Equus TT-WBC520 User manual

CONTACT

OPERATOR’S MANUAL

TT-WBC520 WHEELED

GRASS TRIMMER

IMPORTANT! IT IS ESSENTIAL THAT YOU READ THE INSTRUCTIONS IN THIS

MANUAL BEFORE ASSEMBLING, OPERATING AND MAINTAINING THIS MACHINE.

Sherpa Tools Ltd.

STWT52 WHEELED TRIMMER

If you experience any problems with this product,

please do not return to the store. Contact Sherpa

Tools direct on our UK helpline.

UK Helpline: 01522 283 020

www.sherpatools.co.uk June 2015

TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

Will not start 1. Out of fuel 1. Fill fuel tank

2. Engine not choked properly 2. See TO START ENGINE instructions

(QJLQHÁRRGHG 3. Wait several minutes before trying again

'LUW\DLUÀOWHU &OHDQRUUHSODFHDLUÀOWHU

5. Water in fuel 'UDLQIXHOWDQNDQGFDUEXUHWWRUÀOOZLWKIUHVKIXHO

6. Clogged fuel tank/line 5HPRYHIXHOWDQNRUÀOWHUDQGFOHDQ

7. Loose spark plug wire 7. Make sure plug wire is seated properly on plug

8. Bad spark plug or improper gap 8. Replace spark plug or adjust gap

9. Carburettor out of adjustment 9. Make necessary adjustments

Hard to start 1. Throttle control not set properly 1. Place throttle control in FAST position

