ESPRIT FALCON-80 User manual

1

Esprit Tech (1) 321.729.4287

P.O. Box 360815 Support@EspritTech.com

Melbourne, FL https://www.espritTech.com

32936, USA

FALCON ELECTRONIC SPEED CONTROLLER

USER MANUAL

The FALCON product line represents advanced speed controllers for use exclusively in RC airplane models.

With integrated telemetry and various possibilities of optional user configuration, the controllers offer high

efficiency, low weight and precise motor control.

FEATURES

-Small dimensions combined with high power motor control.

-Over- and undervoltage protection, overtemperature protection, motor-stall protection.

-Configurable current limiter.

-Optically isolated throttle input.

-Safety shutdown when the throttle impulse is lost.

-Configurable acceleration, timing, electromagnetic brake etc.

-Low acoustic noise due to high frequency switching.

-Automatic telemetry detection: Duplex EX, Hott, MSB, S.Bus2.

-Telemetry (RC system dependent): voltage, current, power, capacity, temperature, RPM, energy.

-Telemetry min/max values are logged.

-Configuration through the transmitter or external terminal (JETIBOX/SMART-BOX).

-Firmware updates via USB interface.

-Languages: CZ/DE/EN/FR/IT.

FALCON-80

FALCON-130

Dimensions

57x35x28mm

58x53x28mm

Weight incl. cables

60g

110g

Continuous current

80A

130A

Peak current

120A/2s

180A/2s

Supply voltage

8 –51V

10 –51V

LiPo cells

3 –12

4 –12

LiFe cells

3 –14

4 –14

Cables battery/motor

4mm2/2.5mm2

4mm2/4mm2

Anti-spark circuit

No

Yes

Recommended connectors

G4 (75A), XT90 (90A)

G5.5 (150A)

Temperature range

-10÷110°C

PWM frequency

20kHz

Operating current

50mA

Standby current

4mA

Propeller positioning

With additional Hall-sensor

Telemetry

Duplex EX, Multiplex MSB, Graupner Hott, Futaba S.Bus2

Status LED

Yes

Freewheeling

Yes

BEC

No

Optical isolation

Throttle input only

Maximum RPM

> 300 000 eRPM (2-pole motor)

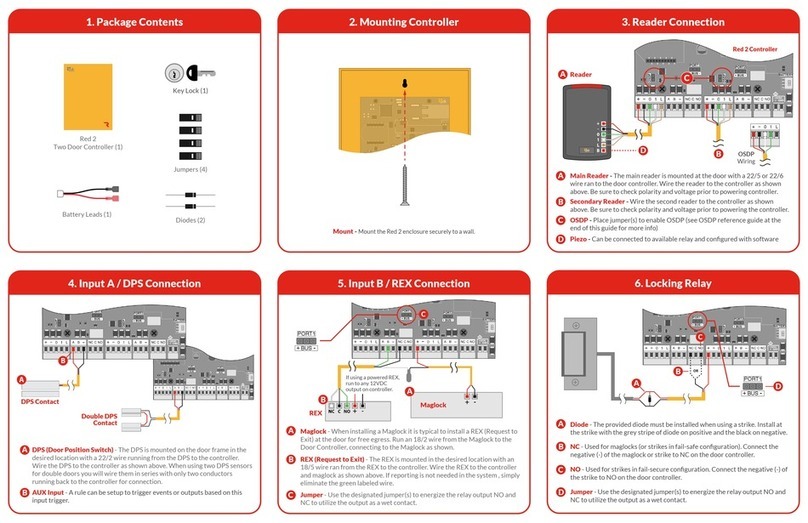

INSTALLATION

Fasten the controller in your model by the screws. Alternatively, you can use Velcro or double-sided adhesive

tape for fixing. Connect the motor and receiver according to the schematic below. You may connect the motor

cables in arbitrary order, as changing direction is done by exchanging any of the two cables (alternatively also

by the “Direction” parameter in the configuration). Turn on the transmitter followed by the receiver –the

receiver uses a dedicated battery. Now you can plug in the main flight pack.

2

Note: The red LED on the controller will light up for two seconds to indicate proper initialization. After the

correct throttle impulse is detected (meaning off position), the controller plays a predefined melody. Now it’s

ready to fly. If the throttle impulse is not detected for more than 4 seconds (e.g. after disconnecting the

receiver battery), the controller will enter standby mode.

Warning: Always use brand new, high quality connectors and make sure that the cables are soldered

perfectly. Any possibility of losing connection during motor run represents a risk of damaging your electronics.

