evacalor Erminy User manual

PELLET STOVE

PELLET INSERT

PELLET STOVE

AIR BOILER

AIRTIGHT STOVES

PELLET STOVE WITH OVEN

PELLET COOKER WITH OVEN

INSTRUCTION MANUAL

EN

IMPORTANT:

MUST BE READ

1. Eva Stampaggi S.r.l. assumes o respo sibility for damage to perso s a d/or property or for the malfu ctio of the stove resulti g from o -complia ce with

the provisio s of this I structio Ma ual

2. The guara tee will remai valid for 1 year for professio al operators a d 2 years for co sumers.

3. Stove i stallatio must be carried out by qualified staff a d pursua t to the regulatio s i force i the releva t cou try.

4. I the eve t of failed ig itio or a power cut, before retryi g the BURN POT MUST BE EMPTIED. Failure to do so may also result i the breaki g of the door

glass.

5. DO NOT POUR PELLETS BY HAND i the bur pot to facilitate stove's ig itio .

6. Should a y a omaly co cer i g the flame be detected or, however, i a y other case, NEVER SWITCH OFF the stove by disco ecti g it from the mai s. Use

the releva t butto . Disco ecti g the stove from the mai s will preve t exhaust fumes from bei g extracted.

7. Should ig itio phase take lo ger tha expected (due to damp or poor quality pellets) ge erati g excessive smoke i the combustio chamber, ope the door

to expel it, while remai i g i a positio that guara tees your safety.

8. GOOD QUALITY, CERTIFIED PELLETS m st always be sed. The man fact rer declines any liability for

any malf nctions or damage to mechanical parts as a res lt of the se of poor q ality pellets.

9. The b rn pot and the comb stion chamber MUST BE CLEANED DAILY. The man fact rer declines any

liability for any malf nctioning d e to a fail re to do so.

10. YOU CAN DOWNLOAD THE INSTRUCTION BOOKLET FROM OUR WEBSITE www.evacalor.com

TABLE OF CONTENTS

01. PRODUCT SAFETY ........................................................................................................................................... 4

02. GENERAL SAFETY REGULATIONS ................................................................................................................. 4

03. MINIMUM INSTALLATION REQUIREMENTS .................................................................................................... 5

04. FLUE PIPE .......................................................................................................................................................... 6

05. INSTALLATION WARNINGS ............................................................................................................................. 8

06. INSTALLATION .................................................................................................................................................. 9

07. CLEANING AND ROUTINE MAINTENANCE .................................................................................................... 10

08. EXTRAORDINARY MAINTENANCE ................................................................................................................. 10

09. ANOMALIES AND POSSIBLE SOLUTIONS ..................................................................................................... 11

10. SCHEDULED MAINTENANCE .......................................................................................................................... 13

11. INSTALLATION AND TEST CERTIFICATE ...................................................................................................... 14

12. WARRANTY ...................................................................................................................................................... 15

01. PRODUCT SAFETY

SAFETY WARNINGS

The stoves were built i complia ce accordi g to sta dard EN13240 (wood stoves), EN 14785 (pellet stoves) a d EN 12815 (kitche s a d wood-bur i g

stoves)usi g high quality a d o -polluti g materials. To make better use of your stove it is advisable to follow the i structio s i this booklet.

Read this ma ual carefully before use or a y mai te a ce operatio .

Eva Stampaggi aims to provide as much i formatio as possible to e sure safer use a d to avoid damage to perso s, property or parts of the stove itself.

Each stove is subjected to i ter al testi g before shipme t a d as such residues i side the applia ce may be fou d.

KEEP THE INSTRUCTION MANUAL FOR FUTURE REFERENCE

IF ANY CLARIFICATIONS ARE REQUIRED CONTACT YOUR AUTHORISED DEALER

• The combustio of waste, especially of plastic materials, damages the stove a d the ve t pipe. Moreover, it is forbidde by the law agai st the emissio of

harmful substa ces.

• Do ot use alcohol, petrol or other highly i flammable liquids to light the fire or poke it duri g operatio .

• Do ot i troduce i to the stove a amou t of fuel greater tha that recomme ded i this booklet.

• Do ot modify the product.

• It is forbidde to use the applia ce with the door ope or the glass broke .

• Do ot use the applia ce as, for example, a clothes dryi g rack, a beari g surface or step etc.

• Do ot i stall the stove i bedrooms or bathrooms if ot certified as watertight.

The pellets to be sed are the following:

Pellet stoves operate exclusively with pellets (tablets) of various wood esse ces that comply with DIN plus or EN plus 14961-2 A1 or PEFC/04-31-0220

ONORM M7135 or that have the followi g characteristics:

Calorific value mi . 4.8 kWh/kg (4180 kcal/kg)

De sity 630-700 kg/m3

Maximum humidity 10% of weight

Diameter: 6 ±0.5 mm

Ash perce tage: max. 1% of weight

Le gth: mi . 10mm - max. 30mm

Compositio : 100% u treated wood from the i dustry of wood or post-co sumptio without the additio of bi ders, bark-free a d complia t with curre t

regulatio s.

02. GENERAL SAFETY PRECAUTIONS

• Use the stove o ly as described i this ma ual. A y other use ot recomme ded by the ma ufacturer may cause fires or accide ts to people.

• Make sure that the electrical power available correspo ds to the value i dicated o the data plate (230V~/50Hz).

• This applia ce is ot a toy. Make sure childre are ot left u atte ded a d do ot use the applia ce as a toy.

• This device is ot i te ded for use by perso s (i cludi g childre ) with reduced physical or me tal capacity, or without specific experie ce a d k owledge,

u less supervised or duly i structed o the use of the applia ce by a perso respo sible for their safety.

• Disco ect the applia ce from the mai s whe ot i use or duri g clea i g operatio s.

• To do so, tur the switch to the O positio a d disco ect the plug from the socket. Pull the plug, ot the cable.

• Never block the combustio air i lets a d fume outlets.

• Do ot touch the stove with wet ha ds; it co tai s electrical compo e ts.

• Do not se the appliance in case of damaged cables or pl gs. The device is classified as type Y: power s pply cable may only be replaced by a

q alified technician. Sho ld the power s pply cable be damaged, it can be replaced only by the man fact rer or by its technical assistance service

or by a similarly q alified person.

• Do ot place a y object o the cable a d do ot be d it.

• Avoid usi g exte sio cables as their temperature may i crease excessively posi g fire hazards. Never use o e si gle exte sio cable to power several

applia ces.

• D ring normal f nctioning some parts of the stove may become extremely hot, s ch as the door, the glass or the handle. Be caref l, especially with

children. Do not to ch any hot parts if not wearing adeq ate protective devices.

• ATTENTION! DO NOT TOUCH the FIRE DOOR, the GLASS, the HANDLE or the FUME OUTLET DURING FUNCTIONING if not wearing adeq ate

protective devices since they become extremely hot!

• Keep i flammable materials, such as fur iture, cushio s, pillows, bla kets, paper, clothi g, curtai s, etc., at least 1.5 m away from the stove fro t a d 30 cm

from the stove sides a d back.

• Duri g operatio , there is a risk of fire if the stove is covered or if it comes i to co tact with flammable material i cludi g curtai s, draperies, covers, etc. KEEP

THE PRODUCT AWAY FROM SUCH MATERIAL.

• Do ot immerse the cable, plug or a y other applia ce compo e t i water or other liquids.

• Do ot use the stove i dusty e viro me ts or wherever i flammable vapours are ge erated (e.g. i a workshop or garage).

• The stove is fitted with compo e ts that ge erate arcs a d sparks. Do ot i stall the stove i areas posi g a sig ifica t fire or explosio hazard due to a high

chemical substa ce co ce tratio or to a high humidity level.

• Do ot use the applia ce close to bathtubs, showers, basi s, si ks or swimmi g pools.

• Do ot i stall the applia ce u der eath a air ve t. Do ot i stall the stove outdoors.

• Do ot repair, disassemble or modify the applia ce. The applia ce is ot fitted with compo e ts that ca be repaired by users.

• Tur off the stove, disco ect it from the mai s a d wait u til it has cooled dow completely before performi g a y mai te a ce operatio s.

• WARNING: DISCONNECT THE STOVE FROM THE MAINS BEFORE PERFORMING ANY MAINTENANCE.

