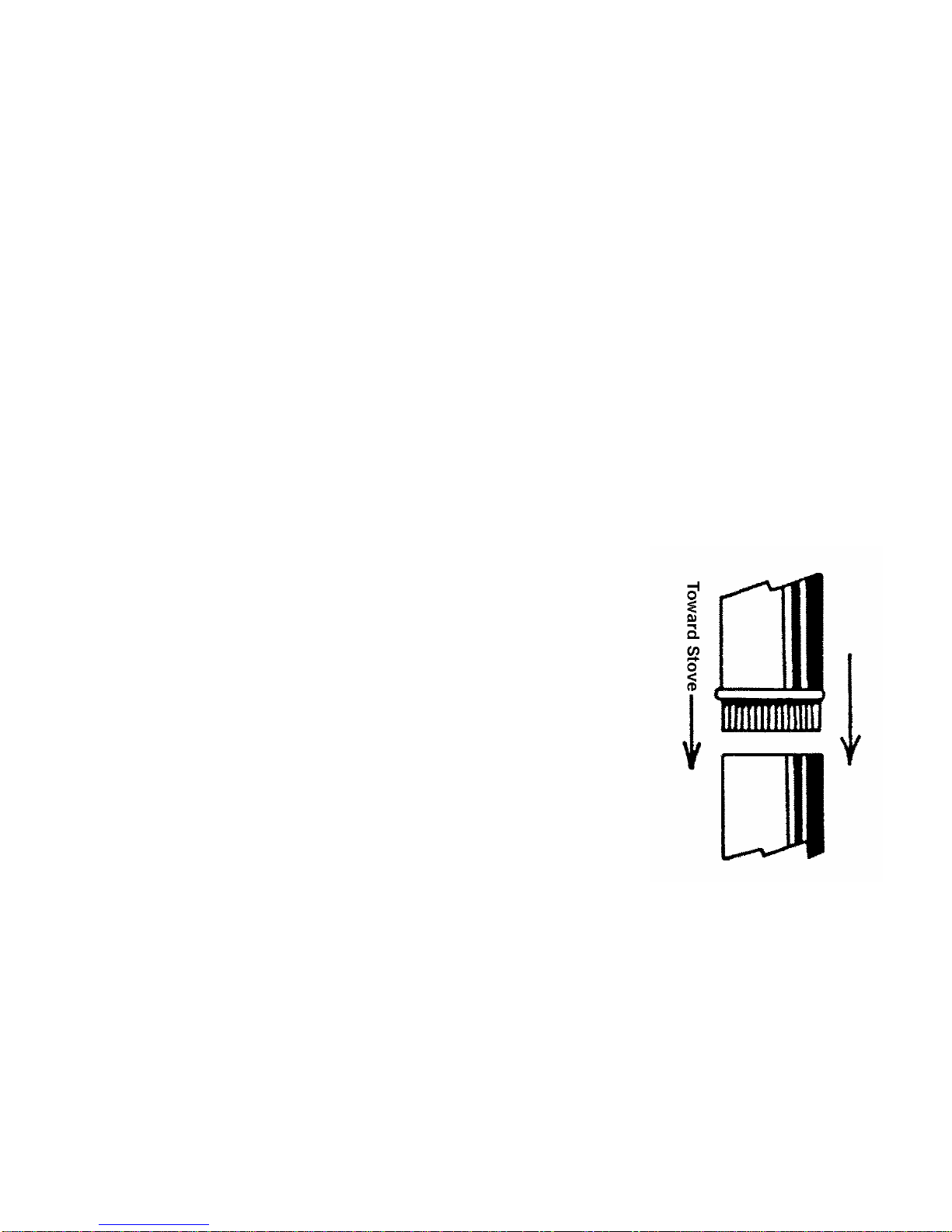

Chimney connector sections must be attached to the stove and to each

other with the crimped end toward the stove. This allows creosote to run

into the stove and not onto the outside of the pipe. All joints, including

transition to chimney connector, should be secured with three sheet

metal screws. Otherwise, in the event of a creosote fire, the connector

may vibrate apart.

For proper operation, the chimney connector should be as short as

possible. Horizontal lengths of chimney connector should have an

upward slope from the stove of ¼ inch per foot.

Maintain 18 inches clearance between the chimney connector and the

wall and ceiling unless a wall protection system is installed.

When installing the stove into a masonry chimney, be sure to check for

signs of deterioration and blockage. Once the chimney is determined to

be safe, installation can proceed. The size of the flue should also be

checked. The chimney must have a fire clay liner or stainless steel lining

must be installed. The stainless steel lining should be single wall pipe, 6

inches in diameter, a minimum 24 gauge. If a flue lining is used, an air

space between the flue liner and the chimney wall of ½ inch must be

maintained.

11

A list of the more important minimum requirements for a properly

constructed chimney follows.