'LUW\DLUÀOWHU &OHDQRUUHSODFHDLUÀOWHU

3. Bad spark plug or improper gap 3. Replace spark plug or adjust gap

4. Stale or dirty fuel 'UDLQIXHOWDQNDQGFDUEXUHWWRUÀOOZLWKIUHVKIXHO

5. Loose spark plug wire 5. Make sure plug wire is seated properly on plug

6. Carburettor out of adjustment 6. Make necessary adjustments

Loss of power 1. Engine is overloaded &OHDQRUUHSODFHDLUÀOWHU

'LUW\DLUÀOWHU &OHDQRUUHSODFHDLUÀOWHU

3. Bad spark plug 3. Replace spark plug

6SHFLÀFDWLRQ77%&0RGHO1R77%&

Engine type: Single cylinder, air-forced cool, 2-stroke

Engine model: 1E44F-5

Displacement: 51.7cc

Rated output power: 1.4kw/7500rpm

Carburetor: Diaphragm type

Ignition: CDI

Fuel tank capacity: 1200ml

Handle Pipe diameter: 25mm

Working pipe diameter:26mm

8MM+9 Alloy transmission shaft

Cutting head: Nylon cutter

ENGINE SPECIFICATION

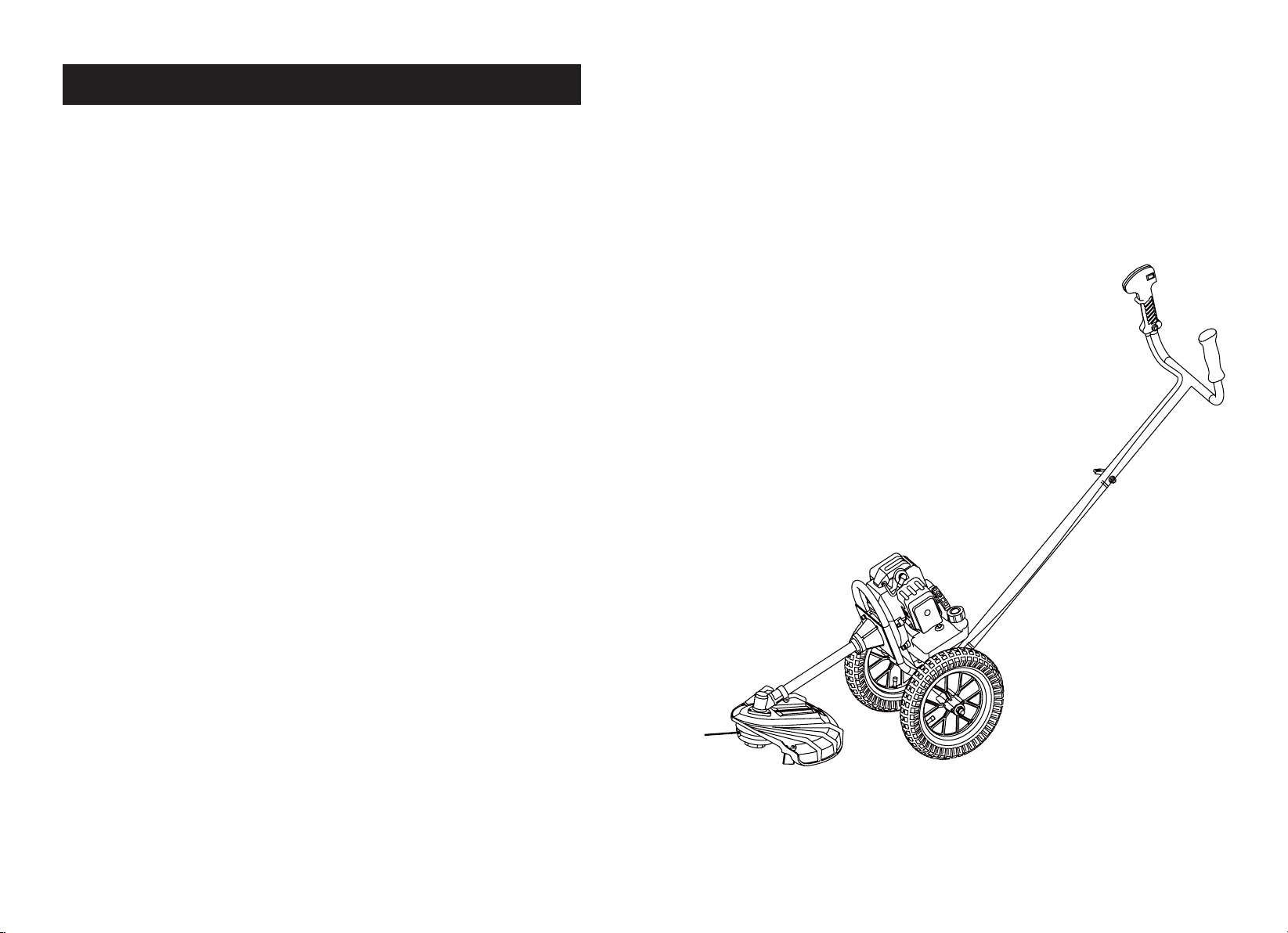

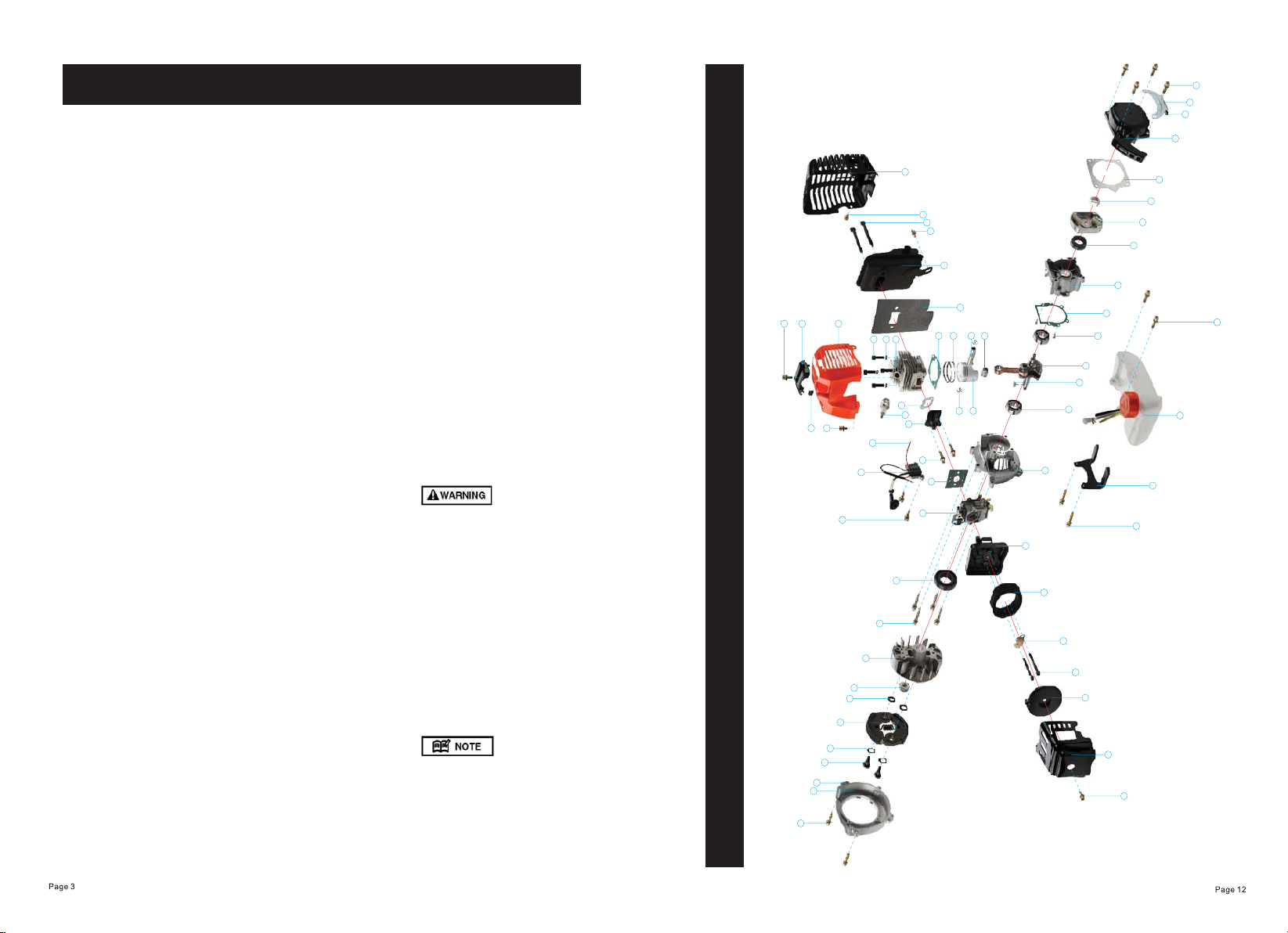

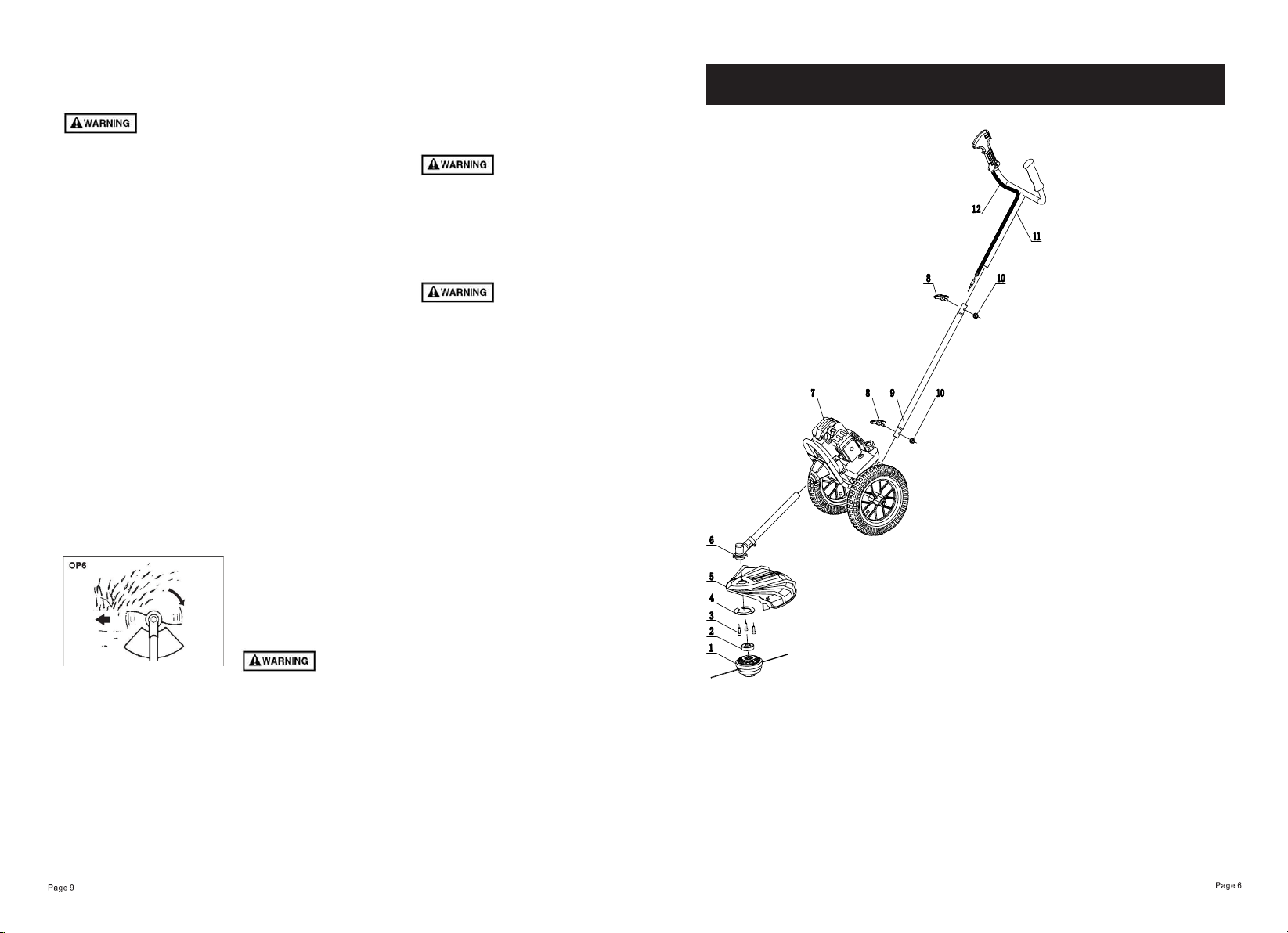

TRIMMER PARTS DIAGRAM

1. Trimmer Head

2. Head Spacer

3. Head Bolts

4. Protection Ring

5. Protection Guard

6. Geared Shaft

7. Engine & Chassis

8. Winged Screw

9. Nut

10. Lower Handle

11. Upper Handle

12. Throttle Cable

SAFETY FIRST

Instructions contained in warnings within this manual marked with a

symbol concern critical points which must be taken into consideration

to prevent possible serious bodily injury, and for this reason you are

requested to read all such instructions carefully and follow them without

fail.

WARNINGS IN THE MANUAL

WARNING

This mark indicates instructions which must be followed in order to

prevent accidents which could lead to serious bodily injury or death.

IMPORTANT

This mark indicates instructions which must be followed, or it leads to

mechanical failure, breakdown, or damage.

NOTE

This mark indicates hints or directions useful in the use of the product.