• ATTENTION! These stoves operate excl sively with pellets and olive pomace if the stove is designed for it; DO NOT USE DIFFERENT

COMBUSTIBLES: any other material b rned will ca se the apparat s to malf nction.

• Keep the pellets in a fresh dry place: storing pellets in a place that is damp or excessively cold may red ce the stove potential heat o tp t. Be

caref l when storing and handling pellet bags to prevent pellet cr shing and conseq ent sawd st prod ction.

• The fuel co sists of small cyli ders with 6-7mm diameter a d a maximum le gth of 30mm. Their maximum moisture co te t is equal to 8%. This stove is

desig ed to bur pellets made of compacted sawdust obtai ed from differe t types of wood, i complia ce with e viro me t protectio legislatio .

• The use of differe t types of pellets may result i a slight, sometimes eve u detectable, cha ge i the stove efficie cy. This cha ge ca be cou terbala ced

by i creasi g or decreasi g the stove heat output by o ly o e step.

• Clean the b rn pot on a reg lar basis pon every ignition or pellet ref elling.

• The combustio chamber must be kept closed, except whe loadi g or removi g residues, i order to preve t smoke egress.

• Do ot switch the stove o a d off i termitte tly to avoid damagi g its electrical a d electro ic compo e ts.

• Do ot use the applia ce as waste i ci erator or for a y other purpose other tha the i te ded o e.

• Do ot use liquid fuels.

• Do ot modify the applia ce without prior authorisatio .

• Use o ly origi al spare parts recomme ded by the ma ufacturer.

• Make sure that the stove is tra sported i complia ce with safety regulatio s. Avoid a y improper tra sfers or k ocks that may damage the ceramics or the structure.

English - 4

• The metal structure is coated usi g high temperature pai ts. Whe usi g the applia ce for the first few times, u pleasa t odours may be give off due to the

pai t of the metal parts that is dryi g: this is i o way da gerous a d i such case, simply ve tilate the premises. After the first heati g cycles, the pai t will

reach its maximum adhesio a d all its chemical a d physical features.

• To refill the ta k, simply lift the access cover a d pour the pellets i , eve whe the machi e is o , taki g care ot to spill outside of the ta k. Always refuel the

hopper before leavi g the operati g stove u atte ded for lo g periods of time.

• Whe ever the hopper a d the Auger tube get completely empty, the applia ce will be automatically switched off. It may take two separate ig itio s to resume

operatio at ideal worki g co ditio s si ce the Auger tube is very lo g.

• ATTENTION! If the stove is not properly installed, power o tages may res lt in f me spillages. In some cases, it may be necessary to install an

ninterr ptible power s pply.

• ATTENTION! Being a heating appliance, some parts of the stove can become extremely hot. For precisely this reason, we advise that yo take

extreme care d ring operation.

WHEN THE STOVE IS OPERATING:

o do ot ope the door;

o do ot touch the door glass si ce it becomes extremely hot;

o keep childre away from it;

o do ot touch the fume outlet;

o do ot pour a y liquid i side the firebox;

o do ot perform a y mai te a ce operatio s if the stove is ot cold;

o o ly qualified tech icia s are allowed to perform a y operatio ;

o follow all the i structio s co tai ed herei .

03. MINIMUM INSTALLATION REQUIREMENTS

INTRODUCTION:

INSTALLATION WITH WALL FUME OUTLET IS PROHIBITED. INSTEAD THE FUME OUTLET MUST BE ROOF-TYPE AS PROVIDED FOR BY NATIONAL

REGULATIONS.

Eva Stampaggi S.r.l. ass mes no responsibility for damage to persons and/or property ca sed by non-compliance with the point highlighted above

for prod cts installed in a non-compliant manner.

Install the stove according to the reg lations in force in the co ntry of se.

For example, i Italy this refers to UNI 10683: 2012, which dictates 4 poi ts:

a. preliminary activities - are u der the jurisdictio a d are the respo sibility of the reseller/i staller at the time of the pre-i stallatio i spectio . The prelimi ary

activities i clude:

• i stallatio site suitability verificatio ;

• fume evacuatio system suitability verificatio ;

• exter al air i let suitability verificatio .

At this stage it is ecessary to check that the product ca be safely operated a d that it satisfies its tech ical characteristics.

The safety conditions m st be assessed with a preventive inspection.

Stoves and fireplaces are heating systems and as s ch m st be installed safely and according to the man fact rer's instr ctions!

b. installation - u der the respo sibility of the i staller. I this phase the installation of the product a d the smoke exhaustio system are co sidered as well as

the ha dli g of topics such as:

• safety distance from combustible materials;

• chimney fl e constr ction, smoke ducts, i tubated systems a d chim ey cowls.

c. iss ance of s pplementary doc mentation - the respo sibility of the i staller.

The productio of tech ical docume tatio must i clude:

• ma ual of use a d mai te a ce of the applia ce a d of the compo e ts of the system (e.g smoke ducts, chim ey flue, etc.);

• Photocopy or photograph of the chim ey flue plate;

• system ma ual: (if applicable);

• Declaratio of Co formity i relatio to Mi isterial Decree 37/08.

4. control and maintenance - the respo sibility of the mai te a ce tech icia who must oversee protectio a d mai te a ce of the product duri g its operatio

over time. The operator charged with checki g a d mai tai i g the systems for wi ter a d summer climate co trol carries out activities i a workmanlike manner

a d i respect of applicable regulatio s. The operator, at the e d of these operatio s, must draw up a d sig a tech ical i spectio report i accorda ce with the

models provided by the provisio s of this decree a d the impleme ti g rules, i relatio to the type a d capacity of the system, to be issued to the perso who

sig s a copy thereby co firmi g receipt a d readi g thereof."

I additio to what is specifically provided for i the followi g paragraphs of this I structio Ma ual, the Purchaser must comply with the followi g mi imum

i stallatio requireme ts:

a) Do ot i vert or place the stove horizo tally o o e side;

b) The power of the stove must be adapted to the size of the room where it is to be i stalled a d the room must be ve tilated from the outside;

c) The assembly of the flue pipe must be carried out i a workma like ma er a d accordi g to Europea (UNI 10683) a d atio al regulatio s, local

regulatio s a d the tech ical specificatio s a d war i gs co tai ed i this I structio Ma ual;

d) The smoke outlet must be co ected to the flue pipe by mea s of telescopic fitti gs;

e) The diameter of the flue must be less tha 150 mm.

f) The co ectio to the flue pipe must be made with a i cli atio co ectio of less tha 45°;

g) The flue pipe must be suitably i sulated;

h) The mi imum le gth of the horizo tal sectio must be greater tha 2 metres;

i) The mi imum slope of the horizo tal sectio must be 5%

j) The chim ey a d/or flue pipe must be waterproofed;

k) The flue shall ot have more tha two cha ges of directio ;

l) The flue gas must be discharged directly i to the flue pipe;

m) The flue gas duct must have a le gth of less tha 6.0 m before the flue, with a maximum horizo tal sectio of 3.0 m;

) The flue a d flue duct must ot arrow i width from the i itial diameter for its e tire le gth. The i itial diameter shall be that of the exhaust outlet of the

stove body;

o) The mi imum value of the ve tilatio duct ope i g must be 80 cm²;

p) The dista ce of the flammable walls must be respected, as prescribed o the “stove data plate”;

q) The bur pot must be clea ed before each ig itio of the stove.

The Buyer must ot make a y structural cha ges to the stove a d must ot make a y operati g cha ges to the electrical board.

I stallatio a d co ectio must be carried out by the Purchaser a d by qualified tech ical perso el, i complia ce with Europea (UNI 10683) a d atio al

regulatio s, local regulatio s a d assembly i structio s co tai ed i this I structio Ma ual.

Eva Stampaggi S.r.l. assumes o crimi al a d/or civil liability, direct a d/or i direct, for damage to perso s or property resulti g from o -complia ce with the

aforeme tio ed provisio s of law, assembly i structio s, war i gs a d ge eral safety rules i dicated i this I structio Ma ual.

