ES AWH9-V5+ User manual

Heat Pump

DC Inverter Air to Water

Before operating this product, please read the

instructions carefully and keep this manual for future use.

User’s manual

User’s manual

AWH9/11-V5+

MBG series

2

1. Before use

1.1 Safety precautions

1.2 Working principle

1.3 Main components

1.4 Specifications

2. Installation

2.2 Tools needed

2.3 Installation of the indoor control unit

2.4 Installation of the monoblock unit

2.5 Accessories

2.6 Wiring

2.7

2.8

2.9

3. Usage

3.1 Introduction of wired controller

3.2 Parameter setting overview

3.6

4. Maintenance

4.1 Attention

4.5

4.6

4.7

4.8 Trouble-shooting

5.

5.1 Outlines and dimensions

5.2 Exploded view

5.3 Wiring diagram

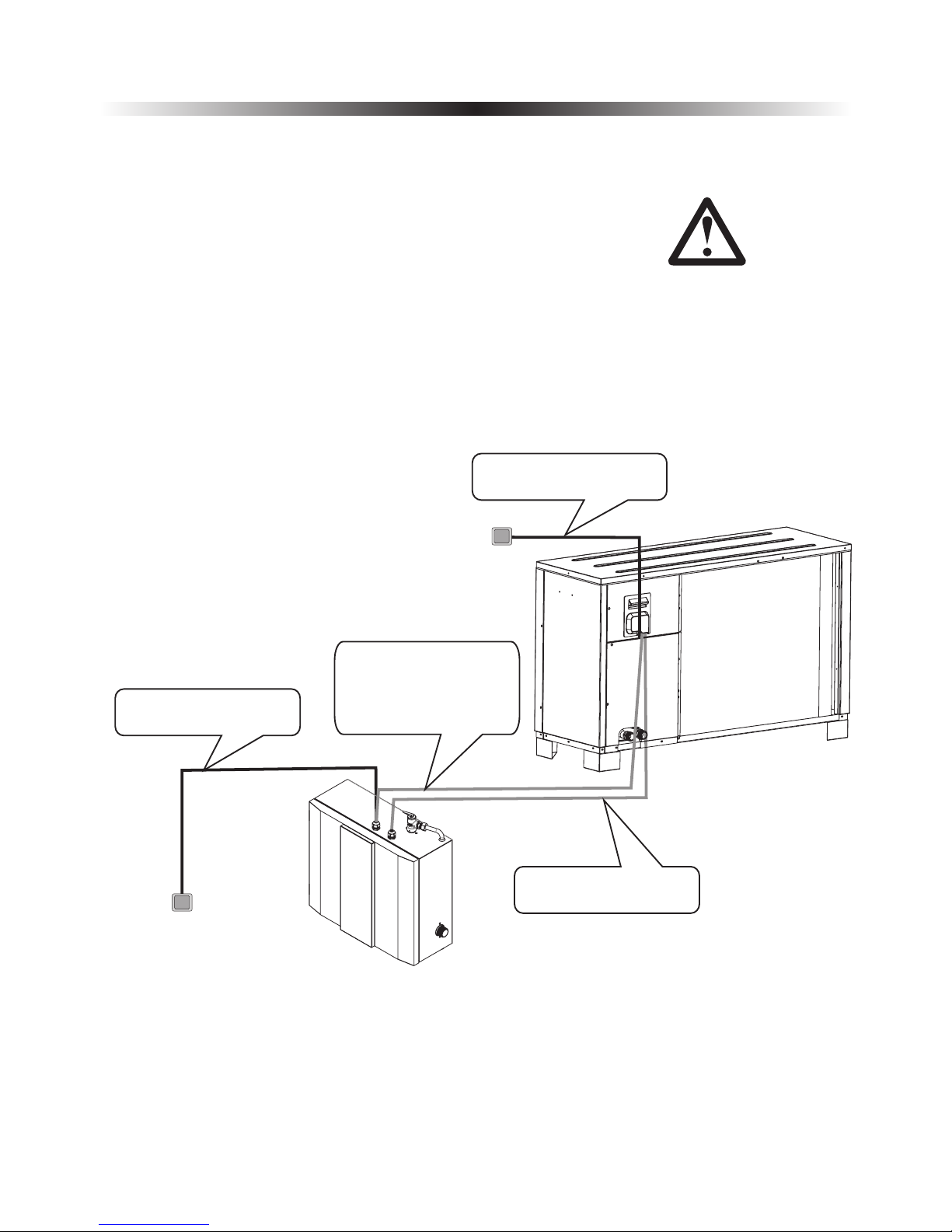

2.1 General application system introduction

Installation of safety valve kit

3.3 Basic operation

4.2 Cleaning of water filter

4.3 Cleaning of plate heat exchanger

4.4 Gas charging

Condenser coil

Service of indoor control unit

Service of monoblock unit

Water pipe connection

Test run

3.4 Advanced setting

3.5 Failure code

Error code

Attached drawing

4

4

6

7

8

11

11

13

13

15

17

18

25

26

27

28

28

30

35

47

58

59

68

68

68

68

68

69

69

72

76

78

78

81

83

Catalogue

3

1. Before use

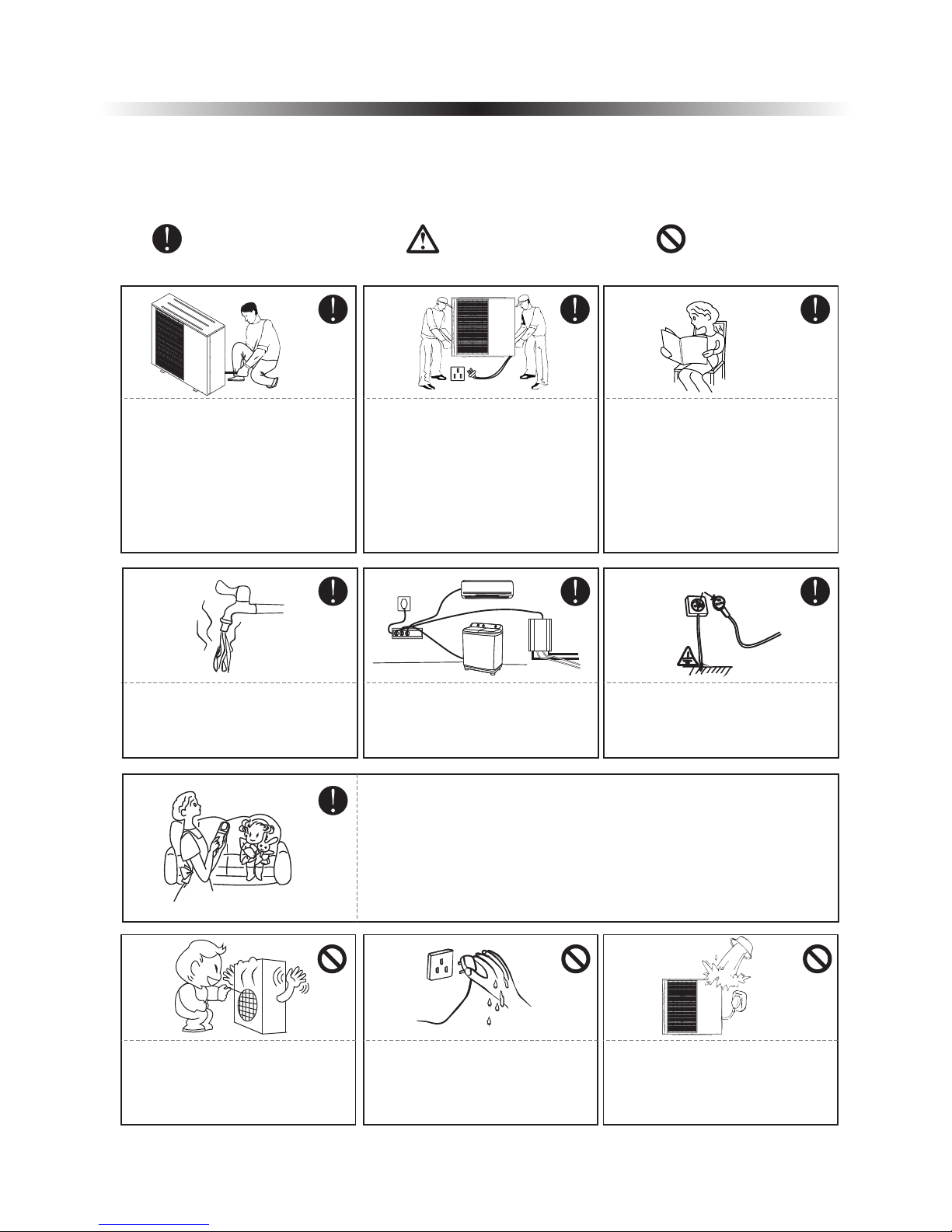

CautionWarning Prohibition

1.1 Safety precautions

The following symbols are very important. Please be sure to understand their meaning, which concerns

the product and your personal safety.

The installation, dismantlement

and maintenance of the unit must

be performed by qualified

personnel. It is forbidden to do any

changes to the structure of the unit.

Otherwise injury of person or unit

damage might happen.

To avoid electrical shock, make

sure to disconnect the power

supply 1 minute or more before

servicing the electrical parts. Even

after 1 minute, always measure the

voltage at the terminals of main

circuit capacitors or electrical parts

and, before touching, make sure

that those voltages are lower

than the safety voltage.

User Manual

Be sure to read this manual before

use.

For sanitary hot water, please

always add a mixture valve before

water tap and set it to proper

temperature.

Ground wire

Use a dedicated socket for this

unit, otherwise malfunction may

occur.

The power supply to the unit must

be grounded.

Do not touch the air outlet grill

when fan motor is running.

Do not touch the power plug with

wet hands. Never pull out the plug

by pulling the power cable.

Water or any kind of liquid is

strictly forbidden to be poured into

the product, or may cause electric

creepage or breakdown of the

product.

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by

children without supervision.