SAFETY INFORMATION

Warning Labels

Symbols on the machine

(1) Read owner’s manual before operating

machine.

(2) Wear head, eye and ear protection.

(3) Wear foot protection.

(4) Wear gloves.

(5) Beware of thrown objects.

(6) Warning / Attention

(7) Keep all children, bystanders and helpers 15

metres away from the brush cutter

For safe operation and maintenance,

symbols are carved in relief on the

machine. Please pay attention to all

instructions, symbols and labels to

ensure safe use.

(a) The port to refuel the “MIXED

PETROL”

Position: FUEL TANK CAP

(b) The direction A to close the choke

The direction B to open the choke

Position: AIR CLEANER COVER

J;OPZ\UP[PZÄ[[LK^P[OVUS`ÅL_PISL

line cutter. Never use cutting blade

made of metal or plastic. Position:

DEBRIS GUARD

(5)(2) (3) (4)(1) (6) (7)

1. Read this manual carefully

until you completely understand

and follow all safety and

operating instructions.

2. Keep this manual handy

so that you may refer to it

later whenever any questions

arise. Also note, if you have

any questions which cannot

be answered herein, contact

Sherpa Tools.

3. Always be sure to include

this manual when selling,

lending, or otherwise

transferring the ownership of

this product.

4. Never allow children

or anyone unable to fully

understand the directions

given in the manual to use the

machine.

WORKING CONDITION

1. When using the product, you

should wear proper clothing

and protective equipment:

(1) Helmet

(2) Ear protectors

(3) Protection goggles or face

protector

(4) Thick work gloves

(5) Non-slip-sole work boots

2. And you should carry with

you:

$WWDFKHGWRROVDQGÀOHV

(2) Properly stored fuel

(3) Spare trimmer line

(4) Things to notify your

working area (rope, warning

signs)

(5) Whistle (for collaboration or

emergency)

(6) Hatchet or saw (for removal

of obstacles)

3. Do not wear loose clothing,

jewellery, short trousers,

sandals, or go barefoot. Do not

wear anything which might be

caught by a moving part of the

unit. Secure hair so it is above

shoulder length.

WORKING CIRCUMSTANCE

1. Never start the engine inside

a closed room or building.

Exhaust gases contain

dangerous carbon monoxide.

2. Never use the product,

a. when the ground is slippery

RUZKHQ\RXFDQ·WPDLQWDLQD

steady posture.

b. At night, at times of heavy

fog, or at any other times when

\RXUÀHOGRIYLVLRQPLJKWEH

OLPLWHGDQGLWZRXOGEHGLIÀFXOW

to gain a clear view of the

working area.

c. During rain storms, during

lightning storms, at times of

strong or gale-force winds, or at

any other times when weather

conditions might make it unsafe

to use the product.

WORKING PLAN

1. You should never use

the product when under the

LQÁXHQFHRIDOFRKROZKHQ

suffering from exhaustion or

lack of sleep, when suffering

from drowsiness as a result

of having taken cold medicine

or at any other time when a

possibility exists that your

judgment might be impaired or

that you might not be able to

operate the product properly

and in a safe manner.

2. When planning your work

schedule, allow plenty of time

to rest. Limit the amount of

time over which the product

is to be used continuously to

somewhere around 30~40

minutes per session, and take

10~20 minutes of rest between

work sessions. Also try to

keep the total amount of work

performed in a single day under

2 hours or less.

,I\RXGRQ·WREVHUYHWKH

working time, or working

manner, Repetitive Stress

Injury (RSI) could occur. If you

feel discomfort, redness and

VZHOOLQJRI\RXUÀQJHUVRUDQ\

other part of your body, see a

doctor before getting worse.

2. To avoid noise complaints,

in general, operate product

between 8am and 5pm on

weekdays and 9am to 5pm

weekends.

Check and follow the local

regulations as to sound level

and hours of operations for the

product.

SAFE OPERATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

28

59

60

14

32

1

58

9

25

26

27

9

ENGINE PARTS DIAGRAM

Note that using any spark plugs

other than those designated

may result in the engine failing

to operate properly or in the

engine becoming overheated

and damaged.

7RLQVWDOOWKHVSDUNSOXJÀUVW

WXUQWKHSOXJXQWLOLWLVÀQJHU

tight, then tighten it a quarter

turn more with a socket wrench.

TIGHTENING TORQUE:

9.8~11.8 N.m

MUFFLER

Inspect periodically, the

PXIÁHUIRUORRVHIDVWHQHUV

any damage or corrosion. If

any sign of exhaust leakage

is found, do not use the brush

cutter and have it repaired

immediately.

Note that failing to do so may

result in the engine catching

RQÀUH

INTAKE AIR COOLING VENT

Never touch the cylinder,

PXIÁHURUVSDUNSOXJVZLWK

your bare hands immediately

after stopping the engine. The

engine can become very hot

when in operation, and doing

so could result in severe burns.

