Euromag FIX+100 User manual

1

Sheet 10010

MAGNETIC TOOLS

PERMANENT LIFTING MAGNETS

APPLICATIONS

TECHNICAL DATA

Lifting and handling of flat and cylindrical

parts

Compact, solid. Safety factor coefficient of 3.

Delivered with test certificate and user manual.

ON/OFF lever locked by security system.

Visual checking of locking system.

REFERENCES

Weight [kg]

Dimensions [mm]

Force [kg]

L

B

H1

H2

B1

F

G

FIX+100

4,2

137

62

66

45

145

31,5

21

100

FIX+300

10,8

199

90

95

65

230

50

38

300

FIX+600

21,2

263

115

107

78

290

58

42

600

FIX+1000

42

303

150

140

88

360

64

50

1000

2

Sheet 10010

MAGNETIC TOOLS

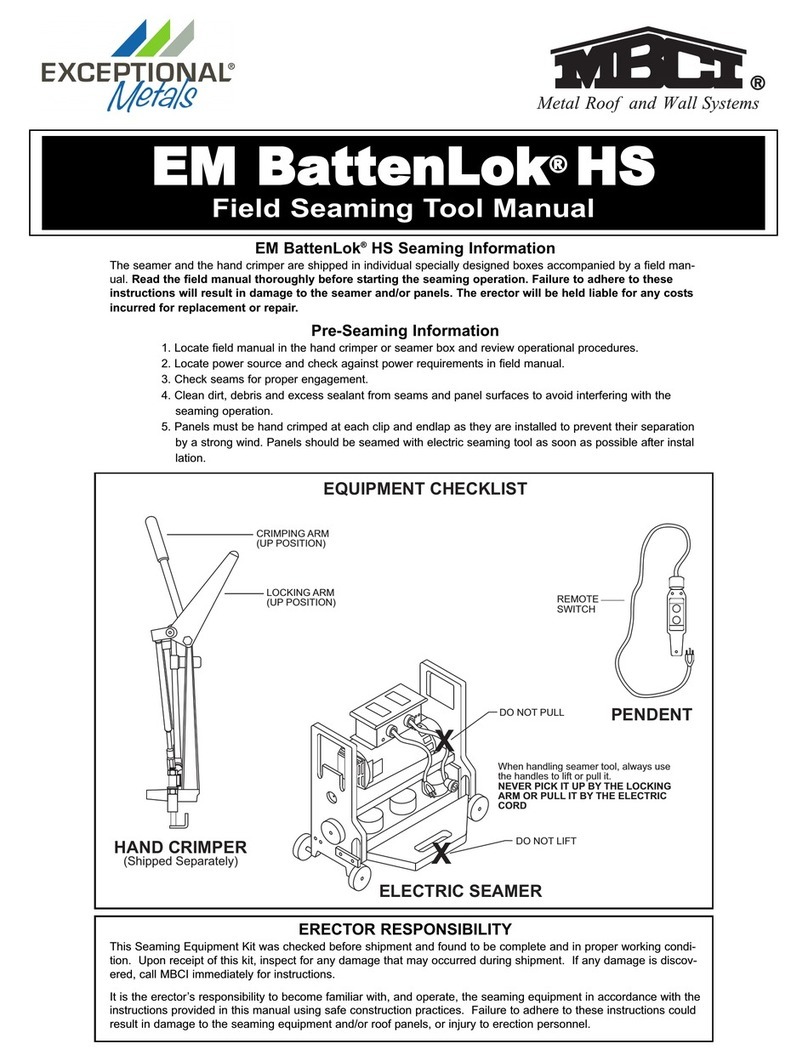

OPERATING AND MAINTENANCE MANUAL FOR FIXES+V2 MODELS

ATTENTION : please read this manual carefully before use

You have just purchased a EUROMAG lifting magnet and we thank you for the confidence you have placed in us.

This manual contains all the information necessary for optimal and safe use. Keep this manual carefully and store

it near the workstation.

Check upon delivery that the lifting magnet is complete and in good condition.

If you notice that the device is damaged and/or incomplete, contact your supplier.

The complete delivery includes:

- Permanent magnet carrier type FIX+V2

- The control lever.

- The user manual with the declaration of conformity including the test report

1. USE AND FEATURES

The permanent magnet carriers of the FIX range are mainly used to hold elements during lifting or handling

operations. They can lift and move flat or cylindrical steel loads and other magnetic materials. They are easy and

safe to use and have a simple and robust design.

2. DESIGN AND SPECIFICATION

2.1 Design :

The FIX+V2 range with permanent magnets has a strong magnetic field created by neodymium magnets. The

start and stop of the magnetic field is controlled by a manual lever. A ring is located on the top of the magnetic

carrier to allow lifting. A V-shaped profile on the base plate holds cylindrical loads.

2.2 Specifications

DETERMINATION OF THE LIFTING FORCE

This lifting force can be reduced by :

1Air gap between the load and the magnet, caused by: surface roughness, paper, paint, damage, presence

of burrs on both the load and the magnet. (see curves on the carrier).

2Low load thickness, which reduces the lifting force (see curves on the carrier).

The curves below are used to calculate the correction to be made (with a combination of the two factors

if necessary).