4

1. Before use

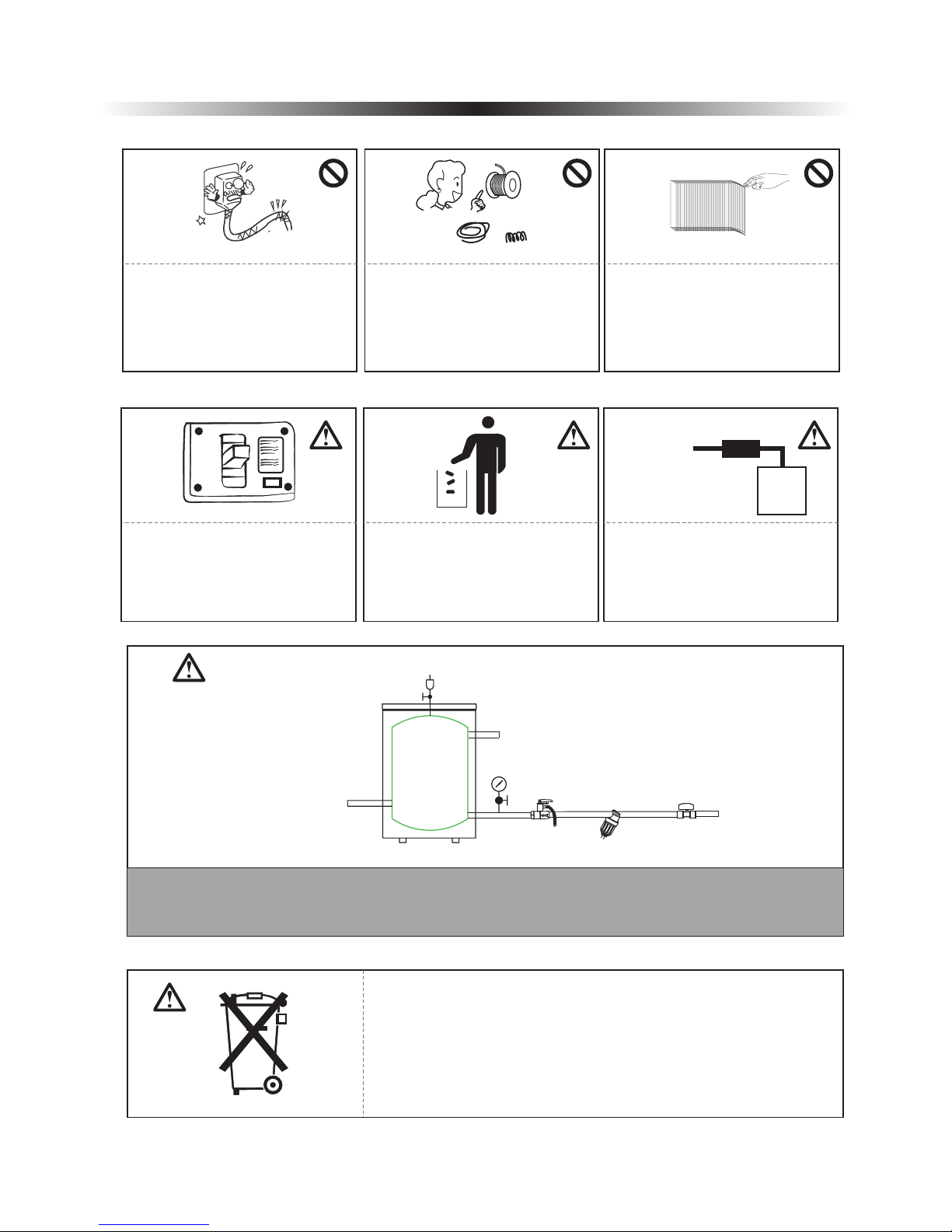

Copper

Steel

Fuse

Main

Power Cable RCD

Indoor

control

unit

When the power cord gets loose

or damaged, always get a qualified

person to fix it.

It is mandatory to use a suitable

circuit breaker for the heat pump

and make sure the power supply to

the unit corresponds to the

specifications. Otherwise the unit

might be damaged.

Disposal of Scrap Batteries(if

there is).Please discard the

batteries as sorted municipal waste

at the accessible collection point.

Installation of a residual current

device (RCD) having a rated

residual operating current not

exceeding 30 mA is advisable.

ON

OFF

Please select the correct fuse or

breaker as per recommended. Steel

wire or copper wire cannot be

taken as substitute for fuse or

breaker. Otherwise, damages

maybe caused.

Be aware fingers might be hurt by

the fin of the coil.

5

This marking indicates that this product should not be disposed with

other household wastes throughout the EU. To prevent possible harm to

the environment or human health from uncontrolled waste disposal,

recycle it responsibly to promote the sustainable reuse of material

resources. To return your used device, please use the return and

collection systems or contact the retailer where the product was

purchased. They can take this product for environmental safe recycling.

System water filling T/P valve

Connect to heating/cooling system

Buffer tank

Connect to heat pump

One way valve

Filter

City water inlet

1. It's suggested to use pure water for filling the system.

2. If use city water for filling, please soften the water and add a filter.

Note: After filling, the system of water system should be 0.15~0.6MPa.

