EVAKCOOL DOWN UNDER Series User manual

SERVICE

MANUAL

FOR MODELS

DU95-DZ

DU75-DZ

DOWN UNDER SERIES

3

DOWN UNDER SERIES

This Service Manual is for service agents only, if this fridge is repaired

by a non-authorised agent the warranty may become void. This

manual outlines the specifications, functions, and fault findings for

the Down Under 75L & 95L Dual Zone Fridge Freezers.

Please read this manual carefully to ensure the correct methods are

taken to diagnose and service these products.

If you require more information, please contact

warranty@evakool.com or 1300 385 665.

Contents

1 Electronic Control Overview ............................................................................. 4

2 Spare Parts Classification & Service Instructions ......................................... 7

3 Product Specifications ...................................................................................... 15

4 Basic Fault Finding ............................................................................................. 18

5 Product Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1. Electronic Control Overview

SCOPE OF FUNCTION:

• ON/OFF: Switches refrigerator ON/OFF when button is pressed for one to two second.

• Set Button: Selects input mode:

- Set temperature

- Set battery protection

- Set Max or Eco mode

• Up and Down Arrows: Press once to increase or decrease values.

• Display

- Temperature

- Error Message

- Voltage Usage Display

- Celsius (°C)

- Battery voltage

- MAX or ECO Mode

- Bin 1 and/or Bin 2

DOWN UNDER SERIES

4

LED Control Panel LED Display

On/O

Button

+/- Buttons

SET

Button

Display

ROOM 2 - Smaller Bin

Automatically set to Celsius

Battery Protection

Mode

Error message

will display here

Temperature

Max or Eco Mode

ROOM 1 - Larger Bin

SETTING THE TEMPERATURE:

Important: The temperatures displayed are only an indication of the average temperatures

may be inside the cabinet. *It is normal for the display temperature to vary +/- 5°C from the

set point when the fridge cycles.

• Hold button for 3 seconds to switch on refrigerator.

• Press button once, Room 1’s temperature will flash (large bin).

• Use the or arrows to increase or decrease the temperature to the desired

setting. The selected temperature appears in the display for a few seconds and will be

applied automatically, the display flashes several times before it returns to the current

temperature.

• Press the button twice to access Room 2’s (smaller/stepped bin) temperature display.

• Use the or the arrows to increase or decrease the temperature to the desired

setting. The selected temperature appears in the display for a few seconds and will be

applied automatically, the display flashes several times before it returns to the current

temperature.

SETTING COMPRESSOR SPEED:

• Press button three times, either ECO or MAX will be displayed.

• Use the and arrows to change between ECO and MAX. The display flashes several

times and will then automatically apply the desired setting.

SETTING BATTERY PROTECTION:

• Press the button four times, the L, M or H will display on the screen.

• Use the and arrows to change between Low, Medium and High settings. The

display flashes several times and will then automatically apply the desired setting.

Battery Monitor Mode L M H

Switch-o voltage at 12V 10.1V 10.5V 11.1V

Restart voltage at 12V 10.9V 11.4V 12.4V

Switch-o voltage at 24V 21.5V 22.3V 24.3V

Restart voltage at 24V 22.7V 23.7V 25.7V

DOWN UNDER SERIES

5

DOWN UNDER SERIES

6

SELECTING ONLY ONE BIN:

If you only require cooling for a small amount of product, you can switch OFF either side

and run only one side.

• Press and hold the arrow for 3 seconds this will turn OFF Room 1 (large bin). Reverse

the procedure to turn back ON.

• Press and hold the arrow for 3 seconds this will turn OFF Room 2 (small/stepped bin).

Reverse the procedure to turn back ON.

SUB MENU:

For temperature display oset and Celsius to Fahrenheit.

Changing Oset: With the fridge plugged into a power source and in the OFF position

press and hold the button for 3 seconds, F1 will display, use the button to scroll

through menu.

Function Setting Temp Range Default

F1 Setting Temp > -6°C -10°C ~ +10 °C -2°C

F2 -7°C >Setting Temp > -12°C -10°C ~ +10 °C -4°C

F3 Setting Temp < -13°C -10°C ~ +10 °C -6°C

F1: Setting the temperature as 0 degree, put the sensor in the middle of cabinet, check

the temperature dierence with the display temperature then choose F1 oset.

F2: Setting the temperature as -10 degree, put the sensor in the middle of cabinet, check

the temperature dierence with the display temperature then choose F2 oset.

F3: Setting the temperature as -18 degree, put the sensor in the middle of cabinet, check

the temperature dierence with the display temperature then choose F3 oset.

Changing Celsius to Fahrenheit: With the fridge plugged into a power source and in the

OFF position press and hold the button for 3 seconds, F1 will display, use the button

to scroll through till CF appears, then use and buttons to change from Celsius to

Fahrenheit. Leave the control panel and aer 5 seconds it will return to the main screen

with changes installed.

DOWN UNDER SERIES

7

Supply Power

Solenoid

LED (Small Bin)

LED (Large Bin)

Fan

Main Harness

Emergency Switch

(not used)

Thermistor (Small)

Thermistor (Large)

2. Spare Parts Classification & Service Instructions

MAIN PCB: (COMP-PBC2.5)

FAULT CODES:

The electronics and compressor are designed and built with its own fault finding system,

which will be displayed on the Main PCB, below is a table of codes relating to faults

displayed.

CODE F AU LT

E1 Battery Protection Failure

E2 Fan Failure

E3 Compressor Start Fault

E4 Min/Max Speed Fault

E5 Overheating Protection

E6 NTC Fault

LL NTC Unplugged

NTC Negative Temperature Coeicient = Thermistor

REMOVAL OF PCB:

To remove the main PCB (DO NOT peel o the sticker), firstly undo the 6 x Phillip head

screws holding the display mounting plate (Part No: HOUSE-DISP-7) to the cabinet. Undo

the 5 x screws holding the PCB to the mounting plate.

Important: Before disconnecting the wires from the PCB, make a note or take a photo of

which wires go to which sockets, remove the wires from the PCB, reverse the procedure to

re-install the new PCB.

FAN: D12BM-12 120mm x 120mm x 25mm (Part No: FAN-C)

We use the above mentioned fan, for the reliability and longevity of a ball bearing fan. The

air flow is good at 72 CFM and is an acceptable noise level for the customer.

REPLACEMENT: (Part No: FAN-C)

To replace the fan if faulty, remove the 10 screws securing the engine bay cover, remove

cover. The fan will be located on the right hand side of the engine bay, undo the 4 x metal

thread screws holding the fan on, trace the wires back to the main PCB unclip old fan from

PCB and fit new (see section on PCB for fan location on page 7), re-attach new fan, (sticker

side facing out), so the air is drawn through the condenser and expelled out through the

engine bay cover vent.

8

DOWN UNDER SERIES

Remove the five screws holding the main display

PCB to the display plate.

Remove the six screws attaching the

display mounting plate.

9

SOLENOID: Sanhua KMV432. 12 Volt 9.4W solenoid. (Part No: SOLENOID-A)

These fridges have 2 separate refrigeration systems and one compressor. The solenoid is

used to direct liquid refrigerant at the drier to the circuit that requires refrigeration. The

electronics sense when either the small or large bin needs cooling and sends a 12 Volt

pulse to the solenoid, either a positive or negative pulse is required to change from one

side to another.

To Test: To see if the solenoid is switching, first turn the refrigerator on, Room 2 (small bin)

will start to refrigerate, feel where the capillary enters the evaporator plate (image 4 & 5).

When it starts to feed, switch OFF that bin (see page 5), the solenoid will then switch over

to the other side, feel where the capillary enters the evaporator if it starts to feed you know

that the solenoid is switching and capillaries are clear, so the issue may be in the PCB

controlling the solenoid.

Warning: Before removing the old solenoid carefully mark or identify the capillaries so

they go back into the correct sides of the solenoid, failing to do so will result in erratic

temperature fluctuations and incorrect temperatures in both sides. Wrap the body of the

solenoid in wet rags before welding, failing to do so will melt the internals and stop the valve

from switching.

To Replace: Once identified, with the use of a capillary cutters, cut o both capillaries,

open the top cap and remove the wires small terminal (red) and large terminal (black),

un-sweat the drier from the condenser as it needs to be replaced, now the system is

opened (image 1). To install a new solenoid, insert the capillaries into their correct tubes

and push in all the way (there is a small dimple in the receiving copper tube to ensure

the capillary cannot be pushed in to far). Unpack the new drier and insert the large pipe

on the solenoid into the exit opening of the drier then insert the discharge tube from the

condenser into the entry opening of the drier.

DOWN UNDER SERIES

Image 1 Image 2 Image 3

Image 4 Image 5

10

DOWN UNDER SERIES

FILTER DRIER: (Part No. DRIER-SOLENOID-1)

We strongly advise to only use Evakool filter driers. Copper spun driers are made with

spring loaded sieves to prevent the desiccant from breaking down and blocking capillaries

(the unit is subject to heavy knocks and vibration as a portable appliance).

COMPRESSOR:

In our range of Australian built Evakool fridges we only use and recommend SECOP

compressors, originally designed and built by Danfoss in Germany, they are the industries

leader in design and performance in 12 Volt compressors.

These compressors are multi speed allowing for Evakool fridges to be programmed to ‘so

start’ to reduce high starting current, ultimately reducing power consumption. Every time

the fridge starts the compressor is programmed to start at its slowest speed (2000 RPM).

Once the fridge is up to speed, the system is primed for 2 minutes and it will then set to the

selected speed (Max or Eco).

Secop compressors have a fault finding system built into the electronic module, listed

below are the codes and their faults.

LED

FLASHES ERROR TYPE

5Thermal cut-out or electronic unit: If the refrigeration system has been too

heavily loaded, or if the ambient temperature is high, the unit will run too hot.

4Minimum Motor Speed Error: If the refrigeration system is too heavily loaded,

the motor cannot maintain minimum speed at approximately 1,850 rpm.

3Motor Start Error: The rotor is blocked if the dierential pressure in the

system is too high (>5 bar).

2Fan over-current cut-out: The fan loads the electronic unit with more than

0.5A avg.

1 Battery protection cut-out: The voltage is outside the cut-out setting.

11

DOWN UNDER SERIES

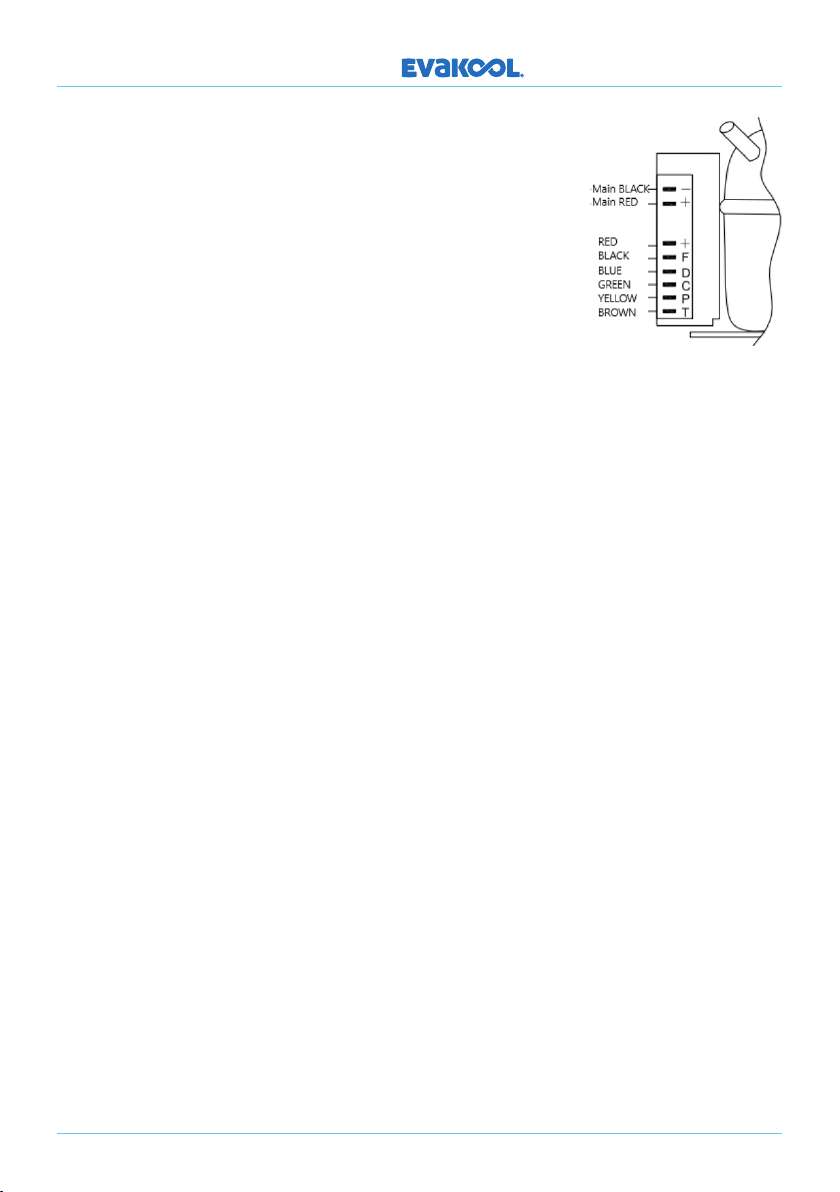

Wiring harness to the Secop Module, see below the color codes to each terminal.

For more information: https://www.portable-box-compressor.com/userdata/pdfs/secop_

portable_box_compressors_10-2015_desb100c102.pdf.

NTC - THERMISTOR: (Part No: NTC-DU)

We have made the thermistors, in these fridges with a removable head for easier

replacement and diagnosis.

Removal: There are 2 x thermistors one in each bin located behind a small plastic vented

hood (Part No. NTC-HOOD-DU). With a small flat blade screwdriver, lever the housing cover

out from the top (see photo below), remove the thermistor head from the housing and

disconnect at the plug. Install the new thermistor then re-install the hood cover.

12

DOWN UNDER SERIES

TESTING:

Test the resistance of the thermistor against the table below, if outside these parameters

replace thermistor.

Temperature Resistance K Ohms

30°C 8.8K Ohms

25°C 9.8K Ohms

20°C 11.8K Ohms

15°C 13.9K Ohms

10°C 16.8K Ohms

5°C 20.6K Ohms

0°C 25.6K Ohms

-5°C 32K Ohms

-10°C 40.7K Ohms

-15°C 51.9K Ohms

-20°C 66.4K Ohms

LED LIGHT: (Part No. LED-DU)

There are 2 x LED lights in the fridge, one in Room 1 and one in Room 2, these lights are

constantly on as long as there is power supplied to the unit, (even in the o position).

Removal: Lever o the LED cover (Part No: LED-CVR-DU) with a small flat blade screwdriver

as per the photo, un-screw the 2 x small Phillip head screws, remove the PCB, un-plug from

connector and replace with new PCB, reverse the procedure to install.

13

DOWN UNDER SERIES

WIRING:

Wiring harnesses in the fridge have been extended, to allow

the display panel to be changed from the le hand side of the

fridge to the right hand side of the fridge. This is for when the

cabinet is to be converted from a right hand motor to a le

hand motor. All connections and wiring are color coded, see

section Main PCB (page 7) for connection locations for wires

to the main PCB. See the illustration here for wire colors and

connections to the compressor module.

CONVERTING THE LIDS AND ELECTRONICS FROM RIGHT TO LEFT:

The cabinet can be converted to open from the opposite side. This is a simple process and

takes approximately 30 minutes to complete.

Tools Required:

• Philips head screwdriver

• 2.5mm Allen key

CONTROL BOARD:

• Remove the screws from the control PCB and the vent shaped like the control PCB on

the opposite side of the cabinet.

• Remove the back cover on the engine bay.

• Re-route the wiring and PCB through to the opposite side, making sure no wires are

unplugged in the process.

• Re-attach the control PCB and vent in their new positions.

LIDS:

• Remove the 4 x black hex head screws holding on the panel with the infinity logo (image

4), this will expose the holes for the hinge screws.

• Open the lids and remove the 2 x screws holding the lid chain to the cabinet, located

next to the LED light (image 1). Once the chain is removed, re-install those screws back

into the holes.

• Remove the screws on all 4 hinges (image 3), (bottom sections of the hinge only) leave

hinges attached to the lids.

• Flip lid over to the other side and re-attach screws to the bottoms of the hinges.

Note: Use only a handheld screwdriver not a cordless drill.

This will reduce the chances of cross threading the screws, lightly fit every screw before

tightening o the lids, make sure they are straight (image 4).

DOWN UNDER SERIES

14

• Fit black panel with infinity logo to the front of the cabinet with black hex head screws,

again lightly fit the screws so that the latch screws will line up. Once the latch is fitted,

align the black panel so that it is level with the top of the cabinet and tighten screws,

then align the latches so they are straight and tighten screws.

• Remove the screw beside the LED light and attach chain, replace the screw.

Important: Room 1 (Large bin) and Room 2 (Small bin).

When the lids are changed over from standard the bins will be opposite to the display, BUT

the display is marked ‘Room 1’ and ‘Room 2’ and the baskets in each compartment are

stickered to the corresponding ‘Rooms’ (image 1 and 2).

Image 1 Image 2

Image 3 Image 4 Image 5

DOWN UNDER SERIES

15

3. Product Specifications

Model No. DU75-DZ DU95-DZ

Gas Charge 60 Grams R134a 70 Grams R134a

New Weight 30kg 33kg

Dimensions (L*W*H) 895.7 x 473.8 x 530 966.3 x 575 x 470

Sound 45dB 45dB

Temp Range +10°C to -18°C +10°C to -18°C

Capacity 75 Litre 95 Litre

Power Supply DC12/24 DC12/24

Rated Power Output 65 Watts 65 Watts

Foam Thickness 50mm 50mm

Climate Class T T

POWER CONSUMPTION:

The engineering of this refrigeration system was done in-house here at Evakool, the system

is very well balanced incorporating extremely eicient rollbond evaporators with an air

cooled copper and aluminum finned condenser and the right amount of insulation to

give perfect cooling and maximum literage in the fridge compartments. We are extremely

happy with the performance of the refrigerator with all of our Australian made fridges

being true tropical rated.

DU75 Down Under 75 Litre - Climate Class ‘T’ Rated

Ambient

Temperature Speed Voltage Fridge

Temp Set

Freezer

Temp Set

Amps consumed

per hour

24°C ECO 12.8 Volts 2°C -16°C 1.45

32°C ECO 12.8 Volts 2°C -16°C 1.99

38°C ECO 12.8 Volts 2°C -16°C 2.65

43°C ECO 12.8 Volts 2°C -16°C 3.16

24°C MAX 12.8 Volts 2°C -16°C 1.51

32°C MAX 12.8 Volts 2°C -16°C 2.1

38°C MAX 12.8 Volts 2°C -16°C 2.8

43°C MAX 12.8 Volts 2°C -16°C 3.58

DOWN UNDER SERIES

16

24°C ECO 12.8 Volts 2°C 2°C 0.68

32°C ECO 12.8 Volts 2°C 2°C 1.05

38°C ECO 12.8 Volts 2°C 2°C 1.68

43°C ECO 12.8 Volts 2°C 2°C 2.09

24°C MAX 12.8 Volts -16°C -16°C 1.77

32°C MAX 12.8 Volts -16°C -16°C 2.44

38°C MAX 12.8 Volts -16°C -16°C 3.05

43°C MAX 12.8 Volts -16°C -16°C 3.75

Test Conditions: 12.8V DC. Controlled test room. Set ambient temperatures. 24hr test period.

Fridge remained closed. No product inside. Fridge 2°C. Freezer -16°C.

DU95 Down Under 95 Litre - Climate Class ‘T’ Rated

Ambient

Temperature Speed Voltage Fridge

Temp Set

Freezer

Temp Set

Amps consumed

per hour

24°C ECO 12.8 Volts 2°C -16°C 1.5

32°C ECO 12.8 Volts 2°C -16°C 2.09

38°C ECO 12.8 Volts 2°C -16°C 2.71

43°C ECO 12.8 Volts 2°C -16°C 3.5

24°C MAX 12.8 Volts 2°C -16°C 1.65

32°C MAX 12.8 Volts 2°C -16°C 2.1

38°C MAX 12.8 Volts 2°C -16°C 2.75

43°C MAX 12.8 Volts 2°C -16°C 3.48

24°C ECO 12.8 Volts 2°C 2°C 0.85

32°C ECO 12.8 Volts 2°C 2°C 1.19

38°C ECO 12.8 Volts 2°C 2°C 1.16

43°C ECO 12.8 Volts 2°C 2°C 2.16

24°C MAX 12.8 Volts 2°C 2°C 0.89

32°C MAX 12.8 Volts 2°C 2°C 1.28

38°C MAX 12.8 Volts 2°C 2°C 1.74

43°C MAX 12.8 Volts -2°C 2°C 2.3

24°C MAX 12.8 Volts -16°C -16°C 1.97

DOWN UNDER SERIES

17

32°C MAX 12.8 Volts -16°C -16°C 2.5

38°C MAX 12.8 Volts -16°C -16°C 3.34

43°C MAX 12.8 Volts -16°C -16°C 4.27

Test Conditions: 12.8V DC. Controlled test room. Set ambient temperatures. 24hr test period.

Fridge remained closed. No product inside. Fridge 2°C. Freezer -16°C.

What is Climate Class?

Refrigerators are designed to work under certain climate conditions which are rated by

climate classes. It indicates the minimum and maximum temperature limits, within which

the refrigerators are able to operate properly.

All fridges and freezers are rated with 4 main climate classes as below:

1. SN (Subnormal) suitable for use under ambient temperature range of 10°C-32°C

(50°F-90°F).

2. N (Normal) suitable for use under ambient temperature range of 16°C-32°C (61°F-90°F).

3. ST (Subtropical) suitable for use under ambient temperature range of 18°C-38°C

(64°F-100°F).

4. SN (Tropical) suitable for use under ambient temperature range of 18°C-43°C

(64°F-109°F).

Note: These abbreviations are conventional because they are regulated by international

standards (IEC Clauses) for refrigeration equipment and do not depend on a maker or a

country of production.

Some fridges and freezers are developed with combined climate classes to allow the

operation within a wider temperature range, like some outdoor locations or special

regions. For example:

1. N - ST suitable to operate under temperatures ranging from 16°C - 38°C (61°F-100°F).

2. SN - T suitable to operate under temperatures ranging from 10°C - 43°C (50°F-109°F).

Why is it so important to choose a fridge with appropriate Climate Class?

Not all refrigerating appliances are suitable for all ambient temperature ranges. Very few

people would check or even know about the characteristics of climate classes, but it is

really important to think twice before the purchase. Here are some reasons:

• If a fridge keeps running under the climate conditions that it is not intended for, it will

consume much more energy to reach the required inside temperature.

• The fridge will not cool the inside product suiciently, which will lead to excessive

condensation.

• The viscosity of the oil in the compressor will increase if it works at ambient temperature

under 10°C (50°F), and with the loss of fluidity, the compressor could be damaged easily.

• The lifespan of the refrigerators will decrease significantly.

18

DOWN UNDER SERIES

4. Basic Fault Finding

Compressor running but not cooling: Probable cause - gas leak.

• Check if there is any heat in the discharge line and condenser, if there is no heat present

there is a likelihood that no gas is in the system.

• Fit gauges to access port and check if there is any refrigerant in the system if there is no

gas present.

• Fill the system with nitrogen and bubble test all the joints in the engine bay, if nothing is

detected in the engine bay STOP TESTING as the leak will be internal and not repairable.

DO NOT spend any more time on the job. Re-seal pipe aer removing access valve.

Important: Do not exceed 100psi or 690Kpa pressure of nitrogen, doing so will destroy the

rollbond evaporators which are not replaceable.

Compressor running but only feeding one side: Probable cause - Solenoid, Main PCB or

capillary blockage.

• Firstly check if the solenoid is switching, turn the refrigerator on, Room 2 (small bin) will

start to refrigerate, feel where the capillary enters the evaporator plate. When it starts

to feed, switch OFF that bin (see page 5) the solenoid will then switch over to the other

side, feel where the capillary enters the evaporator if it starts to feed you know that the

solenoid is switching and capillaries are clear, so the issue may be in the PCB controlling

the solenoid.

• Blocked capillary: we find that capillary blockages are rarer than the 2 described

symptoms above, the drier used is a wide mouth drier so a blockage will not occur there,

the capillaries are pressed into the evaporators and cannot be replaced, so we advise to

stop work on the unit and contact EVAKOOL for further instructions.

Note: Normally where there is a restriction, be it in a drier or capillary, there will be cold and

condensation present as the refrigerant will be expanding at that point.

Compressor running but not

achieving temperature: Probable

cause - Fan has stopped or condenser

is blocked with flu.

• Remove the back cover and check

if fan has stopped or if the fan is still

running.

• Check the condenser to see if

blocked. To do this, turn o fridge,

stand fridge on its end to access

the base, there is a small inspection

DOWN UNDER SERIES

19

panel (see photo), remove panel and inspect the back section of the condenser. If

blocked, remove the fan and blow compressed air from the front of the condenser to

remove flu build up. Replace inspection plate, and test.

Display not showing the right temperature: Probable cause - Thermistor or Main PCB.

• Test thermistor (see page 11) or replace with a new thermistor.

• If the thermistor is OK then the main PCB may need recalibrating, see section SUB MENU

(page 5) for changing display oset.

• If the above doesn’t work, then a new PCB is required.

• If the cabinet has been changed from right hand motor to le hand motor. The customer

might be matching the temperature indicated to the wrong bin (see page 13).

Important: Room 1 (Large bin) and Room 2 (Small bin).

Note: The displayed temperature is only an indication of what the average temperature may

be inside.

E1 Battery protection cut out OR low voltage failure: Probable cause - faulty

component, bad wiring, wrong battery protection setting or flat/faulty battery.

Please Note: Most E1’s are a consumer error not a manufacturing fault and therefore

not covered under warranty (if fault is not found). Refer customer to the manual for

troubleshooting or to call EvaKool.

• With the use of a multimeter start at the source, measure the voltage at the battery to

determine if the battery is flat or not.

• Make sure that the battery protection mode is set on LOW and check the cutout voltage

in the table (page 5).

• Test with multimeter the various components in the cabinet e.g., plug, circuit breaker

etc.

From a service and warranty point of view, the circuit breakers can fail, so make sure this

component is tested.

Handy Hint: Where there is a drop in voltage there is HEAT so feel the components and

visually check for signs of heat; burning, black terminal covers, tainted metal on connectors

etc.

Important: These tests must be done under load (with compressor running), there will be no

voltage drop if the system is not under load.

Note: The cutout voltage is measured at the Secop control module. As a rule of thumb there

will be approximately 0.5 to 0.8 Volt of losses through the wiring and connectors and circuit

breaker inside the unit, this does not include the losses in the customers wiring set-up.

Example: The unit is set on high battery protection, which is 11.1 V cutout at the

compressor, with losses in the fridge (wiring, connections, circuit breaker) of 0.8 Volts,

this is now showing the fridge cutting out at 11.9 Volts at the battery. Now if we include

the lead we supply, the connection in the customers car and the 5 to 6 metres of cable

from the secondary battery to the fridge this could equate to another 1 to 2 Volts of losses

between the battery and the compressor module, NOW we would measure around 12.9 or

13.9 at the battery and the fridge is cutting out.

These figures are conservative standard resting 12 V battery charge:

• 12.8 volts = 100%

• 12.5 volts = 70%

• 12.3 volts = 50%

• 11.4 volts = 20%

At the Battery: 12.8 Volts minus 1.5 Volts for customers wiring and connections.

At the Anderson connector on the fridge: 11.3 Volts minus 0.8 Volts of losses inside the

cabinet.

At the Secop module on compressor: 10.5Volts

You can see in this example that the fridge will not start at all in High or Medium battery

monitor mode.

Battery Monitor Mode L M H

Switch-o voltage at 12V 10.1V 10.5V 11.1V

Restart voltage at 12V 10.9V 11.4V 12.4V

Switch-o voltage at 24V 21.5V 22.3V 24.3V

Restart voltage at 24V 22.7V 23.7V 25.7V

It also shows the importance of correct wiring for vehicles, bigger is better and reduces the

number of connections between the battery and the fridge.

Cable Thickness (Area) 12V Max Cable Length 24V Max Cable Length

(mm2) AWG (m) () (m) ()

2.5 13 2.5 8 5 16

4 11 4 13 8 26

6 9 6 20 12 39

10 7 10 33 20 66

DOWN UNDER SERIES

20

This manual suits for next models

2

Table of contents