Warning: If you start the controller for the first time, or make any significant changes in the setup, please

make sure that the propeller is removed from the motor shaft.

CONTROLLER MODE

It is possible to choose from two basic controller modes:

Normal (ramped) –the preconfigured acceleration time is always applied when accelerating. This is a

default mode for major use.

Fast mode –the preconfigured acceleration is applied only when spinning up from zero revolutions.

After that, a minimum possible delay is used (0.2s for zero-to-full throttle response).

THROTTLE INPUT SIGNAL

The controller expects positive impulses from the receiver with maximum refresh rate up to 400Hz. By default,

with automatic endpoints selected, the controller will work with vast majority of RC systems. In such case, a

minimum throttle impulse is read after startup and the maximum power is dynamically adjusted as soon as you

apply full throttle for the first time.

In case you need exact points on your transmitter stick, where the motor starts and where full throttle is, you

can configure manual endpoints as well.

Note: The controller waits for throttle-low position after startup and also every time the motor is stopped due

to any error condition. If the throttle stick is not at the correct position during startup, the ESC plays a warning

tone.

MOTOR SETTINGS

It is possible to configure many of the motor parameters, including acceleration, timing, motor gear ratio or

number of poles. The gear ratio and number of poles are important for telemetry to measure the motor speed

correctly.

3

Acceleration influences the motor response on the throttle channel. By decreasing the acceleration value, the

motor response gets faster, providing more “locked-in” feeling. However, the motor consumes more current

and the controller generates more heat. We recommend the default acceleration 1.0s for majority of model

types, including electric gliders, scale models, EDFs etc. For 3D aerobatic flight you might go down to 0.5s or

even less (with care). For the fastest motor response, you may also set the “Fast controller mode” in the

Common Settings.

Timing is defined by the motor type and it is usually recommended by the motor manufacturer. It also

influences the motor power and current consumption. Higher timing can increase the motor power but care

must be taken not to overload the system.

Automatic timing: The timing is continuously adjusted by the internal algorithm. This is a universal

solution compatible with most motor types.

Timing 0° - 10°: Recommended for inrunners.

Timing 15° - 20°: Recommended for most outrunners. It offers good power and efficiency combination.

Timing 25° - 30°: The high torque motors with many poles require the highest timing.

Motor type should be modified only in some specific cases where it is necessary by the application. There are

three options available:

“Standard” motor type – recommended for most motor types and applications.

“High torque” – if you have problems with motor synchronization during fast acceleration, use this

mode. Preconditions: large outrunner with more than 20 poles, heavy propeller, large current peaks.

We also recommend increasing timing to more than 20°.

“High speed” – use this mode if your power setup exceeds 250 000 eRPM (revolutions per minute

calculated for a 2-pole motor).

Startup power influences the first few motor revolutions. If you are not satisfied with the automatic mode, you

can set the motor start to be more aggressive (positive values), or as smooth as possible (negative values).

BRAKE CONFIGURATION

The electromagnetic brake is a standard feature of all ESCs used in electric glider models. The FALCON

controller offers several additional parameters to fine tune the braking function. You can use one of the

preconfigured brake settings, or you can specify all the parameters as you wish.

Brake options:

Off: The propeller spins freely without braking.

Soft: Transition from zero to full braking force in 1.0s.

Medium: Transition to full braking force in 0.7s.

Hard: Transition from 70% to 100% braking force in 0.5s.

Manual: You can specify all brake parameters manually:

oStart power –braking force applied from the first moment of applying the brake.

oEnd power –braking force applied after the transition time elapses (usually the full braking

force that stops the motor completely).

oTransition –time between brake start power and brake end power. During this time, the

braking force continuously transits from start to end power.

oWait time –time between unpowering the motor and applying the brake. During this time the

motor spins freely without power.

4

Example: Motor brake with the

following parameters: Start power

= 50%, End power = 100%,

Transition = 0.5s, Wait time = 0.3s.

PROPELLER POSITIONING

The positioning feature allows moving the motor/propeller to the exact position required for safe landing, or

which is just comfortable for further flying. With just a few external components (Hall-sensor and a small

magnet) you can enable this feature and prevent the risk of damaging your propeller during landing. The

magnet needs to be properly fixed to the rotating part (either motor or the propeller), and the Hall-sensor has

to be located in the fuselage, so that the magnet matches the Hall-sensor at the target propeller position. After

enabling the positioning feature in the menu, set also the positioning PWM, so that the motor spins slowly but

smoothly.

Note: Use a high quality CA or Epoxy glue to fix the magnet in the rotating part. You can also drill a small

hollow in the spinner and fix the magnet in it.