1.2 Working principle

1. Before use

Water inlet

Water Outlet

Filter

Water pump

Heat

exchanger

Power supply

Four-way vavle

Compressor

Three-way valve

Refrigerant Filter T-connector

Fan motor

Pressure

check valve

Evaporator

Heating

Cooling

6

Operation panel

Cable gland

Water outlet Water inlet

1.3 Main components

1. Before use

1.3.1 Indoor control unit

7

Pressure Relief Valves

Electric box

Door

Electric box cover

Water pump

1.3.2 Monoblock unit

1. Before use

8

AW9-V5+

AW11-V5+

1. Before use

1.4 Specifications

9

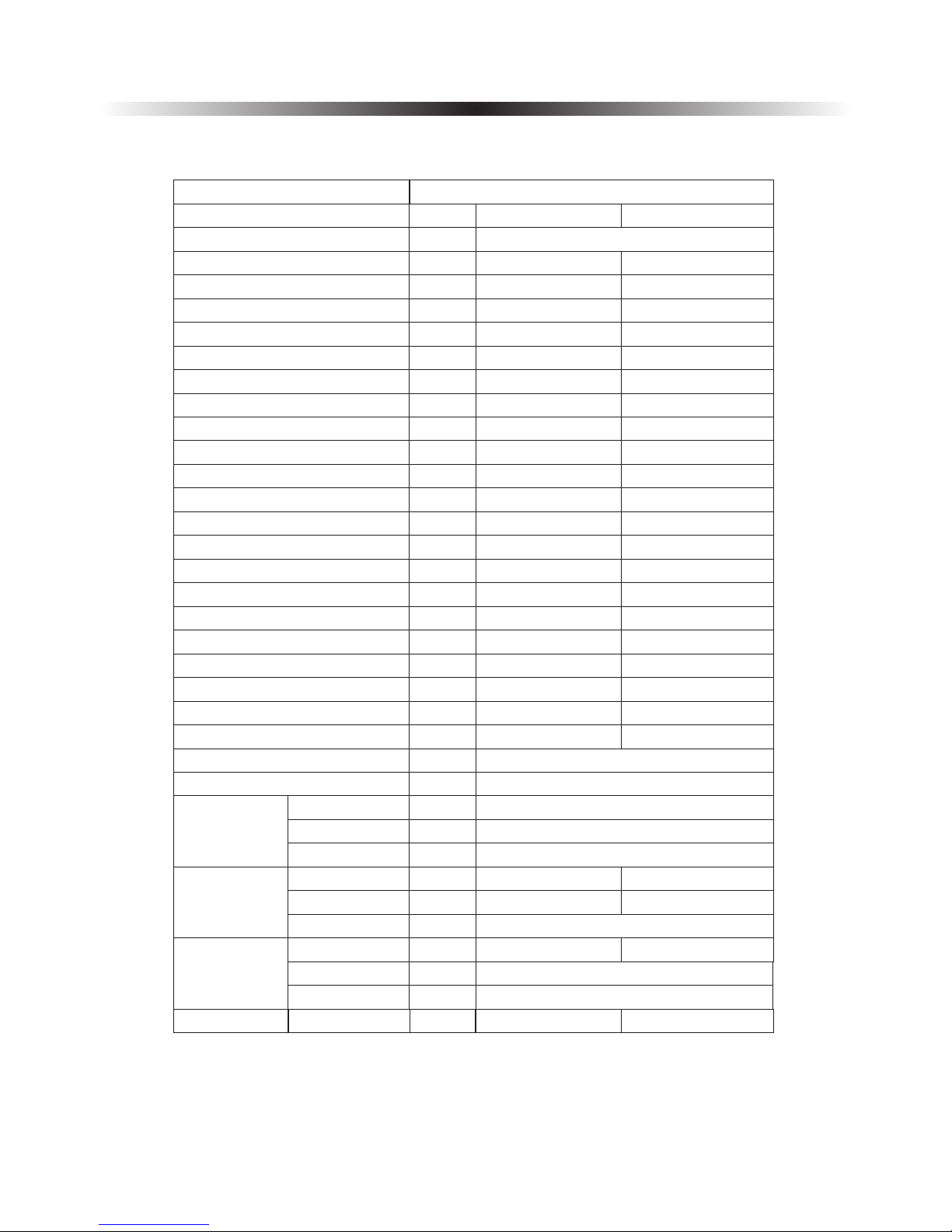

Model

Power Supply V/Hz/Ph

AWH11-V5+

AWH9-V5+

220-240/50/1

Refrigerant

Max. Heating Capacity (1)

C.O.P (1)

Heating Capacity Min./Max.(1)

Heating Power Input Min./Max.(1)

C.O.P Min./Max.(1)

Max. Heating Capacity(2)

C.O.P (2)

Heating Capacity Min./Max.(2)

Heating power input Min./Max.(2)

C.O.P Min./Max.(2)

Max. Cooling Capacity(3)

E.E.R (3)

Cooling Capacity Min./Max.(3)

Cooling Power Input Min./Max.(3)

E.E.R Min./Max.(3)

Max. Cooling Capacity(4)

E.E.R(4)

Cooling Capacity Min./Max.(4)

Cooling Power Input Min./Max.(4)

E.E.R Min./Max.(4)

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

11.510.10

3.824.03

4.67/11.5

4.33/10.10

915/3029

975/2153

3.82/5.05

4.02/4.65

10.7

9.53

2.95

3.17

4.14/10.74.19/9.53

1218/36241230/2990

2.95/3.563.12/3.55

9.2

6.84

2.682.09

4.33/9.24.10/6.84

993/3465

1230/3280

2.685/4.11

2.09/3.32

6.745.05

2.15

1.58

2.17/6.742.34/5.05

924/31321080/3200

2.15/3.01.58/2.40

R410A/1.9

R410A/2.45

Circuit Max. Pressure bar 42

Rated Power Water Pump W

Compressor

Type

Quantity/System

Twin Rotary

1

Oil

Fan

Quantity

Airflow

Rated Power

m³/h

W

31003000

60

1

1

Allowable

Fan Flow

Face Area

Row-Fins/Inch

Tube.Dia

m²

Inch

0.8710.542

Kg

Type of Product DC Inverter Air to Water Heat Pump Unit

Noise Level Indoor/Outdoor 30/56

dB(A)

87

FV50S

3/8 O.D

2 Rows-14

30/56

1. Before use

10

NOTE:

(1) Heating condition: water in/out temperature:30℃/35℃, ambient temperature:DB/WB 7/6℃;

(2) Heating condition: water in/out temperature:40℃/45℃, ambient temperature:DB/WB 7/6℃;

(3) Cooling condition: water in/out temperature:23℃/18℃, ambient temperature:35℃;

(4) Cooling condition: water in/out temperature:12℃/7℃, ambient temperature:35℃.

(5) The specifications are subject to change without prior notice.

For actual specifications of the unit, please refer to the specification stickers on the unit.

Net Dimension (L×D×H)

Packing Dimension (L×D×H)

Net Weight

Packing Weight

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

1215×415×7601064×353×754

500 495 210× ×

1310× ×830520

1130 460 904× ×

94

20

81

98

86

Water Side Heat Exchanger

Allowable Water Flow

Type

Water Pressure Drop

Piping Connection

Min. Water Flow

Rated Water Flow

Max. Water Flow

23

G1”

