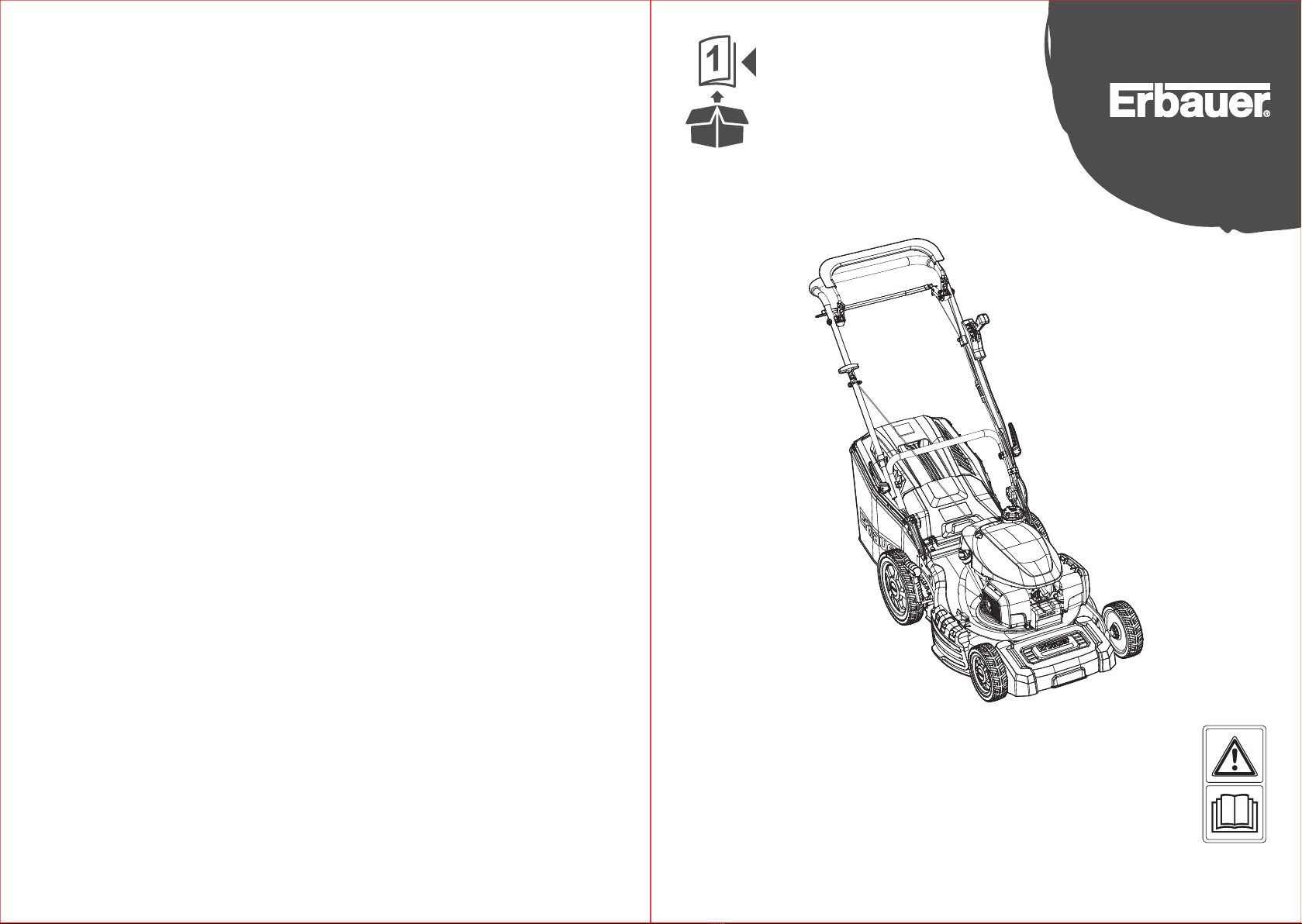

Erbauer ELMP170SP51 User manual

V10820 / BX220IM

EAN: 5059340124438

ORIGINAL INSTRUCTIONS

ELMP170SP51

Product description

Safety instructions

Assembly

Use

Guarantee

Declaration of conformity

Care & maintenance

4

9

20

22

31

39

40

WARNING! Please read all safety

warnings carefully and be sure that

they are fully understood before

handling the tool.

