Contents

Technicalspecifications

Technicaldata...................................................................................................3

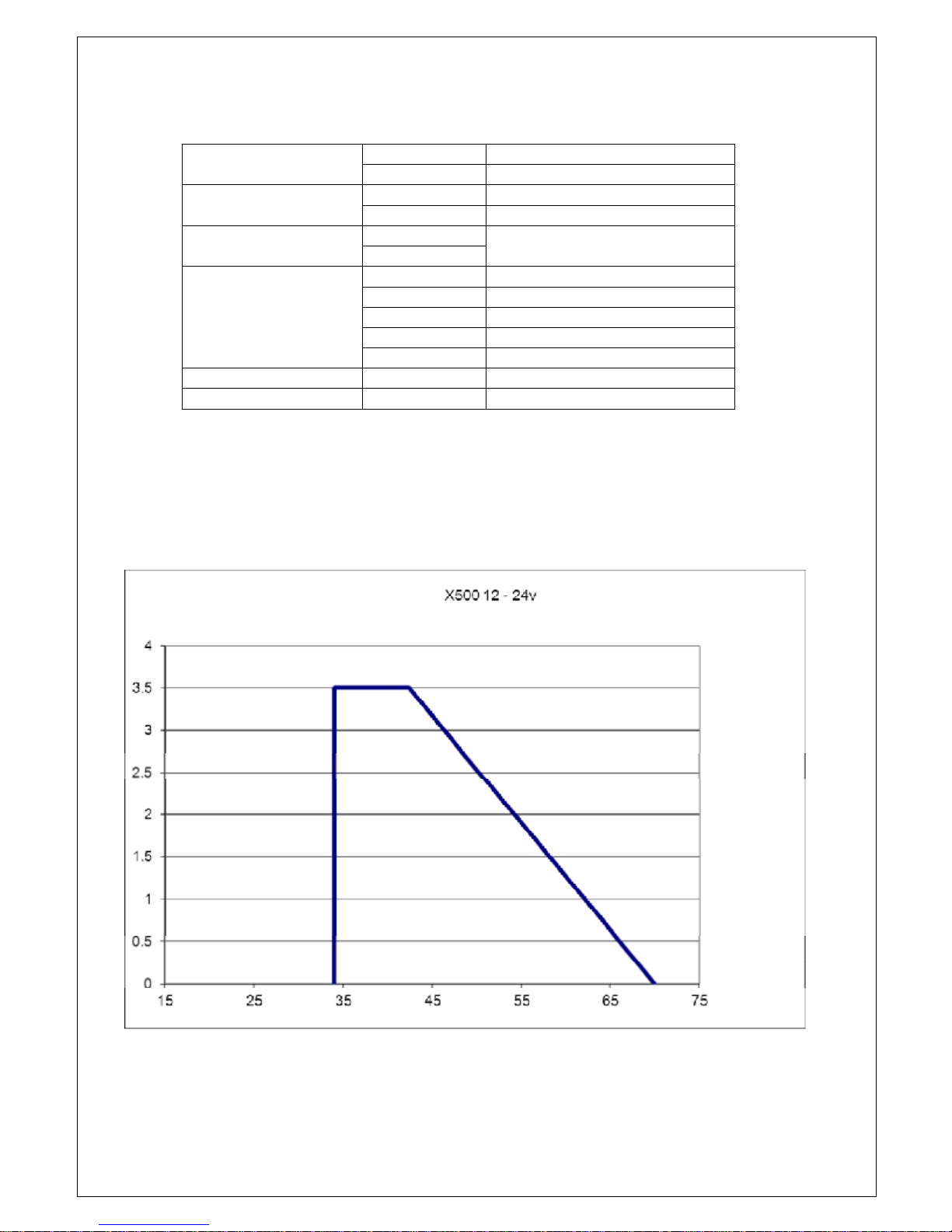

Workingfield.....................................................................................................3