When checking the trimmer to

make sure that it is okay before

using it, check the area around

WKHPXIÁHUDQGUHPRYHDQ\

wood chips or leaves which

have attached themselves

to the brush cutter. Note that

failing to do so could cause the

PXIÁHUWREHFRPHRYHUKHDWHG

and that this in turn could cause

the brush cutter to catch on

ÀUH$OZD\VPDNHVXUHWKDW

WKHPXIÁHULVFOHDQDQGIUHHRI

wood chips, leaves, and other

waste before use.

• Check the intake air cooling

vent and the area around the

F\OLQGHUFRROLQJÀQVDIWHUHYHU\

25 hours of use for blockage,

and remove any waste which

has attached itself to the brush

cutter. Note that it is necessary

to remove the plug guard

shown in Figure in order to be

able to view the upper part of

the cylinder.

If waste gets stuck and causes

blockage around the intake air

cooling vent or between the

F\OLQGHUÀQVLWPD\FDXVHWKH

engine to overheat, and that

in turn may cause mechanical

failure on the part of the brush

cutter. (MA6)

&\OLQGHUÀQ

(2) Intake air cooling vent

(back)

PROCEDURES TO BE

PERFORMED AFTER EVERY

10 HOURS OF USE

5HPRYHWKHPXIÁHULQVHUWD

screwdriver into the vent, and

wipe away any carbon build up.

Wipe away any carbon buildup

RQWKHPXIÁHUH[KDXVWYHQWDW

the same time.

2. Tighten all screws, bolts, and

ÀWWLQJV

3. Check to see if any oil or

grease has worked its way in

between the clutch lining and

drum, and if it has wiped it

away using oil-free, lead-free

gasoline.

BEFORE STARTING THE

ENGINE

1. The area within a perimeter

of 50 feet (15m) of the person

using the product should be

considered a hazardous area

into which no one should enter.

If necessary, yellow warning

rope, warning signs should be

placed around the perimeter

of the area. When work is to

be performed simultaneously

by two or more persons,

care should also be taken

to constantly look around

or otherwise check for the

presence and locations of

other people working so as to

maintain a distance between

HDFKSHUVRQVXIÀFLHQWWR

ensure safety.

2. Check the condition of

working area to avoid any

accident by hitting hidden

obstacles such as stumps,

stones, cans, or broken grass.

Remove any obstacle before

beginning work.

3. Inspect the entire unit

for loose fasteners and fuel

leakage. Make sure that the

cutting attachment is properly

installed and securely fastened.

4. Be sure the debris guard is

ÀUPO\DWWDFKHGLQSODFH

STARTING THE ENGINE

1. Keep bystanders and

animals at least 50feet (15m)

away from the operating

point. If you are approached,

immediately stop the engine.

2. The product is equipped with

a centrifugal clutch mechanism,

so the cutting attachment

begins to rotate as soon as the

engine is started by putting the

throttle into the start position.

When starting the engine, place

the product onto the ground

LQDÁDWFOHDUDUHDDQGKROGLW

ÀUPO\LQSODFHVRDVWRHQVXUH

that neither the cutting part nor

the throttle come into contact

with any obstacle when the

engine starts.

Never place the throttle into

the high speed position when

starting the engine.

3. After starting the engine,

check to make sure that the

cutting attachment stops

rotating when the throttle is

moved fully back to its original

position. If it continues to rotate

even after the throttle has been

moved fully back, turn off the

engine and take the unit to your

authoriwed servicing dealer for

repair.

USING THE PRODUCT

Cut only materials

recommended by the

manufacturer. And use only for

tasks this machine is intended

for.

*ULSWKHKDQGOHVÀUPO\ZLWK

both hands using your whole

hand. Place your feet slightly

apart (slightly further apart than

the width of your shoulders) so

that your weight is distributed

evenly across both legs, and

always be sure to maintain

a steady, even posture while

working.

2. Keep cutting attachment

below waist level.

3. Maintain the speed of the

engine at the level required to

perform cutting work, and never

raise the speed of the engine

above the level necessary.

4. If the unit start to shake or

vibrate, turn off the engine and

check the whole unit. Do not

use it until the trouble has been

properly corrected.

5. Keep all parts of your body

away from rotating cutting

attachment and hot surfaces.

1HYHUWRXFKWKHPXIÁHU

spark plug, or other metallic

parts of the engine while

the engine is in operation or

immediately after shutting

down the engine. Doing so

could result in serious burns or

electrical shock.

IF SOMEONE COMES

1. Guard against hazardous

situations at all times. Warn

adults to keep pets and children

away from the area. Be careful

if you are approached. Injury

PD\UHVXOWIURPÁ\LQJGHEULV

2. If someone calls out or

otherwise interrupts you while

working, always be sure to turn

off the engine before turning

around.

MAINTENANCE

1. In order to maintain your

product in proper working order,

perform the maintenance and

checking operations described

in the manual at regular

intervals.

2. Always be sure to turn off

the engine before performing

any maintenance or checking

procedures.

The metallic parts reach high

temperatures immediately after

stopping the engine.

3. Under no circumstances

should you ever take apart the

product or alter it in any way.

Doing so might result in the

product becoming damaged

during operation or the product

becoming unable to operate

properly.