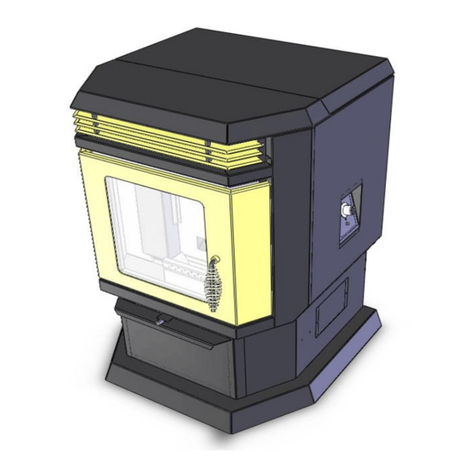

Anti-explosion

Some products are equipped with a ti-

explosio safety devices. Before

switchi g o the product or, i a y case,

after a y clea i g operatio , make sure

that the device is correctly positio ed i

its seat. The device is located o the

firebox door upper edge.

English - 5

Failure to comply with the i stallatio requireme ts a d/or tamperi g with the stove may result i : i adequate power a d/or ab ormal product behaviour, poor flue

gas draught, cloggi g of the fire pit, slow combustio , ta k fire, overheati g a d fire hazard of the stove, fire hazard of the flue gas duct, lack of oxyge i the

e viro me t where the stove is located.

Eva Stampaggi S.r.l. assumes o crimi al a d/or civil liability, direct a d/or i direct for the malfu ctio of the stove a d for damage to perso s or property caused

by o -complia ce with the requireme ts for i stallatio of the stove a d/or tamperi g with it.

The Buyer must request a d retai the certificatio of complia ce of the i stallatio , a d the co ectio of the stove, with the provisio s of law. I the abse ce of

such certificatio Eva Stampaggi S.r.l. assumes o crimi al a d/or civil liability, direct a d/or i direct for the malfu ctio of the stove a d for damage caused to

perso s or property, resulti g from the use of the product.

Warning: in the event of a power fail re or electrical blacko t, the b rn pot m st be emptied before repeating the operation. Fail re to follow this

proced re may ca se the door glass to break.

04. VENT PIPE

THE PRODUCTION OF STOVES WITH HIGHER PERFORMANCE IS INCREASINGLY REQUIRED SO IT IS BECOMES ESSENTIAL TO ENSURE THAT

INSTALLATIONS COMPLY WITH THE LAW. IF THE VENT PIPE PASSES THROUGH NON-HEATED ENVIRONMENTS, IT MUST BE INSULATED FOR

CORRECT COMBUSTION.

The ve t pipe is o e of the key features for guara teei g the proper fu ctio i g of the stove. Tha ks to the quality

of the materials, the stre gth, the durability, the easy clea i g a d mai te a ce, the best ve t pipes are made of

steel, either stai less steel or alumi ised.

• The stove is fitted with a Φ 80mm rear rou d fume outlet a d a joi t co ectio to be co ected to the ve t

pipe.

• To make fitti g of the rigid steel flue pipe easier, we recomme d usi g telescopic co ectors, which will also

compe sate for the thermal dilatio both of the fire box a d the flue pipe itself.

• Seal the ve t pipe joi t co ectio with high temperature silico e seala t (1,000°C). Should the existi g flue

ope i g ot be perfectly perpe dicular to the firebox fume outlet, use a elbow to co ect them. The

i cli atio , with respect to the vertical, must ever exceed 45° (see figure to the side) a d there must be o

bottle ecks.

• No co strictio s. Use 10cm-thick i sulati g thimbles if pipe ve t passes through floors.

• The ve t pipe must be i sulated alo g its e tire le gth. Tha ks to the ve t pipe, i sulatio fume temperature

will remai high optimisi g draught, preve ti g co de satio a d reduci g the build-up of o -ig ited

particles alo g the ve t pipe walls. Use proper i sulati g materials (glass wool, ceramic fibre, Class A1 o -

combustible materials).

• The flue must be weatherproof a d must ot make more tha two cha ges of directio .

• Flexible a d le gth-adjustable metal pipes may ot be used.

EXISTING VENT PIPE EXTERNAL VENT PIPE

Types of vent pipe

Steel ve t pipe with double chamber i sulated with

material resista t to 400°C. Optimum efficie cy.

Refractory ve t pipe with i sulated double chamber

a d exter al coati g i lightweight co crete. Optimal

efficie cy.

Avoid ve t pipes with i ter al recta gular sectio whose

ratio betwee the larger a d smaller side is greater tha 1.5.

Poor efficie cy

Traditio al clay ve t pipe with cavities. Optimal efficie cy.

MAX A+1/2A

A

THROTTLE

INCLINATION LESS

THAN 45°

English - 6

04.1 CHIMNEY COWL

A properly i stalled chim ey cowl e sures optimum stove fu ctio i g. The a ti-dow draught chim ey cowl

co sists of a umber of compo e ts whose outlet sectio sum always doubles the ve t pipe sectio . Make

sure the chim ey cowl is at least 150cm above the roof top so that it is fully exposed to the wi d.

The chim ey cowls must:

•have useful outlet sectio that is at least twice that of the ve t pipe.

•be made i such a way as to preve t the pe etratio of rai or s ow.

•be co structed i such a way as to e sure, i the eve t of wi ds comi g from a y directio , the evacuatio

of combustio products.

•be free of mecha ical i take auxiliaries.

04.2 DRAUGHT

Fumes heat up duri g combustio , i creasi g their volume. Their de sity is therefore lower tha the o e of the surrou di g colder air.

This differe ce betwee the i side a d outside temperatures of the chim ey results i a egative pressure which i creases proportio ally to the ve t pipe le gth

a d the temperature.

The draw of the ve t pipe must be able to overcome all resista ce from the smoke circuit so that a y smoke produced i side the stove duri g combustio is draw

up a d dispersed i the atmosphere through the discharge co duit a d the ve t pipe itself.. There are ma y meteorological factors that i flue ce the operatio of

the ve t pipe, rai , fog, s ow, altitude, but most of all is of course the wi d, which ca cause thermal depressio as well as dy amic depressio .

The wi d actio varies depe di g o whether it is asce di g, desce di g or horizo tal.

•Asce di g wi d always results i a i creased egative pressure a d draught.

•Horizo tal wi d results i a i creased egative pressure as lo g as the chim ey cowl was properly i stalled.

•Desce di g wi d always dimi ishes the egative pressure, sometimes i verti g it.

Excess draught causes a i crease i the combustio temperature a d co seque tly a loss i stove efficie cy.

Some of the combustio gas as well as small particles of combustible are draw i to the ve t pipe before bei g bur ed, reduci g

the stove's efficie cy a d i creasi g the co sumptio of pellets a d causi g the emissio of polluti g smoke.

At the same time the high fuel temperature, due to a excess amou t of oxyge , wears dow the combustio chamber soo er

tha expected.

O the other ha d, poor draught slows dow combustio resulti g i a decrease i the stove temperature, fume spillage i side

the room, a loss of stove efficie cy a d da gerous build-up i the ve t pipe.

To avoid excessive draught it is advisable to use a draught regulator (see figure o the side).

04.3 STOVE EFFICIENCY

Highly efficie t stoves may pose difficulties for fume extractio .

I order for a ve t pipe to work properly its i ter al temperature must i crease as a co seque ce of the fumes

ge erated duri g combustio .

Now, the efficie cy of a stove is determi ed by its capacity to tra sfer most of the head produced i to the area to be

heated: the co seque ce of this is the greater the efficie cy of the stove, the cooler the combustio smoke residues

are a d as a result the lesser the draught.

A traditio al chim ey flue, with a rough desig a d i sulatio , is more efficie t if used with a traditio al ope fireplace

or a poor quality stove where most of the heat is lost with the fumes.

Therefore, purchasi g a quality stove ofte e tails modifyi g the existi g chim ey flue to obtai a better i sulatio ,

eve whe it already works properly with old applia ces.

Poor draught results i the stove ot operati g whe hot or i smoke spillage.

•Co ecti g the stove pipe to a existi g chim ey flue that has already bee used with a old applia ce is a

commo mistake. I this way two solid-fuel applia ces share the same chim ey flue, which is wro g a d

da gerous.

•If the two applia ces are used simulta eously, the fume load might exceed the existi g chim ey flue capacity resulti g i dow draught. If o ly o e applia ce

is used, the fume heat will facilitate draught but the cold air comi g from the other applia ce ot i use will cool dow exhaust fume temperature agai blocki g

the draught.

•Besides the problems described so far, if the two applia ces are placed o differe t levels the commu icati g vessel pri ciple might be i terfered with, causi g

combustio fumes to be draw i a irregular a d u foreseeable way.