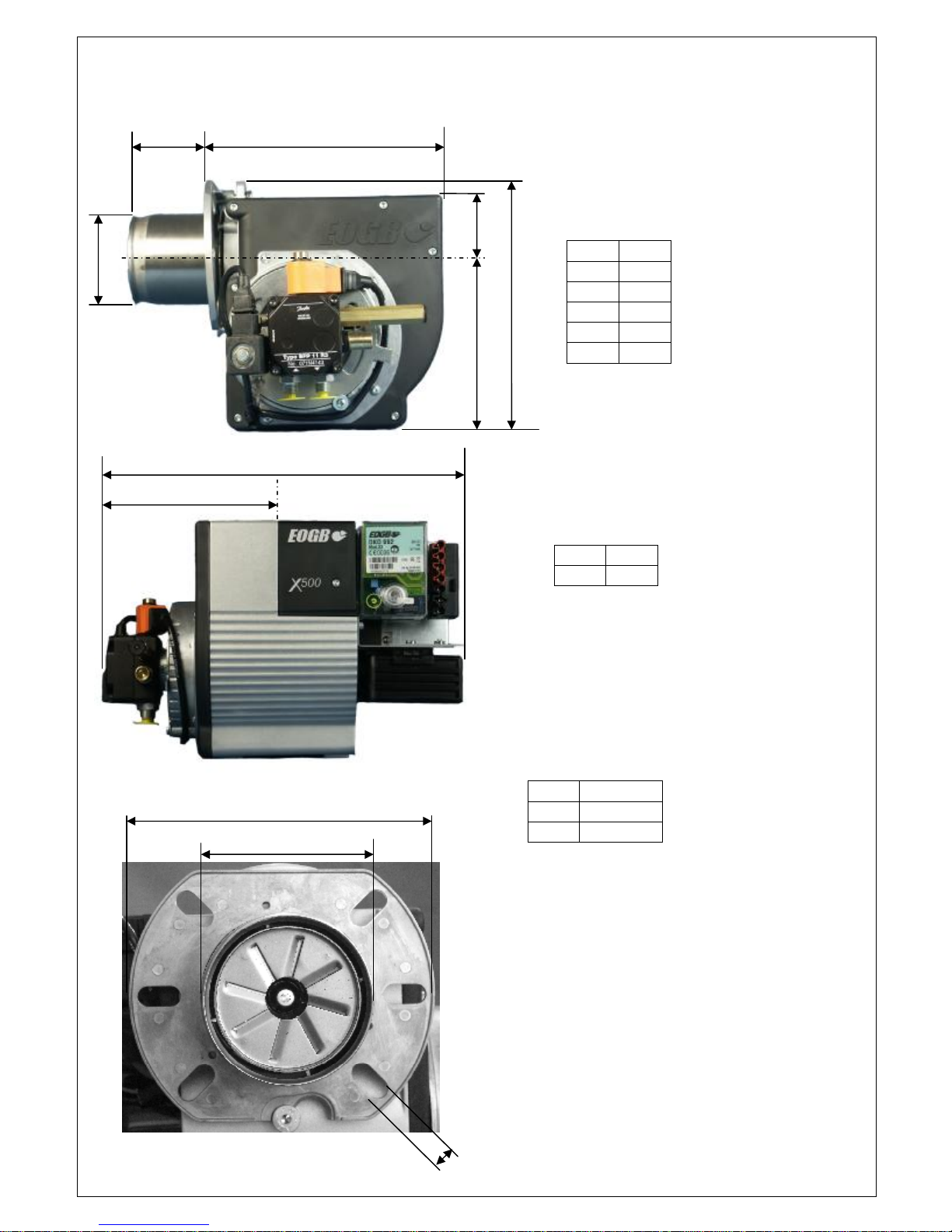

Dimensions........................................................................................................4