HANDLING FUEL

1. The engine of the product

is designed to run on a mixed

fuel which contains highly

ÁDPPDEOHSHWURO1HYHUVWRUH

FDQVRIIXHORUUHÀOOWKHWDQN

of the unit in any place where

there is a boiler, stove, wood

ÀUHHOHFWULFDOVSDUNVZHOGLQJ

sparks, or any other source of

KHDWRUÀUHZKLFKPLJKWLJQLWH

the fuel.

2. Never smoke while operating

WKHXQLWRUUHÀOOLQJLWVIXHOWDQN

:KHQUHÀOOLQJWKHWDQN

always turn off the engine and

allow it to cool down. Take a

careful look around to make

sure that there are no sparks or

RSHQÁDPHVDQ\ZKHUHQHDUE\

before refuelling.

4. Wipe spilled fuel completely

using a dry rag if any fuel

spillage occurs during

refuelling.

5. After refuelling, screw the

fuel cap back tightly onto the

fuel tank and then carry the

unit to a spot 10feet (3m) or

more away from where it was

refuelled before turning on the

engine.

TRANSPORTATION

1. When hand-carrying the

product, cover over the cutting

part if necessary, lift up the

product and carry it paying

attention to the blade.

2. Never transport the product

over rough roads over long

distances by vehicle without

removing all fuel from the fuel

tank. If doing so, fuel might leak

from the tank during transport.

Maintenance, replacement, or

repair of the emission control

device and systems may be

performed by any non-road

engine repair establishment or

individual.

• Always be sure to stop the

engine before inspecting the

brush cutter for problems or

performing maintenance.

• Never alter the brush cutter or

take the engine apart.

• Things to check before using

brush cutter.

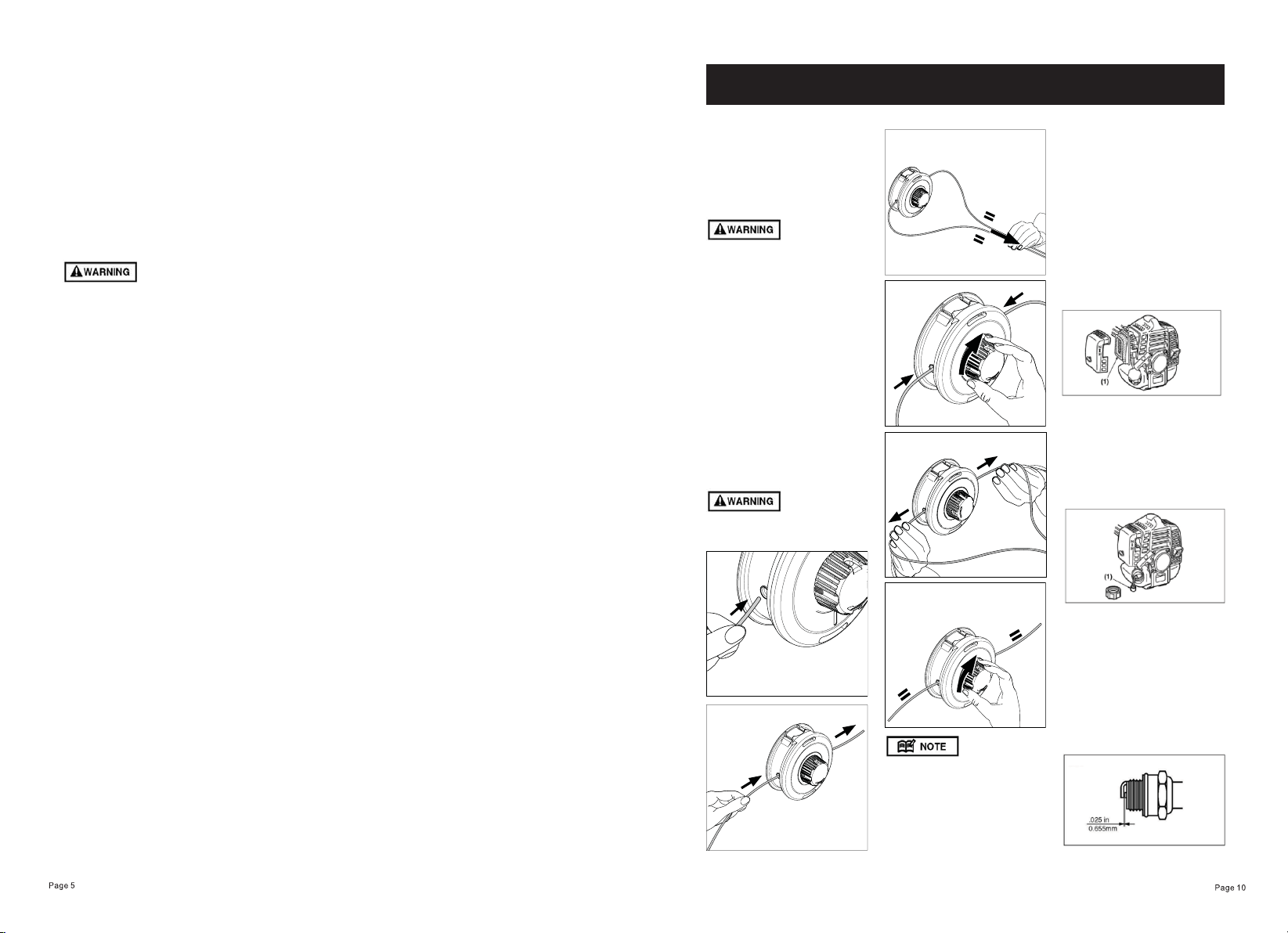

REFILLING TRIMMING LINE

For replacement line, use a

diameter of 3.0mm. The spool

is capable for a line up to 4m

on the head. Avoid using a

larger line as it may cut down

the trimming performance.