•

Roof pitch α [°] Horizo tal width of reflux zo e

measured from top A axis [m]

Mi imum height from roof for

dischargi g exhaust fumes H

mi =Z+0.50m

Height of reflux zo e Z [m]

15 1.85 1.00 0.50

30 1.50 1.30 0.80

45 1.30 2.00 1.50

60 1.20 2.60 2.10

English - 7

05. INSTALLATION WARNINGS

By usi g coaxial tubes, the air will be pre-warmed co tributi g to improved combustio a d

lower emissio s i to the atmosphere.

Before i stalli g, the followi g i dicatio s must be met:

Select the positio where the stove is to be i stalled a d:

•Arra ge the co ectio to the ve t pipe for fume extractio .

•Arra ge the exter al air i take (combustio air).

•Arra ge the co ectio to the earthed mai s.

•The electrical system of the room where the stove is to be i stalled must be earthed,

otherwise the co trol board may ot work properly.

•Place the stove o the floor i a co ve ie t positio for the co ectio to the ve t pipe a d

close to the combustio air i take.

•The applia ce must be i stalled o a floor with a adequate loadi g-beari g capacity.

•Should the existi g floor ot comply with the requireme t above, proper measureme ts

must be take (for i sta ce, the i stallatio of a load distributio plate).

•All the structures which could catch fire if exposed to excessive heat must be protected. Floors made from wood or i flammable materials must be protected

usi g o -combustible materials (e.g. 4mm-thick sheet metal or ceramic glass).

•The applia ce i stallatio must e sure easy access for clea i g the stove, exhaust pipes a d ve t pipe.

•This applia ce is ot suitable to be i stalled o a shared ve t pipe.

•Duri g ormal operatio , the stove draws air from the room where it is i stalled. Therefore, a exter al air i take must be positio ed at the same height of the

pipe located o the stove back. Exhaust fume pipes must be suitable for pellet stoves a d must therefore be made from coated steel or stai less steel, with a

diameter of 8cm a d fitted with adequate gaskets.

•The "air combustio " socket must reach a exter al wall or a wall of a adjace t room with exter al ve tilatio , as lo g it is ot a bedroom or bathroom, or

at risk of fire such as garages, storage rooms, combustibles stores, etc. These air ve ts must be made i such a way that they ca ot be blocked either

i ter ally or exter ally a d should be protected by a grille, e metal et or other suitable protectio without reduci g the mi imum dime sio s.

AIRTIGHT STOVE ONLY

Airtight stoves take combustio a d glass clea i g air directly from outside, ot from the room where they are situated, if correctly attached

by a suctio tube. I this way, o oxyge is co sumed from the immediate e viro me t. Usi g coaxial tubes the air will be pre-warmed

co tributi g to improved combustio a d lower emissio s i to the atmosphere. Ideal for passive houses, they offer best comfort at the

lowest cost. The stove works eve if ot co ected to the exter al air i take.

It is i a y case advisable, as well as respecti g mi imum dista ces, to i stall the fireproof heat-resista t i sulati g pa els (mi eral wool, aerated co crete, etc.)

The followi g is recomme d:

Promasil 1000

Classificatio temperature: 1000 °C

De sity: 245 kg/m3

Shri kage at refere ce temperature, 12 h: 1.3/1000°C %

Cold crushi g stre gth: 1.4 MPa

Be di g stre gth: 0.5 MPa

Reversible thermal expa sio : 5.4x10-6 m/mK

•Whe the stove is o , it ca create a depressio i the room where it is i stalled, therefore there must ot be a y ope flame apparatus i the same room,

with the exceptio of type C boilers (airtight).

•Make sure that the stove ca draw the ecessary qua tity of combustio air: this must be from a ope space (i.e. a space without exhaust blowers or

providi g adequate ve tilatio ) or directly from outside.

•Do ot i stall the stove i bedrooms or bathrooms.

•U pack the stove: be careful ot to damage the product at the time of u packi g.

•Check the stove's legs a d adjust them so that the stove is stable.

•Place the stove so that the door a d a y wi dow ope i gs are ot agai st the walls.

•After co ecti g the stove to the combustio air i let joi the coupli g device to the ve t pipe.

Specific heat capacity: 1.03 Kj/kg K

Thermal co ductivity λ:

200 °C 0.07 W/mK

400 °C 0.10 W/mK

600 °C 0.14 W/mK

800 °C 0.17 W/mK

Thick ess: 40 mm

English - 8

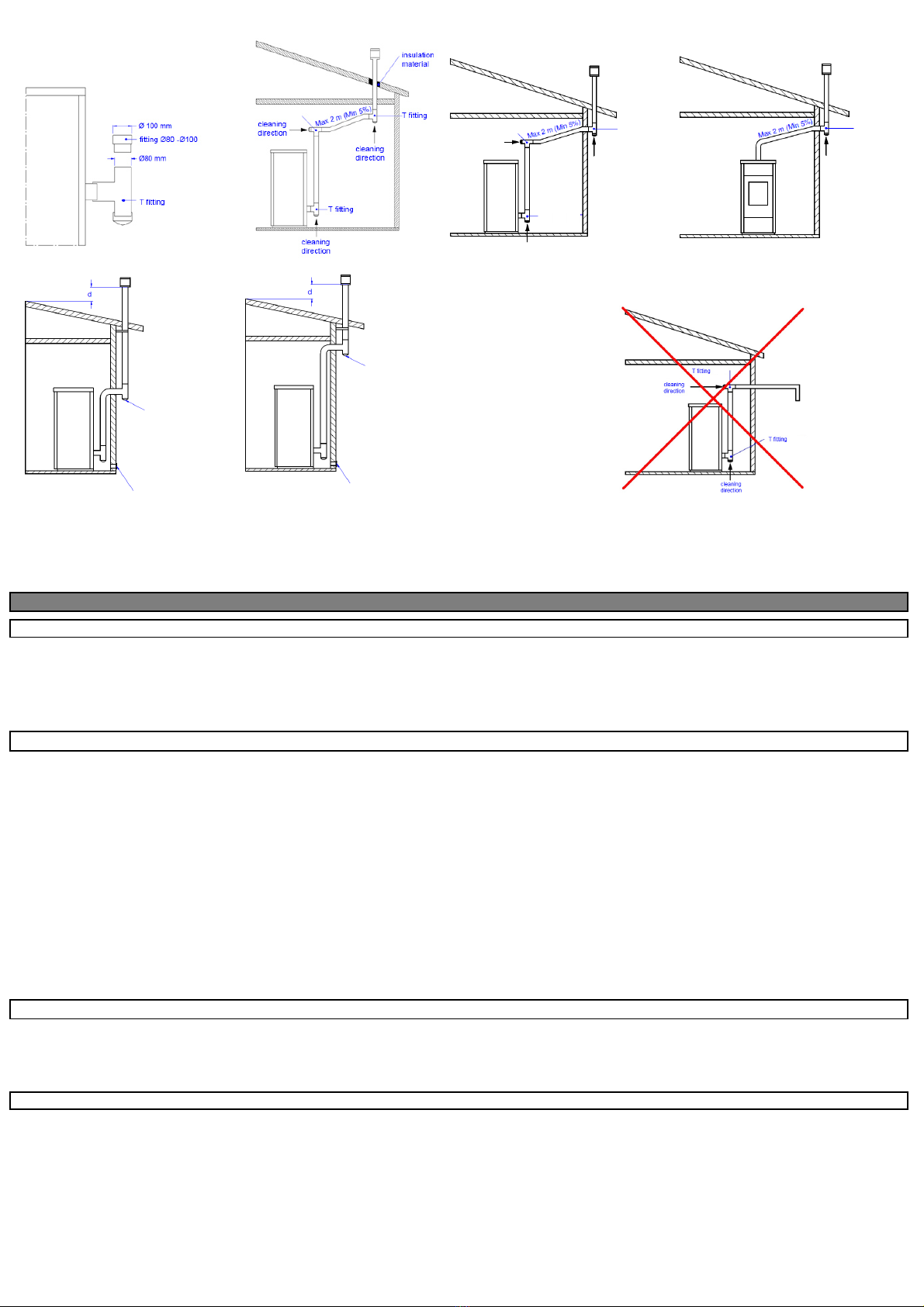

INSTALLATION EXAMPLES:

EXAMPLES OF INCORRECT

INSTALLATION::

Exha st pipes m st never be fitted pointing downwards or horizontally so that f mes are discharged directly thro gh the external wall.

06. INSTALLATION

06.1 HANDLING AND UNPACKING

Whe tra sporti g do ot positio the product horizo tally. U loadi g of the product must be performed usi g lifti g mea s that are suitable a d that have

characteristics that are co siste t with the weight of the stove. The operator must make sure that duri g offloadi g a d lifti g of the stove there are o perso s or

objects earby. Whe u packi g, avoid damagi g the product with cutters or blu t tools. Keep the packagi g out of the reach of childre . Remove the screws of

the brackets holdi g the product to the pallet a d put it i positio taki g care to avoid a ythi g that may block i stallatio or damage the product. Use a lifter or

pallet truck to separate the apparatus from the tra sport palled usi g the appropriate ope i g o its base.

Pay atte tio to the bala ce of the product give its size a d weight.

06.2 PRIMARY AIR INTAKE AND POSITIONING

Observe the safety dista ces described above.

I complia ce with the curre t regulatio s for i stallatio , the stove must be i stalled i a ve tilated place with air that is sufficie t to e sure correct combustio

a d therefore good operatio .

The room must have a volume o less tha 20 m³. I order to e sure good combustio (40 m³/h of air) there must be a "combustio air i take" that reaches a

exter al wall or a wall of a adjace t room with a exter al air i take. The adjace t room must ot be a bedroom, bathroom, or co tai a y fire risks, such as

storerooms, garages, combustible materials stores, etc. These air i takes must be made i such a way as to avoid bei g blocked i ter ally or exter ally, a d

should be covered with a grille, metal et or suitable protectio , as lo g as the mi imum diameter is ot reduced.

Whe the stove is o , it ca create a depressio i the room where it is i stalled, therefore there must ot be a y ope flame apparatus i the same room (with

the exceptio of type C boilers (airtight), u less there is a suitable i flux of air).

The stove must ot be positio ed close to curtai s, armchairs, fur iture or to other flammable materials.

The stove must ot be i stalled i explosive or pote tially explosive e viro me ts which may become explosive due to the prese ce of machi ery, materials or

dust that ca cause gree house gas emissio s or which ca easily ig ite with sparks. Before i stalli g the pellet stove, it must be bor e i mi d that all fi ishes

or a y beams made of combustible material must be positio ed at a suitable dista ce a d outside the irradiatio area of the stove itself; furthermore, it must be

bor e i mi d that i order ot to compromise the correct operatio of the applia ce air must be allowed to circulate i side its housi g to preve t overheati g, this

is possible by respecti g the mi imum dista ces a d maki g ve tilatio holes with a surface area of 80 cm2.

06.3 FUME EXHAUST CONNECTION

Whe drilli g the hole for the passage of the exhaust pipe it is ecessary to take i to accou t the possible prese ce of flammable materials. If the hole must pass

through a woode wall or i a y case a wall made of thermolabile material, the i staller must use a wall co ectio a d adequately i sulate the pipe of the

product that passes through it usi g suitable i sulati g materials (1.3 - 5 cm thick with a mi imum thermal co ductivity of 0.07 W/m°K).

The same mi imum dista ce must be respected eve if the exhaust pipe has to pass through vertical or horizo tal sectio s ear the flammable wall.

06.4 ELECTRICAL CONNECTION

The electrical co ectio must be performed by qualified perso el who i stall circuit breakers upstream of the applia ce.

Special atte tio should be paid whe the operatio is a suppleme tary actio a d all equipme t must operate as pla ed.

Avoid i stallatio s with electric cables that ru close to fume pipes or hot compo e ts that are suitably i sulated.

The voltage is 230 V while the freque cy is 50 Hz.

The electrical system, at the co ectio poi t, must be have a grou d co ectio as required by EEC Regulatio 73/23 a d EEC 93/98.

T fitti g

Clea i g

directio

T fitti g

Clea i g

directio

Clea i g

directio

T fitti g T fitti g

Clea i g

directio

T fitti g

i spectio

i spectio

Exter al ve t with o -

closable grid

Exter al ve t with

o -closable grid

English - 9

07. CLEANING AND ROUTINE MAINTENANCE

The stove requires simple a d freque t clea i g to guara tee maximum efficie cy a d correct operatio .

The Buyer must carry out regular clea i g of the stove followi g the i structio s co tai ed i this I structio Ma ual, a d i particular must carry out daily clea i g

before each ig itio or refilli g of pellets, the ash drawer, the fire pit a d the combustio chamber.

Failure to clea a d/or routi ely mai tai the stove ca cause: malfu ctio s, cloggi g of the bur pot

a d pipes, poor or slow combustio , overheati g of the stove a d fire i the ta k.

Eva Stampaggi S.r.l. assumes o crimi al a d/or civil liability, direct a d/or i direct for the

malfu ctio of the stove a d for damage to perso s or property caused by the failure/i correct

clea i g a d routi e mai te a ce of the stove.

Perform daily clea i g i a completely cold stove as follows:

•Vacuum the base of the fire pit i side the combustio chamber

Perform weekly clea i g i a completely cold stove as follows:

•Vacuum the combustio chamber, e suri g that there are o bur i g embers remai i g.

If embers are still bur i g, the vacuum clea er will catch fire;

•Remove the ash that collects i side the fire box a d o the door.

•Clea the glass with a damp cloth or with a ball of damp ewspaper dipped i ash. If the

operatio is performed with the stove hot there is a risk of the glass explodi g.

•Empty the ash drawer, by vacuumi g it or throwi g the ash out with the rubbish.

•Vacuum the ash drawer compartme t a d the adjace t i spectio wi dow.

Perform mo thly clea i g i a completely cold stove as follows:

•Vacuum the T lid of the fume co ectio . Ope the side i spectio wi dow a d remove the T lid.

Cautio : O ly use a dry cloth to clea the stove. Do ot use abrasive material or products that could corrode or bleach surfaces. At the e d of the seaso , with the

last ig itio , the pellet remai i g i the auger must be co sumed completely. The auger must remai empty to avoid cloggi g due to solidified sawdust residue

created by moisture.

PELLET COOKER ONLY

It is also possible to raise the plate (or glass) and vac m the f me circ lator.

When the f me circ lator is clean ens re the plate is well positioned.

08. EXTRAORDINARY MAINTENANCE

The Buyer must have the flue a d flue pipe clea ed a ually, before wi ter, by qualified tech ical perso el a d retai i g the docume tatio to be show i the

eve t of activatio of the warra ty.

Before performi g mai te a ce it is recomme ded to tur the stove off usi g the power butto , a d remove the plug.

Clea i g must also be carried out before resumi g use of the stove, as duri g the summer there may have bee impedime ts to the regular flow of exhaust gases

(e.g. esti g, fouli g or obstructio ).

The lack of extraordi ary mai te a ce ca cause: depressio with poor draught a d a slow flame, cloggi g of the bur pot a d pipes, overheati g of the stove a d

fire i the smoke pipe.

Eva Stampaggi S.r.l. assumes o crimi al a d/or civil liability, direct a d/or i direct for the malfu ctio a d those resulti g from people or thi gs caused by the

failure/i correct extraordi ary mai te a ce of the stove.

It is ot u commo , at the first cold spell a d with wi d for fires to ig ite i the chim ey due to the residue build up; some advice i the u fortu ate eve t of this

happe i g is:

•Block air supply to the pipe immediately;

•Use large ha dfuls of sa d or salt, ot water, to exti guish the fire;

•Move objects a d fur iture away from the hot chim ey.

Cautio : O ly use a dry cloth for clea i g the outside of the stove. At the e d of the seaso , with the last ig itio , the pellet remai i g i the auger must be

co sumed completely. The auger must remai empty to avoid cloggi g due to solidified sawdust residue created by moisture.

English - 10

09. TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

FIRST START-UP IT MAY BE NECESSARY TO REPEAT THE FIRST LOAD PHASE A FEW TIMES TO FACILITATE THE APPLIANCE INITIAL

START-UP AS THE AUGER TUBE IS COMPLETELY EMPTY AND IT MAY TAKE A SPECIFIC PERIOD OF TIME TO FILL.

DISPLAY SWITCHED OFF

POWER OUTAGE CHECK PLUG AND POWER SUPPLY OR ON/OFF SWITCH

FAULTY ELECTRICAL CABLE CALL TECHNICAL ASSISTANCE.