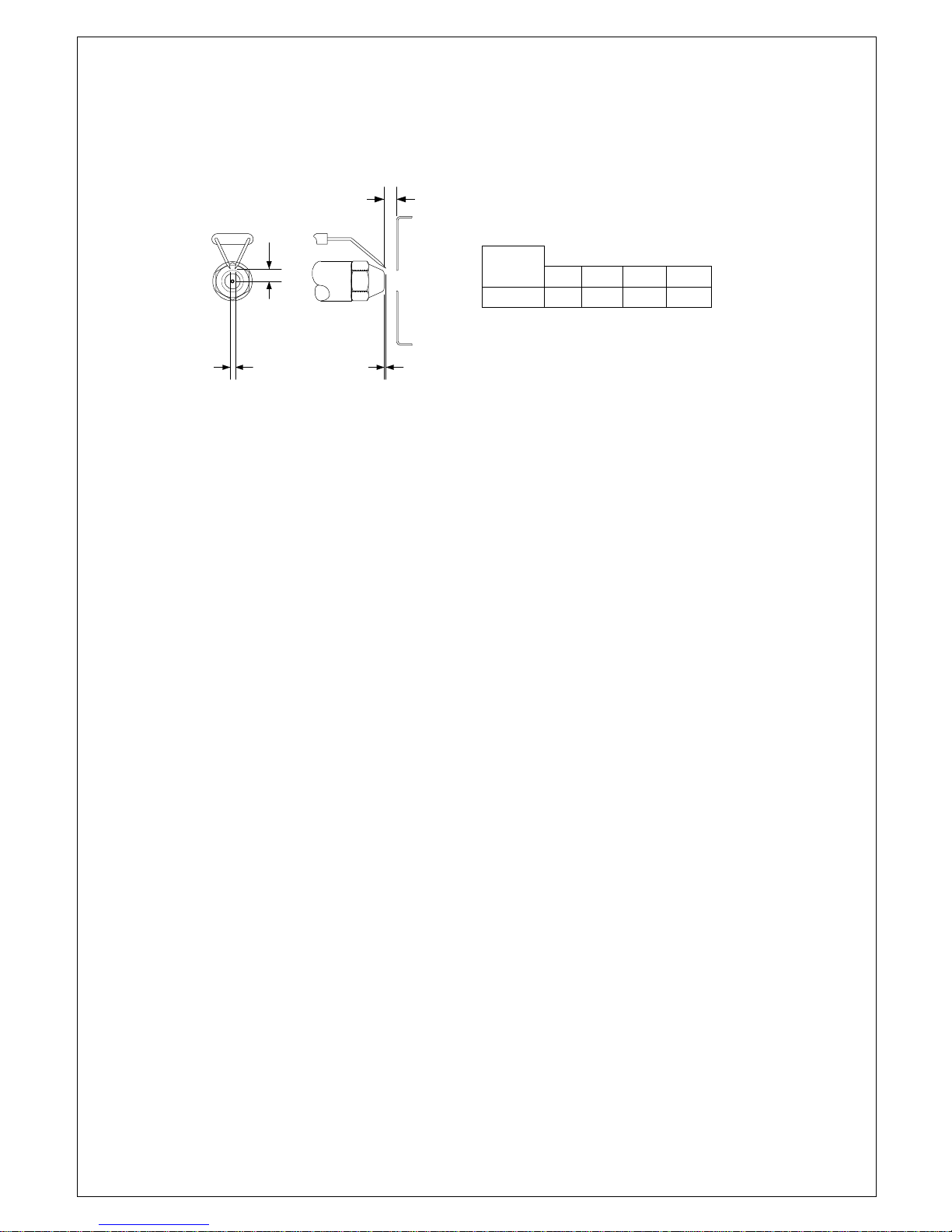

Headandelectrodesettings.............................................................................5