Warning: Do not use higher PWM than necessary otherwise the motor may overheat.

MOTOR IDENTIFICATION

Some motor brands contain an integrated temperature sensor compatible with the FALCON speed controller.

This sensor (T125) might be used as a standalone telemetry sensor with Duplex/Hott/S.Bus2 telemetry

support. Alternatively, the sensor can be directly connected to the Input port „A“ of the controller (see the

picture above). From this moment on, the FALCON controller will know the basic motor parameters (minimum

acceleration, recommended timing, gear ratio, number of poles…) and motor temperature as well. Some

parameters are adjusted automatically (gear ratio, poles), the other settings are configured after resetting the

controller to factory defaults.

5

ACTIVE FREEWHEELING

“Active freewheeling”or “Active braking” is a feature of the speed controller that reduces heat generated by the

ESC during partial load operation. This mode is useful for aerobatic pilots who want not only fast acceleration,

but also rapid deceleration. The motor follows throttle stick input in both ways and the pilot feels more

“locked-in”.

CURRENT LIMITER

The current limiter is a part of safety controller features. It doesn’t stop the motor but rather continuously

monitors the immediate current consumption and adjusts the motor power. You can enable this feature, specify

the maximum allowed current and the ESC will reduce the motor power immediately as soon as the current

threshold is exceeded. After the current returns back to the safe level, the motor power is restored.

BATTERY PROTECTION

The integrated battery protection is based on undervoltage detection and reducing motor power, alternatively

shutting down the motor completely. You are free to set the number of cells (or leave automatic detection) and

low voltage threshold per cell. Supported battery types are NiXX (1.2V), LiFe (3.6V max) and LiIo/LiPo (4.2V

max).

ANTISPARK FEATURE

The FALCON-130 controller contains an additional circuit which can be optionally used to prevent sparks when

the battery is connected. This circuit is linked to the flight pack using a separate cable. Use the antispark cable

only for precharging the controller. Never use the cable for powering the motor or any external electronic

components.

Usage

1. Connect the Minus (-)

battery pole.

2. Connect the antispark

cable to the Plus (+)

battery pole.

3. Connect the Plus (+)

battery pole.

Note: If you use the power connectors with integrated antispark mechanism, it is not necessary to use the

antispark feature of the ESC anymore. For example, the XT90 connectors with integrated antispark can be

used.

6

STATUS CODES

The status codes are shown on the screen (JETIBOX/SMART-BOX) if any kind of error condition occurs. If any

status code is set, the red LED continuously flashes.

Available status codes:

Low voltage (UL): The battery voltage got below the threshold specified in the battery protection menu

and the controller either reduced the maximum power, or shut down the motor completely.

High voltage (UH): In case you use a weak battery or wall power supply, the voltage might rise above

the initial level during braking. In such case the alarm is set and all braking functions are disabled.

High current (IH): The current got higher than the maximum peak current defined in the product

specification (120A for FALCON-80, 200A for FALCON-130).

High temperature (T100, T110, T120): The temperature got above the safety threshold level. The

numerical value specifies maximum detected temperature and safety protocol which has been applied.

Commutation error (COM): A synchronization error has been detected during the motor operation. It

usually occurs when the motor stops abruptly, or in case of very fast acceleration for some specific

setups. This error could mean a serious issue in the motor-controller installation.

TELEMETRY AND SETTINGS

Plug the red data cable into the sensor slot of the JETIBOX / SMART-BOX (or corresponding receiver). Power it

up with a battery (4.5 - 8.4V). Now you can safely configure the controller using the arrows on the terminal.

The FALCON ESC is compatible with JETIBOX programming. The JETIBOX menu is divided into five sections:

Actual values –displays the latest telemetry values together with minimums and maximums.

oAvailable telemetry: Voltage, current, capacity, RPM, power (percent), temperature.

oIf the motor chip ID is connected, also motor identification and temperature are shown.

oReset Min/Max - press left+right buttons together to reset all minimums and maximums.

Common settings –basic settings of the controller

oController mode –basic controller mode (normal or fast).

oStartup beep –choose a melody played after the controller initialization.

oStandby beep –you can activate short repeated beeps as an indication of a powered motor

drive.

oMotor endpoints, motor start, motor full –settings related to throttle input signal decoding.

oCapacity reset –you can choose at which moment the capacity and consumed energy are reset.

Power on –the capacity is cleared after initialization. However, the capacity from the

previous run is shown initially, until you start the motor.