0.520.43

0.310.26

0.620.51

Material

Heating

Cooling

Operating Ambient Temp. range

Operating Inlet Water Temp. range

Water Volume

mm

mm

mm

mm

Kg

Kg

Kg

Kg

Kpa

Inch

L/S

℃

℃

℃

Kg

18

-25~46

0~55

7~75

4.5

Plate Heat Exchanger

Stainless Steel+Copper

Model

Type of Product DC Inverter Air to Water Heat Pump Unit

23

600×520×260

AWH9-V5+ AWH11-V5+

500 495 210× ×

600×520×260

2. Installation

11

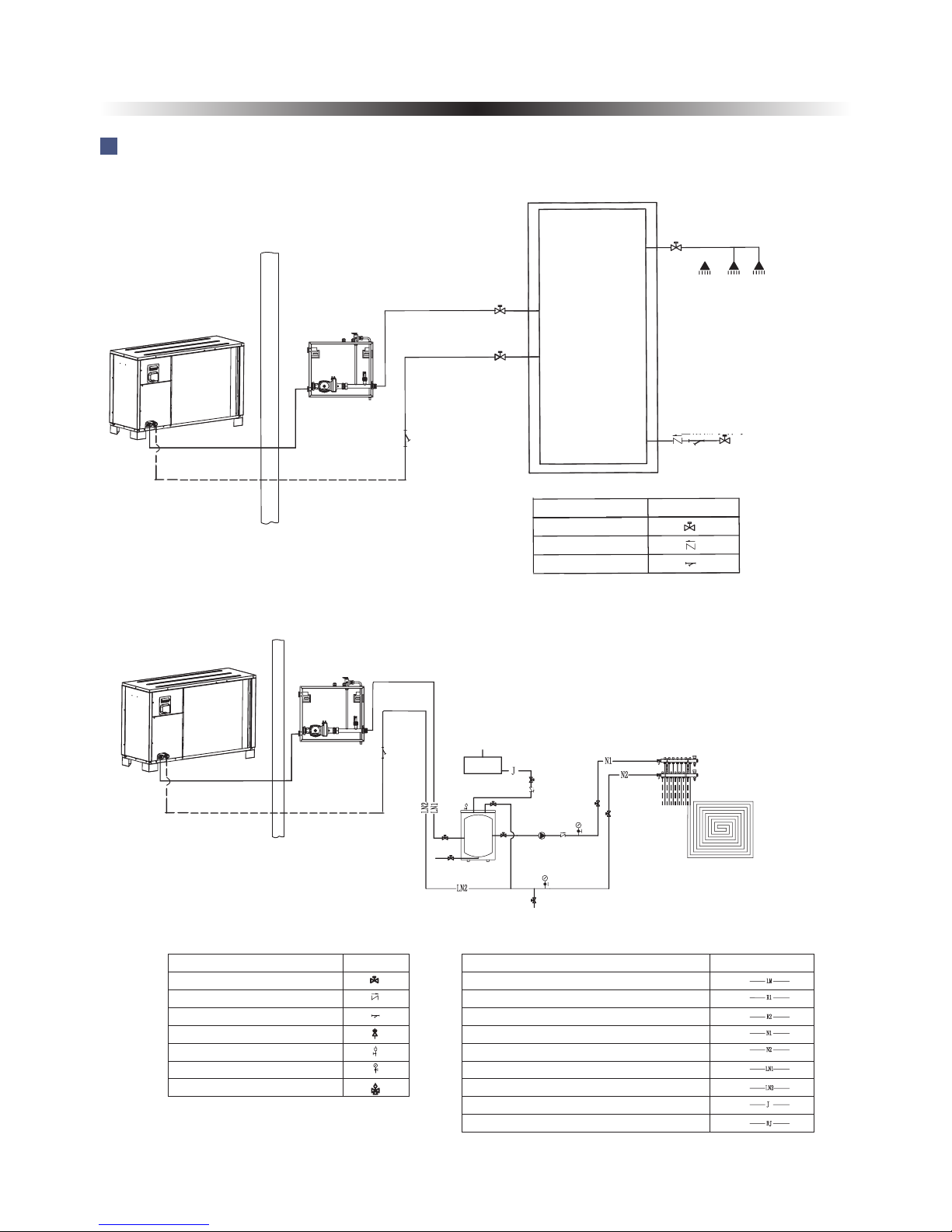

2.1 Application system introduction

To city water

Water discharge outlet

De25

De 32

De 32

De40

De 40

De 25

De25

De 32

De 32

UP S 25/ 80

热水出 水 口G1"

生活热水补水口

G1"

G1"