1

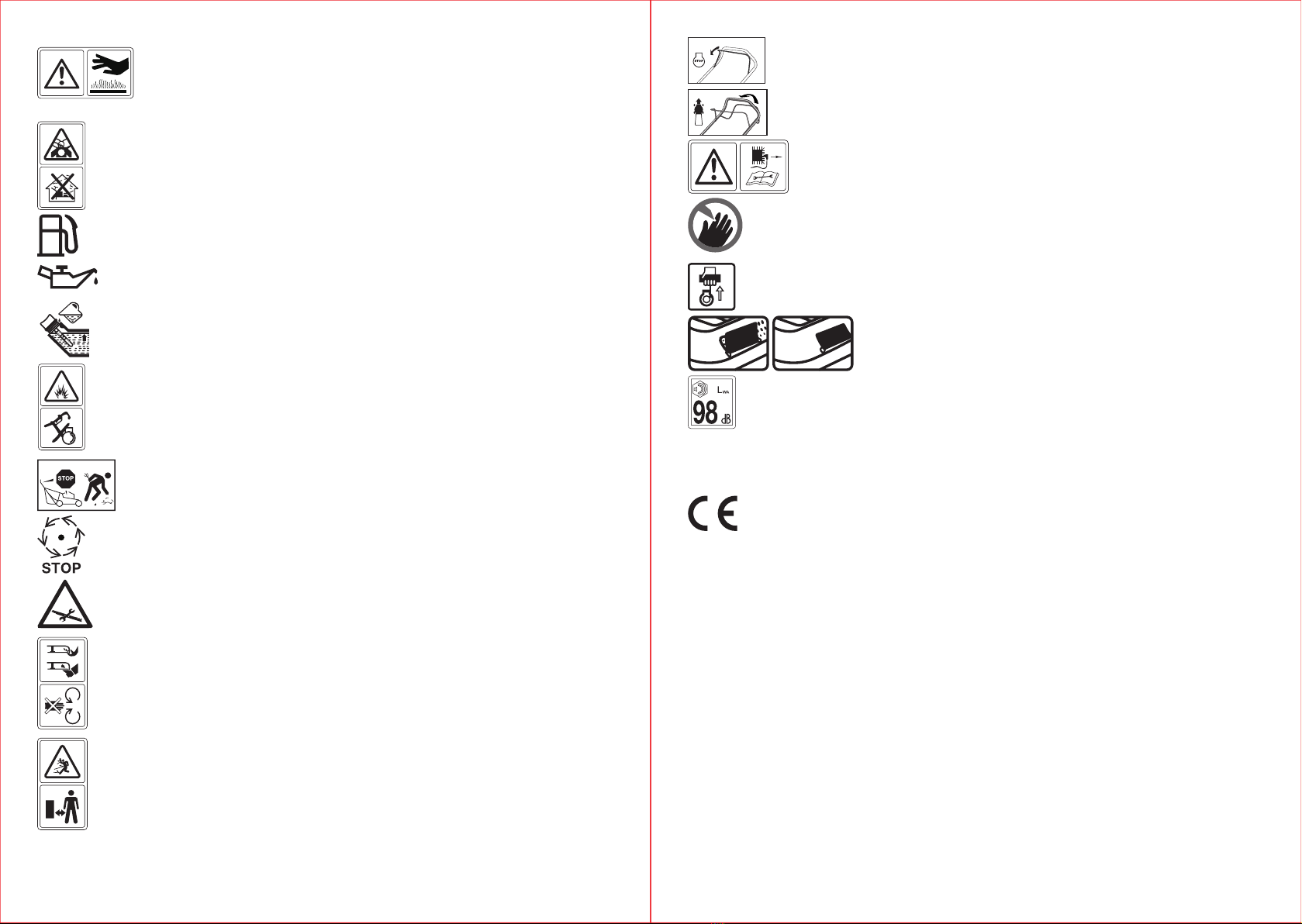

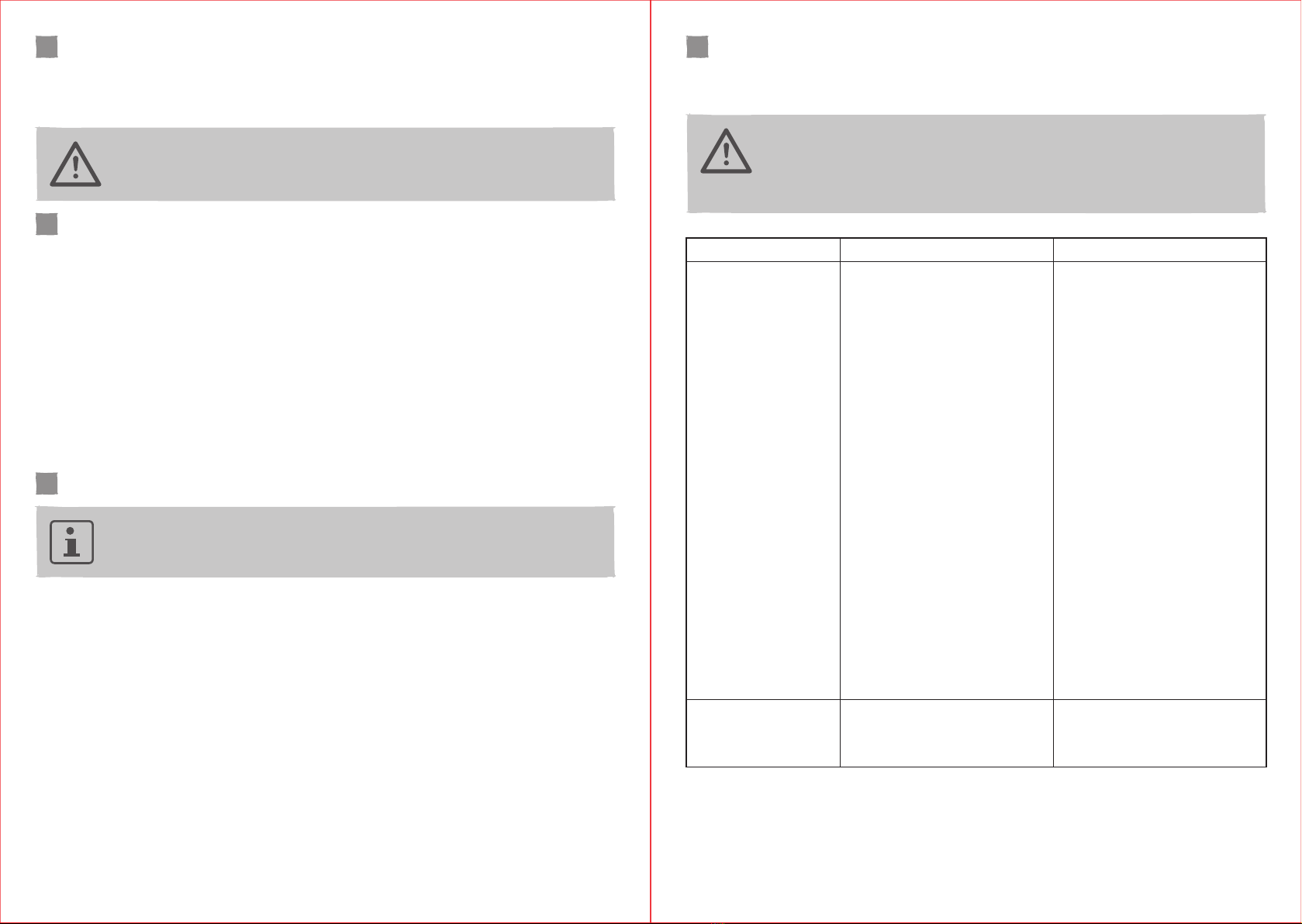

PRODUCT DESCRIPTION

1. Brake clutch

2. Handle

a. Transportation handle

3. Drive bar

4. Upper handle bar

5. Speed lever

6. Lower handle bar

7. Drive wire

8. Brake wire

9. Side lever (x2)

a. Washer *

b. Nut *

10. Wire clip

11. Fuel tank cap

12. Airltercase

a. Filter *

b. Cover *

13. Spark plug connector

14. Wheel

15. Muer

16. Sidedeectorguard

a. Lock buckle

17. Oil tank cap with dipstick

18. Lever for cutting height adjustment

19. Lower handle bar knob (x2)

a. Bolt *

20. Reardeectorguard

21. Grass catcher

a. Handle

b. Hatch

22. Starter wire

23. Recoil starter handle

a. Hook

24. Mulching insert

a. Unlock button

25. Side discharge attachment

26. Spark plug wrench

27. Cutting means (blade)

a. Spindle

b. Ring

c. Washer

d. Lockingange

e. Hex bolt

28. Oil drain screw

29. Rear discharge chute

30. Fuelshut-ovalve

31. Water hose connector

32. Engine operator’s manual *

Parts marked with * are not shown in this overview. Refer to the

respective section in the instruction manual.

4

Product description

7

8

9a

9b

1

2

3

4

5

6

11

2a

12

13

14

15

16a

16

18

17

19

20

10

21a

21

22

23

24a

24 25

26

9

21b

23a

30

31

5

1

19

6

19a

2

6

4

3

9

9a

9b

4

6

4

20

21

51

2

24

20

6

2

24a

1

27

27a

27b

27c

27d

27e

272829

6

7

25

16a

16

8

9

11

10

5 mm

11 12

13

1 cm

max

min

17

14

7

15 16 1

2

17

2

3

18

5

19

23a

23

4

20 4

23

23a

21 21b 22

21b

8

23

1

2

18

24

2

25 26

1

3

27 28

31

9

Safety instructions

PETROL POWERED LAWNMOWERS SAFETY WARNINGS

WARNING Read all safety warnings, instructions, illustrations and

specicationsprovidedwiththisproduct.Failuretofollowallinstructions

listedbelowmayresultinelectricshock,reand/orseriousinjury.

Save all warnings and instructions for future reference.

1) TRAINING

a) Read the instructions carefully. Be familiar with the controls and the proper

use of the product.

b) Never allow children or people unfamiliar with these instructions to use the

product. Local regulations can restrict the age of the operator.

c) Never mow while people, especially children or pets, are nearby.

d) Keep in mind that the operator or user is responsible for accidents or hazards

occurring to other people or their property.

e) The operators must receive a proper training in the use, adjustment and

operation of the product, including prohibited operations.

2) PREPARATION

a) While mowing, always wear protective footwear and long trousers. Do not

operate the product when barefoot or wearing open sandals.

b) Thoroughly inspect the area where the product is to be used and remove

all stones, sticks, wires, bones, and other foreign objects.

c) WARNING-Petrolishighlyammable.

• Storefuelincontainersspecicallydesignedforthispurpose.

• Refuel outdoors only and do not smoke while refuelling.

• Add fuel before starting the engine. Never remove the fuel tank cap or add

petrol while the engine is running or when the engine is hot.

• If petrol is spilt, do not attempt to start the engine. Move the product away

from the area of spillage and avoid creating any source of ignition until

fuel vapours have dissipated.

• Replace all fuel tank and container caps securely.

d) Replace faulty silencers.

10

e) Before using, always visually inspect to see that the blades, blade bolts

and cutter assembly are not worn or damaged. Replace worn or damaged

blades and bolts in sets to preserve balance.

f) CAUTION! Do not touch rotating cutting means.

g) Engine brake (brake clutch): Use the brake clutch to stop the engine. When

you release the clutch, the engine and the blade stop automatically in a

few seconds. To mow, hold the bar in the working position. Before you start

to mow, check the brake clutch several times to be sure that it is working

correctly. Ensure that the brake wire can be smoothly operated (e.g. is not

catching or kinking in any way).

3) OPERATION

a) Donotoperatetheengineinaconnedspacewheredangerouscarbon

monoxide fumes can accumulate.

b) Mowonlyindaylightoringoodarticiallight.

c) Donotoperatetheproductwhilebeingtired,illorundertheinuenceof

alcohol or drugs.

d) Avoid operating the product in wet grass, where feasible.

e) Always be sure of your footing on slopes.

f) Walk, never run.

g) Mow across the face of slopes, never up and down.

h) Exercise extreme caution when changing direction on slopes.

i) Donotmowexcessivelysteepslopes,neardrop-os,ditchesorembankments.

j) Avoid using the product in bad weather conditions especially when there is

a risk of lightning.

k) Use extreme caution when reversing or pulling the product towards you.

l) Stop the blade(s) if the product has to be tilted for transportation when

crossing surfaces other than grass, and when transporting the product to

and from the area to be mowed.

m) Never operate the product with defective guards, shields, or without safety

devices,forexamplemulchinginsert,deectorsand/orgrasscatchers,in

place.

n) Do not change the engine governor settings or overspeed the engine.

o) Do not alter or tamper with any sealed adjustments for the engine speed control.

p) Do not tamper or disable any product’s safety systems or features.

q) Ensure and regularly check that all starting interlocks and operator presence

controls are functioning correctly.

r) Stop the product according to instructions in this manual before leaving the

operator’s position and park it in a safe location.

s) Start the engine carefully according to instructions and with feet well away

from the blades.