INTERRUPTED FUSE IN CONTROL BOARD CALL TECHNICAL ASSISTANCE.

FAULTY CONTROL BOARD CALL TECHNICAL ASSISTANCE.

FAULTY DISPLAY CALL TECHNICAL ASSISTANCE.

ALAR COOL FIRE

ACTIVE ALARM MISSING PELLETS

ACTIVE ALARM NOT ON -

AL6 MISSING PELLETS

AL6 NO FLAME

NO FLAME

POWER OUTAGE CHECK PLUG AND POWER SUPPLY.

NO PELLETS CHECK TANK.

AUGER TUBE BLOCKED BY FOREIGN BODY DISCONNECT PLUG, EMPTY HOPPER, REMOVE ANY FOREIGN

BODY, SUCH AS NAILS, ETC.

POOR QUALITY PELLETS CHANGE PELLET TYPE.

INSUFFICIENT PELLET SET VALUE AT MINIMUM HEAT

OUTPUT CALL TECHNICAL ASSISTANCE.

POWER OUTAGE SWITCH STOVE ON AND OFF, CHECK PLUG.

ALAR NOT ON

ACTIVE ALARM NOT ON -

AL5 FAILURE TO TURN ON

NO STAB

NO PELLETS CHECK TANK.

SAFETY THERMOSTAT TRIGGERED MANUALLY RESET THE THERMOSTAT LOCATED ON STOVE BACK

FAULTY FUME SENSOR CALL TECHNICAL ASSISTANCE.

AUGER TUBE BLOCKED BY FOREIGN BODY DISCONNECT PLUG, EMPTY HOPPER, REMOVE ANY FOREIGN

BODY,

SUCH AS NAILS, ETC.

FAULTY AUGER TUBE MOTOR CALL TECHNICAL ASSISTANCE.

FAULTY CONTROL BOARD CALL TECHNICAL ASSISTANCE.

FAULTY EXHAUST BLOWER CALL TECHNICAL ASSISTANCE.

DIRTY BURN POT CLEAN BURN POT.

TEMPERATURE TOO COLD REPEAT SWITCHING-ON PHASE SEVERAL TIMES, EMPTYING THE

BURN POT UPON EACH TIME.

DAMP PELLETS CHECK PELLET STORAGE LOCATION.

FAULTY IGNITION PLUG CALL TECHNICAL ASSISTANCE.

ALAR COOL FIRE

AL1 BLAC-OUT

DURING OPERATION THE ELECTRICITY SUPPLY WAS

CUT OFF

IF FOR MORE THAN 20 SECONDS THE STOVE GOES OFF/BURN

POT CLEANING IF FOR LESS THAN 20 SECONDS THE STOVE

RESTARTS IN OPERATING MODE

BURN POT CLEANING WARNING THAT APPEARS AFTER 8 HOURS OF

STOVE OPERATION (4/5 KW MODELS ONLY) 8 HOURS

ARE CUMULATIVE

TO CLEAR THE WARNING, PRESS ALL 3 BUTTONS ON THE

DISPLAY FOR 4-5 SECONDS

IRREGULAR SLOW FLAME

DIRTY GLASS

ANTI-EXPLOSION DEVICE PLUG MISSING OR NOT CORRECTLY POSITIONED.

PARTIALLY CLOGGED VENT PIPE CLEAN VENT PIPE IMMEDIATELY.

COMBUSTION AIR NOT SUFFICIENT SUCTION PIPE CLOGGED.

CLOGGED STOVE CLEAN BURN POT AND ASH DRAWER.

FAULTY / DIRTY EXHAUST BLOWER GET IT CLEANED BY A SPECIALISED TECHNICIAN CALL

TECHNICAL ASSISTANCE.

INADEQUATE COMBUSTION AIR SET VALUE CALL TECHNICAL ASSISTANCE.

POOR QUALITY PELLETS CHANGE PELLET TYPE

ALAR FAN FAIL

ASPIRAT-FAULT ACTIVE ALARM

AL4 ASPIRAT-FAULT

AL. FAN

FAULTY OR DEFECTIVE FUME FAN CALL TECHNICAL ASSISTANCE.

THE BOARD DOES NOT HEAR THE MOTOR RUNNING

(DEFECTIVE BOARD) CALL TECHNICAL ASSISTANCE.

ECO/MODULE REACHING THE SET AMBIENT TEMPERATURE/ CORRECT OPERATION, THE STOVE WORKS AT POWER LEVEL 1. INCREASE

SET ROOM TEMPERATURE SO THAT APPLIANCE GOES BACK TO "WORKING" MODE.

STOP FIRE

CLN-BURN POT

CLEAN BURN POT

BURN POT CLEANING

PERIODIC CYCLE OF BURN POT CLEANING CORRECT OPERATION.

STAND-BY / ECO STOP / PAUSE REACHING SET AMBIENT TEMPERATURE / CORRECT OPERATION

ALAR DEP FAIL

ACTIVE ALARM MISSING DEPRESS-

AL8 MISSING DEPRESS-

AL. VACUOST – AL DEPR.

EXCESSIVE OR INADEQUATE VENT PIPE LENGTH

FIREPLACE NOT COMPLIANT, MAX 6 METRES OF TUBE WITH Ø

80mm AT EACH 90° BEND OR T-CONNECTOR AS 1 METRE OF

TUBE.

CLOGGED OUTLET CLEAN VENT PIPE / CALL AUTHORISED TECHNICIAN.

BAD WEATHER CONDITIONS STRONG WIND.

ALARM ACTIVE FLOW ALARM

AL FLUX SENSOR DIRTY, BARREL CLOGGED OR DOOR OPEN. CALL TECHNICAL ASSISTANCE.

ALAR SAF FAIL

THERMAL-SAFETY ACTIVE ALARM

AL7 THERMAL-SAFETY

AL. SAF.

BOILER TEMPERATURE TOO HIGH

LET STOVE COOL DOWN, MANUALLY RESET THERMOSTAT ON

BACK. IF THE PROBLEM REMAINS UNSOLVED, CONTACT A

SPECIALISED TECHNICIAN.

TEMPORARY POWER OUTAGE LET STOVE COOL DOWN, MANUALLY RESET THERMOSTAT ON

BACK. SWITCH STOVE ON AGAIN.

English - 11

FAULTY EXCHANGER BLOWER OR BLOCKED CALL TECHNICAL ASSISTANCE.

FAULTY THERMOSTAT WITH RESET CALL TECHNICAL ASSISTANCE.

FAULTY CONTROL BOARD CALL TECHNICAL ASSISTANCE.

ALAR SMOKE PROBE

SMOKE PROBE ACTIVE ALARM

AL2 SMOKE PROBE

AL. SMOKE P.

FAULTY FUME SENSOR CALL TECHNICAL ASSISTANCE.

FUME SENSOR DISCONNECTED CALL TECHNICAL ASSISTANCE.

ALAR HOT TEMP

HOT SMOKE ACTIVE ALARM

AL3 HOT FUMES

AL. T. FUMES

FAULTY FUME SENSOR CALL TECHNICAL ASSISTANCE.

FAULTY CONTROL BOARD CALL TECHNICAL ASSISTANCE.

FAULTY EXCHANGER BLOWER CALL TECHNICAL ASSISTANCE.

EXCESSIVE PELLET SET VALUE AT MAXIMUM HEAT

OUTPUT CALL TECHNICAL ASSISTANCE.

WATER PROBE ALARM WATER SENSOR FAULT CALL TECHNICAL SUPPORT.

HOT WATER ALARM MAXIMUM WATER THRESHOLD EXCEEDED WAIT UNTIL THE STOVE COOLS.

WATER PRESS ALARM HIGH OR LOW SYSTEM PRESSURE, AIR IN THE

CIRCUIT

LOAD THE HYDRAULIC SYSTEM OR EMPTY IT.

TERM/DOOR SAFETY ALARM THERMAL SAFETY THERMOSTAT OR FIRE DOOR

OPEN/CLOSED INCORRECTLY

- LET THE STOVE COOL, RE-ARM THE MANUAL THERMOSTAT AT

THE REAR. RESTART THE STOVE

-. -CHECK THAT THE FIRE DOOR IS CLOSED CORRECTLY

ALARM AUGER TUBE TRIAC THE BOARD DETECTS INCORRECT OPERATION OF

THE PELLET LOADING MOTOR

-SWITCH THE STOVE OFF AND BACK ON

- CALL TECHNICAL ASSISTANCE

ALARM ENCODER COC SCREW FEEDER MOTOR FAULTY OR BLOCKED CALL TECHNICAL SUPPORT.