For safety reasons, do not use

metal reinforced line.

We recommend using Oregon

Duoline 3.00mm (part no.

106502E)

AIR FILTER

7KHDLUÀOWHULIFORJJHG

will reduce the engine

performance. Monthly check

DQGFOHDQWKHÀOWHUHOHPHQW

in warm, soapy water as

required. Dry completely before

installing. If the element is

broken or shrunk, replace with

a new one.

$LUÀOWHU

FUEL FILTER

When the engine

runs short of fuel supply, check

WKHIXHOFDSDQGWKHIXHOÀOWHU

for blockage.

)XHOÀOWHU

SPARK PLUG

6WDUWLQJIDLOXUHDQGPLVÀULQJ

are often caused by a fouled

spark plug. Periodically clean

the spark plug and check that

the spark gap is in the correct

range.

When you take off the spark

plug, twist and pull off the cap.

MAINTENANCE

LINE HEAD USAGE

1. Always wear eye protection

such as safety goggles. Never

lean over the rotating cutting

head. Rocks or other debris

could be thrown into eyes

and face and cause serious

personal injury.

2. Keep the debris guard

attached in place at all times

when the unit is operated.

TRIMMING GRASS AND

WEEDS

•Always remember that the TIP

of the line does cutting. You

will achieve better results by

not crowding the line into the

cutting area. Allow the unit to

trim at its own pace.

1. Hold the unit so the head

is off the ground and is tilted

about 20 degrees toward the

sweep direction. (OP6)

2. You can avoid thrown debris

by sweeping from your right to

the left.

3. Use a slow, deliberate action

to cut heavy growth. The rate

of cutting motion will depend on

the material being cut. Heavy

growth will require slower

action than will light growth.

4. Never swing the unit so hard

as you are in danger of losing

your balance or control of the

unit.

5. Try to control the cutting

motion with the hip rather than

placing the full workload on the

arm and hands.

6. Take precautions to avoid

wire, grass and dead, dry, long-

stem weeds from wrapping

around the head shaft. Such

materials can stall the head

and cause the clutch to slip,

resulting in damage to the

clutch system if repeated

frequently.

ADJUSTING THE LINE

LENGTH

• Your brush cutters is equipped

with a bump feed type nylon

line head that allows the

operator to advance the line

without stopping the engine.

When the line becomes short,

lightly tap the head on the

ground while running the

engine at full throttle.

• Each time the head is

bumped, the line advance

about 1 inch(25.4 mm). For

better effect, tap the head on

bear ground or hard soil. Avoid

bumping in thick, tall grass

as the engine may stall by

overload.

• The rotating parts fastened

incorrectly may cause serious

accident to the operator.

• Make sure that the head is not

bent, warped, cracked, broken

or damaged.

,I\RXÀQGDQ\HUURUWRWKH

head, discard it and change

new one.

• By using the harness, hang

the unit on your right side.

Adjust the harness length

so that the cutting head may

become parallel to the ground.

• Make sure to use harness and

cutting attachment guard. If not,

it is very dangerous when you

slip or lose your balance.

• If the grass or other object

gets caught in the head, or

if the unit starts to shake or

vibrate, turn off the engine and

check the head.

• Turn off the engine and make

sure the head has completely

stopped before checking the

blade, and removing any object

got caught in.

1. INSTALLING HANDLE

Insert the lower handle (9) into

the mounting cup at the bottom

of the drive unit (7). Align holes

and thread handle screw (8)

through the handle and tighten

nut (10). Insert upper handle

(11) into top of lower handle (9).

Align holes and thread handle

screw (8) through the handle

and tighten nut (10).

Remove side cover from engine

unit (7) using hex key. Pass

throttle wiring under engine and

fuel tank and then up in front

of engine. Insert throttle cable

into place and tighten screw

to secure. Push both pairs of

electric connectors together to

secure. Ensure the wires are

connected with the matching

colour wire from the engine.

2. INSTALLING SHAFT

Line shaft (6) up with entry

point at bottom of engine (7).

,QVHUWDQGSXVKÀUPO\LQWR

place. Ensure the bottom

end of the shaft is pointing

straight down in preparation of

attaching protection shield and

cutting head. Push the upper of

the two bolts through shaft and

tighten. Then tighten the lower

bolt to clamp around the shaft.

3. INSTALLING PROTECTION

SHIELD

Align the protection guard (5)

with the head of the shaft (6).

Attach the protection guard (5)

and ring (4) with the three bolts

supplied (3).

4. INSTALLING CUTTING

HEAD

Push spacer (2) onto shaft

underneath protection guard(5).