11

t) Do not tilt the product when starting the engine or switching on the engine,

except if the product has to be tilted for starting. In this case, do not tilt it

more than necessary and lift only the part which is away from the operator.

Always ensure that both hands are in the operating position before returning

the product to the ground.

u) Keep hands and feet away from the cutting means at all times and especially

when switching on the engine.

v) Do not put hands or feet near or under rotating parts. Keep clear of the

discharge opening at all times.

w) Never pick up or carry a product while the engine is running.

x) In case of any situation mentioned below, stop the engine and disconnect

the spark plug connector. Make sure that all moving parts have come to a

complete stop:

• before clearing a blockage or unclogging chute,

• before checking, cleaning or working on the product,

• after striking a foreign object. Inspect the product for damage and make

repairs as necessary

• if the product starts to vibrate abnormally (check immediately)

> inspect for damage

> replace or repair any damaged parts

> check for and tighten any loose parts

• whenever you leave the product

• before refuelling

y) Nevertouchtheexhaust,exhaustguardorcoolingnswhentheengineis

hot.

z) Never carelessly touch hot parts of the product. While the product is in

operation and shortly after that, its parts such as the exhaust, engine, and

other surfaces are extremely hot! Risk of burns! Pay attention to the markings

on the product.

za) Make sure that the air vents of the combustion engine are clear. Keep the

air vents free of dust, dirt particles, gases and fumes.

zb) Never start or run the engine indoors. The exhaust fumes are dangerous,

containing carbon monoxide, an odourless and deadly gas. Operate this

product only in well ventilated outdoor areas.

4) MAINTENANCE AND STORAGE

a) Follow the maintenance and repair instructions of this product. Never carry

outanymodicationsoftheproduct.Neverchangethepresetgovernor

speed or the engine and product settings. Information about maintenance

and repair are provided in this instruction manual.

12

b) Keep all nuts, bolts and screws tight to be sure that the product is in safe

working condition.

c) Improper maintenance or using non-genuine parts not recommended by the

manufacturer may lead to malfunction/failure of the product. Many accidents

are caused by poorly maintained products.

d) Never store the product with petrol in the tank inside a building where fumes

canreachanopenameorspark.

e) Toreducetherehazard,keeptheengine,silencerandpetrolstoragearea

free of vegetative material and excessive grease.

f) Allow the engine to cool before storing in any enclosure.

g) Clean and maintain the product before storage.

h) Check the grass catcher frequently for wear or deterioration.

i) If the fuel tank has to be drained, this should be done outdoors.

j) Wear protective gloves when removing and re-assembling the cutting means.

k) Replace worn or damaged parts for safety. Only use replacement blades

and spare parts recommended by the manufacturer.

l) Ensure that only replacement cutting means of the right type are used.

5) FUEL HANDLING

a) Before refuelling, stop the engine, disconnect the spark plug connector

andlettheproductcool.Fuelandfuelvapoursarehighlyammable.Take

care when handling fuel. Never smoke when you are refuelling the product.

Donotrefueltheproduct,ifthereisanopenreinthevicinity!

b) Alwaysusesuitableaidssuchasfunnelsandllernecks.Donotspillany

fuel on the product or its exhaust system. There is a risk of ignition. Remove

spilt fuel carefully from all parts of the product. Any residue which may be

present must be completely removed before the product is operated!

c) Fuel fumes can ignite. Never use the product in environments where there

is a risk of explosion.

d) Petrol engines produce toxic carbon monoxide exhaust fumes. Breathing

carbon monoxide can cause nausea, fainting or even death.

e) Never breathe in any fuel fumes, when you are refuelling the product. Never

llthefueltankinenclosedspaces,suchasbasementsorsheds.Thereis

a risk of poisoning and explosion!

f) Avoid skin contact with petrol.

g) Do not eat or drink, while you are refuelling the product. If you have swallowed

petrol or oil, or if petrol or oil has got into your eyes, then seek medical advice

immediately.

h) Closethefueltankcapimmediatelyafterllingthefueltank.Makesurethat

it is properly closed.

i) Neverusetheproductwithoutanairlter.

13

j) Fuel vapour pressure may build up inside the fuel tank depending on the

fuel used, weather conditions and the venting system. To reduce the risk

of burns and other personal injuries, remove the fuel tank cap carefully to

allow any pressure build-up to release slowly.

k) Beawareofrerisks,explosionandinhalationrisks.

l) Do not smoke while operating the product, handling fuel or near fuel.

m) Ensure the spark plug connector is securely attached. A loose connector

may cause electrical arcing that could ignite combustible fumes and cause

areorexplosion.

n) Check regularly for leaks from the fuel tank cap and fuel lines.

o) Tightenthefueltankcapthoroughlyafterrellingthefueltank.

p) Do not operate the product if it is leaking fuel. Do not remove the fuel tank

cap while the engine is running.

q) Usecautionwhenhandlingfuel.Toavoidanyaccidentalres,movethe

product at least 3 metres from the fuelling point before starting the engine.

r) Donotstorecontainerslledwithfuelorrellthefueltankinanyplace

wherethereisaboiler,stove,woodre,electricalsparks,weldingsparks,

orothersourcesofheatorrewhichmightignitethefuel.

s) If any fuel spillage occurs during refuelling, use a dry rag to wipe spills and

allow remaining fuel to evaporate before starting the engine again.

t) If you have spilt fuel on yourself or on your clothes, change your clothes

and wash any part of your body that has come in contact with fuel before

starting the engine again.

u) Iffuelisignited,putouttherewithadrypowderreextinguisher.

v) Storefuelincontainersspecicallydesignedforthispurpose.

6) VIBRATION AND NOISE REDUCTION

To reduce the impact of noise and vibration emission, limit the time of operation, use low-

vibration and low-noise operating modes as well as wear personal protective equipment.

Take the following points into account to minimise the vibration and noise exposure risks:

a) Only use the product as intended by its design and these instructions.

b) Ensure that the product is in good condition and well maintained.

c) Use correct attachments for the product and ensure they are in good condition.

d) Keep tight grip on the handles/grip surface.

e) Maintain this product in accordance with these instructions and keep it well

lubricated (where appropriate).

f) Plan your work schedule to spread any high vibration tool use across a

longer period of time.

14

7) EMERGENCY

Familiarise yourself with the use of this product by means of this instruction manual.

Memorise the safety directions and follow them to the letter. This will help to prevent

risks and hazards.

a) Always be alert when using this product, so that you can recognise and

handle risks early. Fast intervention can prevent serious injury and damage

to property.

b) Stop the engine and disconnect the spark plug connector if there are

malfunctions.Havetheproductcheckedbyaqualiedprofessionaland

repaired, if necessary, before you operate it again.

c) Incaseofrestoptheengineanddisconnectthesparkplugconnector.Take

re-extinguishingmeasuresimmediatelyiftheproductswitchisnolonger

accessible.

WARNING!Neverusewatertoextinguishtheproductonre.Burningfuel

must be extinguished with special extinguishing agents! We recommend

thatyoukeepasuitablereextinguisherwithinreachinyourworkarea!

Werecommendtohavedrypowderreextinguisheralwaysavailable.

8) RESIDUAL RISKS

Even if you are operating this product in accordance with all the safety requirements,

potential risks of injury and damage remain. The following dangers can arise in connection

with the structure and design of this product:

a) Health defects resulting from vibration emission if the product is being used

over long periods of time or not adequately managed and properly maintained.

b) Injuries and damage to property due to broken attachments or the sudden

impact of hidden objects during use.

c) Dangerofinjuryandpropertydamagecausedbyyingobjects.

d) Burns, if touching hot surfaces.

WARNING!Thisproductproducesanelectromagneticeldduring

operation!Thiseldmayundersomecircumstancesinterferewithactive

or passive medical implants! To reduce the risk of serious or fatal injury,

we recommend persons with medical implants to consult their doctor and

the medical implant manufacturer before operating this product!