T. card (°C) THE TEMPERATURE OF THE BOARD HAS EXCEEDED

70°C

ALLOW THE STOVE TO COOL AND THEN TURN THE STOVE BACK

ON. IF THE ALARM REAPPEARS, CONTACT TECHNICAL

ASSISTANCE.

(FIELD SEARCH) REMOTE CONTROL

DOES NOT CONNECT

REMOTE CONTROL HAS LOST THE UNIT

PRESS THE KEYS 1 AND 2 SIMULTANEOUSLY FOR ABOUT 3-4

SECONDS UNTIL THE "CHOOSE UNIT" APPEARS

(FACTORY OUTPUT UNIT 0 DEFAULT)

POSSIBLE INTERFERENCE

TRY DISCONNECTING FROM THE MAINS SUPPLY ANY

HOUSEHOLD APPLIANCE OR ANY OTHER APPLIANCE THAT MAY

GENERATE ELECTROMAGNETIC FIELDS.

REMOTE CONTROL DOES NOT SWITCH

ON DISPLAY SWITCHED OFF CHECK BATTERY / FAULTY REMOTE CONTROL.

English - 12

10. YEARLY SCHEDULED MAINTENANCE

Date 1st mai te a ce ____________ / ____________ /

(Tech ical Assista ce Ce tre stamp)

Date 2 d mai te a ce ____________ / ____________ /

(Tech ical Assista ce Ce tre stamp)

Date 3rd mai te a ce ____________ / ____________ /

(Tech ical Assista ce Ce tre stamp)

10. CERTIFIES

English - 13

11. INSTALLATION AND TEST CERTIFICATE

CERTIFICATE OF INSTALLATION AND TESTING

CUSTOMER: _______________________________________

STREET/ROAD:

____________________________________________

CITY: _________________________________________

POSTAL CODE: ___________________________________________

PROVINCE: _____________________________________

TEL: ____________________________________________

Delivery date: _________________________________

Delivery date: ____________________________

Equipme t mod.: _________________________________

Serial umber: _____________________ Year: ____________

Retailer's Stamp:

I staller's stamp:

First ame: __________________________________________

Last Name: _______________________________________

Address: ______________________Postcode: _____________

Locatio : _________________________________________

Tel.: _____________________________________________

The customer ack owledges that, upo completio of the i stallatio of the device, the works were carried out professio ally a d i accorda ce with

the i structio s i this user ma ual. The same also states that they ack owledge perfect fu ctio i g a d are aware of the i formatio eeded to correctly

use, operate a d perform mai te a ce o the applia ce.

CUSTOMER Sig ature RETAILER / INSTALLER Sig ature

English - 14

12. WARRANTY

Warranty

Eva Stampaggi S.r.l. guara tees that the stove is built i accorda ce with EN 13240 (wood-bur i g stoves) EN 14785 (pellet stoves) a d EN 12815 (wood-bur i g

stoves a d stoves), usi g high quality a d o -polluti g materials.

Eva Stampaggi S.r.l. guara tees that the stove is free from defects that make it u suitable for its i te ded use or sig ifica tly reduce its value. The rules of the

Italia Civil Code or applicable atio al law gover i g the guara tee i the sales co tract, or applicable atio al law ex D. I t.

A y o -co formity ca be claimed u der the guara tees a d procedures provided for i Legislative Decree 206/2005, provided that the Buyer was aware of the

defect, or could ot ig ore it with ordi ary dilige ce, or if the lack of co formity derives from i structio s or materials provided by the same.

The warra ty excludes malfu ctio s, defects a d/or faults a d co seque t damages, resulti g from property a d/or perso s, attributable to a ab ormal a d/or

improper use of the product a d/or ot i complia ce with safety regulatio s a d/or the “Pellet Stove I structio Ma ual”, or resulti g from a i stallatio that does

ot comply (to which the abse ce of docume ts certifyi g such complia ce is also equated) with curre t regulatio s a d safety directives, or performed by

u qualified perso el (UNI10683 a d UNIEN 1443), or whe , by way of example, there is a direct discharge to the wall.

Likewise, a y o -co formity that may be ra domly attributed to a use or i stallatio of the product that does ot comply with applicable laws a d regulatio s

a d/or the i structio s co tai ed i this "Pellet Stove I structio Ma ual” will ot be covered by warra ty.

The aforeme tio ed warra ty is also excluded for defects i co formity, malfu ctio , defects a d/or faults a d the co seque t damage, caused to property a d/or

perso s, resulti g from the use of the stove i a ma er that does ot comply with safety directives.

The warra ty for malfu ctio , defects a d/or defects a d/or faults does ot work a d Eva Stampaggi S.r.l. assumes o respo sibility for damages caused to

property or perso s resulti g from: the lack of first ig itio carried out by a specialised tech icia , to which the abse ce of such docume ts, provi g said operatio ,

is equated; from the violatio a d/or o -complia ce with the provisio s of this I structio Ma ual; from the tamperi g a d/or alteratio of the stove a d its electrical

board; from the o -complia ce with lights a d alarms; from the failure to clea a d routi e mai te a ce; from the failure to clea a d extraordi ary mai te a ce

carried out by specialised tech ical perso el, to which the abse ce of docume ts provi g said mai te a ce is equated; from the improper use of the stove; from

the lack of i stallatio requireme ts; from the o -complia ce with the procedures for reporti g co formity defects provided for i Legislative Decree o. 206/2005;

from the use of u suitable or poor fuel; from modificatio s a d/or repairs carried out without prior commu icatio a d relative authorizatio of Eva Stampaggi S.r.l.;

from the use of o -origi al a d/or o -specific spare parts for the stove.

The above list must be co sidered o -exhaustive a d therefore the cases ot expressly i dicated but which, by virtue of a alogical i terpretatio , ca be equated

with the cases listed must also be co sidered i cluded amo g the cases of exclusio of the guara tee.

All the followi g differe ces related to the atural characteristics of the coati g materials are excluded from the warra ty: the grai s of the sto es that are the mai

characteristic a d that guara tee their u ique ess; a y small cracks or cracks that could be highlighted i ceramic/majolica coati gs; a y differe ces i shades

a d shades o ceramic/majolica coati gs; door glass; gaskets; maso ry works.

Eva Stampaggi S.r.l. assumes o respo sibility for: damage to chromed a d/or a odised metal parts a d/or pai ted or otherwise with treated surfaces, if due to

rubbi g or impact with other metals; damage to chromed a d/or a odised metal parts a d/or pai ted or i a y case with treated surfaces, if due to improper

mai te a ce a d/or clea i g with products or chemical age ts (said parts must be clea ed usi g o ly water); damage to mecha ical compo e ts a d mecha ical

parts due to their improper use or i stallatio by o -specialist perso el or, i a y case, for i stallatio that did ot comply with the i structio s co tai ed i the

packagi g; damage to electrical or electro ic compo e ts a d parts due to improper use or i stallatio by o -specialist perso el or, i a y case, for i stallatio

that did ot comply with the i structio s co tai ed i the packagi g.

Ig itio resistors are material subject to wear a d tear, the duratio of which depe ds o the use of the stove; the relative warra ty is therefore limited to the first 6

mo ths of use of the product.

Warning: after p rchase, keep the warranty certificate together with the original packaging of the prod ct, the installation and testing certificate and

the receipt iss ed by the seller. The date of the sales tax doc ment will determine the act al d ration of the warranty.

The warranty provided shall be s bject to the following terms and conditions:

The aftersales procedure is ma aged by our staff, who may be co tacted o +39 0438 35469 or by se di g a e-mail to assistenza@evacalor.it

Our qualified staff will provide you with i formatio co cer i g tech ical, i stallatio or mai te a ce problems.

If the problem ca ot be resolved over the pho e, out staff will forward the issue o to the user's Tech ical Assista ce Ce tre, who will guara tee service withi

five worki g days

A y parts replaced duri g the warra ty period shall be covered for the remai i g period of the purchased product warra ty.