3Composition of the load to be lifted :

3

Sheet 10010

MAGNETIC TOOLS

The values mentioned in the tables above apply to E24 (S 235 JR) steel. For other materials, the lifting

force decreases according to the following percentages :

4Lenght and width of the load. A very long part will bulge (air gap).

5A reduced contact surface between the polar faces and the load.

6During the transport of the load, the magnet must be perfectly horizontal.

Never exceed the maximum weight and/or dimensions corresponding to the material thicknesses

mentioned in the tables.

Never place the magnet on a large hole or bore in the part.

A load must cover as much as possible all 2 poles (or equally).

HAZARDOUS APPLICATIONS

-Never lift several loads at once.

-Never lift a load by the narrowest side.

-Never put the lifting magnet with its longitudinal side in the longitudinal direction of the load.

3. SAFETY INSTRUCTIONS

Never use this lifting magnet until you have read and understodd this manual.

1Persons wearing a

pacemaker or other

medical device may

only use the magnet

after consulting a

specialist (stay at least

2 metres away for

safety reasons).

2Never remove the warning and/or instruction signs from the device.

3Always use safety glasses, gloves, shoes and safety helmet.

4Never put yourself under the load.

5Never transport the load above or near other people.

6Never use this magnet as a means of anchoring, lifting, supporting or transporting people.

7Warn those present when lifting a load begins.

8Always use a hook with a safety tab.

9Ensure that the weight and dimensions of the load to be lifted do not exceed the CMU.

10 Never use a damaged or malfunctioning magnet.

11 Do not activate the magnet until it is placed on the load.

12 Do not deactivate the magnet until the load is placed on a stable surface.

13 Never lift more than one load at a time.

14 Never leave a suspended load unattended.

15 The temperature of the charge or environment must not exceed 80°C.

Max.

force

on flat

load

Max.

force

on

round

load

Min.

thickne

ss on

flat

load

Min-Max

round load

diameters

Max. load

length

Max. operating

temperature

(daN)

(daN)

(mm)

(mm)

(mm)

℃

FIX 100

100

50

15

25-60

1500

<80

FIX 300

300

150

20

50-100

1500

<80

FIX 600

600

300

30

100-180

2000

<80

FIX 1000

1000

500

40

150-350

2500

<80

Matériaux FIX+ 100 FIX+ 300 FIX+ 600 FIX+ 1000

(%) (kg) (kg) (kg) (kg)

Acier E24-2 (S235 JR) 100 100 300 600 1000

Acier A 50-2 (St 52) 96 96 288 576 960

Acier coulé 90 90 270 540 900

Acier inoxydable 430F 50 50 150 300 500

Fonte 45 45 135 270 450

Nickel 10 10 30 60 100

Acier inoxydable 304 0 0 0 0 0

Force de levage maximale pour différents matériaux

4

Sheet 10010

MAGNETIC TOOLS

16 Do not lift hazardous materials (explosive, radioactive, etc.)

17 Do not lift parts on which moving loads are placed.

18 Do not use in explosive atmospheres.

USE

Before using the lifting magnet, first read the safety instructions.

1 Before each use, check the condition of the magnet. Carefully wipe the magnet poles and the contact

surface of the load. Remove any burrs/irregularities that may be present.

2 Place the magnet on the load and position it so that the load remains horizontal during lifting (determine

the centre of gravity of the load as best you can).

3 Grasp the handle and arm the magnet by rotating the lever by about 135° until the safety device locks it

in the magnetization phase, thus preventing it from being deactivated. Once this has been checked, you can

release the lever.

4 Lift the load a few centimetres and then hit it hard to ensure a good grip. Never put yourself under the

load!

5 Guide the load by holding it by the corners. Avoid knocks, swings and shocks. Never put yourself under

the load and keep the load in a horizontal position!

6Carefully place the load on a stable support. Grasp the lever and unlock the safety device. Deactivate the

magnet by returning the lever to its initial position, at the stop. You can now release the lever.

Never arm or disarm the magnet while it is on a non-magnetic part or in the air.

Attention ! After neutralizing the magnet, a light load can remain stuck to the magnet.

Never release the lever until it is in the final position.

MAINTENANCE AND CONTROL OF THE LIFTING MAGNET

• Before each use :

Visually check the magnet assembly. Thoroughly clean the polar faces of the magnet and remove any alterations

or barbs, if necessary with a file. Do not use the magnet when you notice defects. Check the operation of the

lever and locking system.

• Every week :

Check the assembly for deformation, cracks or other defects. If the lifting eye is deformed or worn by more than

10%, it must be replaced. Check the nameplate for presence and legibility.

Check the condition of the poles. If they are defective, they must be machined by your supplier, and then check

the lifting force.

• Every year :

Have the lifting force of your magnet checked at least once a year by your supplier or an authorised agent.

Never use a damaged or incomplete lifting magnet.

The warranty on FIX+V2 models is 12 months. This warranty does not cover defects caused by:

1- non-observance of the operating and maintenance instructions or abnormal use

2- abnormal wear and tear

3- modification or repairs not carried out by Euromag or an authorised agent

When matching your lifting magnet, always indicate the date on the nameplate.

This manual suits for next models

3

Table of contents