MATCH LIGHT FIRE AND START-UP

1. Filling the Hopper and Start-Up:

CAUTION: FUEL HOPPER LID MUST BE CLOSED

BEFORE OPERATING UNIT. MAINTAIN HOPPER SEAL

IN GOOD CONDITION. DO NOT OVERFILL HOPPER!

THE EASYFIRE WILL HOLD ABOUT 60 LBS. OF

PELLETS.

Open the top lid and fill the hopper with pellets (Figure 11).

Make sure hopper lid is fully closed. Open the front

door and fill the burn pot with a hand full of pellets.

IMPORTANT: The air-wash and burn tray must be

seated flush and must sit even in the tray. Air leaking

around the burn tray will create a poor burn (Figure 14).

Light the pellets in burn tray using any approved pellet fuel

starter.

Allow pellets to burn for approximately 1 minute, or

until pellet ignition has been achieved. Close door and

turn the control knob to the "FAN" position. Allow fire to

burn for several minutes. When the pellets are well lit, turn

the control knob to "LOW" for approximately 10 minutes

then turn up to "HI". We recommend that you run the

heater on “Medium” or "HI" for about 30 minutes in order to

get the heat exchanger hot before turning it to "LOW". You

will need to burn the heater for a few hours before deciding

which setting is best for your particular needs.

NOTE: CAUTION MUST BE TAKEN WHEN INSTALLING

BURN POT OR OPERATING DOOR NOT TO DAMAGE

CERAMIC GLASS. DO NOT ATTEMPT TO OPERATE

HEATER IF GLASS BECOMES DAMAGED IN ANY

WAY!

CAUTION: BOTH THE MAIN DOOR AND THE ASH

DRAWER MUST BE PROPERLY ADJUSTED AND

FULLY CLOSED TO FORM AN AIR-TIGHT SEAL FOR

PROPER STOVE OPERATION. FAILURE TO SECURE

DOOR AND DRAWER MAY CAUSE OVER FEEDING

AND HIGH TEMPERATURE SHUT DOWNS.

DO NOT USE GRATES OR OTHER METHODS OF

SUPPORTING FUEL IN BURN POT OR INTERIOR OF

STOVE.

