Manual

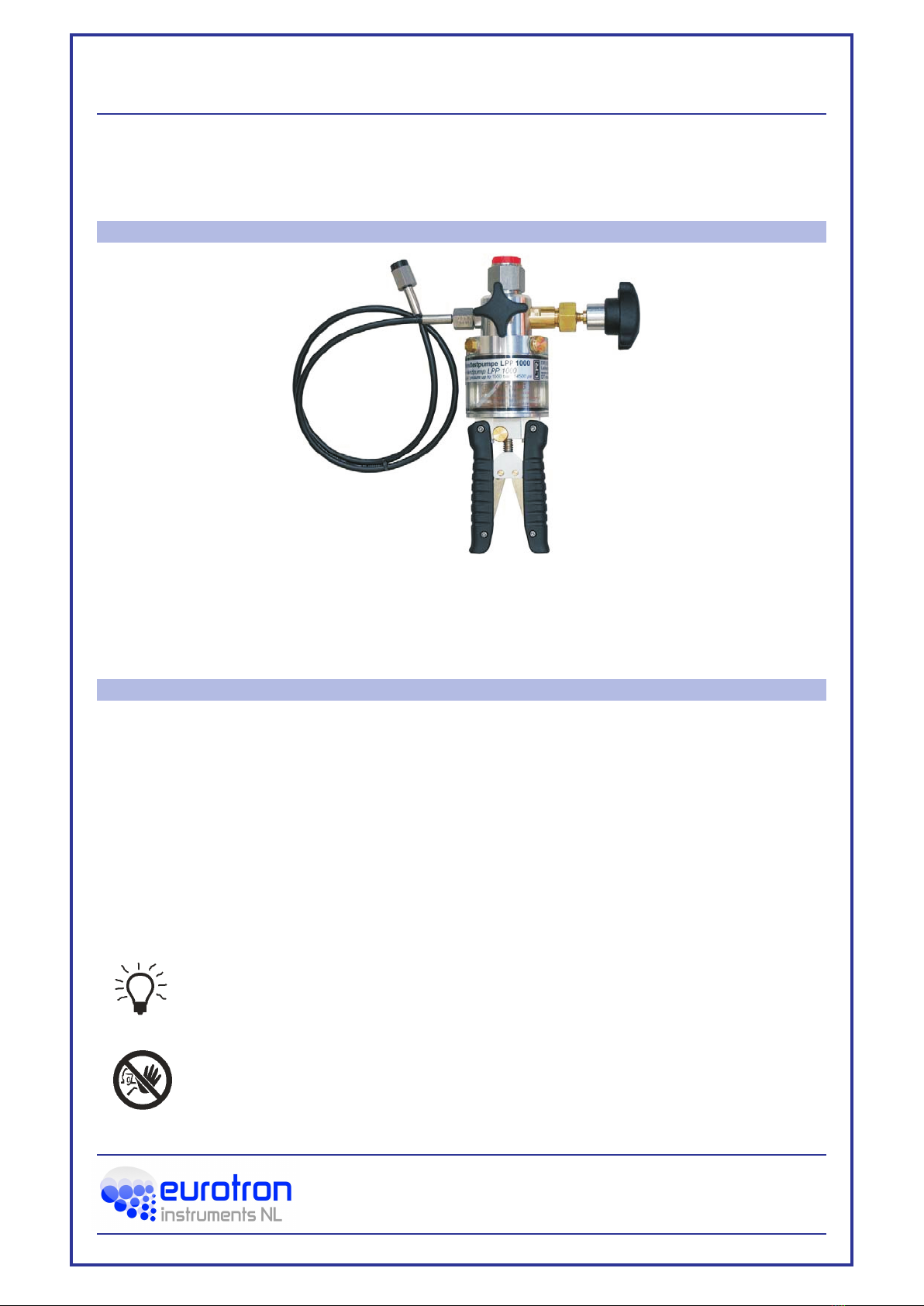

Hydraulic Hand Pump PGS 700 - max. pressure 700 bar

Hydraulic Hand Pump PGS 1000 - max. pressure 1000 bar Page 4

5. Maintenance instructions

Prior to connecting the reference instrument and the test specimen, the sealing gasket in

the two connectors should be checked for correct position and wear, and should be

replaced, if and when necessary.

A service kit (Order-No. PGS700-SK) consisting of spare sealing gaskets and o-rings, is

available as an accessory.

6. Cause of fault

7. Technical Data

8. Order Data / accessories

PGS-700-OEM Pump only, 0/700 bar, c/w 1/2" BSP F rotating Adapter

PGS-1000-OEM Pump only, 0/1000 bar, c/w 1/2" BSP F rotating Adapter

PGS700-TC Transit case

PGS-BSP Set of BSP adapter, 1/4" BSP M to 1/8", 3/8", 1/2" BSPF and 1/2" BSP M

PGS-NPT Set of NPT adapters, 1/4" BSP M to 1/8", 3/8", 1/4", 1/2" NPT F

PGS-A-N14I-G38A 3/8" BSP M to 1/4" NPT F - for reference port

PGS-A-G14I-G38A 3/8" BSP M to 1/4" BSP F - for reference port

PGS-A-N14I-G14A 1/4" BSP M to 1/4" NPT F - for test point

PGS700-A-G14 1/4" BSP M to 1/4" BSP M adapter for pressure hose fitting

PGS700-SK Set of sealing and O’ring for PGS 700 / PGS 1000

HTH-1000-1 High pressure hose (1500 bar), 1 mt - 1/4" BSP F rotating

HTH-1000-2 High pressure hose (1500 bar), 2 mt - 1/4" BSP F rotating

HTH-1000-3 High pressure hose (1500 bar), 3 mt - 1/4" BSP F rotating

NOTE: HTH-1000 include PGS700-A-G14 adapter

Eurotron Instruments Benelux B.V.

Berk 21, 9351 XB Leek, The Netherlands

www.eurotronbenelux.nl info@eurotronbenelux.nl

T +31 (0) 594 69 6131, F + 31 (0) 8422 77692

(Rel. 080806) • All technical modifications reserved. Without engagement

?If the pressure cannot be generated correctly of if the set pressure does not stay

stable, this is likely to be caused by the incorrectly positioned or selected sealing

gaskets. Please also check wether any adapters used on the test specimen have been

tightened sufficiently to eliminate leaks.

?Before assuming there is a leak in the calibration test pump: First of all, check if the

relief valve (2) is closed.

?If the test pump has not been used for a longer period of time, the first lift may be

somewhat sluggish. This effect will disappear again during further operation.

?By no means apply any force to the operating elements of the calibration test pump.

?Never connect an external pressure supply system to the PGS 700 or PGS 1000

calibration test pump.

Pressure : PGS 700: 10 000 psi / 700 bar

PGS 1000 : 14 500 psi / 1000 bar

Medium : mineral oil based hydraulic fluid or clean water, free of

calcium-carbonate /scale (no distilled water!)

Pressure Port : 3/8" BSP F for reference port c/w 1/2" BSP F adapter

Test Point 1/4" BSP F

Fine adjustment : Fine adjustment valve / volume control

Material : Anodized aluminum, brass, plastic and Stainless steel

Dimension : 280 x 170 x 120 mm (no test hose)

Eurotron Instruments Benelux B.V.

9351 VL Leek, The Netherlands

www.eurotronbenelux.nl info@eurotronbenelux.nl

T +31 (0) 594 696131, F + 31 (0) 594 820224

(Rel. 080806) • All technical modifications reserved. Without engagement

Vossenkamp 7a,