15

01 Technical specications

General

Dimensions: approx. 166 x 54 x 110 cm

Product mass with empty tanks and in the normal

operating conguration: approx. 33 kg

Fuel tank capacity: 910 ml (cm³)

Petrol type: #95, unleaded

Engine oil capacity: 400 ml (cm³)

Engine oil type: 4-stroke engine oil

(e.g. SAE 10W-30)

Specic fuel consumption at max. engine power: 368 g/kWh

Fuel consumption at max. engine power: 1.24 kg/h

Cutting means: blade type: 40 MnB

blade thickness: 3 mm

Cutting width: 51 cm

Cutting height: 25 - 75 mm

Grass catcher volume: 65 l

Engine

Engine model: HONDA GCV170

Engine type: air cooled, 4-stroke engine

Engine displacement: 167 cm3

Maximum operating engine speed

(rotational frequency): 2800 min-1

Nominal power: 3.1 kW

Spark plug type: BPR5ES

Spark plug gap: 0.7-0.8 mm

Carburettor: SE475

Sound level

Sound pressure level at operator’s position LpA:85.8 dB(A)

Uncertainty K: 3 dB(A)

Sound power level LWA:96.5 dB(A)

Uncertainty K: 1.86 dB(A)

Guaranteed sound power level LWA

(acc. to 2000/14/EC amended by 2005/88/EC): 98 dB(A)

Vibration level

Hand-arm vibration ahw:5.213 m/s2

Uncertainty K: 1.5 m/s2

16

The sound values have been determined according to noise test code given in

EN ISO 5395-1 and EN ISO 5395-2, using the basic standards ISO 3744 and ISO 11094.

Wear hearing protection, especially when sound pressure is over 80 dB(A).

The declared vibration value has been measured in accordance with a standard test

method (according to EN ISO 5395-1 and EN ISO 5395-2) and may be used for

comparing one product with another. The declared vibration value may also be used

to evaluate the exposure for the user caused by vibration in advance.

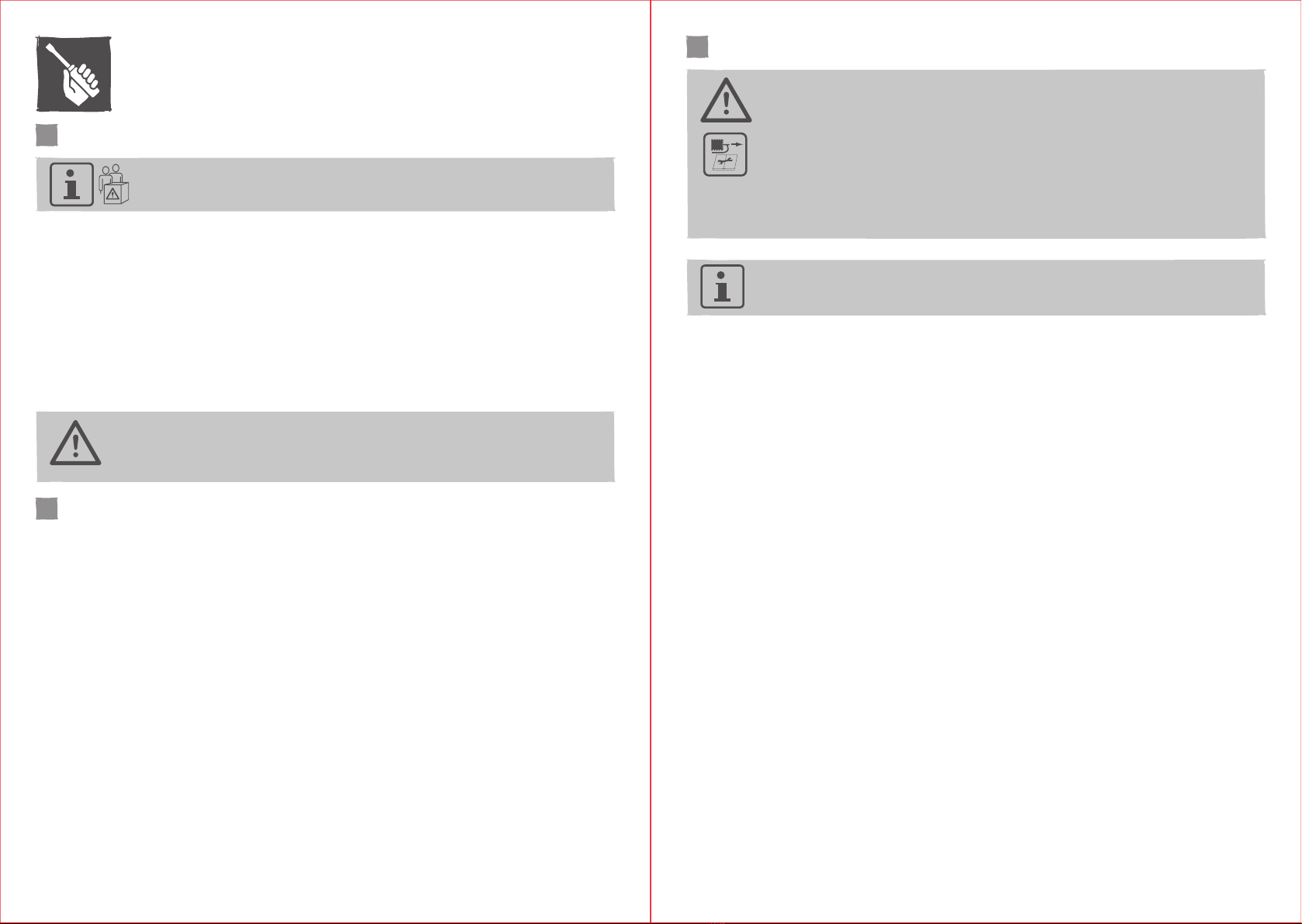

WARNING!Depending on the actual use of the product the vibration values

can from the declared total. Adopt proper measures to protect yourself

against vibration exposures. Take the whole work process including times

the product is running under no load or switched into consideration!

Proper measures include among others regular maintenance and care

of the product and accessories, keeping hands warm, periodical breaks

and proper planning of work processes!

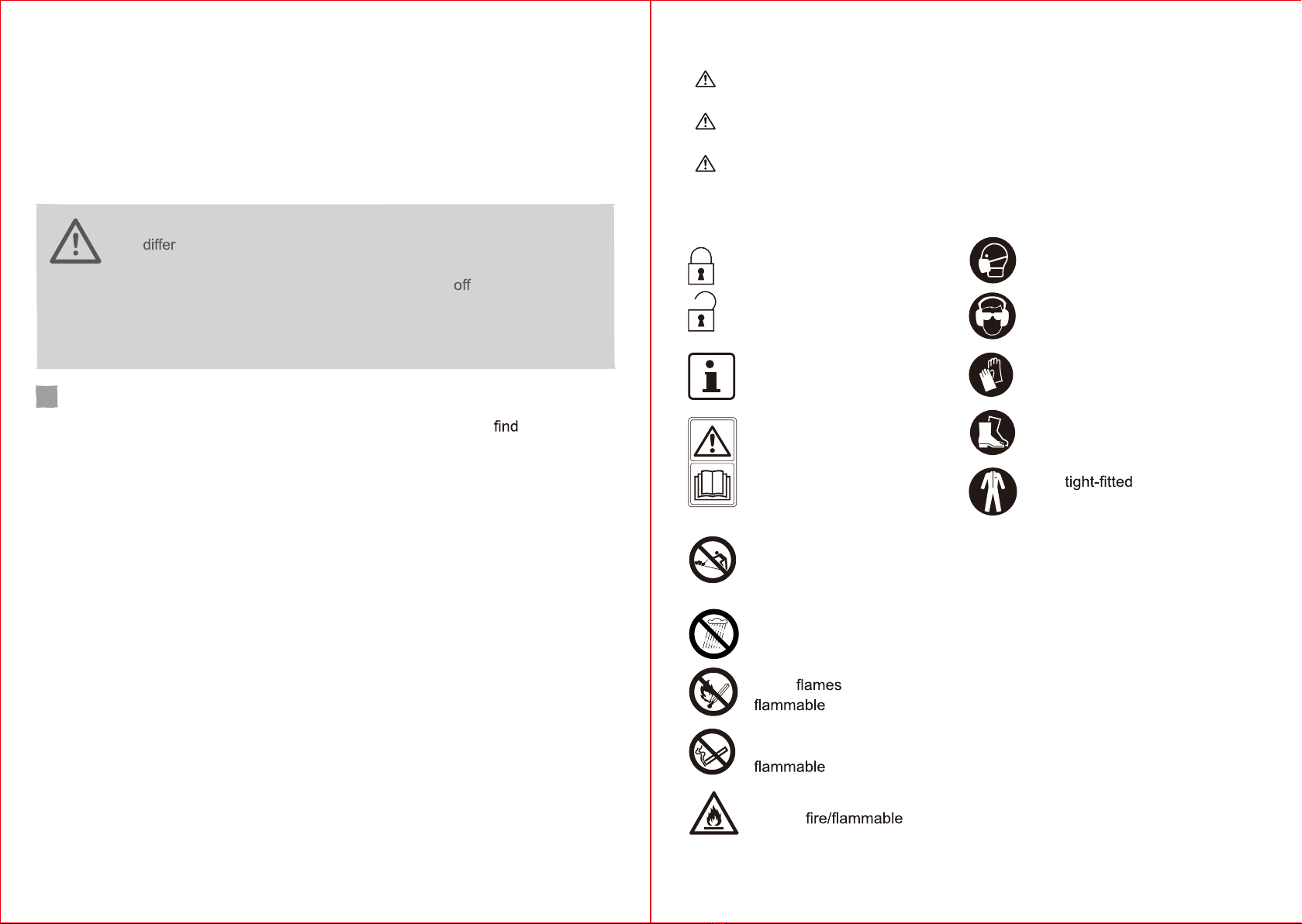

02 Symbols

On the product, the rating label and within these instructions you will among others

the following symbols and abbreviations. Familiarize yourself with them to reduce

hazards like personal injuries and damage to property.