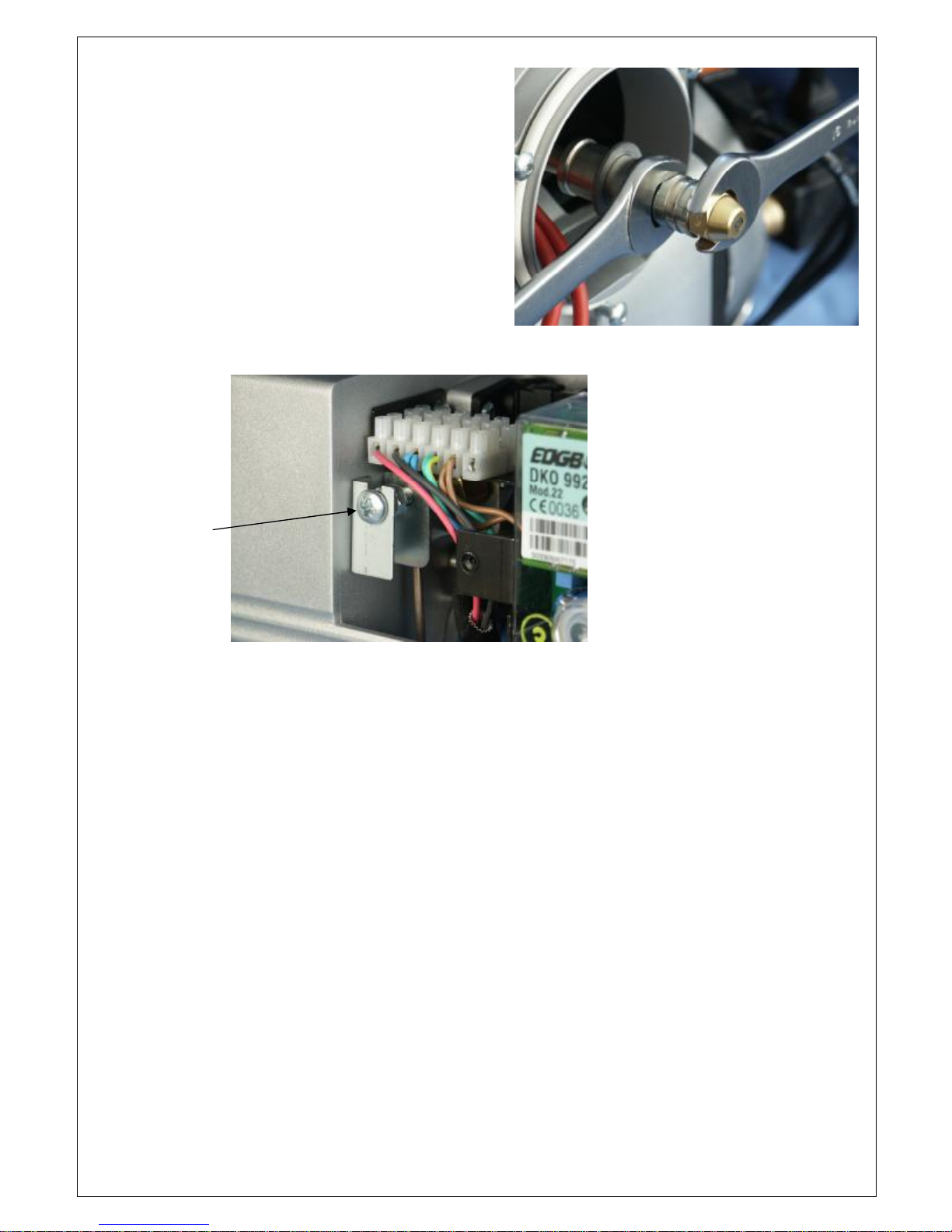

Components......................................................................................................6

Burner installation

Mountingontotheappliance............................................................................7

Electricalconnection.........................................................................................7

Fuelsupply........................................................................................................7

Airsupply...........................................................................................................7

Burneroperation

Beforestart-up..................................................................................................8

Start-upprocedure............................................................................................8

Normaloperating mode....................................................................................9

Burnerservicing

Combustionhead..............................................................................................10