Voltage change –the capacity is cleared after you connect a battery with similar (or

greater) voltage compared to the maximum battery voltage from the previous run. This

means that each time you connect a fully charged battery of the same chemistry and

number of cells, the capacity will be cleared.

Manual –the capacity/energy is never cleared and you must perform the reset

manually.

7

oLanguage –you can choose the language of the JETIBOX screen.

Motor settings –settings related to motor parameters.

oDirection, acceleration, timing, startup power, motor type, gear ratio, motor poles –see

the Motor Settings chapter.

oBrake related settings –see the Brake configuration chapter.

oProp position, positioning PWM –see the chapter Propeller positioning.

oMotor Enabled (0/1) –motor operation can be enabled or disabled based on the logical state

of the specific input “IN B.2”(connector pinout from left to right: 1 = Hall sensor input, 2 =

Motor enable input, 3 = 3.3V, 4 = Ground).

oFreewheeling –enables freewheeling/active braking motor operation.

Protection –ESC and battery protection settings.

oLow battery –behavior when the battery is discharged. Either set to slowly reduce the motor

power, or shut down the motor immediately. The minimum safe voltage is based on number of

cells (cell count) and voltage per cell.

oLimit current –enable this feature to prevent high current peaks and system overload.

oLimit power at 100°C –you can edit the maximum allowed PWM after the controller

temperature exceeds 100°C. The model must be operable, but the temperature must not

increase anymore.

Service –In this menu you can view the device version and reset it to the default factory configuration.

JETIBOX Menu Structure

Available EX telemetry

1. Battery voltage [V]

2. Motor current [A]

3. Capacity [mAh]

4. Speed [RPM]

5. PWM [%]

6. Power [W]

7. Running time [s]

8. Energy [Wmin] –useful feature for

competitions where total energy is

limited (F5B, F5D).

9. Temperature [°C]

10. External temperature [°C] – if the

motor identification chip is

connected, the ESC forwards motor

temperature in its own telemetry.

11. Motor status:

0 = Initial state,

1 = motor running,

2 = braking,

3 = positioning started,

4 = position found.

8

Graupner Hott Menu Structure

The FALCON controller is recognized by default as an “Air-ESC” sensor.

Futaba and Multiplex connection

Futaba and Multiplex systems do not offer wireless device configuration. The telemetry transmission is

possible with the following fixed sensor slots:

Futaba S.Bus2 slot

Note

Multiplex MSB slot

RPM

2

Choose RPM sensor on slot 2.

6

Current

3

Choose SBS01C current sensor on

slot 3.

3

Voltage

4

2

Capacity

5

4

Temperature

6

Choose Temp125 sensor on slot 6.

5

PWM (0-100%)

7

Choose Temp125 sensor on slot 7.

-

Note

Manual detection in the menu Linkage –Sensor.

Automatically detected by

the transmitter.

SAFETY INFORMATION

Operate the FALCON controller always in dry environment and within the device limits stated in this

guide. Never expose the device to excessive heat or cold outside the working area.

Provide sufficient airflow to prevent controller overheating.

Never exceed the maximum allowed operating voltage of the controller/motor.

Do not increase the cable length between the controller and motor. In case you need to lengthen the

wires between the controller and battery to more than 40cm (in total), solder some high capacity low-

ESR capacitors (220-470uF) every 30cm in parallel to the power wires.

Always use high quality connectors in good condition. Replace them if any visible sign of wearing

appears.

Always remove the propeller prior to making any changes in drive setup.

Never disconnect the ESC from the battery while the motor is spinning.

Do not remove the cover and heat sink from the device and do not try to implement any changes or

modifications. This can lead to a total destruction and to the denial of any warranty claims.

Always check the polarity of the connection. Never inverse the polarity –this could lead to total

destruction.

9

FIRMWARE UPDATE

Firmware updates for the FALCON ESC are transferred from a PC via the USB interface. The required programs

and files are available at www.espritmodel.com.

Install the MAV Manager software and the USB drivers on your computer. Check the system requirements.

1) Make sure that the battery flight pack is disconnected and the FALCON ESC is unpowered.

2) Connect the USB interface to your PC, run MAV Manager - Updater and select the correct COM Port.

3) Connect the FALCON ESC according to the picture below –use the red (telemetry) port. The controller

will be automatically detected.

4) Select the correct *.BIN file and press the Update button.

WARRANTY

We grant a warranty of 24 months from the day of purchase under the assumption that they have been

operated in conformity with these instructions at recommended voltages and that they were not damaged

mechanically. Warranty and post warranty service is provided by the manufacturer.

10

This manual suits for next models

2

Table of contents