kW Kilowatt ml Millilitre

cm3Cubic centimetre g/kWh Gram per kilowatt per hour

/min or min-1 Per minute kg/h Kilogram per hour

mm Millimetre °C Degree Celsius

cm Centimetre dB(A) Decibel (A-rated)

kg Kilogram m/s2Metres per second squared

l Litre

yyWxx

17

Description of signal words:

DANGER! The signal word that indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious injury.

WARNING! The signal word that indicates a hazard with a medium level of

risk which, if not avoided, could result in death or serious injury.

CAUTION! The signal word that indicates a hazard with a low level of risk

which, if not avoided, could result in minor or moderate injury.

NOTE! Indicates a practical tip, advice or practice not related to personal

injury.

Lock/to tighten or secure.

Unlock/to loosen.

Note/Remark.

Caution/Warning.

Read the instruction manual.

Mow across the face of slopes, never up and down.

Do not expose the product to rain or wet conditions.

Open in the work area, around the product and in the vicinity of

materials are prohibited!

Do not smoke in the work area, around the product and in the vicinity of

materials!

Risk of materials.

Wear respiratory protection.

Wear hearing protection.

Wear eye protection.

Wear protective gloves

(compliant to EN ISO 21420)

Wear protective, slip-resistant

safety footwear

(compliant to EN ISO 20345)

Wear protective clothing

(compliant to EN ISO 13688)

Manufacturing date code; year of manufacturing (yy) and week of manufacturing

(Wxx)

18

Hot surface, do not touch! High temperatures on the product’s

surfaces and structural parts that could cause burns, if they are

touched. The product can also stay hot for a longer period of time

after the operation!

Petrol engines produce toxic carbon monoxide exhaust fumes.

Breathing carbon monoxide can cause nausea, fainting or even

death. Do not operate the engine indoors!

Only refuel unleaded petrol!

Add engine oil.

Checkandrelloil.

Stop the engine before refuelling the fuel tank. Flammable material.

Keepawayfromre.Donotaddfuelwitharunningengine.

Inspect the area where the product is to be used and remove all

objects which can be thrown by the product. If objects are hidden

while operating, stop the engine and remove the objects.

Cutting means continues to rotate after the engine is stopped.

Wait until all components have completely stopped before touching

the product.

Pay particular attention when working on the blades!

Keep hands and feet away from sharp rotating parts – risk of injury!

When cleaning, repairing or inspecting, make sure the cutting

means and all moving parts have stopped. Disconnect the spark

plug connector, and keep the cap away from the plug to prevent

accidental starting.

Objects thrown by the product could hit the operator or other

bystanders. Always ensure that other people and pets remain

at a safe distance from the product when it is in operation. In

general, children must not come near the area where the product

is operating.

19

Release the brake clutch to stop the engine and the cutting means.

Pull the drive bar to engage the wheels.

Switchtheproductoanddisconnectthesparkplugconnector

before assembly, cleaning, adjustments, maintenance, storage and

transportation.

Keep hands and feet away.

Engine manual start; recoil starter.

GO STOP

The grass catcher hatch open (GO) and close (STOP)

position.

Guaranteed sound power level value in dB.

ELMP170SP51

E_Erbauer, LMP_Petrol lawnmower, 170_ Engine model,

SP_Self-propelled,51_Cutting width 51cm

The product complies with the applicable European directives and

an evaluation method of conformity for these directives was done.

20

Assembly

01 Unpacking

The product is heavy, ask another person for assistance if required.

1. Unpackallpartsandlaythemonaat,stablesurface.

2. Remove all packing materials and shipping devices, if applicable.

3. Makesurethedeliverycontentsarecompleteandfreeofanydamage.Ifyound

that parts are missing or show damage do not use the product but contact your

dealer. Using an incomplete or damaged product represents a hazard to people

and property.

4. Ensure that you have all the accessories and tools needed for assembly and

operation. This also includes suitable personal protective equipment.

WARNING! The product and the packaging are not children’s toys!

Children must not play with plastic bags, sheets and small parts! There

isadangerofchokingandsuocation!

02 You will need

(items not supplied)

> Suitable personal protective

equipment

> Fuelfunnelwithlter

> Suitable engine oil (SAE10W-30)

> Suitable fuel (unleaded petrol)

> Container to collect fuel

> Container to collect oil

> Lubrication oil/grease

> Foamairlteroil

> Torque wrench (40-45 Nm)

> First aid kit

> Drypowderreextinguisherreadily

available

(items supplied)

> Spark plug wrench (26)

> Engine operator’s manual (32)

21

03 Assembly

WARNING! The product must be fully assembled before the operation!

Do not use a product that is only partly assembled or assembled with

damaged parts!

Follow the assembly instructions step-by-step and use the pictures

provided as a visual guide to assemble the product easily!

Disconnect the spark plug connector (13) from the spark plug! Reconnect

it after assembly.

NOTE: Take care of small parts that are removed during assembly or

when making adjustments. Keep them secure to avoid loss.

Handle bars

1. Unfold the lower handle bar (6) to the desired height. Align the holes of the lower

handle bar (6) and one of the 3 mounting holes of the main unit (Fig. 1).

2. Secure the lower handle bar position with the lower handle bar knob (19) and the

bolt (19a) (Fig. 1). Repeat on the other side.

3. Unfold the upper handle bar (4) and hold it with the brake clutch (1) facing upwards

(Fig. 2). Align the mounting holes of the upper handle bar (4) and the lower handle

bar (6).

4. Fix the upper handle bar (4) to the lower handle bar (6) with the side levers (9) ,

washers (9a) and nuts (9b) through the mounting holes (Fig. 3). If the side lever (9)

cannot be folded, loosen it by 2 or 3 turns, then fold again.

5. Attach the drive wire (7) and brake wire (8) to the lower handle bar (6) with the

wire clip (10).

Grass catcher installation

1. Liftthereardeectorguard(20)andholditinplace(Fig.4).

2. Align the hooks of the grass catcher (21) with the rods and hang them onto (Fig. 4).

3. Carefullyreleasethereardeectorguard(20)afterwards.

Mulching insert installation

1. Openthereardeectorguard(20),holditinpositionandinsertthemulching

insert (24) into the rear discharge chute (29) (Fig. 5). Ensure the unlock button (24a)

snaps in place.

2. Press the unlock button (24a) to release and remove the mulching insert (24) (Fig. 6).

22

Side discharge attachment installation

1. Liftandholdthelockbuckle(16a)upwardstounlockthesidedeectorguard(16)

(Fig. 7).

2. Openthesidedeectorguard(16)andholditintheopenposition(Fig.7).

3. Hook the side discharge attachment (25) underneath the rods. Release the side

deectorguard(16)(Fig.8).

Use

Intended use

This petrol lawnmower ELMP170SP51 is designated with a power output of 3.1 kW.

1. The product is intended for mowing grass in domestic gardens only. It must not be

used to mow unusually high, dry or wet grass (e.g. pasture grass) or for shredding

leaves.

2. For safety reasons it is essential to read the entire instruction manual before the

rstoperationandtoobservealltheinstructionstherein.

3. This product is intended for private domestic use only, not for any commercial use.

It must not be used for any purposes other than those described.

Before you start

01 Protection

02 Fuel and engine oil

This product is equipped with a 4-stroke engine. Before operation, it is necessary to

add suitable fuel and engine oil separately.

23

WARNING! This product contains a separate operator’s manual for the

engine. Service the engine with proper petrol and engine oil as instructed

in the separate engine operator’s manual (32).

It is important to read and understand these instructions of the engine

and the equipment.

SAVE THESE ORIGINAL INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING!Fuelandoilarehighlyinammable!Fumeswillexplodeif

lit!Ensurethattherearenonakedamesaroundtheproduct!Donot

smokewhilellingfuelandoil!.

>Useproperfunnels.Avoidspillingandoverllingthetanks.

> Always dispose of fuel, used oil and objects contaminated with them in accordance

with local regulations.

Fuel

NOTE: Take care of small parts that are removed during assembly or

when making adjustments. Keep them secure to avoid loss.

> Always use clean, fresh unleaded petrol. Purchase fuel in quantities that can be

used up within 30 days.

> Avoid getting dirt, dust or water in the fuel tank.

1. Placetheproductonastable,levelsurface.Werecommendlayinganon-ammable

sheet under the product.

2. Unscrew and remove the fuel tank cap (11) (Fig. 9).

3. Add suitable fuel into the fuel tank. Leave a minimum 5 mm of space between the

top of the fuel and the inside edge of the tank to allow for expansion (Fig. 10).

4. Wipe any spilt fuel with a soft cloth and reattach the fuel tank cap (11).

24

NOTE:Petroldeterioratesovertime.Itmaybediculttostarttheengine

if you use petrol which has been kept for more than few days. Empty the

fuel after every use. Run the product dry of fuel in idle before storage.

NOTE:Fuelcandamagepaintandplastic.Whenllingthetank,take

care not to spill any fuel. Damages caused by spills are not covered by

the guarantee.

Fuel shut-o valve

Thisproductisequippedwithafuelshut-ovalve(30).

1. To open the valve, turn it anti-clockwise (Fig. 11).

2. To close the valve, turn it clockwise (Fig. 12).

NOTE: Close the valve (30) after operation, and before storage and

maintenance.

Engine oil

WARNING! This product is not supplied with oil. However, for manufacturing

reasons, it is possible that a small quantity may be in the engine! Before

operatingthisproduct,itisessentialtollitwithoil(4-strokeengineoil,

e.g. SAE 10W-30)!

Engineoilhasasignicantinuenceonengineperformanceandservice

life. Non-detergent or 2-cycle engine oils will damage the engine and

should not be used - see the separate engine operator’s manual (32).

1. Placetheproductonaatandevensurface.

2. Unscrew and remove the oil tank cap (17).

3. Gradually add good-quality engine oil (SAE 10W-30). Allow the oil to settle.

4. Checktheoillevelfrequentlywhilelling.Wipeooildipstick(17)andinsertitinto

the tank opening without tightening the cap, and then remove the dipstick again.

5. The oil level must be between the oil level markings (approx. 400 ml). Add more

oilifnecessary.Donotoverll(Fig.13).

6. Afterllingoil,wait1minuteandthenrechecktheoillevel.

7. Wipe the spilt oil with a soft cloth and reattach the oil tank cap (17).

25

Product functions

01 Handle adjustment

1. Loosen the lower handle bar knob (19) by turning it anti-clockwise. Take out the

bolt (19a) from the mounting holes of the main unit. Repeat on the other side.

2. Unfold the lower handle bar (6) to the desired height.

3. Secure the lower handle bar position with the lower handle bar knob (19), and the

bolt (19a) (Fig. 14, 15). Repeat on the other side.

02 Brake clutch

1. Pull the brake clutch (1) towards the handle (2) and hold it in position when starting

the engine and during operation (Fig. 16).

2. Release the brake clutch (1) to stop the engine.

03 Drive bar (self-propelled function)

Use the self-propelled function as assistance during operation; the rear wheels (14)

are automatically driven by the engine; you do not need to push the product manually.

1. When the engine is running, pull the drive bar (3) towards the handle (2) to engage

the wheels (14) (Fig. 17).

2. Pull the speed lever (5) backward to speed up. Choose one of the 5 speed settings

(Fig. 18).

3. To disengage the wheels (14), push the speed lever (5) back to the 1 setting, and

release the drive bar (3).

04 Recoil starter

The recoil starter handle (23) is positioned at the top of the engine.

1. Pull the brake clutch (1) towards the handle (2) and hold it in position.

2. Stand behind the handle (2).

3. Place the recoil starter handle (23) onto the hook (23a) located on the right-hand

side of the upper handle bar (4) (Fig. 20).

4. Pull the recoil starter handle (23) lightly until you feel resistance then pull it rapidly.

Do it repeatedly until the engine starts (Fig. 19).

5. During operation rest the recoil starter handle (23) onto the hook (23a) (Fig. 20).

WARNING! Never twist the starter cord around your hand! Only pull on

the recoil starter handle (23)!

26

WARNING! Do not suddenly release the recoil starter handle (23)! Allow

the rope to return slowly and in a controlled manner each time it is pulled!

05 Grass catcher

Thegrasscatcher(21)isequippedwithahatch(21b)thatindicatesthellingvolume

during operation.

1. When the hatch (21b) is opened the grass catcher (21) has enough volume left to

collect grass (Fig. 21).

2. When the hatch (21b) is closed the grass catcher (21) is full and must be emptied

(Fig. 22).

WARNING! Attach the grass catcher (21) when using this product

(it is allowed to use the product without the grass catcher (21) only

whenmulching)-dangerofyingobjects!Alwayscarrythegrass

catcher by its handle (21a).

Emptying

WARNING! Before removing the grass catcher (21) stop the engine and

wait until the blade (27) comes to a complete stop.

Empty the grass catcher (21) frequently during use. Do not wait until it is full. We

recommend emptying when it is 90% full.

1. Liftthereardeectorguard(20)andholditinplace.

2. Liftthegrasscatcherhooksotherodsandplacethegrasscatcher(21)onthe

ground.

3. Remove the grass clippings from the rear discharge chute (29) into the grass

catcher (21). Use a proper tool such as a brush.

WARNING! Never use your hands or feet to remove grass clippings from

the rear discharge chute (29)!

4. Empty the grass clippings onto a compost heap.

5. Re-tthegrasscatcherhooksontotherods.

27

Grass catcher inspection

During use the grass catcher (21) material is subjected to normal wear and tear.

An excessively worn grass catcher may allow the objects to be thrown towards the

operator. Replace a worn grass catcher to prevent possible injury.

06 Mulching insert

NOTE: Mulching means cutting and returning the grass clippings to the

lawninonestep:thegrassclippingsarecutveryneandthendistributed

evenly back onto the lawn. Under normal conditions, the mulched grass

will biodegrade quickly to provide nutrients to the lawn.

1. Openthereardeectorguard(20),holditinpositionandinsertthemulching

insert (24) into the rear discharge chute (29) (Fig. 5). Ensure the unlock button (24a)

snaps in place.

2. Press the unlock button (24a) to release and remove the mulching insert (24) (Fig. 6).

07 Side deector guard

1. Liftandholdthelockbuckle(16a)upwardstounlockthesidedeectorguard(16)

(Fig. 7).

2. Openthesidedeectorguard(16)andholditintheopenposition(Fig.7).

3. Hook the side discharge attachment (25) underneath the rods. Release the side

deectorguard(16)(Fig.8).

Operation

01 General operation tips

1. Before each use:

> Check the product and accessories for damage and whether they are properly

xed.Donotusetheproductifitisdamagedorshowsandsignsofwearand

tear.Takecareofanyproblemyoundorhavetheproductcheckedbyqualied

specialist.

>Checkthefuelandoillevel.Rellifnecessary.

> Look around and underneath the product for signs of oil or fuel spill.

> Check each control for proper operation.

> Check blades (27) for wear.

> Make sure that all bolts and screws are tightened.

>Checkiftheairlter(12a)isclean.

2. Always push the product using the handle (2). Keep the handle bar dry and free

from lubricant to ensure safe support.

28

3. Ensure that the air vents are always unobstructed and clear. Clean them if necessary

with a soft brush. Blocked air vents may lead to overheating and damage the

product - refer to the engine operator’s manual (32).

4. Stop the engine immediately if you are disturbed while working by other people

entering the working area. Always let the blades (27) come to a complete stop

before leaving the product unattended.

02 Cutting height adjustment

WARNING! Before adjusting the cutting height, stop the engine

and wait until the blade (27) comes to a complete stop.

Thisproductcanbeadjustedto7dierentheightsettings.Neworthickgrassmay

require a higher cutting height and a narrower cutting path.

1. Push the lever for cutting height adjustment (18) towards the wheel (14) (Fig. 23,

step 1), and then move it forward or backward to the desired cutting height

(Fig. 23, step 2).