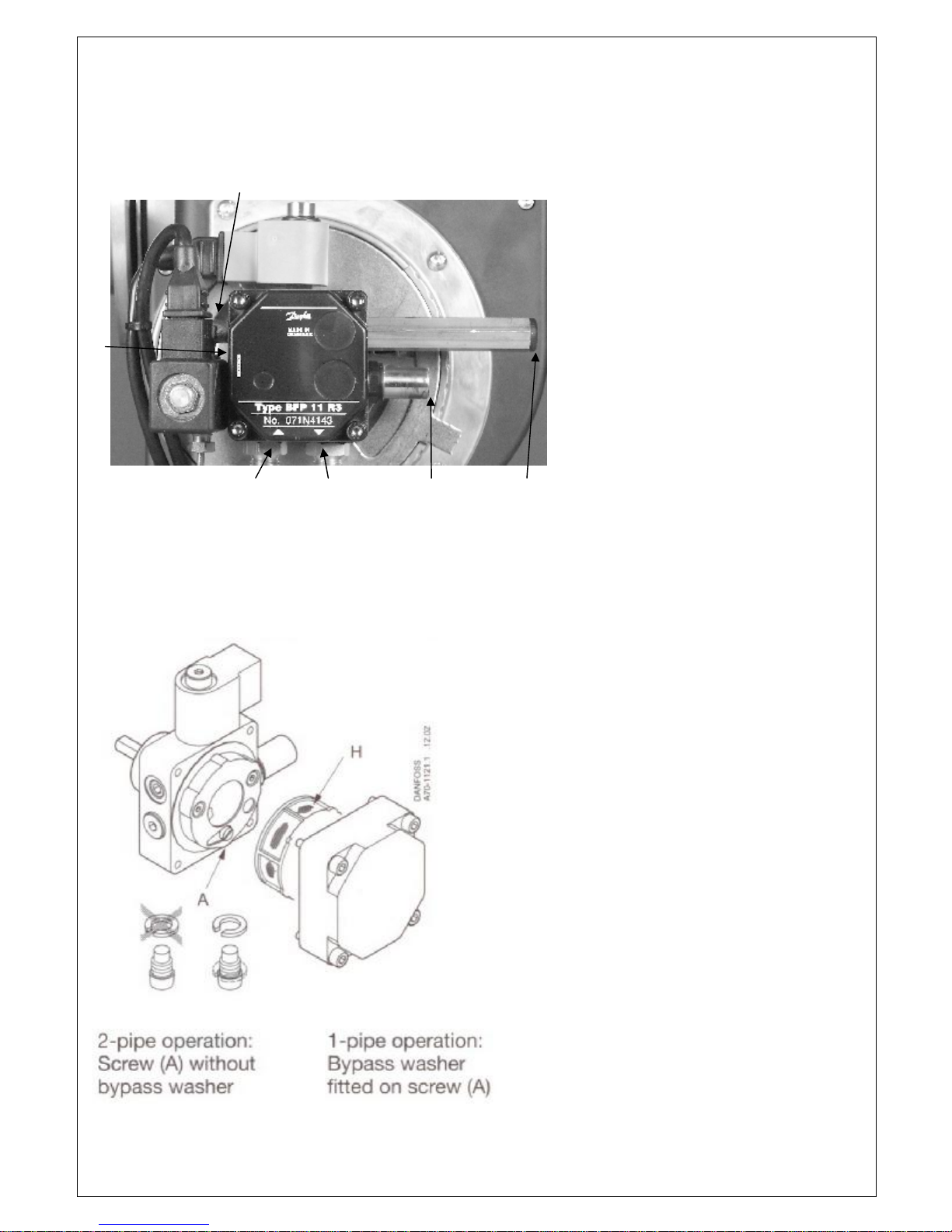

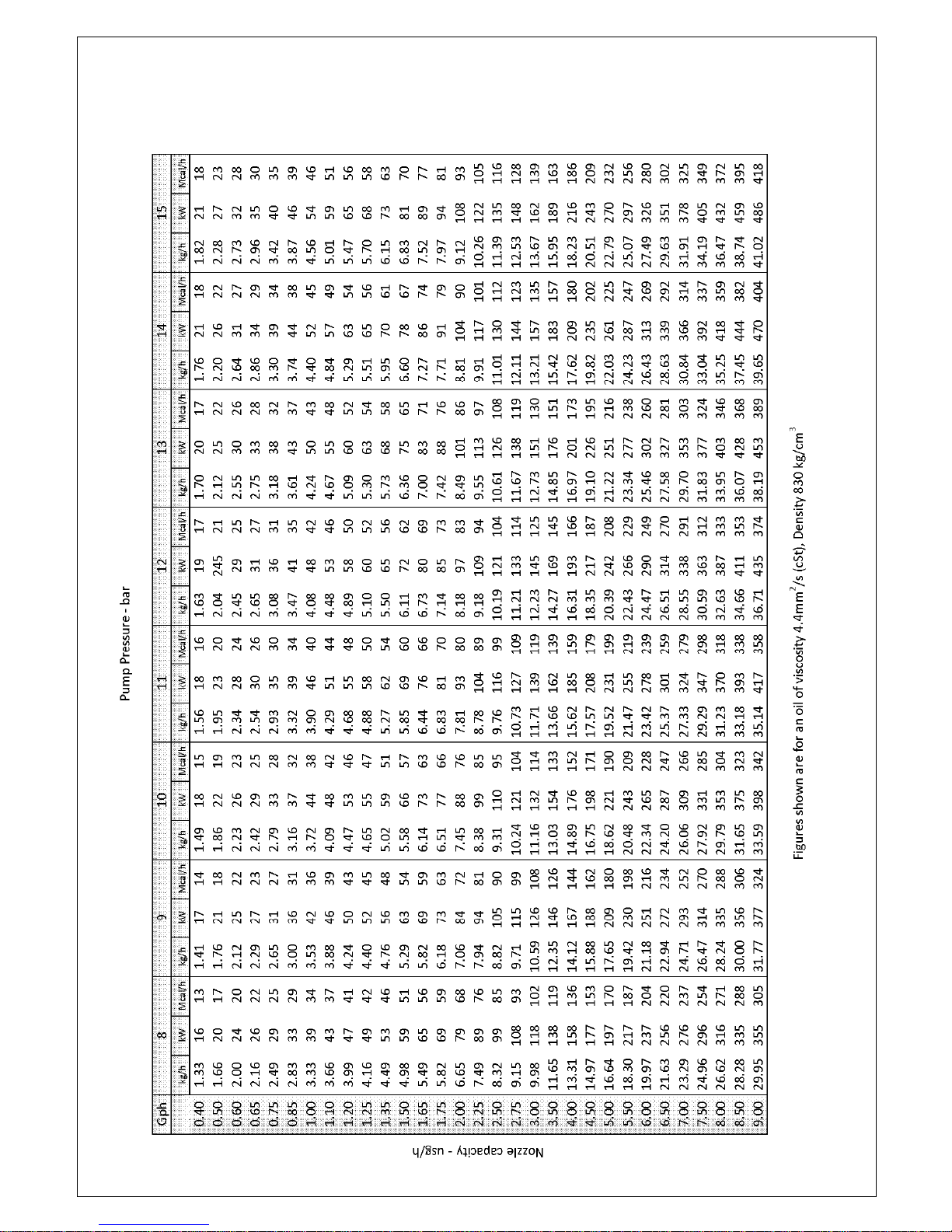

Oilpump............................................................................................................12

Oilsupplylinetables.........................................................................................14