G1"AH-200L

40~50℃

Application 1: Sanitary hot water

Hot water outlet

City water inlet

Application 2: Floor heating system

Name Drawing

Ball valve

One way valve

Filter

Drain outlet

30L buffer tank

Floor heating

distribution system

Name Drawing

Ball valve

One way valve

Filter

Safe valve

Air discharge valve

Water pressure gauge

Motor three way valve

Refrigerant pipe

Hot water outlet pipe

Hot water inlet

Heating water outlet pipe

Heating water inlet pipe

Cooling/heating water outlet pipe

Cooling/heating water inlet pipe

City water inlet pipe

Sanitary hot water outlet pipe

Name Drawing

2. Installation

12

De32

De3 2

De40

De4 0

De25

De25

De32

De32

UPS 2 5 /80

12

11

9

10

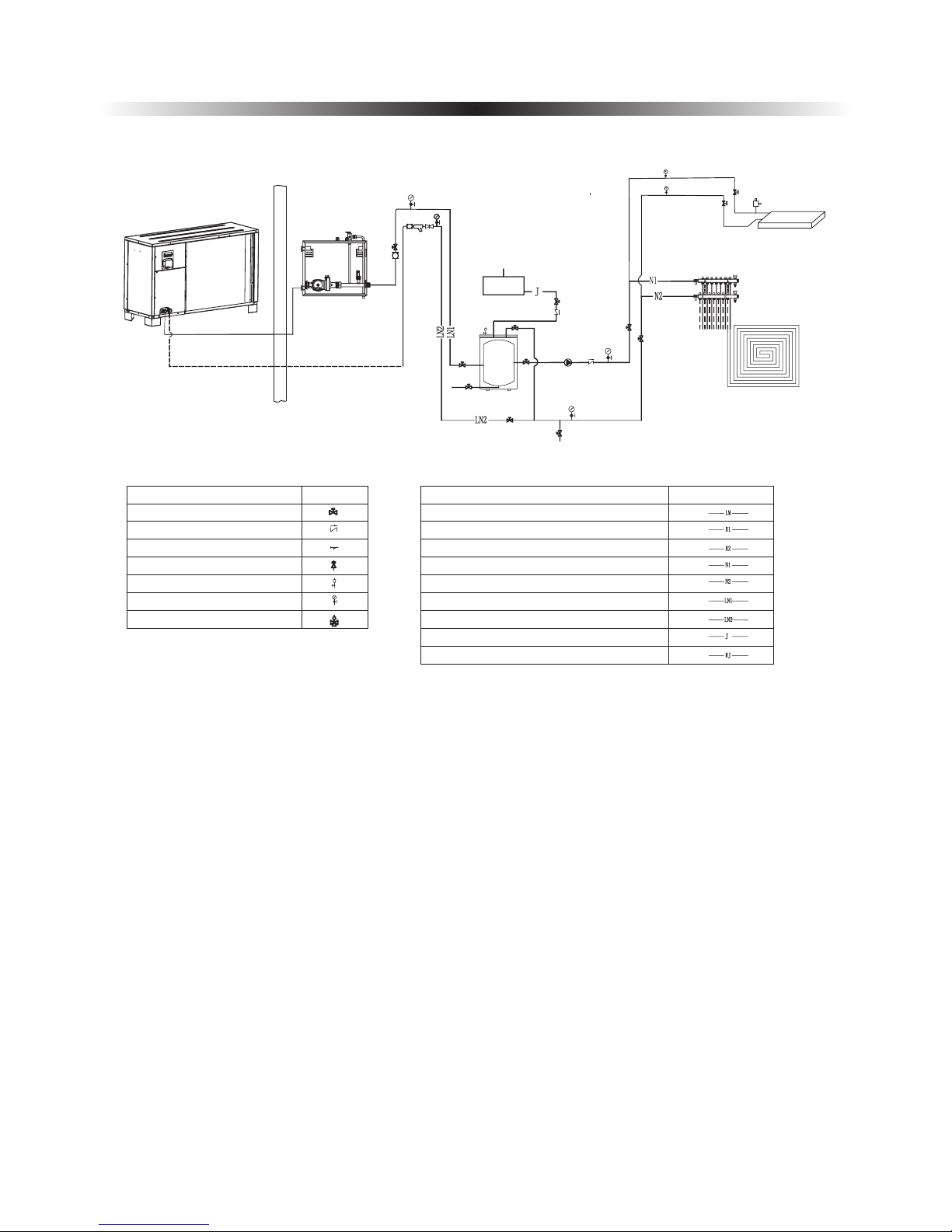

Application 3: Heating and cooling system

Fan coil unit

Floor heating

distribution system

To city water

Drain outlet

30L buffer tank

Water discharge outlet

De25

Name Drawing

Ball valve

One way valve

Filter

Safe valve

Air discharge valve

Water pressure gauge

Motor three way valve

Refrigerant pipe

Hot water outlet pipe

Hot water inlet

Heating water outlet pipe

Heating water inlet pipe

Cooling/heating water outlet pipe

Cooling/heating water inlet pipe

City water inlet pipe

Sanitary hot water outlet pipe

Name Drawing

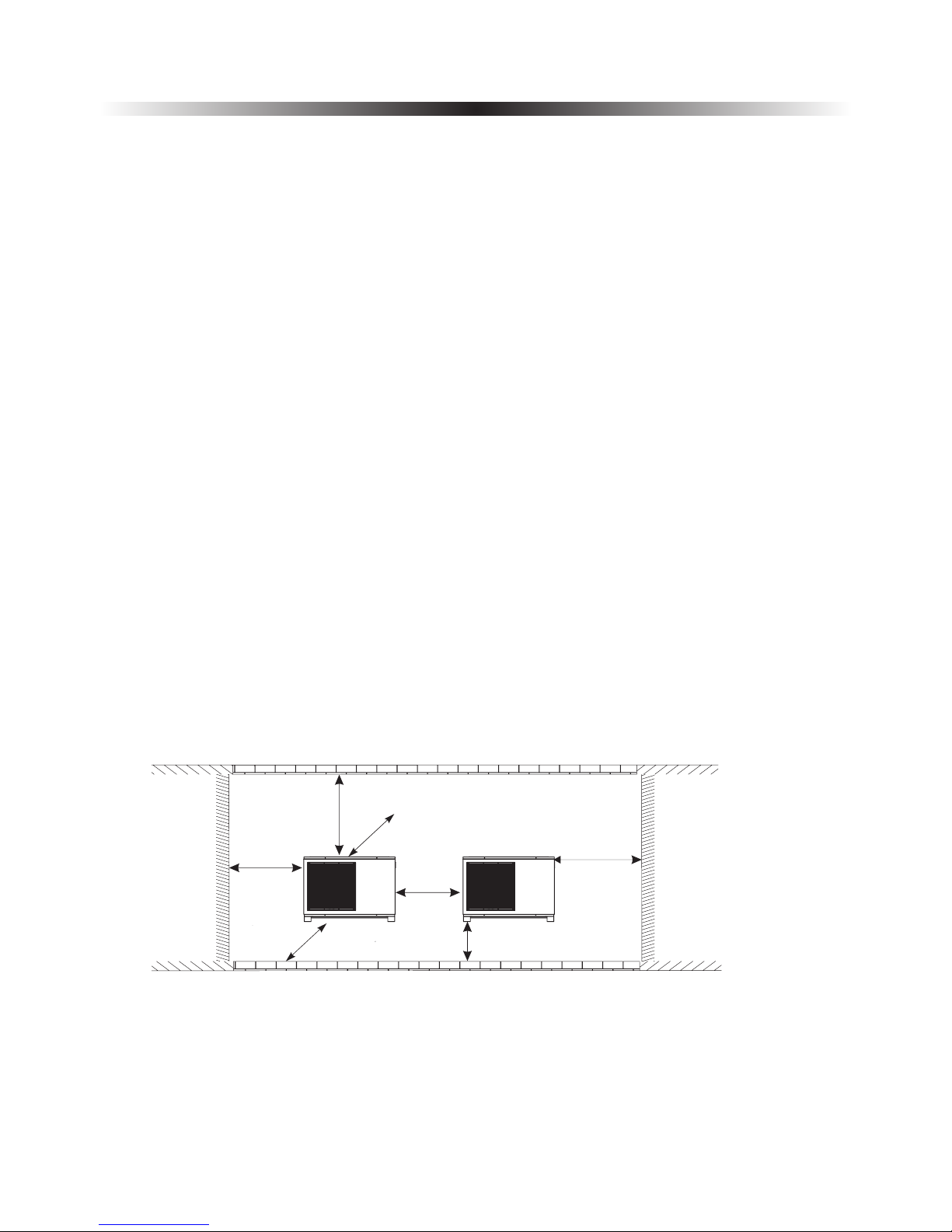

The installation of the product should be handled by professional installers or under their

instructions.

>500mm

>100mm >100mm

>500mm

2. Installation

2.2 Tools needed

2.3 Installation of the indoor control unit

Most people already have the tools needed for

installation: spirit level, pencil, crosshead

screwdriver, drill, 8 mm. concrete drill bit, detection

drill, square, tape measure or ruler, tape width 65

mm, hole saw about 80 mm (deviation in size may

occur), knife and two adjustable spanners or pliers

(and possibly torque wrench).

2.3.1 Installation notes

1)

2) The indoor unit shall be placed in dry and well-ventilated environment.

3) Indoor unit mustn't be installed in an environment where volatile, corrosive or flammable liquid

or gas exists.

4)

The indoor control unit should be installed indoors and mounted on the wall, with water outlet

downwards.

control

control

control

Please choose a suitable position to install the indoor control unit as follows:

Enough space should be left around the indoor unit for futher maintenance.

13

2.3.2 Installation

Indoor unit should be mounted on the wall as per procedures below:

1) Take out the expansion bolts and mounting board from accessory and put the mounting board on the

wall horizontally; Mark on the wall the location for bolts through the holes on mounting board.

2) Drill holes with proper diameter for expansion bolts.

3)

4)

5)

6) Hang the indoor unit onto the mounting board and make sure it's placed well before you let go

your hands. The installation is finished.

control

Unscrew the nuts out from the expansion bolts.

Fix the mounting board on the expansion bolts a little bit, but don't be too tight.

Use a hammer to pound the expansion bolts into the drilled holes. Fasten the nuts by turning the wrench

to fix the mounting board on the wall.

control

2. Installation

12 3

45 6

Note:

You must choose very firm wall for installation otherwise the bolts may get loose and unit be damaged!

If it's wood wall, please use self-tapping screws in accessory instead of bolts. Please hang