2. Release the lever (18) and ensure it engages into place properly.

NOTE: If you are not sure what cutting height should be selected, start

with a maximum height and check the appearance of the lawn after

mowing a small area. Adjust the setting if necessary.

WARNING! Ensure that the lever (18) engages between two of the

grooves!

03 Starting

WARNING! Before starting, place the product on a stable, level surface

free of high grass! Clean the underside of the product!

Start the engine carefully according to instructions. Keep your feet well

away from the blade (27).

Stay ready. The product starts moving forward once you pull the drive

bar (3) towards the handle (2).

Do not tilt the product when starting the engine.

29

1. Pull the brake clutch (1) towards the handle (2) and hold it in position.

2. Stand behind the handle (2).

3. Place the recoil starter handle (23) onto the hook (23a) located on the right-hand

side of the upper handle bar (4) (Fig. 20).

4. Pull the recoil starter handle (23) lightly until you feel resistance then pull it rapidly.

Do it repeatedly until the engine starts (Fig. 19).

5. During operation rest the recoil starter handle (23) onto the hook (23a) (Fig. 20).

6. Hold the brake clutch (1) and pull the drive bar (3) towards the handle (2) (Fig. 18).

The product moves forward and starts mowing.

WARNING! The starting position should be as described in the instruction

manual.Fig.24illustratesthedenedstartingposition.Theoperator

should start the engine behind the handle (2). Do not start the engine

while standing on the side of the product as shown on Fig. 25.

NOTE:Iftheenginedoesnotstart,itmaybeooded.Floodingiscaused

by too much fuel injected into the combustion chamber and can prevent

theenginefromstarting.Toresolveoodingfollowthebelowprocedure:

1. Remove the spark plug located under the spark plug connector (13)

and dry it - see the separate engine operator’s manual (32).

2.Waitfor10minutesuntilfuelvapoursandretthesparkplug.Clean

up any spilt fuel and move the product at least 3 metres away before

startingtheenginetoavoidanyaccidentalre.

3. Start the engine.

04 Stopping

1. Push the speed lever (5) back to the 1 setting, and release the drive bar (3) (Fig. 26).

2. Release the brake clutch (1) to stop the engine and blade (27) (Fig. 26).

05 Mowing

NOTE: Avoid mowing when the grass is wet from rain or dew. Wet grass

may form clumps which interfere with the mulching action and reduce

runtime. The best time to mow grass is late afternoon when the grass is

dry and the newly cut area will not be exposed to direct sunlight.

30

Preparing the product according to required application

Function Grass catcher (21) Mulching

insert (24)

Side discharge

attachment (25)

Grass collection installed removed removed

Mulching removed installed removed

Side discharge removed installed installed

Self-propelled function

Use the self-propelled function as assistance during operation; the rear wheels (14)

are automatically driven by the engine; you do not need to push the product manually.

1. When the engine is running, pull the drive bar (3) towards the handle (2) to engage

the wheels (14) (Fig. 17).

2. Pull the speed lever (5) backward to speed up. Choose one of the 5 speed settings

(Fig. 18).

3. To disengage the wheels (14), push the speed lever (5) back to the 1 setting, and

release the drive bar (3).

General tips

1. Make sure that the lawn is clear of stones, sticks, wires or other objects that could

damage the product or its engine.

2. Do not cut wet grass because it tends to stick to the underbody of the product,

preventing the proper discharge of grass clippings, and it could also cause you to

slip and fall.

3. Nevercutomorethanone-thirdofthetotallengthofthegrassforahealthylawn.

In the autumn, lawns should only be cut as long as there is growth.

4. Slowly push the product forward. If needed, use the self-propelled function for

assistance.

5. Mowinslightlyoverlappingrows.Themosteectivepatternformowinglawnsis

straight lines along one of the sides. This keeps the rows even and ensures that

all the lawn is cut without missing any spots (Fig. 27).

6. Circlearoundowerbeds.Whenreachingaowerbedinthemiddleofthelawn,

cut a row or two around the circumference of the bed.

7. Pay particular attention when changing direction.

8. Empty the grass catcher (21) regularly.

WARNING! Extensive vibration of the product during operation is an

indication of damage! Stop the engine immediately. The product should

be promptly inspected and repaired!

31

Care & maintenance

01 The golden rules of care

DANGER! Proper maintenance is essential for safe and trouble free

operation. Improper maintenance, or failure to address a problem instantly

can cause a malfunction which can result in serious injury or even death.

WARNING! Stop the engine, disconnect the spark plug connector (13)

and let the product cool before performing inspection, maintenance and

cleaning work!

Do not touch the rotating blade (27).

1. Keep the product clean. Remove debris after each use and before storage.

2. Regular and proper cleaning helps to ensure safe operation and prolongs the life

of the product.

3. Inspect the product before each use for worn and damaged parts. Do not operate

itifyoundbrokenandwornparts.Replacewornpartsasnecessaryorcontact

an authorised service centre for repair before using the product again.

WARNING! Only perform repairs and maintenance work according to

theseinstructions!Allfurtherworksmustbeperformedbyaqualied

specialist!.

02 Cleaning

1. Clean the product with a slightly damp cloth and mild soap. Use a brush for areas

that are hard to reach.

2. In particular, clean the air vents after every use with a cloth and brush - refer to

the engine operator’s manual (32).

3. Remove stubborn dirt with high pressure air (max. 3 bar).

4. Clean the underbody and cutting means (27) using the water hose connector (31).

NOTE: Do not use chemical, alkaline, abrasive or other aggressive

detergents or disinfectants to clean this product as they might be harmful

to its surfaces.

32

03 Maintenance

Before and after each use, check the product and accessories for wear and damage.

If required, exchange them for new ones as described in this instruction manual.

Observe the technical requirements.

WARNING! It is required to tip the product when performing the

maintenance. The fuel tank must be empty, or fuel can leak which could

resultinreorexplosion.

NOTE: Always empty the fuel tank and keep the spark plug upside down.

Otherwise,thefuelorengineoilmightcontaminatetheairlter(12a)/

sparkplugandmightmakeitdicultstarttheengine.

04 Spare parts/Replacement parts

The parts of this product mentioned in the maintenance table may be replaced by the

consumer. Spare parts are available at an authorised dealer or through our customer

service.

05 Engine maintenance

Refer to the engine operator’s manual (32) for maintaining below parts:

Airlter Engine oil Valve play

Spark plug Carburettor Muer

Fuel

06 Repair

This product does not contain any parts that can be repaired by the consumer. Contact

anauthorisedservicecentreorasimilarlyqualiedspecialisttohaveitcheckedand

repaired.

07 After use

1. Stop the engine, disconnect the spark plug connector (13) and let the product cool.

2. Check, clean and store the product as described in the maintenance table.

33

Maintenance table

Part To do Before/

after

each

use

First

month

or

5 hours

Every

3 months

or 25 hours

Every

6 months

or

50 hours

Every year

or

100 hours

Every

2 years

or

250 hours

Engine oil check x

replace x

Airlter

check x

clean x

replace x

Spark plug

check/

adjust x

clean x

replace x

Spark plug cap clean x

Fuel tank clean x

Fuel tube clean Every 2 years (replace if necessary)

Cutting means replace Replace the cutting means (27) after 50 hours of mowing, or 2 years

whichever is sooner regardless of condition.

34

08 Underbody and cutting means

WARNING! Wear protective gloves when working on the cutting

means (27) and close to it! Use proper tools to remove debris, e.g. a

wooden stick! Never use your bare hands!

Always use original spare parts for replacement. The cutting means

must be replaced by an identical type with the reference number

DAYE 2105200348. Do not attach any other type of cutting means (27)!

The replacement of the cutting means (27) should be done by an

experienced operator! Rework or sharpening blades is not recommended

unless it is done by a repair service or a similarly specialist!

NOTE:We strongly recommend jacking the product when performing

inspection and work on the cutting means (27). Avoid tilting the product

in order to prevent fuel and oil leakages.

1. Keep the underbody and cutting means (27) clean and free of debris. Remove

clippings from the rear discharge chute (29).

2. Check all nuts and bolts periodically for tightness before the operation. After

prolonged use, especially in sandy soil conditions, the cutting means (27) will

become worn and lose some of the original shape. The cutting will be

reduced, and the cutting means (27) should be replaced.

3. Keep the cutting means (27) sharp to ensure a good cutting performance. Replace

a worn or damaged cutting means with a new one of the same type or have it

sharpened by a specialist.

4. If jacking the product is not possible, tilt it to the right side so that the fuel tank

cap (11) side is up. This helps to prevent fuel leakage and harder starting due to

of the carburettor.