While locking the gear shaft

by inserting the hexagon bar

into the upper holder and the

housing, rotate the cutting

head to engage threads. Hand

tighten it securely.

4. INSTALLING TRIMMER

LINE

See diagram below.

ASSEMBLY

3HWUROLVYHU\ÁDPPDEOH

Avoid smoking or bringing any

ÁDPHRUVSDUNVQHDUIXHO

• Wipe up all spills before

starting the engine.

• Make sure to stop the

engine and allow it cool before

refuelling the unit.

.HHSRSHQÁDPHVDZD\IURP

the area where fuel is handled

or stored.

• Never use oil for 4 cycle

engine use or water cooled

2-cycle engine.

• Never use “FUEL WITH

NO OIL (NEAT UNLEADED

PETROL)”.

• Never use fuel laced with

water.

• Mixed fuels which have

been left unused for a period

of one month or more may

clog the carburetor or result in

the engine failing to operate

properly. Put remained fuel into

an air-tight container and keep

it in the dark and cool room.

• Please ask for “mixed

gasoline for air-cooled 2-cycle

engines” at your nearest gas

station, or use fuel made by

putting unleaded gasoline for

automobiles and air-cooled

2-cycle engine oil into a mixing

container in accordance with

the following ratios and then

shaking to mix well.

Mixing ratios:

When using commercially

available 2 stroke oil:

40:1

OIL

It is recommended that you use

a high quality 2 stroke oil in this

machine with an ethanol shield.

Sherpa recommends use of

B3C oil in the wheeled trimmer,

when using this product you

are able to mix petrol to oil at

a 50:1 ratio, as opposed to the

usual 40:1 with other 2 stroke

oils.

Ethanol Shield 2 Stroke Oil

reduces engine temperature

&&7SURWHFWVDJDLQVWVSHFLÀF

forms of corrosion, reduces

exhaust smoke output and

extends engine life. This oil will

stabilise fuel for up to a year.

100ml - B3C2ST1S

1l - B3C2STLRT

STORAGE

Aged fuel is one of major

causes of engine starting

failure. Before storing the unit,

empty the fuel tank and run

the engine until it uses all the

fuel left in the fuel line and the

carburetor. Store the unit indoor

taking necessary measures for

rust prevention.

FUEL

STARTING ENGINE

The cutting head will start

rotating upon the engine starts.

5HVWWKHXQLWRQDÁDWÀUP

place. Keep the cutting head

off the ground and clear of

surrounding objects as it will

start rotating upon starting of

the engine.

2. Ensure the choke lever to

the closed position (down).

(OP2)

(1) Choke lever

(2) Closed position

(3) Open position

3. Set the ignition switch to the

“start” position.

4. Push the primer bulb pump

ÀYHRUVL[WLPHV23

5. While pulling the throttle

trigger all the way in, push the

throttle lock button, and release

the throttle, then the throttle

lever is in the “Start position”.

(OP3)

(4) Ignition switch

(5) Throttle lock button

(6) Throttle trigger

6. Move the choke lever to the

open position (up) (OP2).

7. Pull out the starter rope

quickly to start engine. (OP4)

Avoid pulling the rope to its end

or returning it by releasing the

knob. Such actions can cause

starter failures.

8. Close choke by moving

leaver (1) to closed position

(down).

9. Run engine for a 10-20

seconds before releasing

throttle lock button by gently

pulling on throttle trigger and

releasing again.

10. Allow the engine to warm

up for several minutes before

starting operation.

1. When restarting the engine

immediately after stopping it,

leave the choke open (OP2)

and push the primer pump

several times (OP4).

2. Overchoking can make the

engine hard to start due to

excess fuel. If the engine failed

to start after several attempts,

open the choke and repeat

pulling the rope, or remove the

spark plug and dry it.

STOPPING ENGINE

1. Release the throttle lever

and run the engine for a half

minute.

2. Shift the ignition switch to the

STOP position.

Except for an emergency,

avoid stopping the engine while

pulling the throttle lever.

ADJUSTING IDLING SPEED

(OP5)

1. If the engine tends stop

frequently at idling mode, turn

the adjusting screw clockwise

a fraction.

2. When the cutting head keeps

rotating after releasing the

trigger, turn the adjusting screw

anticlockwise.

Warm up the engine before

adjusting the idling speed.

OPERATION

(6)

(5)

Table of contents

Popular Trimmer manuals by other brands

Ryobi

Ryobi RY34440 Replacement parts list

Bosch

Bosch Art 2300 Easytrim Accu instruction manual

Coopers of Stortford

Coopers of Stortford Victor Tools H224 Instructions for use

hecht

hecht 675 Instructions for use

Husqvarna

Husqvarna 325R X-SERIES Operator's manual

Shindaiwa

Shindaiwa DH254 Owner's/operator's manual

Black & Decker

Black & Decker 616081-00 instruction manual

RedMax

RedMax CHTZ2400 Owner's/operator's manual

Premier

Premier StakCut 724 instruction manual

Cosmopolitan

Cosmopolitan KLR928981478 instruction manual

Stihl

Stihl HSA 50.1 instruction manual

EINHELL

EINHELL RG-ET 7535 Original operating instructions