the mounting board directly onto the wood wall without drilling holes. The wood wall must be firm

enough. Wood walls that are too thin, too brittle or humid are not adequate for installation.

expansion

14

2.4 Installation of the monoblock unit

2.4.1 Installation notes

1) The monoblock unit can be located in a open space, corridor, balcony, and roof.

2) The unit shall be placed in dry and well-ventilated environment;

3) unit mustn't be installed in an environment where volatile, corrosive or flammable liquid or

gas exists.

4) Please don't install unit close to bedroom or living room, because there is some noise when

it's running.

5) When installing the unit in harsh climatic conditions, sub-zero temperatures, snow, humidity..., please

raise the unit above the ground by about 50cm.

6) Please ensure there is drainage system around the location, to drain the condensate water under

defrosting mode.

7) When installing the unit, tilt it by lcm/m for rain water evacuation.

8)

9) Please don't install the indoor control unit and unit in damp locations, otherwise it may

cause short-circuit or corrosion of some components. The unit should be free from corrosive and

moisture surrounding. Otherwise the lifetime of the unit might be shortened.

10) Please ensure enough space around the unit, for better ventilation and maintenance.

Please refer to the illustration below.

monoblock monoblock

Monoblock

monoblock

monoblock

monoblock

monoblock

monoblock

monoblock

If the unit is

installed in humid environment, electronic components may get corroded, or short-circuited because of

heavy humidity.

It's recommended to install an awning above the unit, to protect the snow from clogging in

the air inlet and outlet and ensure the normal running.

Install unit far away from the exhaust port of kitchen, to avoid oil smoke entering

into unit and adhering to heat exchanger. It's hard to clean up.

2. Installation

15

≥650mm

≥400mm

≥150mm( )Back space

≥1500mm

()

Front

space

≥500mm

≥500mm

≥500mm

( )Above ground

2. Installation

2.4.2 Installation

User can either use the dedicated mounting bracket from the supplier, or prepare a suitable bracket for the

unit installation. Make sure the installation meets following requirements:

1) The unit must be installed on flat concrete blocks, or a dedicated mounting bracket. The bracket should

be able to support at least 5 times of unit’s weight.

2) All nuts must be tightened after the bracket is fixed; otherwise, it may cause damage to the equipment.

3) User should double check and make sure the installation of unit is firm enough.

4) The bracket can be of stainless steel, galvanized steel, aluminum and other materials as required by the

user.

5) Besides the mounting bracket, the user can also install the monoblock unit on two concrete blocks, or a

raised concrete platform. Please make sure that the unit is securely fastened after installation.

6) Please see the dimensions of unit when choose a suitable wall bracket. monoblock

≥500mm

◆ Hole for piping kits should lean to outside a little bit

(≥8 degrees), to keep rain water or condensate water

from flowing back indoors.

≥8°

Sleeve

Shield

16

2.5 Accessories

Accessories below are delivered together with the product .

Please check in time. If there is any shortage or damage, please contact local distributor.