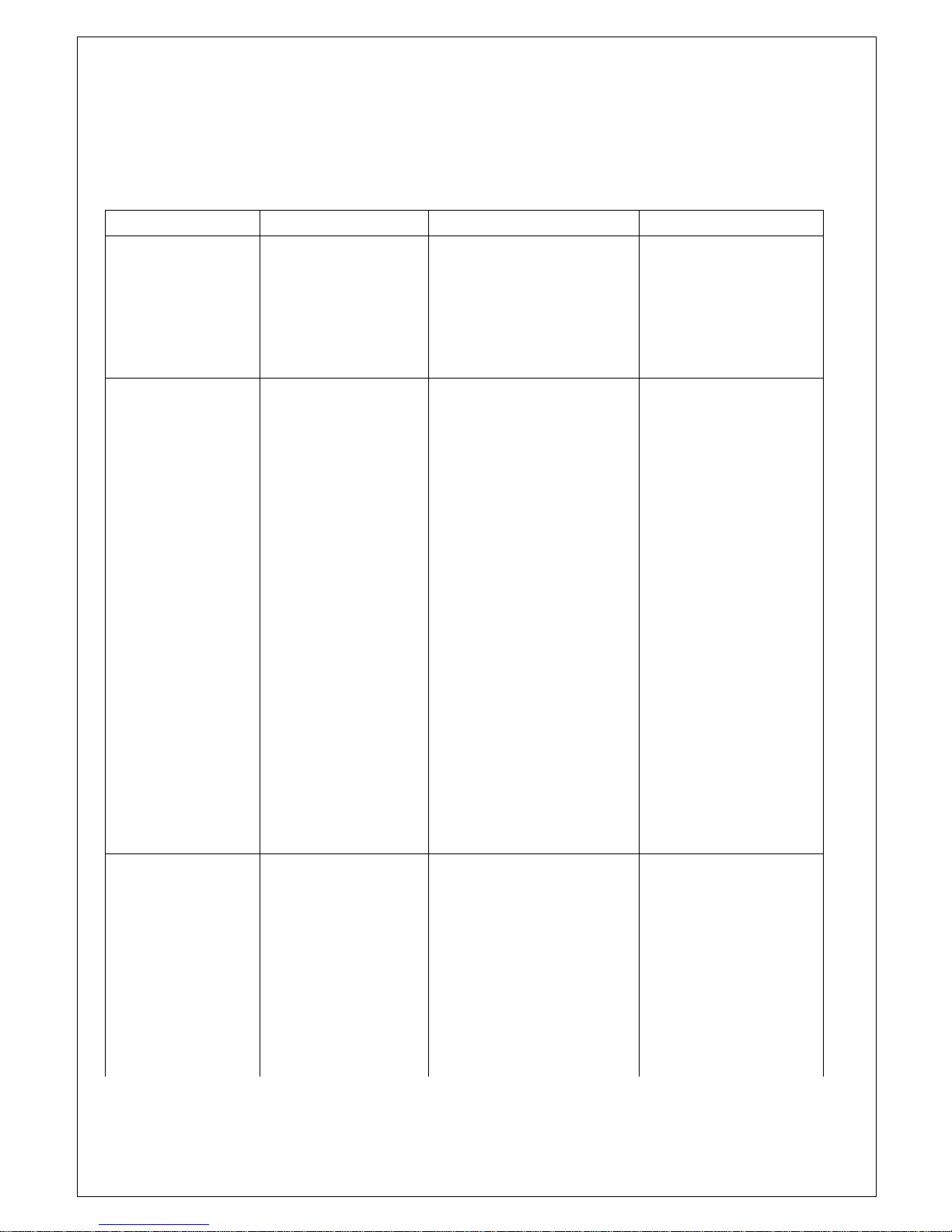

Nozzle table.......................................................................................................15

Faultfinding table.............................................................................................16