5. Loosen the hex bolt (27e) anti-clockwise and remove it together with the locking

(27d), washer (27c) cutting means (27), and ring (27b) (Fig. A).

6. Replace the cutting means (27) with a new one of the same type. Slide the ring

(27b) into the slot on the spindle (27a) and then the cutting means (29), washer

(27c), locking (27d) and hex bolt (27e). Tighten the hex bolt clockwise with

40-45 Nm force to ensure safe operation of the product (Fig. A).

DANGER! If the cutting means (27) are not torqued properly, they could

become loose and be thrown from the product and seriously hurt or kill

the operator or bystanders.

35

NOTE:Replace the cutting means (27) after 50 hours of mowing,

or 2 years whichever is sooner regardless of condition. If the cutting

means (27) is cracked or damaged, replace it immediately.

7. Lubricate the cutting means (27) after each use to prolong their life span. Apply

lubrication oil/grease along the edges of the cutting means (27).

27a

27b

27d

27e

27

27c

A

09 Underbody and cutting means cleaning

NOTE: Do not use pressure washer for cleaning. It may force water to

enter the vital areas of the product.

1. Set the cutting height to the lowest position using the lever (18).

2. Connect a water hose with a quick connector to the water hose connector (31)

(Fig. 28). Turn on the water supply.

3. Start the engine.

4. Pullthe brake clutch (1) to engage the blades (27). Keep for 1 minute.

5. When the grass clippings stop coming out of the underbody, stop the engine.

6. Turnthe water supply and detach the water hose from the water hose connector (31).

7. Start the engine and let it run for 2 minutes to dry the underbody.

10 Grass catcher

1. Inspectthe grass catcher (21) before each use. Do not use it if you any damage.

2. Clean the grass catcher (21) after operation using water.

3. Let the grass catcher (21) dry thoroughly before storing.

36

11 Brake and drive wires

Check the performance of the brake wire (8) and the drive wire (7) before each use.

Askaqualiedspecialisttoadjustitifnecessary.

WARNING! Do not use the product with a defective or loose wires!

12 Transportation

1. Stop the engine and disconnect the spark plug connector (13).

2. Adjust the height to the highest position as described in the “Cutting height

adjustment” section.

3. Attach transportation guards, if applicable.

4. Always move the product by the handle (2).

5. If a suitable loading ramp is not available, ask another person for assistance when

loading the product on a vehicle.

6. Protect the product from any heavy impacts or strong vibrations which may occur

during transportation in vehicles.

7. Secure the product with tie-down straps to prevent it from slipping or or falling over,

loss of fuel, damage and injury.

13 Storage

NOTE: Good storage conditions are important for keeping your product

trouble-free.

1. Stop the engine and disconnect the spark plug connector (13).

2. Closethefuelshut-ovalve(30)byturningitclockwise.

3. Clean the product as described in the “Cleaning” section.

4. Loosen the side levers (9). Loosen the lower handle bar knob (19) by turning it

anti-clockwise. Take out the bolt (19a). Repeat on the other side.

5. Fold the lower (6) and the upper handle bars (4).

6. Store the product and its accessories in a well-ventilated dry storage area.

7. Always store the product in a place that is inaccessible to children. The ideal storage

temperature is between 10 °C and 30 °C.

8. We recommend using the original package for storage or covering the product with

a suitable cover or enclosure to protect it against dust.

9. For long-term storage (more than 5 days), drain the fuel tank as described in engine

operator’s manual (32).

37

14 Troubleshooting

Suspectedmalfunctionsareoftenonesthattheuserscanxthemselves.Therefore

check the product using this section. In most cases the problem can be solved quickly.

WARNING! Only perform the steps described within these instructions!

All further inspection, maintenance and repair work must be performed

byanauthorisedservicecentreorasimilarlyqualiedspecialistifyou

cannot solve the problem yourself!

Problem Possible cause Solution

1. Engine does

not start

1.1 Not enough fuel in the

fuel tank

1.1 Add fuel

1.2 Spark plug is wet 1.2 Dry spark plug

1.3 Spark plug is damaged 1.3 Replace spark plug

1.4 Spark plug connector is

loose

1.4 Attach properly

1.5 Lever for cutting height

adjustment is not in the

correct position for the

prevailing conditions

1.5 Move the lever to

correct position

1.6 Airlterisdirty 1.6 Cleantheairlter

1.7 Spark plug is loose 1.7 Tighten the spark plug

(25 to 30 Nm)

1.8 Spark plug gap is

incorrect

1.8 Set gap between

electrodes between

0.7-0.8 mm

1.9 Faulty ignition module 1.9 Contact an authorised

service centre

1.10Fuelshut-ovalveis

closed

1.10Openthefuelshut-o

valve

2. Engine stops 2.1 Not enough fuel in the

fuel tank

2.1 Fill fuel

2.2 Cutting mean is blocked 2.2 Remove blockage

38

Problem Possible cause Solution

3. Enginedicult

to start or loses

power

3.1 Dirt, water or stale fuel

in the fuel tank

3.1 Drain fuel and clean

tank. Fill the tank with

clean, fresh fuel

3.2 Vent hole in fuel tank

cap is clogged

3.2 Clean or replace the

fuel tank cap

3.3 Airlterisdirty 3.3 Cleanairlter

4. Engine

operates

erratically

4.1 Spark plug is defective 4.1 Install new, correctly

gapped plug

4.2 Spark plug gap is

incorrect

4.2 Set gap between

0.7-0.8 mm

4.3 Airlterisdirty 4.3 Cleanairlter

5. Engine idles

poorly

5.1 Airlterisdirty 5.1 Cleanairlter

5.2 Air vents are clogged 5.2 Remove debris from

vents

5.3 Cylindernsare

blocked

5.3 Remove debris from

cylinderns

6. Engine skips at

high speed

6.1 Gap between electrodes

of the spark plug is too

close

6.1 Set gap between

0.7-0.8 mm

7. Engine

overheats

7.1 Air vents are clogged 7.1 Remove debris from

vents

7.2 Incorrect spark plug 7.2 Install the correct spark

plug

8. Unsatisfactory

results

8.1 Cutting mean is dull 8.1 Replace with a new one

8.2 Cutting height is

incorrect

8.2 Adjust cutting height

9. Excessive

vibration/noise

or exhaust

9.1 Cutting mean is dull/

damaged

9.1 Replace with a new one

9.2 Bolts are loose 9.2 Tighten all bolts

9.3 Incorrect petrol type 9.3 Drainthefuelandllthe

correct type

39

Recycling and disposal

1. Old products are potentially recyclable and do not, therefore, belong in your

household rubbish. You are requested to assist us and our contribution to saving

resources and protecting the environment by handing in this product at an equipped

collection centre (if there is one available).

2. Petrol, oil, used oil, a mixture of oil and petrol and objects soiled with oil e. g. cleaning

cloths do not belong in the household rubbish. Dispose of oil-contaminated items

in accordance with the local guidelines and hand them in at recycling centres.

3. The product comes in a package that protects it against damage during shipping.

Keep the package until you are sure that all parts have been delivered and the

product is function properly. Recycle the package afterwards.

Guarantee

This product carries a guarantee of 36 months (45 days trade) starting from the day of

purchase. Please retain your receipt as a proof.

Thisguaranteespecicallyexcludeslossesdueto:

• Normal wear and tear, including accessory wear

• Overload, misuse or neglect

• Failure of consumable items (such as batteries)

• Repairs attempted by anyone other than an authorized agent

• Accidental damage caused by foreign objects or substances

• Lack of routine maintenance

• Failure to follow manufacturer’s guidelines

• Loss of use of the goods

Due to continuous product improvement, we reserve the

righttochangetheproductspecicationwithoutpriornotice.

Thisguaranteedoesnotaectyourstatutoryrights.

For any inquiries relating to the guarantee please contact

your retailer: If you purchased this product in B&Q store or

website then call 0333 0143101. If you bought this product

in SFX outlet or website then call 03330 112 112.

This manual suits for next models

1

Table of contents

Other Erbauer Lawn Mower manuals

Popular Lawn Mower manuals by other brands

Metalcraft

Metalcraft SCAG POWER EQUIPMENT SWZU Series Operator's manual

Mac allister

Mac allister MLM1737 Original instructions

Lawn-Boy

Lawn-Boy GoldPro Series Operator's manual

Cozy Cab

Cozy Cab A-11271 Mounting instructions

GAMA

GAMA GLM-32E-2 Instruction manual & recipes

Euro Systems

Euro Systems M250 EVO Translation of original user instructions