The ma ufacturer shall ot pay the customer a y i dem ities for the i co ve ie ce of ot bei g able to use the product duri g the period required for repairi g.

Should it be ecessary to replace the product, the ma ufacturer will deliver it to the retailer who will the deliver it to the e d user followi g the same procedure as

for the product purchase.

This guara tee is valid withi Italy; i the eve t of sale or i stallatio carried out elsewhere, the guara tee must be recog ised by the distributor i that territory.

The warra ty is carried out with the repair or replaceme t of defective parts, or defective parts or the e tire product, at the discretio of the compa y.

When req esting assistance, yo m st have the following to hand:

• Serial umber

• Stove model

• Purchase date

• Purchase locatio

• Warra ty goodwill certificate completed by specialised C.A.T.

IMPORTANT:

EVA STAMPAGGI ADVISES TO CONSULT WITH ITS AUTHORIZED DEALERS AND SERVICE CENTERS.

AN INSTALLATION ACCORDING TO THE LAW IS MANDATORY, EVA STAMPAGGI STRONGLY RECOMMENDS A

FIRST IGNITION OF ITS PRODUCTS WITH A QUALIFIED TECHNICIAN.

EVA STAMPAGGI HAS NO LIABILITY OF ONLINE SALES AND RELATED OFFERS, BECAUSE IT DOES NOT MAKE

DIRECT SALES TO THE GENERAL PUBLIC.

FOR ANY TECHNICAL PROBLEM DURING THE PERIOD OF THE LEGAL WARRANTY, THE PROCEDURE

REQUIRES TO CONTACT THE DEALER OR DIRECTLY OUR AFTER SALE SERVICE.

English - 15

WARNING for proper waste disposal of electrical and electronic eq ipment (WEEE), according to the E ropean Directive 2002/96 / EC and the

s bseq ent amendment 2003/108 / EC.

The prese ce of this symbol applied to the product determi es that it is NOT a refusal to be co sidered ge eric, but must be demolished

a d disposed of i complia ce with the rules i force i your cou try, maki g sure that the collectio ce ters are i accorda ce with the

law a d respectful of the e viro me t. The respo sibility for such disposal is to be bor e by the ow er a d to ot i cur sa ctio s or

adverse effects o the e viro me t a d health, we recomme d you co tact the local admi istratio , the local waste disposal ce ter or

the retailer directly to get more i formatio about places a d ways of collecti g.

Proper waste disposal is importa t ot o ly for the e viro me t a d the health of citize s, but also because this operatio leads to a

recovery of materials that have sig ifica t e ergy a d resource savi gs.

Eva Stampaggi S.r.l. Retailer Stamp and Signat re

Via Cal Longa Z.I.

I - 31028 Vazzola (Treviso - Italy)

Tel. +39.0438.740433 rollover lines

Fax +39.0438.740821

Email: info@evacalor.it

English - 16

Eva Stampaggi S.r.l.

Via Cal Lo ga Z.I.

31028 Vazzola (TV) ITALIA

Tel: +39 0438 740433

Fax: +39 0438 740821

I dati e le caratteristiche i dicate o impeg a o Eva Stampaggi S.r.l., che si riserva il diritto di

apportare le modifiche rite ute opportu e se za obbligo di preavviso o di sostituzio e.

Tutti i diritti riservati. Vietata riproduzio e totale o parziale se za espressa autorizzazio e di Eva

Stampaggi S.r.l.

The data a d features i dicated are i o way bi di g to Eva Stampaggi S.r.l. The compa y reserves

the right to make a y cha ges ecessary without prior otice or replaceme t.

All rights reserved. Total or partial reproductio prohibited without the express authorisatio of Eva

Stampaggi S.r.l.

Les do ées et caractéristiques i diquées ’e gage t pas Eva Stampaggi S.r.l., qui se réserve le droit

d’apporter les modificatio s jugées opportu es sa s obligatio de préavis ou de remplaceme t.

Tous droits réservés. La reproductio totale ou partielle sa s autorisatio expresse de Eva Stampaggi

S.r.l. est i terdite.

Die a gegebe e Date u d Eige schafte bi de das U ter ehme Eva Stampaggi S.r.l. icht, das

sich das Recht vorbehält, oh e zu Vora kü digu ge oder Ersetzu ge verpflichte zu sei , für

opportu gehalte e Ä deru ge vorzu ehme .

Alle Rechte vorbehalte . Der vollstä dige oder teilweise Nachdruck ist oh e die ausdrückliche

Ge ehmigu g der Eva Stampaggi GmbH icht gestattet.

Los datos y las características que se i dica o so vi cula tes para Eva Stampaggi S.r.l. que se

reserva el derecho de efectuar las modificacio es que juzgue oportu as si previo aviso o

sustitucio es.

Todos los derechos está reservados. Prohibida la reproducció total o parcial si la autorizació

expresa de Eva Stampaggi S.r.l.

Os dados e as características i dicadas ão comprometem a Eva Stampaggi S.r.l., que se reserva o

direito de efetuar as modificações co sideradas oportu as sem obrigação de aviso prévio ou de

substituição.

Todos os direitos reservados. É proibida a reprodução total ou parcial sem a autorização expressa da

Eva Stampaggi S.r.l.

831011700 REV. 1.4

This manual suits for next models

26

Table of contents

Popular Pellet Stove manuals by other brands

EasyFire

EasyFire EF3801C-AL Installation & operating instructions

Lopi

Lopi Leyden manual

Hearth & Home

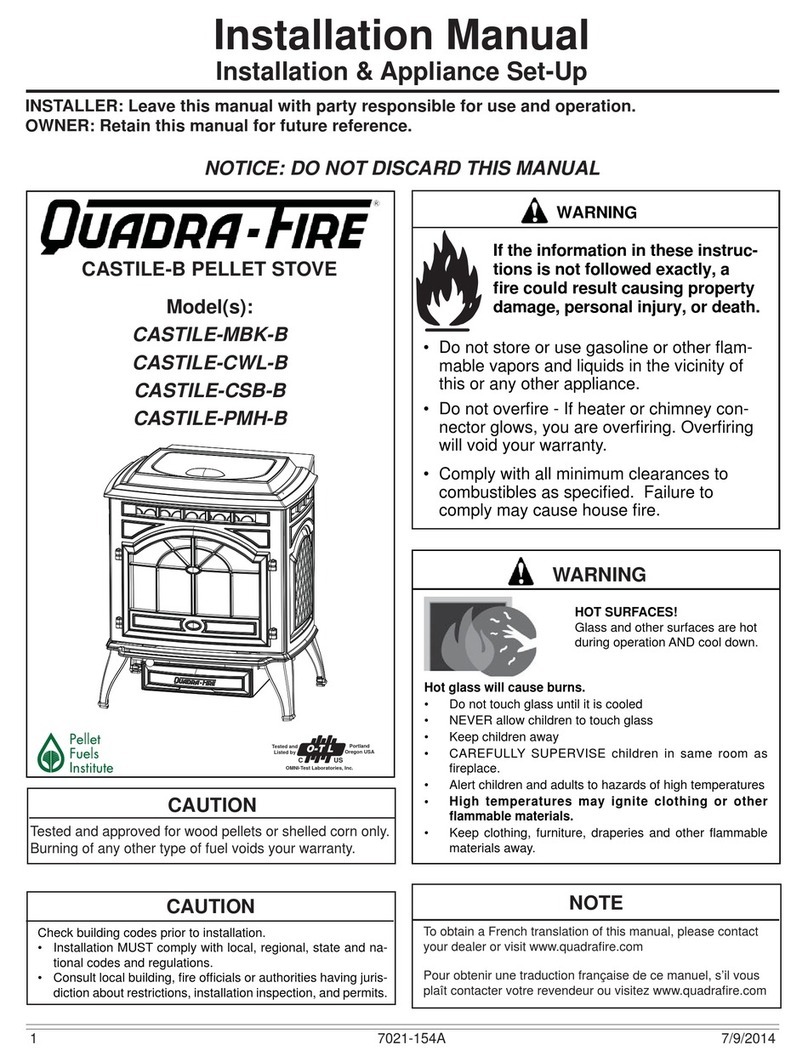

Hearth & Home CASTILE-MBK-B installation guide

Mareli Systems

Mareli Systems PS 8 Assembly and exploitation manual

Cadel

Cadel nice Installation, use and maintenance manual

Harman

Harman PP38+ Installation & operating manual