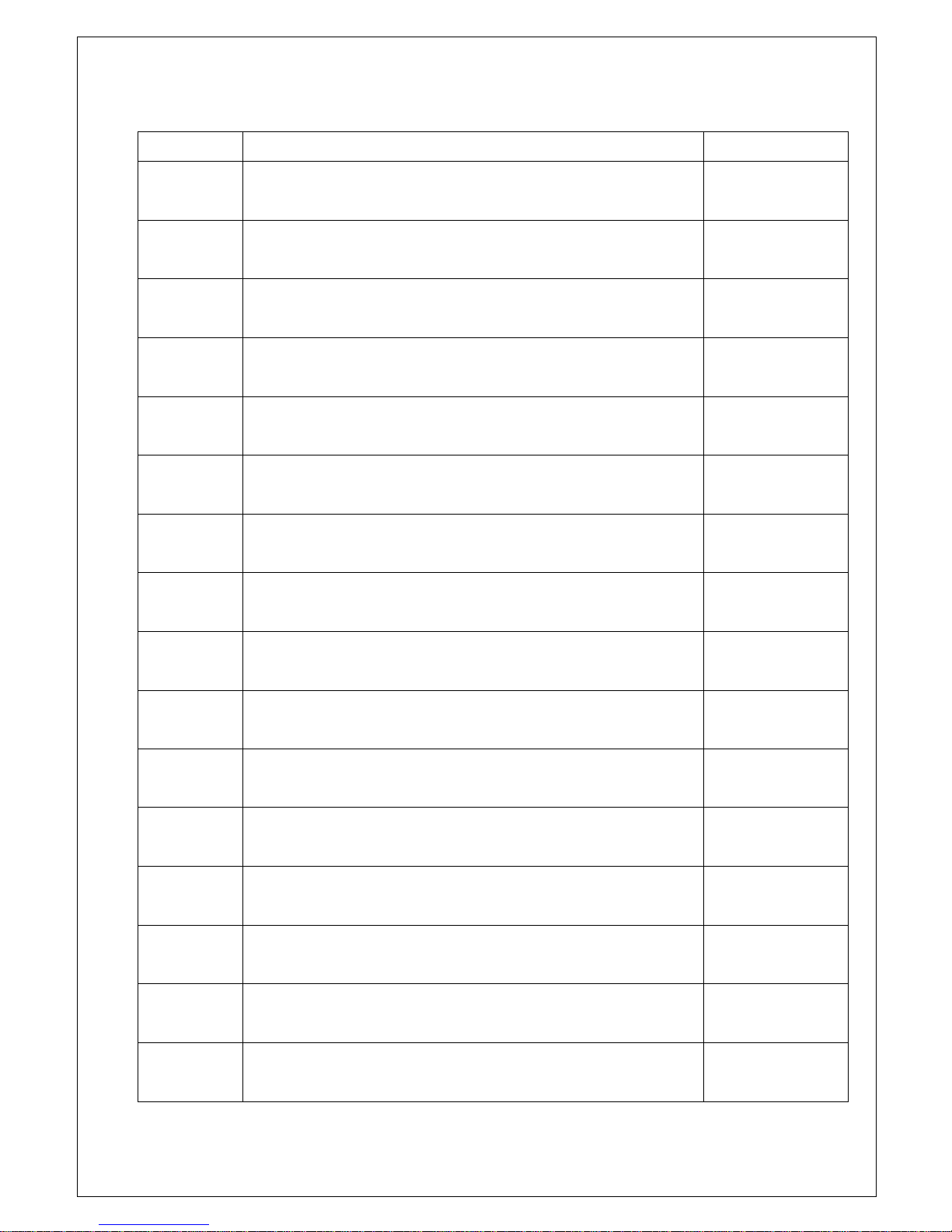

Commissioningreportsheet.............................................................................18

Burnerservicerecord........................................................................................19

Notes.................................................................................................................20

Importantnote

Thecontentsofthemanualmustbereadandfollowedpriortothefittingandcommissioningoftheburner.

Anywork onthisburnermustbecarriedoutbyasuitablyqualified, andexperienced,engineer.

Anyelectricalorfuel supplymustbeisolatedbeforeanywork iscarriedout.

TheinstallationmustbecarriedoutinaccordancewithcurrentElectricalRegulationsand allrelevantBuilding

Regulations.