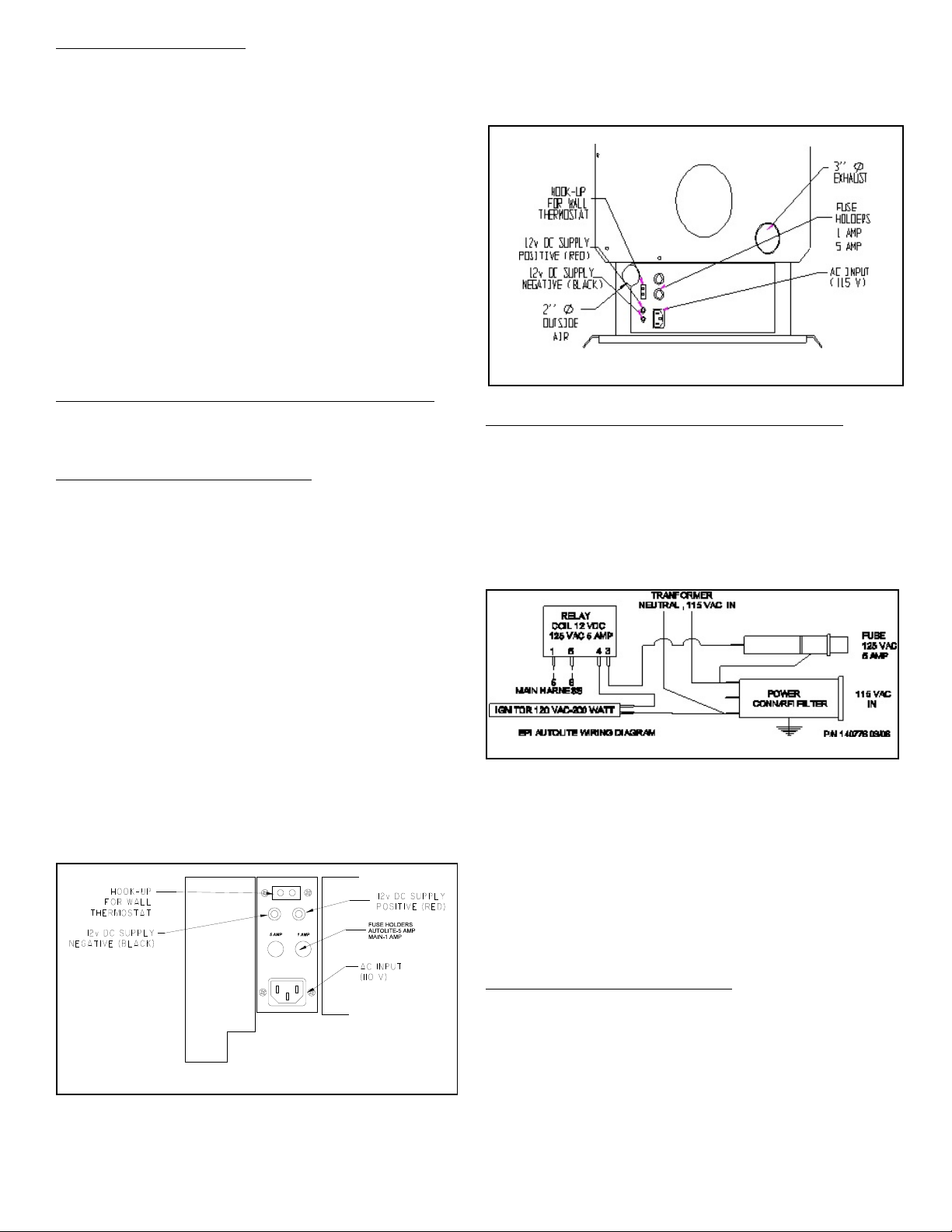

2. Control Functions: Control functions on the Easyfire

are as follows: OFF, FAN, LOW, MEDIUM, HIGH,

CLEAN. Here is how each function works:

A. When the Control Knob is turned to FAN, a timer is

activated and you will have about ten (10) minutes to

get the pellets lit and reach a minimum temperature.

Should the pellets not light in the 10 minutes simply

turn the knob to OFF and begin again. This will give

you another 10 minutes to get the pellets lit. The

reason for the timer function is so that the heater will

automatically shut down if the fire goes out. Pellets do

not feed in the FAN position.

B. In the LOW position, the EASYFIRE will be feeding

approximately 1 to 1½ lbs. of pellets per hour and the

flame will fluctuate between 1" and 6" in height.

C. In the MEDIUM position the EASYFIRE will be feeding

approximately three (3) pounds of pellets per hour and

the flame will fluctuate between 3" and 8" of fire.

D. In the HIGH position the EASYFIRE will be feeding

approximately 4.5 lbs. per hour and the flame will

fluctuate between 3" and a full flame. The fan speed

will increase accordingly as the heater automatically

adjusts itself based on temperature inside the heater

(see G below).

E. The CLEAN position is to be used only when the heater

is not burning and you wish to clean out the

accumulated ash in the front of the fire area. See

CLEAN OUT section of maintenance instructions.

F. After the heater is running for several hours and you

wish to turn it off simply turn the knob to OFF. The

heater will continue running until it cools down and

then will automatically shut itself down.

G. REMEMBER: Each feed position will fluctuate because

the microprocessor is automatically adjusting the feed

and air based on temperature. This means the pellet

feed rate and flame height will change accordingly

based on quality of pellet and heat loss of dwelling.

DISPOSAL OF ASHES

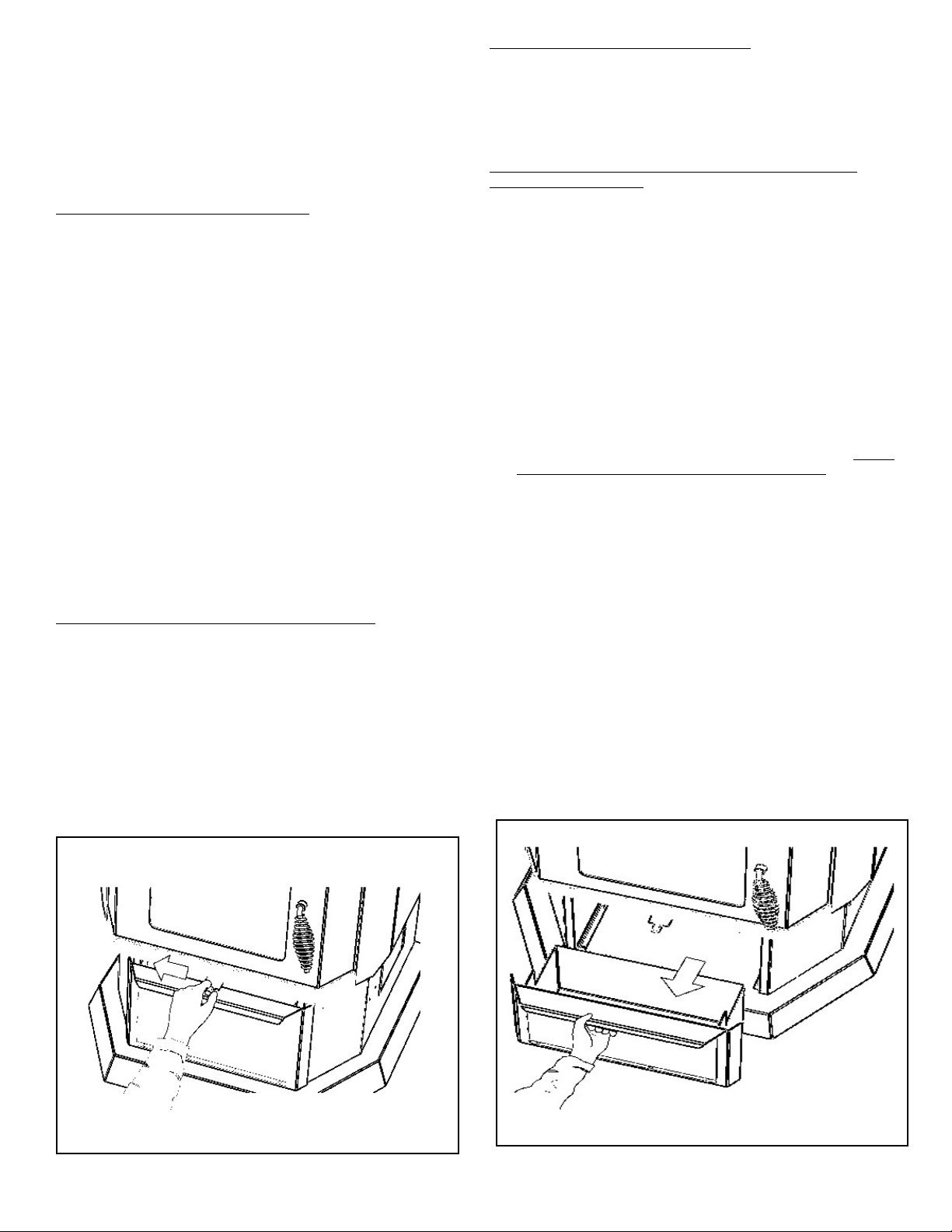

To dump ash from firebox, move lever to left several times

allowing spring to return against stop (Figure 15 & 16).

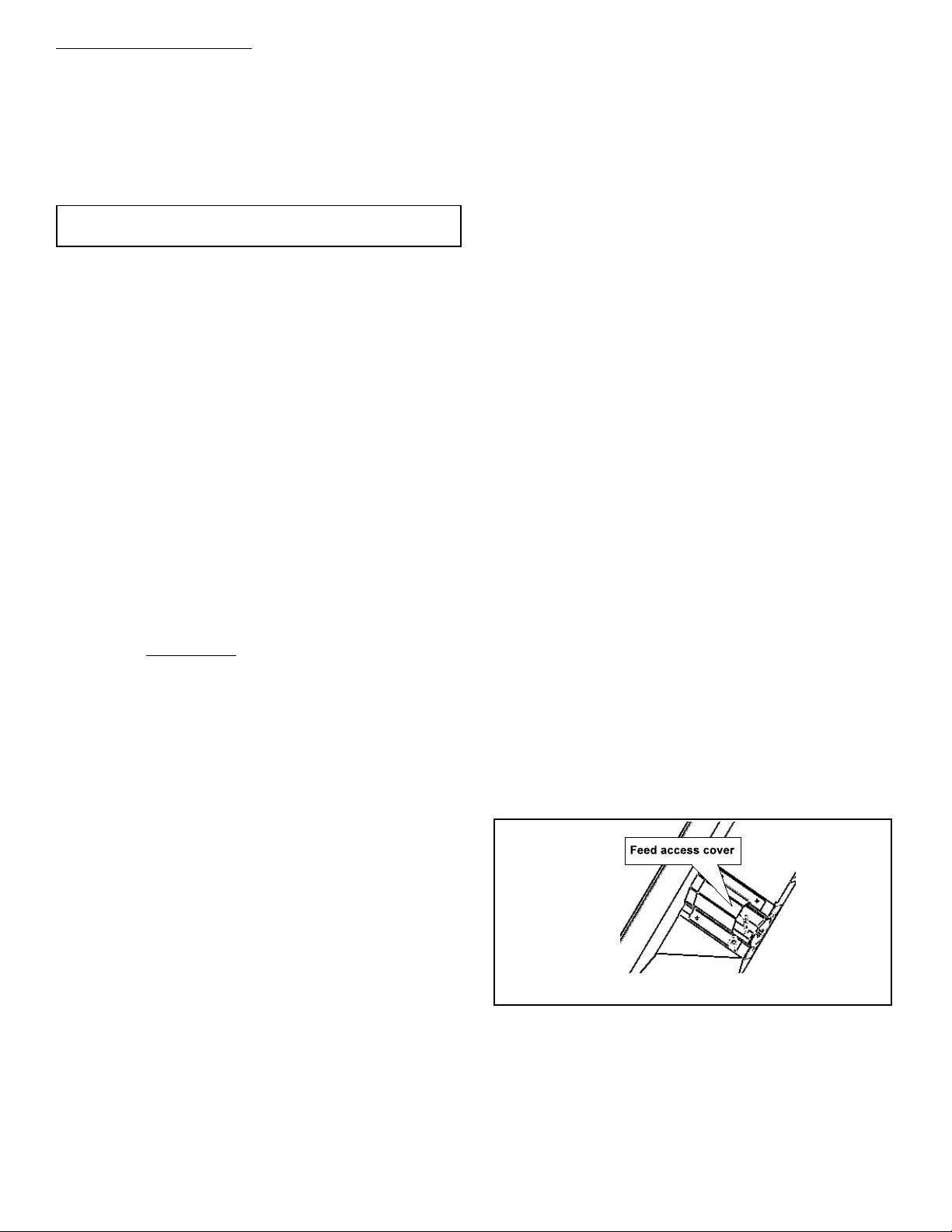

Once ash box is full, box should be placed in a non-

combustible floor or on the ground, well away from all

combustible materials pending final disposal. If the ashes

are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container

until all cinders have been thoroughly cooled.

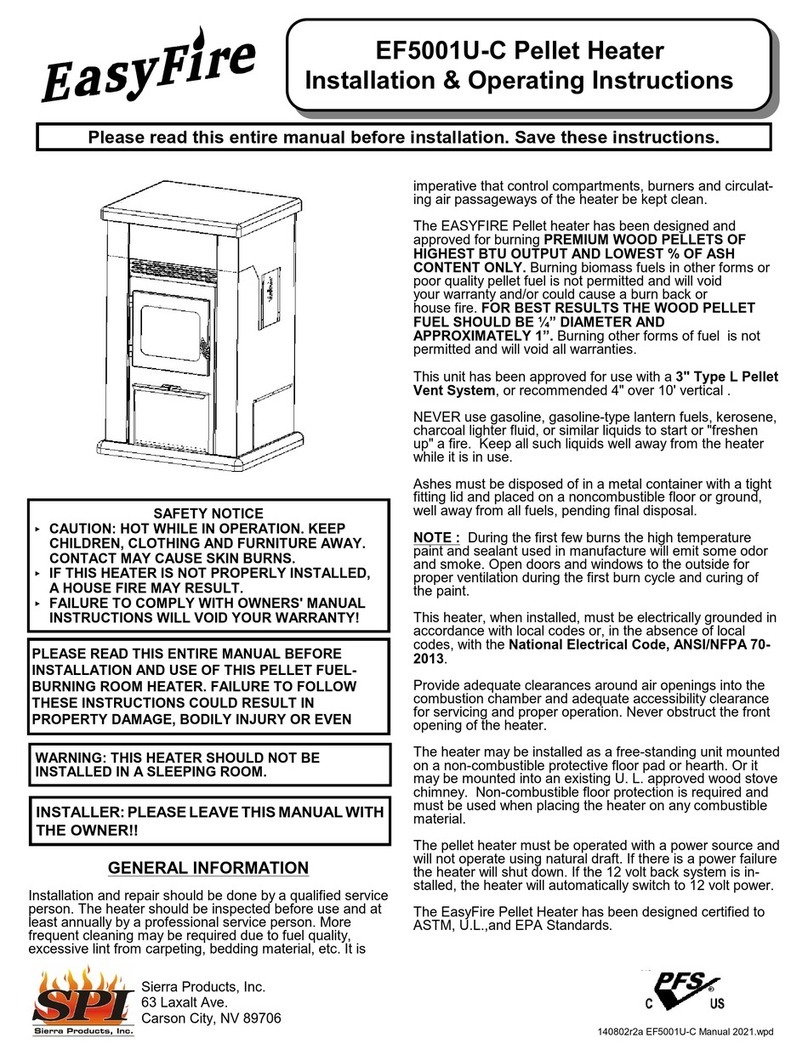

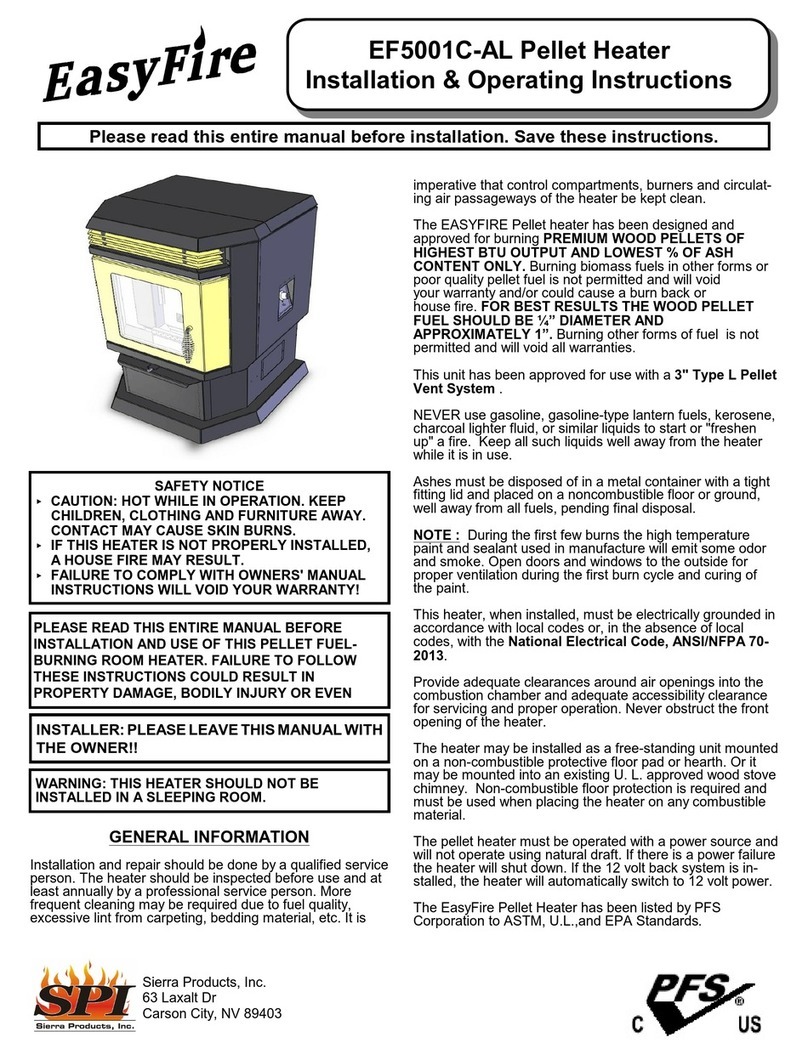

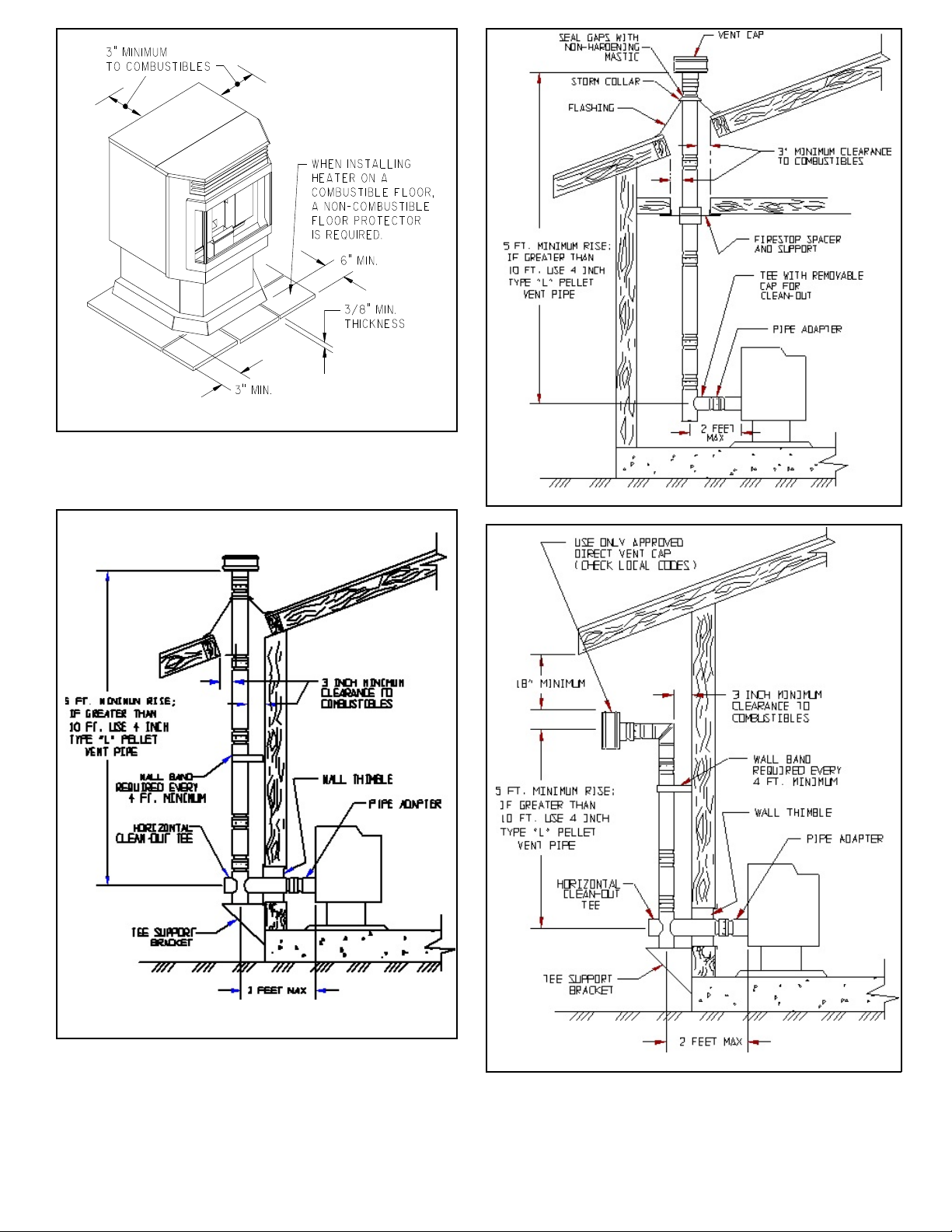

OPTIONAL 12V HOOK-UP & OPERATION

1. The EASYFIRE 12V back up can be purchased as an

option and includes the following components:

a. Deep cycle sealed 12V battery.

b. Battery connector cables for hook-up to the heater.

2. In order to hook-up the battery and engage the 12V

backup system simply connect red cable to red terminal

on the heater (see Figure 6) and to positive connector

on battery [the terminal marked (+)] and connect the

black cable to the black terminal on the heater and to

the negative connector on the battery (the terminal

marked (-). If you hook up the cables backwards the red

LED light above the terminal receptacles will come on. If

hooked up properly this LED will glow green.

WARNING - MAKE SURE RED CABLE GOES TO RED

TERMINAL (POSITIVE CONNECTOR) AND BLACK

CABLE GOES TO BLACK TERMINAL (NEGATIVE

CONNECTOR).

3. If you decide to purchase your own 12V back up system

we recommend a sealed gel cell battery. Failure to

install the proper battery could cause physical harm to

you and your property and will also void the heater

warranty.

4. When the battery is properly connected and the heater

plugged in, the following will happen automatically:

a. The heater will automatically switch to 12V power if

there is a power failure, and switch back when power

is restored.

b. The battery will be trickle charged as long as the

heater is plugged into 110 AC wall outlet. Do not use

extension cords. The trickle charge will not recharge

7