Safety Instruction

Installation

Troubleshooting

Opration

Before operation, read the instructions and follow safety rules as below.

WARNING-Be sure to install the pump properly before operation and install the Earth leakage

. Failure to follow the precautions may lead to hazards if current leakage or

electric shock occur.

circuit breaker

CAUTION-Do not extend the length of power cable without consulting your supplier. The

insulation resistance could be reduced significantly and cause electric shock. If the power cable

is extended, do not immerse the splice in water.

Before installation, check your local electrical and plumbing codes. Those regulations provide further

information for your safety.

1.Be sure main power supply (breaker) is “OFF” when connect wiring with pump and float switch.

2.Be sure the power cable is not twist together during installation.

3.Make sure correct voltage and confirm wiring connection with pump and float switch correct and

fixed, then you can turn on the main power(”On”on breaker).

Electrical Connections

All wiring, electrical connections, and system ground wire must comply with any local codes and

ordinances and perform correctly by a qualified electrician.

1.Be sure to install a ground wire to the pump before operation and install the circuit breaker and

overload protector to prevent the motor from burning out. Failure to follow the precaution may lead

to hazards if current leakage or electric shock occurs.

WARNING-DO NOT operate pump while anybody is in water, electric shock could occur

during electric leakage.

1.SHUT OFF the power before maintenance.

2.Properly put panel in ventilated place and prevent from humidity, and keep out of reach of children.

3.The normal user is not allowed to dissemble the panel to do any repair/service works without any

knowledge/training about the pump and relevant safety. Only qualified person with proper tools

and knowledge should attempt service the pump.

Maintenance

-3-

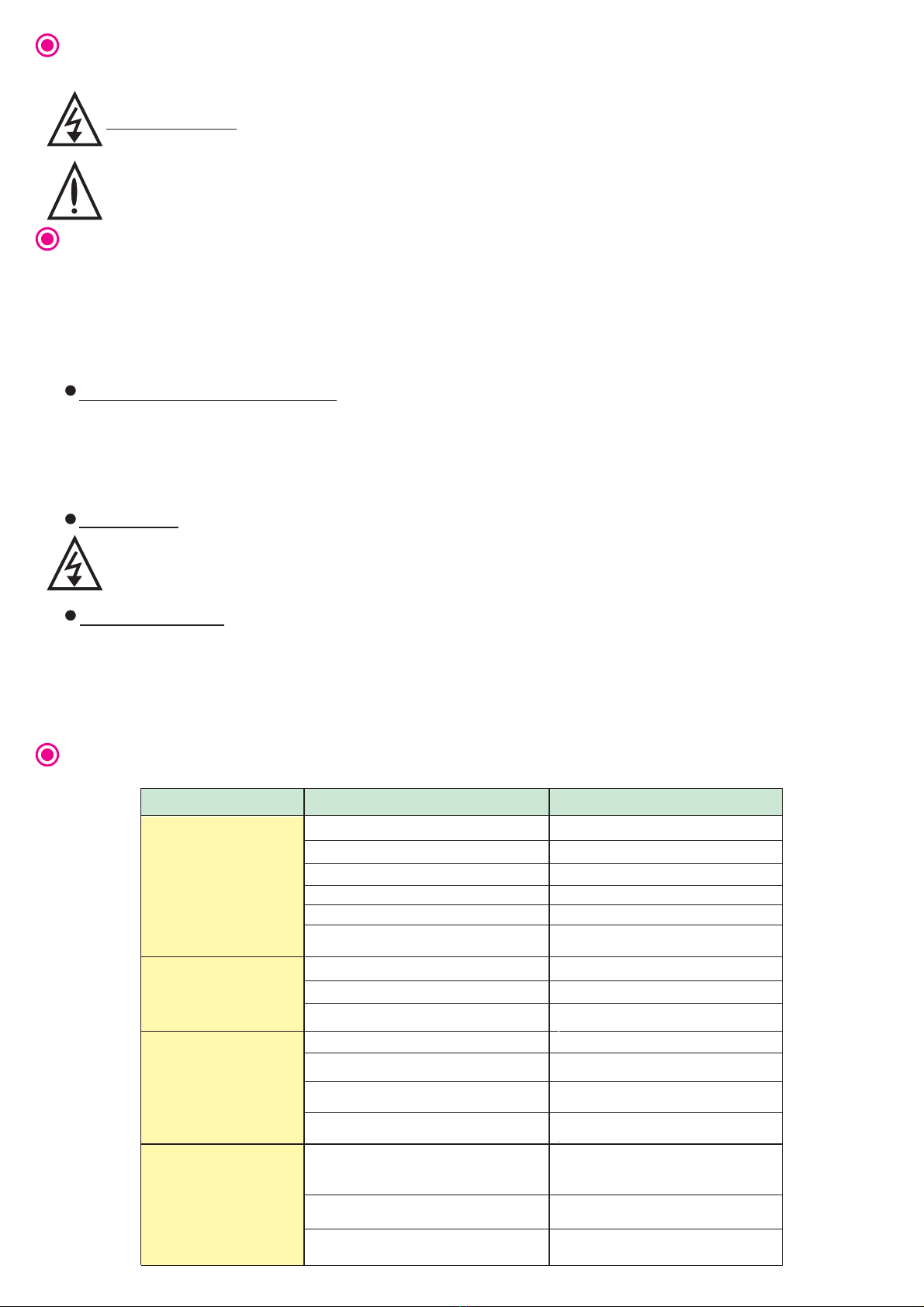

Malfunction /Cause Solutions

Unusual phenomenon

Pump is not working

When pump starts, it

will stop immediately.

The capacity is not

enough or the head is

low

The pump system can’t

stop running.

No voltage or power is off. Re-starts the power

Cable wire is fractured Replaces it

Fuse or circuit burns up Replaces it

Power source has poor contact Re-connects it again.

Voltage drops Adjusts power & voltage

3 phase voltage is unstable Adjusts power; replaces

impeller

Liquid contains mud or sand

Liquid viscosity is too high

Reverse phase in 3 phase Replaces 2 wires in 3 phase

wires.

Clean pump impeller

Replace suitable pumps

Impeller is stuck or damaged Cleans or replaces it

Replaces 2 wires in 3 phase

wires.

Motor reverse phase

Pressure “Off” setting is too high,

Off point is higher than Max.head

of pump.

Pump discharge piping system is

water leakage

No air inside pressure tank or

diaphragm inside tank is broken

Refill air(1bar) in pressure tank

or replace new tank

Adjust down “Off” pressure point

on pressure switch

(read page No.1)

Check pipe system

Pipeline or valve is leaking or stuck Checks where the leakage is

in pipeline or valve

Actual performance can’t reach

customer requirements

Replaces it to better pump

model