Name Quantity Picture

User’s manual

Drain pipe 1

Safety valve kit 1

1User Manual

2. Installation

Indoor control unit

bracket

1

Expansion bolts 2

Name Quantity Picture

17

Name Quantity Picture

1

1

TR-Room temperature sensor

TC-water temperature sensor for cooling

TH-water temperature sensor for heating

1

Communication cable between indoor control unit and

monoblock unit

Communication cable

Signal cable between indoor control unit and monoblock

unit 1

1

TW-Water temperature sensor for hot water

◆

◆

◆

◆

◆

◆

◆

◆

◆

It is recommended to use a suitable circuit breaker for the heat pump;

The power supply to the heat pump unit must be grounded.

The wiring should be done by professional person.

The wiring should be comply with the local industry regulation.

The wiring should be done after the unit is powered off.

Cable should be fixed tightly, to ensure it won’t get loose.

Don't connect several parts of cables together to use.

Make sure the power supply in the local coincide with the power supply marked in rating label.

Make sure power supply, cable and socket can meet the requirement of the input power of the unit.

2.6 Wiring

2. Installation

Installation sketch

18

Signal cable between

indoor and outdoor unit

Main power

in user side

Heat pump unit power

supply

Aluminum foil electric

heating piece power cable

between indoor control

unit and monoblock unit

Heat pump monoblock unit

power supply

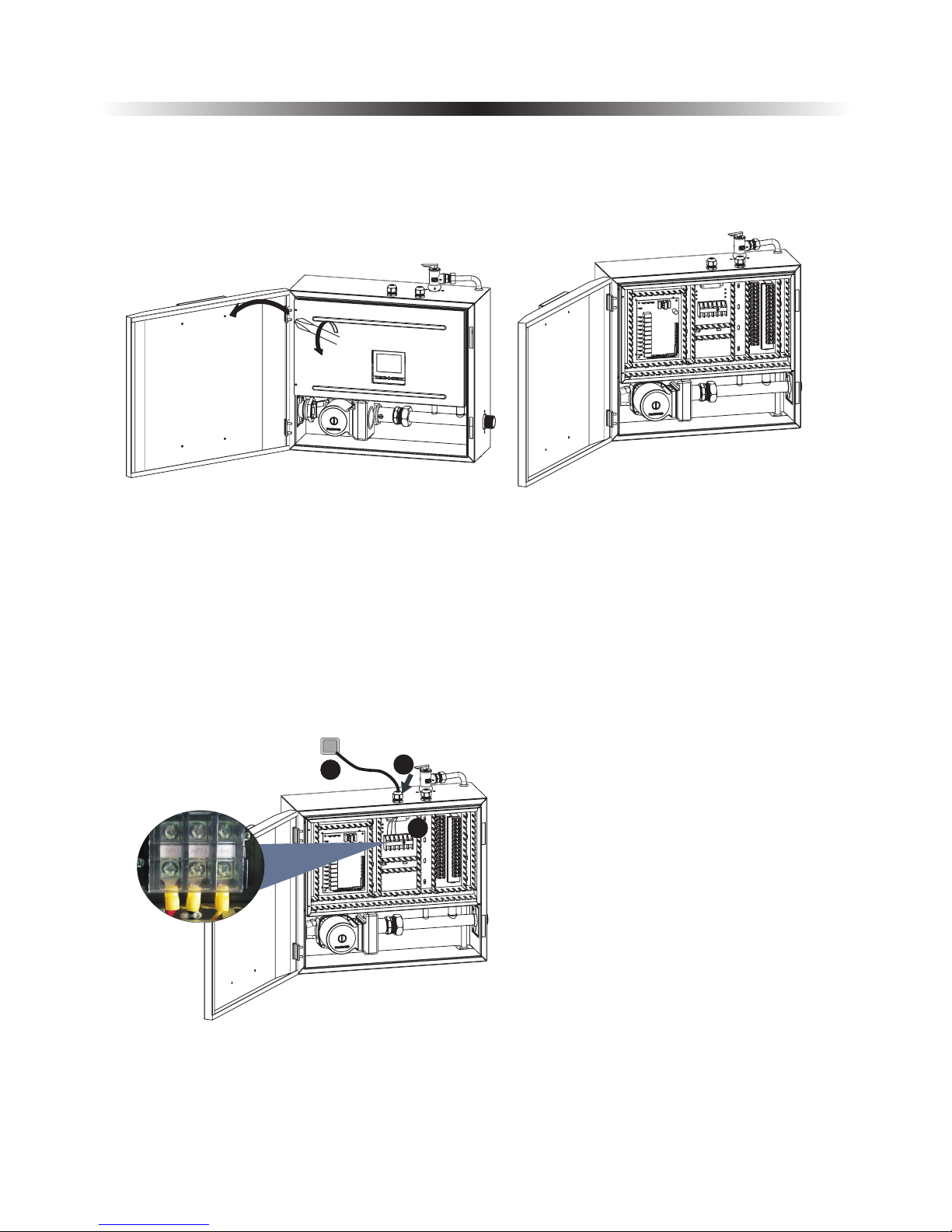

1) Heat pump unit power supply

Get a power cable in suitable length that complies to the local safety regulations.

Before wiring, open the indoor control unit front panel and take off the electronic box cover.

A. Insert one end of this cable through the

cable gland on bottom of the indoor control

unit, and connect it with heat pump power

supply terminals (G, N, L).

B. Fasten the cable gland to ensure the cable

won't get loosen.

C. Connect the other end to the city power

supply.

2. Installation

19

A

B

C

G N L

2. Installation

20

2) Monoblock unit power supply.

C

B

A

Get a power cable in suitable length that complies to the local safety regulations.

A. Insert one end of this cable through the cable gland on back of the outdoor control unit,

and connect it with heat pump power supply terminals (G, N, L).

B. Fasten the cable gland to ensure the cable won't get loosen.

C. Connect the other end to the city power supply.

This manual suits for next models

1

Table of contents

Other ES Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual