Everlasting BASIC TRAY User manual

1

ENGLISH

BLAST CHILLERS / SHOCK FREEZERS

BASIC TRAY

Use and maintenance manual

Rev.6-20 Matricola / Serial number

1

ENGLISH

Thank you for choosing this product.

Please read the warnings contained in this manual carefully, as they provide important information

regarding safe operation and maintenance.

Make sure to keep this manual for any future reference by the various operators.

In some parts of the manual, the symbol appears, indicating an important warning that must

be observed for safety purposes.

CHAPTER 1 BOUNDARY CHARACTERISTICS OF OPERATION

The blast chiller has been designed and built to operate in optimal conditions at temperatures of

up to +43°C, with adequate air circulation. In places with characteristics that are different from the

requirements, the stated performance cannot be guaranteed.

The supply voltage must be 230V +/- 10% 50Hz as standard, or as indicated on the EC label.

The following table shows the cooling and/or freezing capacity in kg.

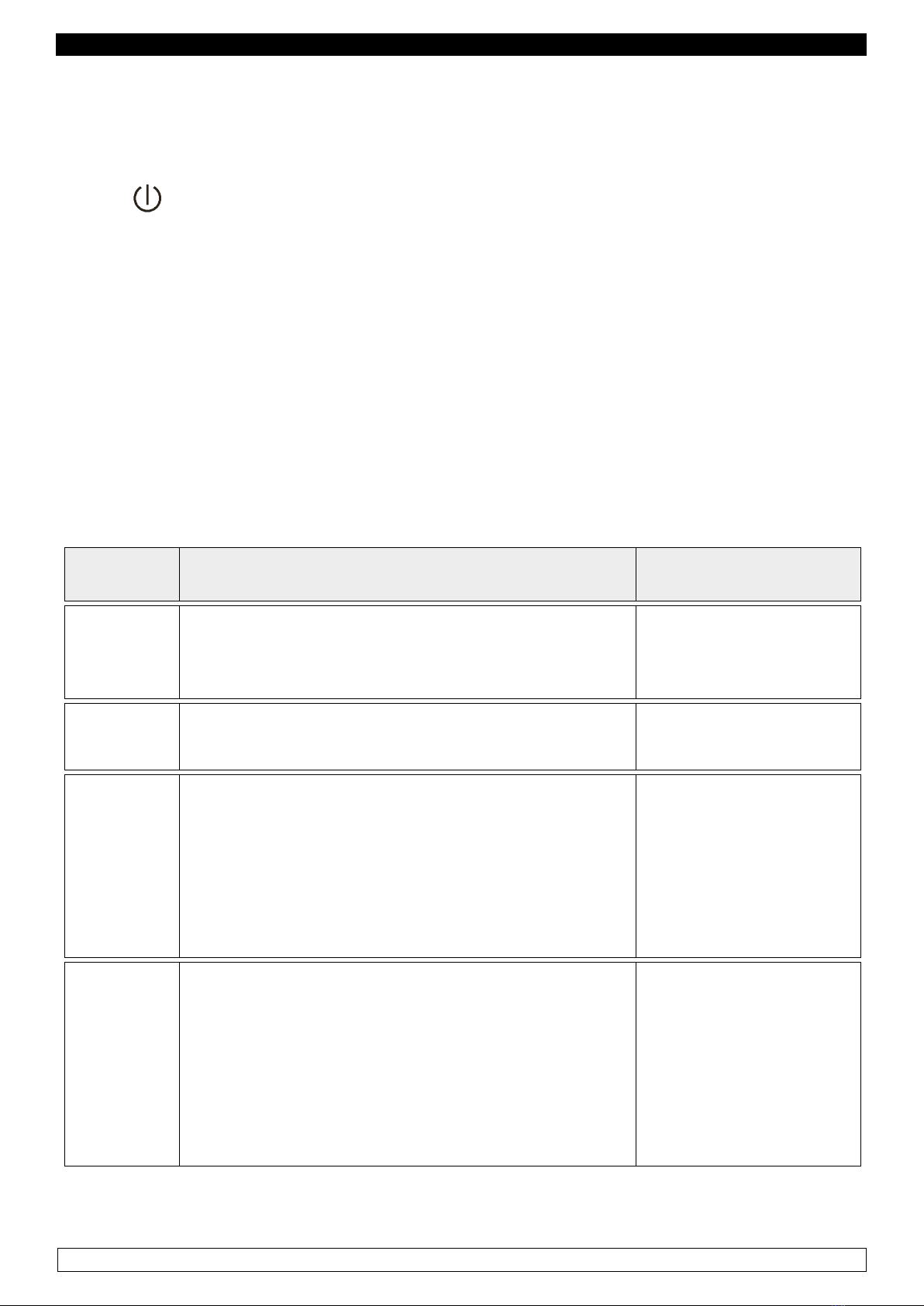

Model Blast chilling +90°C / +3°C Rapid freezing +90°C / -18°C

BASIC TRAY MINI 7 Kg. 5 Kg.

BASIC TRAY 04 10 Kg. 7 Kg.

BASIC TRAY 05 16 Kg. 12 Kg.

BASIC TRAY 07 24 Kg. 16 Kg.

BASIC TRAY 10 33 Kg. 23 Kg.

BASIC TRAY 15 50 Kg. 35 Kg.

N.B.: the times and quantities in kg above are valid for products with a maximum thickness of 4 cm.

Maximum time:

Positive chilling: 90 min, Freezing: 240 min

The blast chiller complies with the European directives as described in detail in theAnnex “EC Declaration

of Conformity”

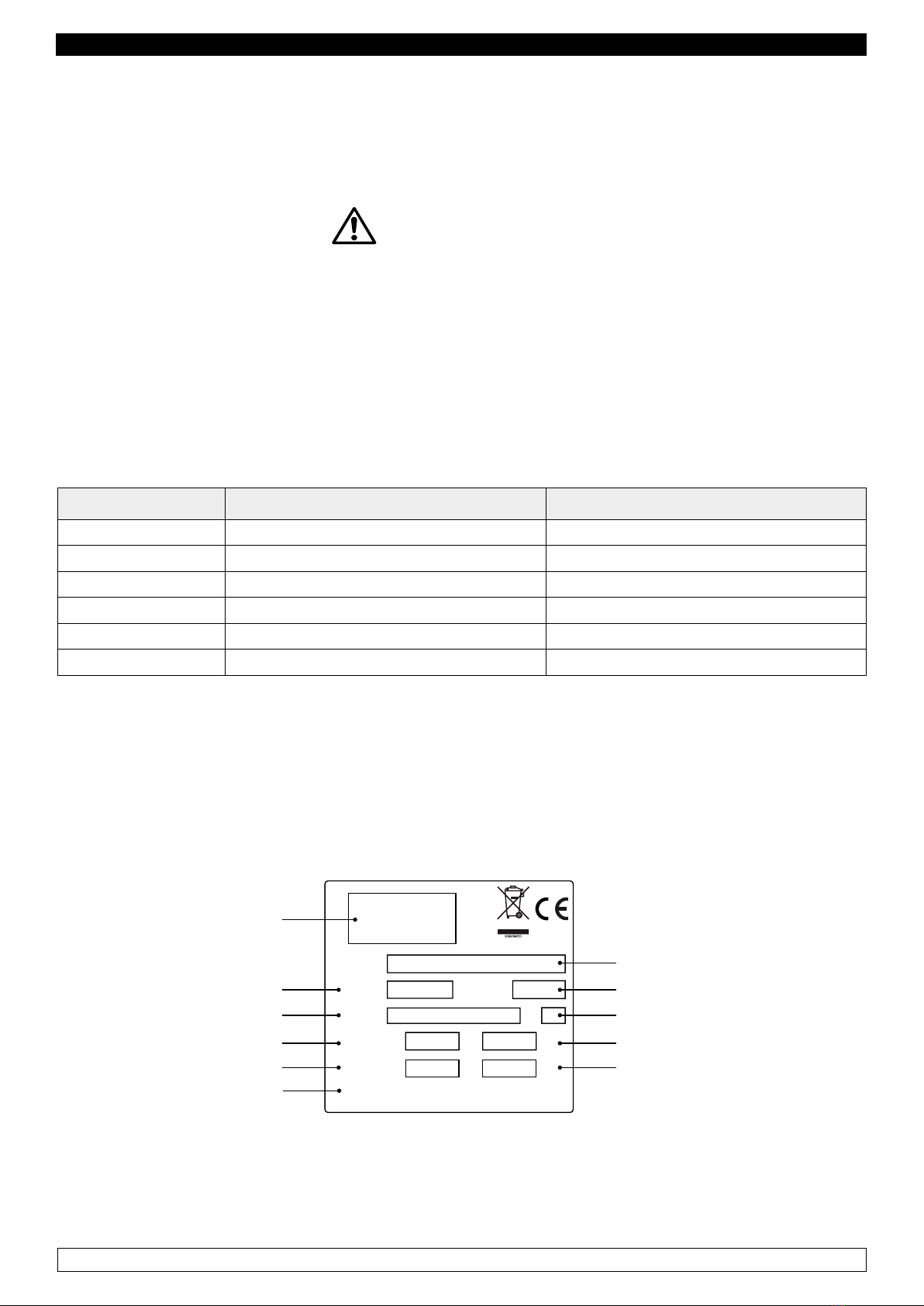

The technical specifications of the blast chiller are listed on the CE label placed on the rear side of the body

.

AKw

Kg

CL.

Matricola

Ser. Number

Modello

Model

Cod.Art

Code

Tensione

Tension

Assorbimento

Absorption

Gas

Gaz

IP20, CLASS 1

Model

Registration Number

Climate class

Electrical power

Quantity of coolant

Manufacturing Company

Code article

Operating voltage

Power consumption

Type of coolant

Degree of protection

2

ENGLISH

ATTENTION: any request for intervention, technical support and spare part must refer to the SERIAL

NUMBER on the CE label, on the manual cover or on the compressor motor. The producer declines any

responsibility for any improper or not reasonably foreseen usage of the blast chiller and for any operation

carried out by neglecting the indications listed on the manual.

The main general safety standards are listed below:

- Do not use or place electrical devices inside the refrigerated compartments if they are not of the

type recommended by the manufacturer

- Do not touch the blast chiller with damp or wet hands or feet

- Do not use the blast chiller barefoot

- Do not insert screwdrivers or other objects between the guards or moving parts

- Do not pull the power cord to unplug the blast chiller from the electricity network

- The blast chiller is not intended to be used by persons (including children) with physical or mental

problems, or lack of experience and knowledge, unless they are controlled or instructed in using the

unit by a person responsible for their safety. Children must be supervised to ensure that they do not

play with the appliance.

- Before carrying out any cleaning or maintenance, disconnect the blast chiller from the mains power

supply by turning off the main switch and pulling the plug

- In the event of failure and/or malfunction of the blast chiller, turn it off and to refrain from any attempt

to repair or intervene directly. It is necessary to exclusively contact a qualified technician.

The blast chiller is composed of a modular single body insulated with expanded polyurethane with

42 kg/m3 density, internally covered in Stainless Steel AISI 304 and externally by different materials.

In the design and construction, all measures have been adopted to ensure a blast chiller that complies

with safety and hygiene requirements, such as: rounded interior corners, deep drawing with drain on

the outside for the condensate liquids, no rough surfaces, fixed guards on moving or dangerous parts.

The products must be stored in observance of the load limits given in the table, in order to ensure

an efficient circulation of air inside the blast chiller.

Load capacity

Tipo/Type

BASIC

TRAY

MINI

BASIC

TRAY

04

BASIC

TRAY

05

BASIC

TRAY

07

BASIC

TRAY

10

BASIC

TRAY

15

GN 2/3

Nr° 3

Pitch 53 mm.

GN 1/1

Nr° 4

Pitch

70 mm.

Nr° 5

Pitch

52,5 mm.

Nr° 7

Pitch

35 mm.

GN 1/1

Nr° 5

Pitch

70 mm.

Nr° 6

Pitch

52,5 mm.

Nr° 9

Pitch

35 mm.

GN 1/1

Nr° 7

Pitch

70 mm.

Nr° 9

Pitch

52,5 mm.

Nr° 13

Pitch

35 mm.

GN 1/1

Nr° 10

Pitch

70 mm.

Nr° 12

Pitch

52,5 mm.

Nr° 19

Pitch

35 mm.

GN 1/1

Nr° 15

Pitch

70 mm.

Nr° 20 Pitch 52,5 mm.

Nr° 30

Pitch

35 mm.

Nr° 2 Nr° 4 Nr° 6 Nr° 9 Nr° 12 Nr° 18

-Nr° 1 Nr° 2 Nr° 3 Nr° 4 Nr° 6

The installation must be performed exclusively by a qualified technician

3

ENGLISH

1.1 It is prohibited to remove the guards and safety devices

t is absolutely forbidden to remove safety guards.

The manufacturer disclaims any liability for accidents due to failure to comply with this obligation.

1.2 Information on emergency operations in the event of fire

- disconnect the blast chiller from the power source or cut off the power supply

- do not use water jets

- use dry chemical or CO2 extinguishers

CHAPTER 2 CLEANING THE REFRIGERATOR

Since the blast chiller will be used to store food, cleaning is necessary for hygiene and health

protection purposes. The cleaning of the blast chiller has already been carried out at the factory. It

is suggested, however, to carry out an additional cleaning of the internal parts before use, making

sure that the power cord is unplugged.

2.1 Cleaning the interior and exterior cabinet

For this purpose the following are indicated

- the cleaning products: water and mild, non-abrasive detergents. DO NOT USE SOLVENTS AND

THINNERS

- methods for cleaning: wash the interior and exterior parts with warm water and mild soap or with a

cloth or sponge with suitable products

- disinfection: avoid substances that can alter the organoleptic characteristics of the food

- rinsing: cloth or sponge soaked in warm water. DO NOT USE WATER JETS

- frequency: weekly is recommended, the user can set different frequencies depending on the type

of food being stored.

REMARK : Clean frequently the door seals.

Some preserved products could release some enzymes that could damage

the seals causing its quick deterioration.

For the cleaning, use only specific products for this purposes, available also

on request on our sales network.

2.2 Cleaning the condenser

The efficiency of the blast chiller is compromised by the clogging of the condenser, therefore it is

necessary to clean it on a monthly basis. Before carrying out this operation, switch off the blast chiller,

unplug the power cord and proceed as follows:

With the aid of a jet of air or dry brush, eliminate, in a vertical movement (Fig.

1), the dust and lint deposited on the fins. In the case of greasy deposits, we

recommend using a brush moistened with special cleaning agents. At this

point, proceed to clean as done with the models with fixed front panel. When

the operation is completed, restart the blast chiller. Evaporators installed above

the appliances are cartaphoresis-treated to reduce corrosion problems.

During this operation, use the following personal protective equipment: goggles, respiratory

protection mask, chemically resistant gloves (gasoline-alcohol).

A

L

C

O

O

L

Fig.1

4

ENGLISH

CHAPTER 3 PERIODIC CHECKS TO BE CARRIED OUT

The following are the points or units of the blast chiller that require periodic checks:

- integrity and efficiency of door seals

- integrity of the grilles in contact with food

- integrity of the fixing hinges of the doors

- integrity of the power cord of the blast chiller

3.1 PRECAUTIONS IN CASE OF LONG PERIODS OF INACTIVITY

A long period of inactivity is defined as a stoppage of more than 15 days.

It is necessary to proceed as follows:

- switch off the blast chiller and disconnect it from the power supply

- carry out a thorough cleaning of the interior cabinet, shelves, trays, guides and supports, paying

special attention to critical points such as the joints and magnetic gaskets, as indicated in Chapter 2.

- leave the door partly open to prevent air stagnation and residual humidity

CHAPTER 4 PREVENTIVE MAINTENANCE

4.1 Restarting after a long period of inactivity

Restarting after long inactivity is an event that requires preventive maintenance.

It is necessary to perform a thorough cleaning as described in chapter 2.

4.2 Control of the warning and control devices

We recommend that you contact your dealer for a service or maintenance contract that includes:

- cleaning of the condenser

- verification of the coolant load

- verification of the full cycle operation

- electrical safety

CHAPTER 5 EXTRAORDINARY MAINTENANCE AND REPAIR

All maintenance activities that have not been described in previous chapters are considered

“Extraordinary Maintenance.” Extraordinary maintenance and repair are tasks reserved exclusively

to the specialist personnel authorized by the manufacturer.

No liability is accepted for actions carried out by the user, by unauthorized personnel, or with the use

of non-original replacement parts.

5

ENGLISH

CHAPTER 6 TROUBLESHOOTING

Problems may occur, in the blast chiller, identified as shown in the table:

TROUBLE DESCRIPTION POSSIBLE CAUSES HOW TO REPAIR IT

the blast chiller does not turn on no power supply check the plug, socket, fuses, line

other contact technical support

the refrigeration unit does not start the set temperature has been reached set new temperature

defrosting in progress wait until the end of cycle / turn power off

and on again

control panel failed contact technical support

other contact technical support

the refrigeration unit runs conti-

nuously but does not reach the set

temperature

location is too hot aerate more

condenser is dirty clean the condenser

insufficient coolant contact technical support

stop the condenser fan contact technical support

insufficient sealing of doors check the seals / provision of goods

evaporator completely frosted manual defrosting

other contact technical support

the refrigeration unit does not stop at

the set temperature

command panel failed contact technical support

Pr1 temperature sensor failed contact technical support

block of ice on the evaporator

misuse see chapter 1.

device to defrost press the manual defrost

defrost probe Pr3 damaged contact technical support

accumulation of water or ice in the

drip tray

drain clogged clean the pipette and the drain

blast chiller is not level check levelling

CHAPTER 7 INSTRUCTIONS FOR REQUESTING ASSISTANCE

For any technical problem and for intervention, assistance and spare-part requests it is necessary

to exclusively revert to one’s dealer, providing the code and the serial number indicated on the

specification label attached to the appliance.

CHAPTER 8 SAFETY AND ACCIDENT PREVENTION

The blast chiller has been built with suitable measures to ensure the safety and health of the user.

The following are the measures taken to protect against mechanical risks:

- stability: The blast chiller, even with the grilles removed, has been designed and built in such a way

that under the intended operating conditions, its stability is suitable for use without risk of overturning,

falling or unexpected movement

- surfaces, edges, corners: the accessible parts of the blast chiller are, within the limits allowed by

their functions, free of sharp angles and sharp edges, as well as rough surfaces likely to cause injury

- moving parts: were designed, constructed and arranged to avoid risks. Certain parts are equipped

with fixed guards so as to prevent risks of contact which may result in injury

6

ENGLISH

The following are the measures taken to protect against other risks:

- electricity: The blast chiller has been designed, built and equipped so as to prevent risks electrical,

in accordance with the specific legislation in force

- noise: The blast chiller has been designed and built in such a way that risks resulting from the

emission of airborne noise are reduced to the minimum level

8.1 safety devices adopted

It is absolutely forbidden (Fig. 2) :

- to tamper with or remove the evaporator housing casing that protects the user against the risk of

being cut by the evaporator fins and the movement of the motor fan inside.

- remove the labels applied at the inner edge of the engine compartment, showing the technical

specifications (1) and the instructions for grounding (2)

- remove the label applied on the evaporator guard and near the electrical wiring inside the engine

compartment, which warns the user to turn off the power supply before working on the unit (3)

- to remove the labels applied inside the engine compartment, indicating grounding (4)

- to remove the label applied on the power cord, indicating the type of power supply (5)

The manufacturer declines any responsibility for the safety of the blast chiller if this were to happen.

Fig.2

8.2 Indications for optimal operation

- do not obstruct the motor-compartment air intakes (place at minimum 50 cm from ceiling)

- place the foodstuffs on the appropriate shelves or containers. Do not place them directly on the

bottom, or leaning against the walls, doors or fixed guards

- close the doors carefully

- always keep the defrost water drain hole clear of obstructions

- limit, to the extent possible, the frequency and duration of door opening. Each opening causes a

change in the internal temperature

- perform periodically current maintenance (see chapter 3)

7

ENGLISH

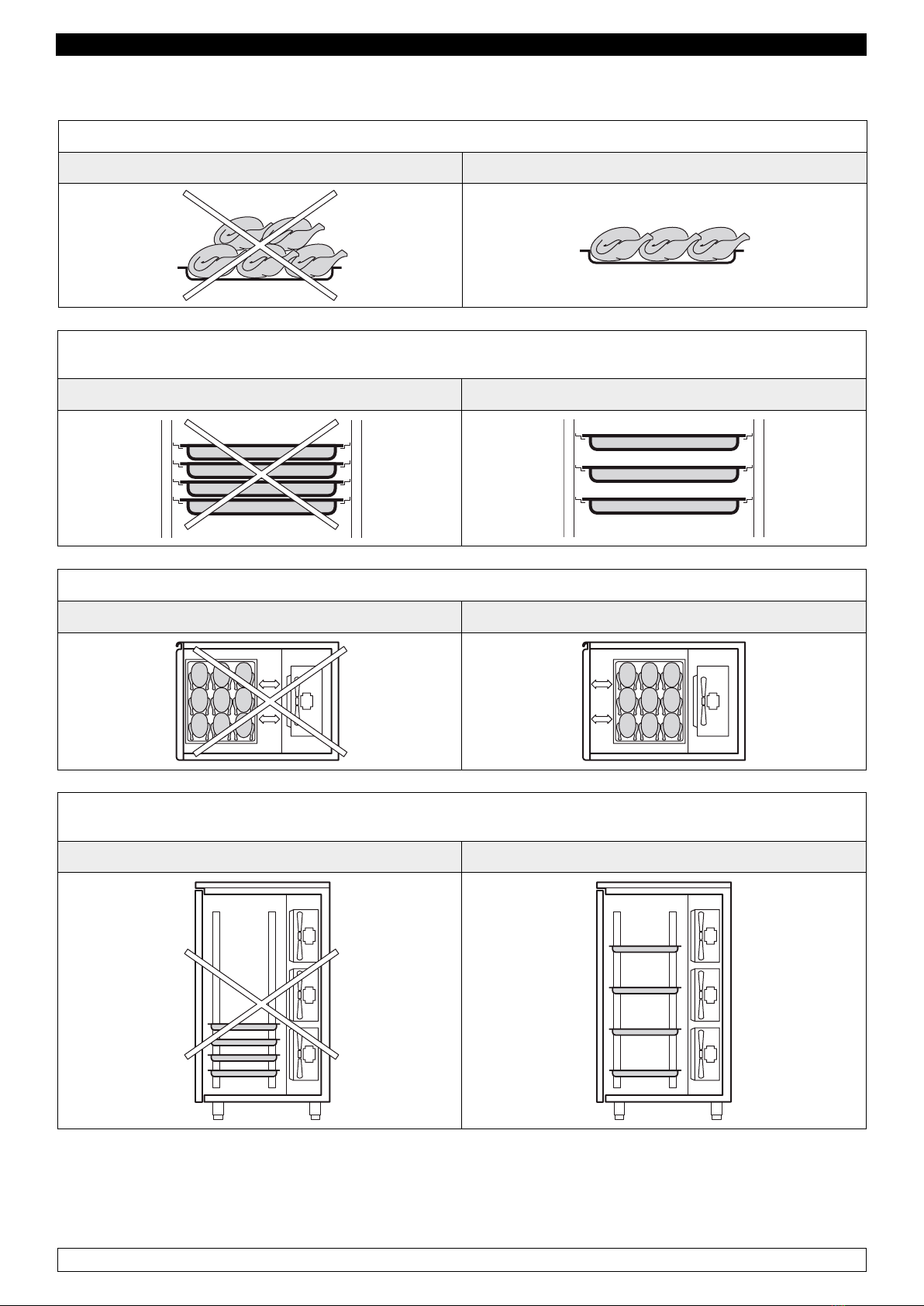

CORRECT LOAD BLAST CHILLER

AVOID overloading the blast chiller beyond the set limits shown in the table

NO OK

Do not place the trays too close to each other so as to avoid uneven air circulation inside the blast

chiller

NO OK

Do not place the trays too far away from the evaporator

NO OK

Do not concentrate the trays in one area of the blast chiller in case the load is not complete; distribute

its height evenly

NO OK

In case of interruption or failure of the power supply circuit, prevent the opening of the doors in order to

maintain a uniform temperature inside the blast chiller.

If the problem persists longer than a few hours it is recommended to move the material to a suitable place.

8

ENGLISH

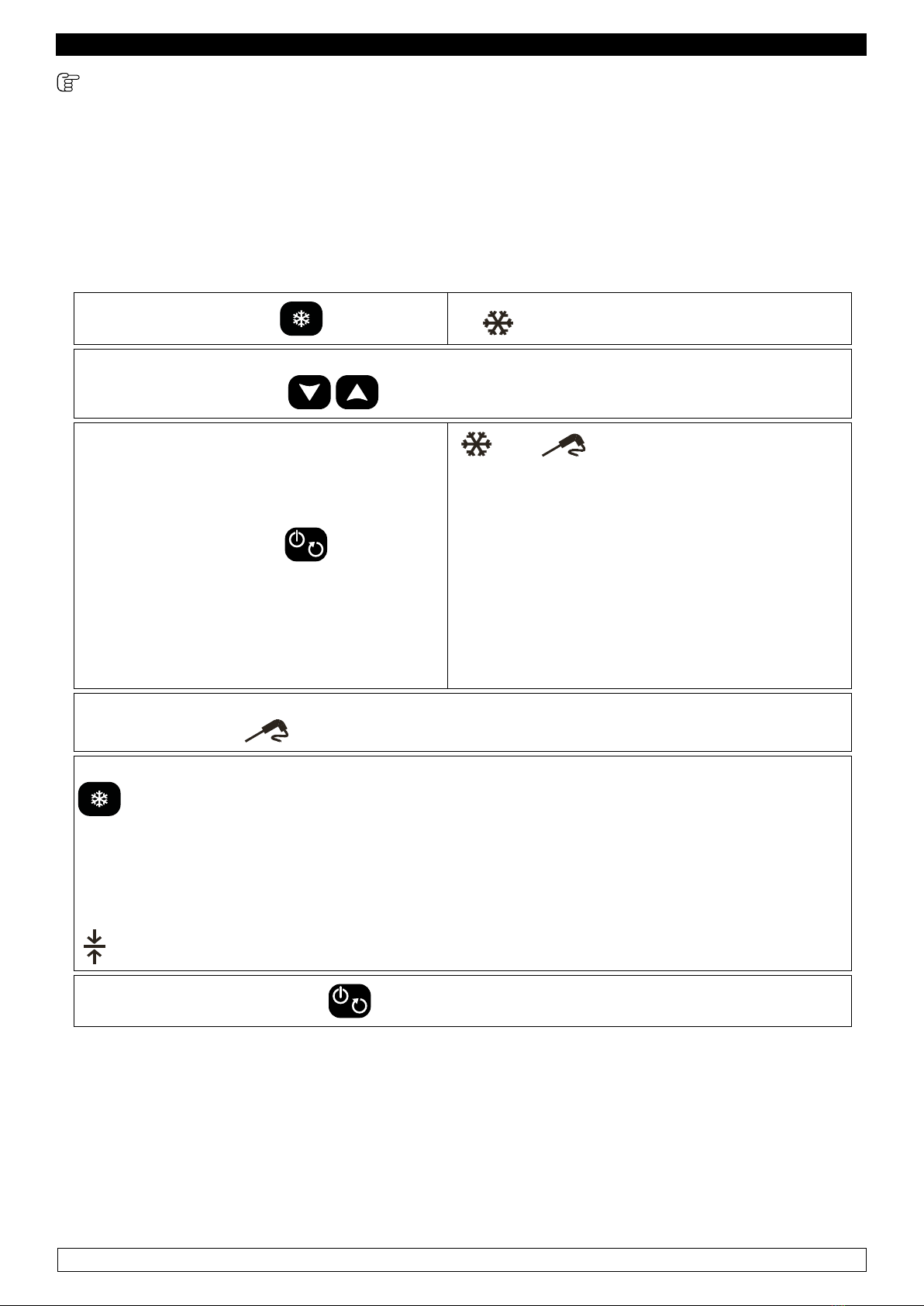

CHAPTER 9 CONTROLS

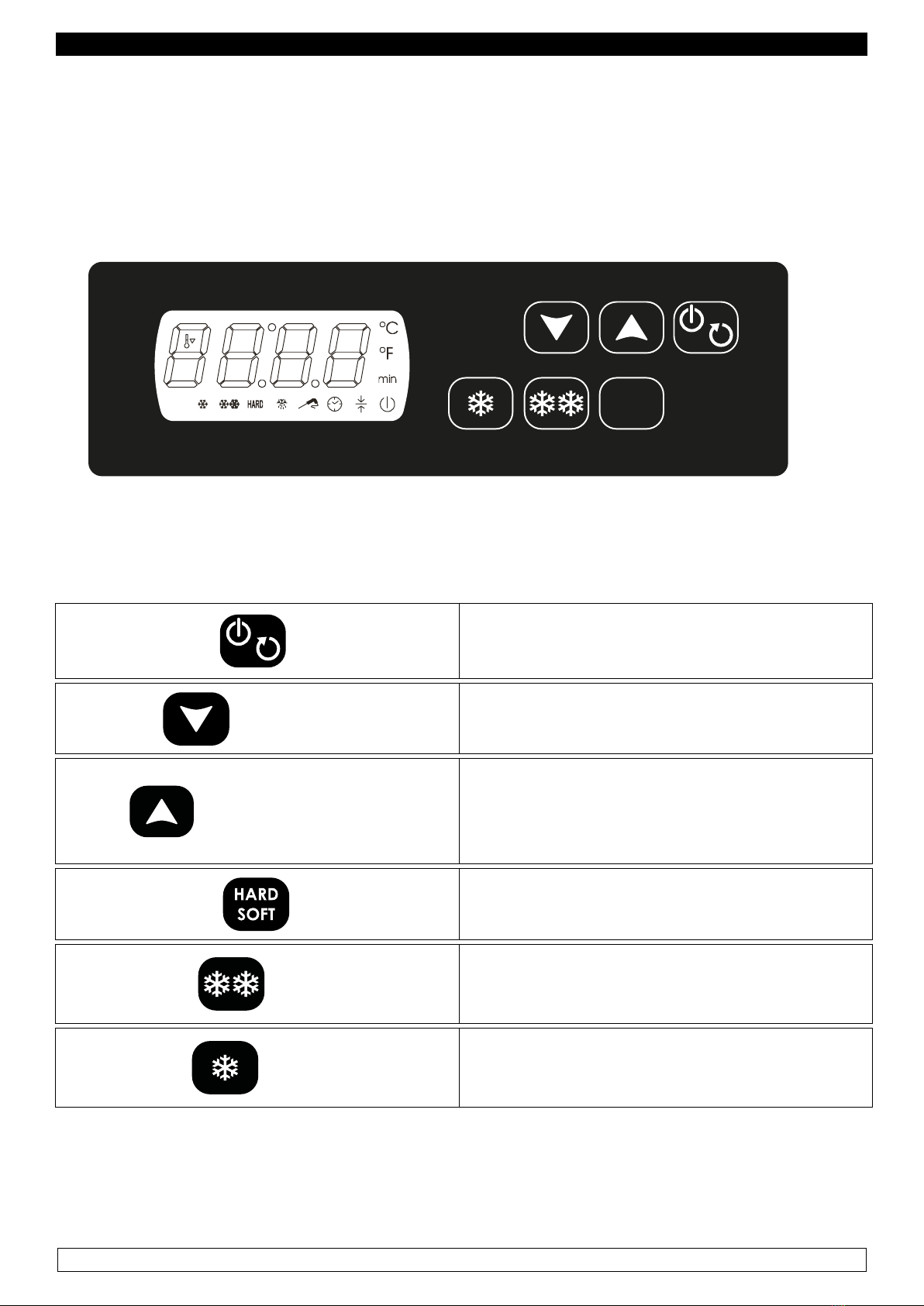

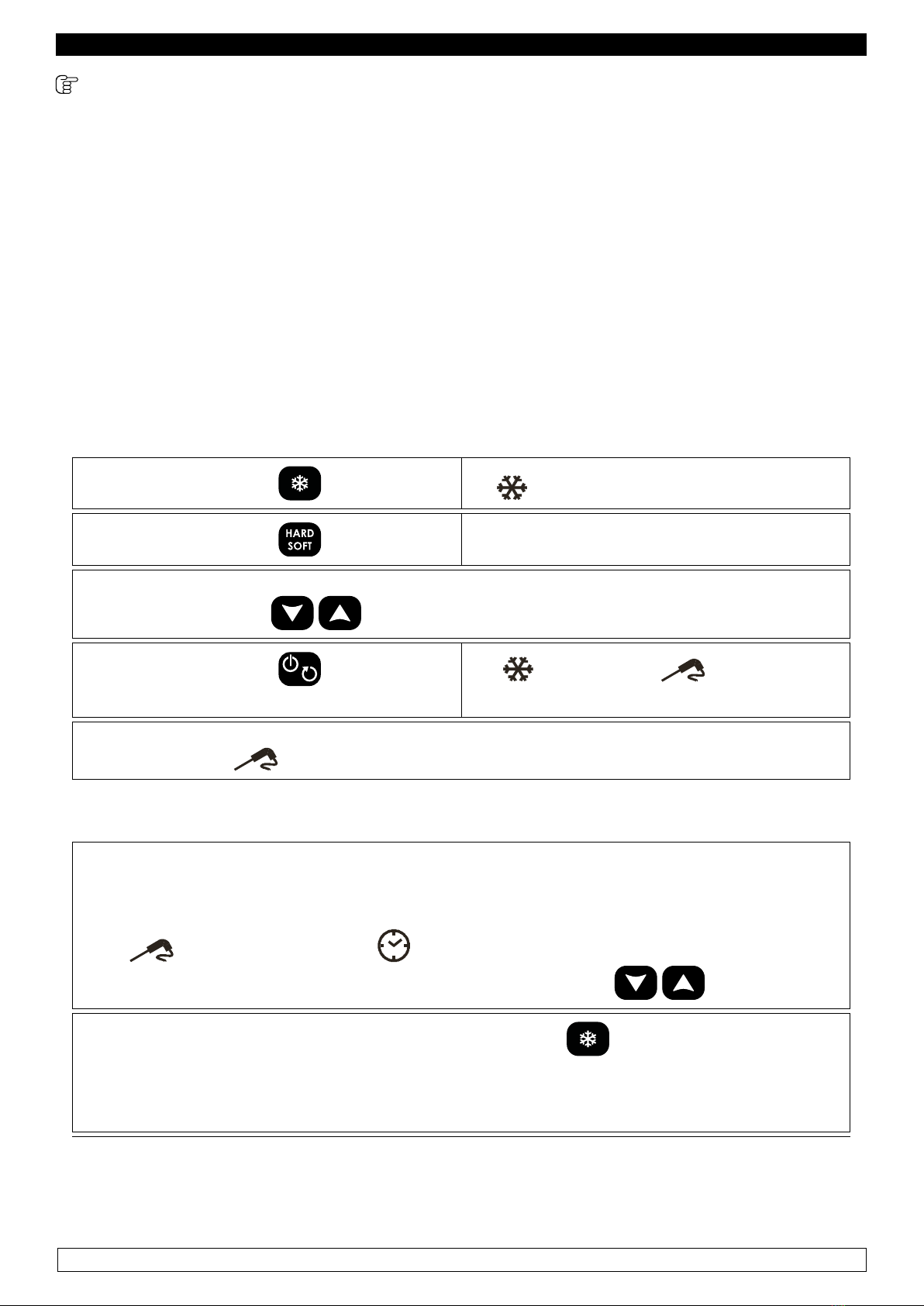

9.1 Description of the controls and of the keys ( Fig. 3)

The control panel is a digital thermoregulator for cold, and it is provided with 6 keys with specific

functions:

HARD

SOFT

Fig.3

The control keys of the blast chiller are:

START/STOP Key

Turns the blast chiller on or off, Pressing the key

for 3 seconds and allows you to start or stop a

cycle

DOWN Key

Reduces a value.

UP Key

Increases a value.

When control board is in “ON” mode, it activates

a manual defrosting cycle, pressing the key for 4

seconds. Only if the evaporator requires it.

HARD / SOFT Key

For selecting a Hard or Soft cycle.

FREEZING Key

Turns on a freezing cycle.

CHILLING Key

Turns on a positive chilling cycle.

Nb. To silence the acoustic BUZZER, press and release any key.

9

ENGLISH

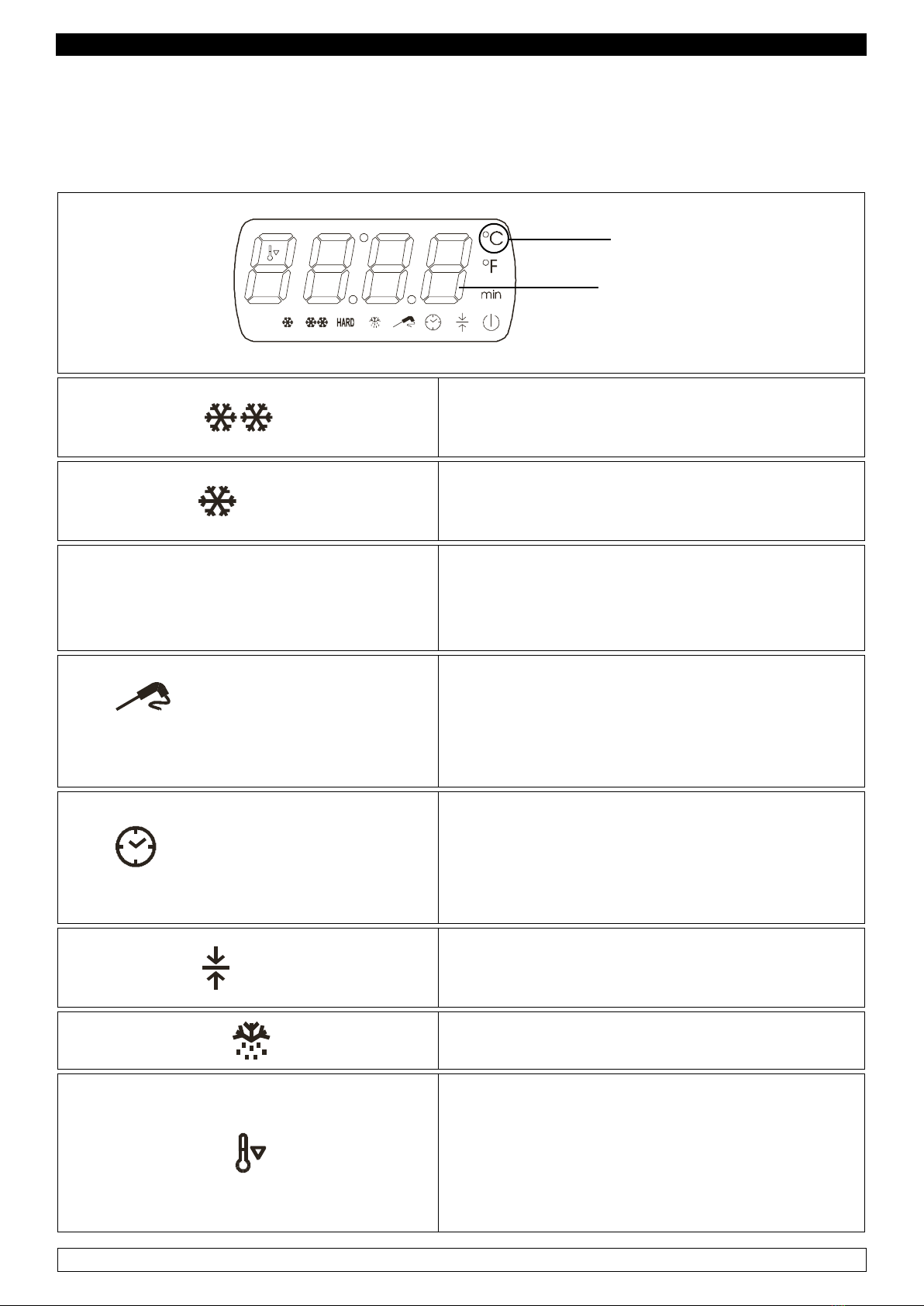

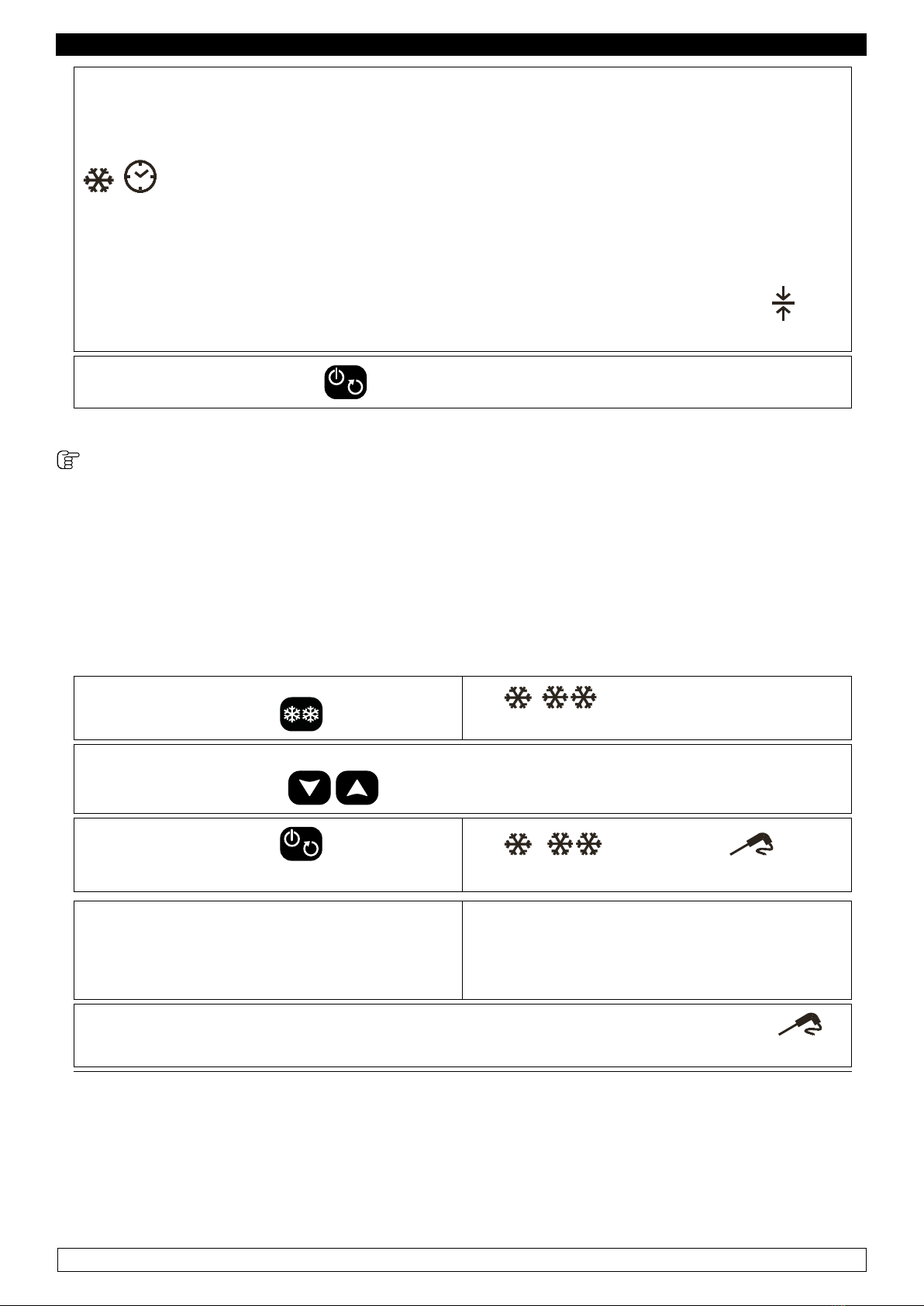

Display

Visualization is carried out through a display where you can see four digits , once on, they turn blue,

and twelve icons. For ease of reference, from now on the four digits will be designed as “display”,

and each icon will be identified singularly.

DIGIT

ICONS

FREEZING Icon

►Flashes while selecting a freezing cycle

►Remains on during the freezing cycle

CHILLING Icon

►Flashes while selecting a chilling cycle

►Remains on during the chilling cycle

HARD Icon

HARD CHILLING / FREEZING

►Flashes while selecting a Hard chilling or freezing

cycle

►Remains on during the Hard chilling or freezing

cycle

Icons

TEMPERATURE-BASED CHILLING / TEM-

PERATURE-BASED FREEZING ICON

►Remains on while selecting:

- A chilling cycle with core probe

- A temperature-based freezing cycle

►Flashes during the test attesting that the core probe

has been correctly inserted

Icons

TIME CHILLING / TIME FREEZING ICON

►Remains on:

- While selecting a time chilling cycle

- While selecting a time freezing cycle

STORAGE Icon

►Remains on during a storage cycle

►Flashes when displaying the room’s temperature

DEFROSTING Icon ►Remains on while defrosting is being carried out

PRECOOLING Icon

►Remains on while precooling is being carried out,

and the room’s temperature has reached the pre-set

parameters

►Flashes when precooling is being carried out, and

the room’s temperature has not reached the pre-set

parameters

10

ENGLISH

FAHRENHEIT °F Icon ►Remains on when displaying a temperature mea-

sured in Fahrenheit degrees

CELSIUS °C Icon ►Remains on when displaying a temperature mea-

sured in Celsius degrees

MINUTES min Icon ►Remains on when displaying a time lapse ex-

pressed in minutes (e.g. the duration of a chilling /

freezing cycle)

OFF Icon

►Remains on when the device is connected and

is OFF.

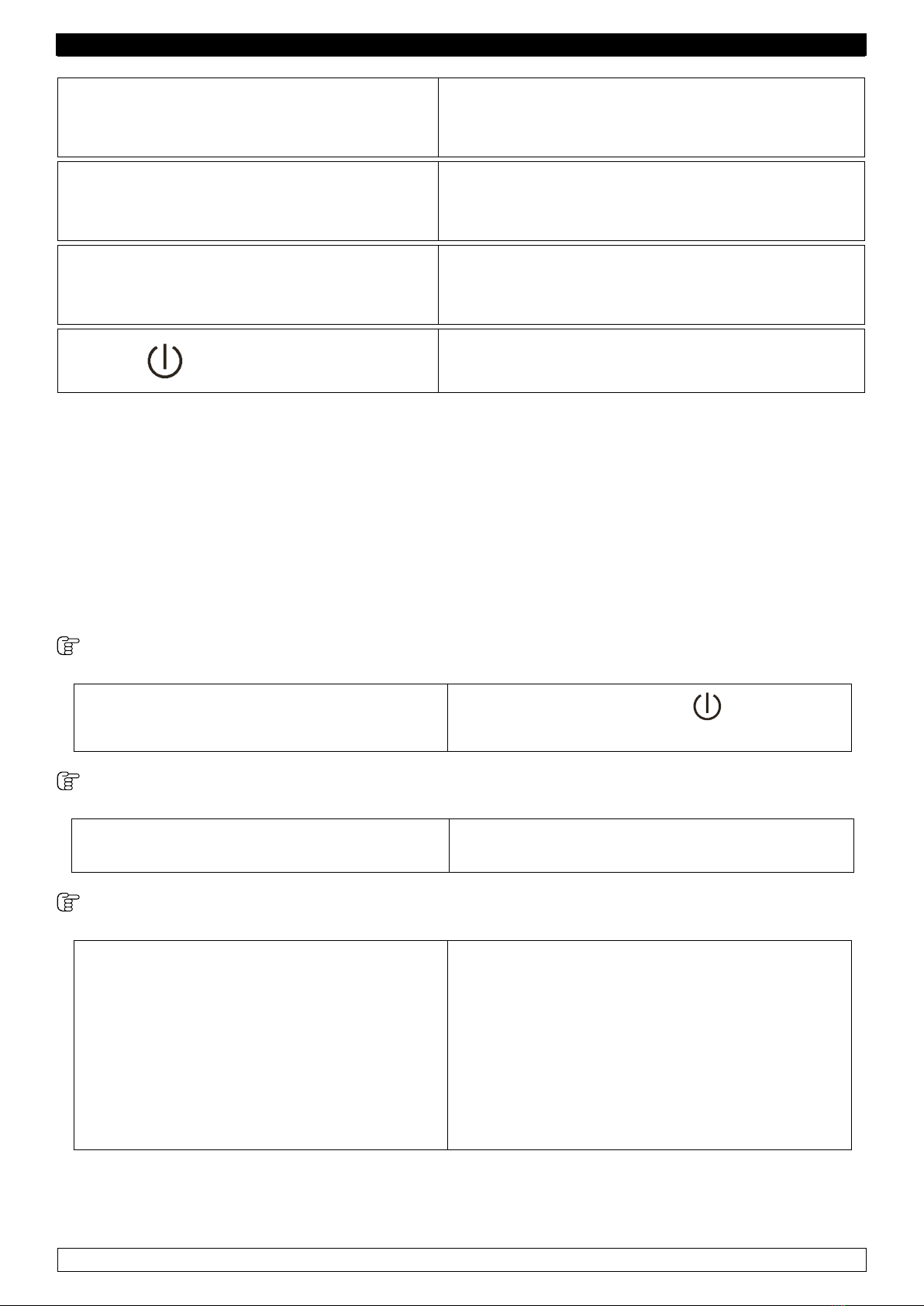

9.2 INSTRUCTION FOR USE

9.2.1 Start-up

Before starting up the blast chiller, please make sure that the power wiring and the connection have

been performed as per dispositions in chapter 15.

When the control board is fed, a two-seconds lamp test is carried out.

There are 3 statuses of functioning:

OFF status:

►the blast chiller is being fed and is off The display only shows the icon, coloured

in red.

ON/STAND-BY status:

►the blast chiller is being fed, is on and waiting

for a working cycle to be carried out.

The display shows the room’s temperature

RUN status:

►the blast chiller is being fed, is on, and a

working cycle is being carried out.

The display shows the following information:

►if a chilling or freezing cycle with core probe

is being carried out, the display shows the

temperature detected by the probe

►if a chilling cycle or a time-based freezing is being

carried out, the display shows the time remaining

before the end of the current cycle

►if a storage cycle is being carried out, the display

shows the room’s temperature

11

ENGLISH

9.2.2 Turn on/off

- Make sure the keyboard is not locked (chapter 11) and that no procedures are being carried out.

Press the START/STOP (ON/OFF) key for 3 seconds to turn on and off the blast chiller.

The icon turns on or off.

9.2.3 Operation

The blast chiller carries out chilling or freezing cycles, which can be Hard and Soft, time-based (set-

ting the duration of the cycle) and temperature-based (checking the core temperature of the product

via core probe).

Before each working cycle, a precooling may be carried out (Par. 9.2.12).

Before each cycle with a core probe, a test is carried out, to make sure the probe has been correctly

inserted; if it is not inserted, time-based cycles will start automatically continued in time.

Each chilling / freezing cycle is followed by a storage cycle.

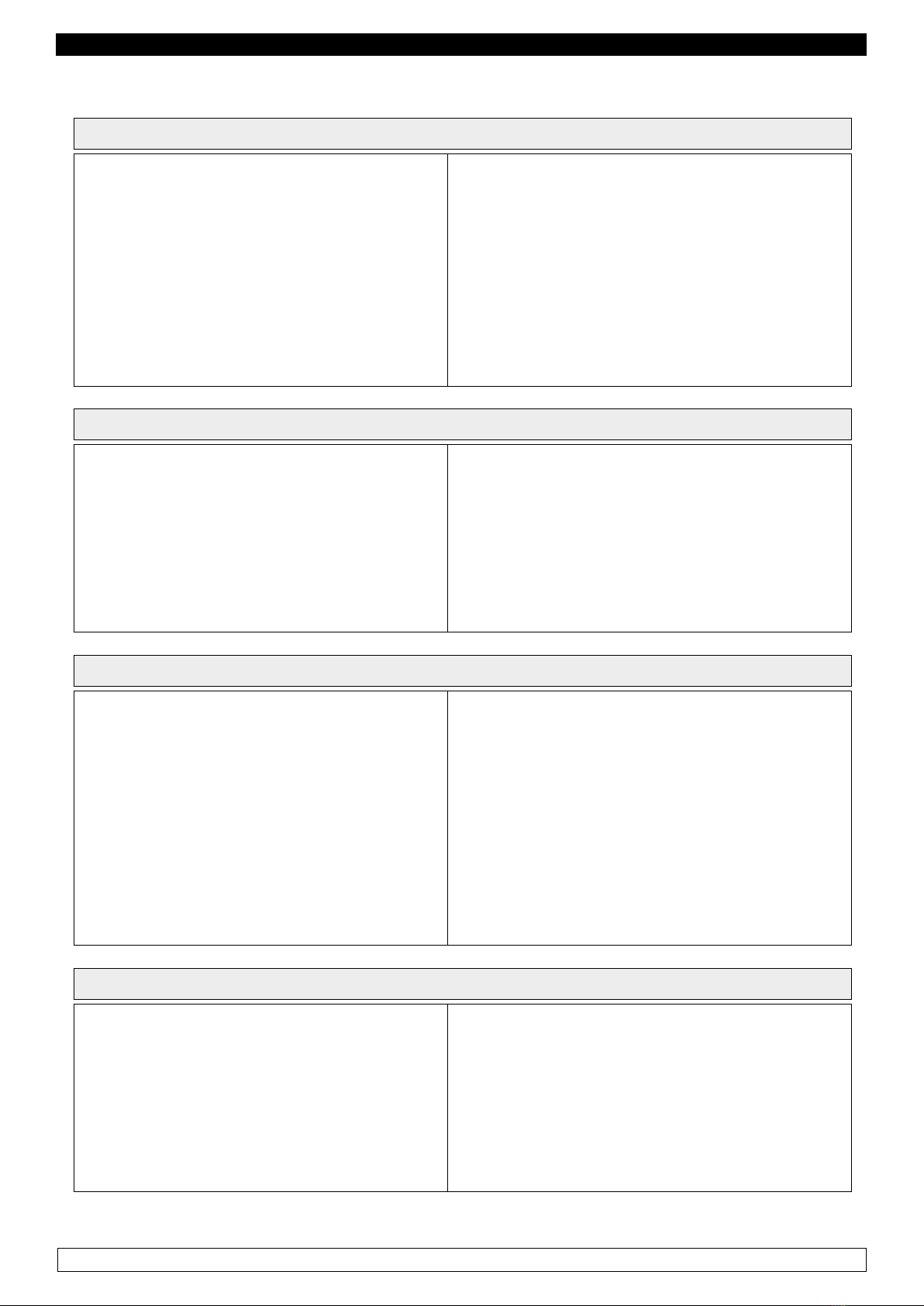

CHILLING

TYPE

TEMPERATURE

RANGE

SUGGESTED

PRODUCTS

CHILLING

SOFT

►Core temperature of the product +90°C / +3°C

►The air temperature inside the room never goes

below zero.

Delicate, thin or small

products such as vegeta-

bles, rice and fried pro-

ducts.

CHILLING

HARD

►Core temperature of the product +90°C / +3°C

►The air temperature inside the room reaches -20°C.

Ideal for dense, fat, big in

size or packed products.

FREEZING

SOFT

►Core temperature of the product +90°C / -18°C

►The air temperature inside the room reaches 0°C

during the rst phase, and reaches even -40°C during

the second phase.

Ideal for any foodstuff

that, once freezed, is due

to be stored for many

weeks or months. Soft

freezing is suitable for

delicate and small pro-

ducts, needing a softer

freezing process

FREEZING

HARD

►Core temperature of the product +90°C / -18°C

►The air temperature inside the room reaches -40°C

Ideal for any foodstuff

that, once freezed, is due

to be stored for many

weeks or months. Hard

freezing is suitable for

products that are big in

size and are not affected

by a fast temperature

decrease.

12

ENGLISH

DESCRIPTION OF CYCLES

POSITIVE CHILLING WITH CORE PROBE

SOFT - Chapetr 9.2.4

►Room temp. setpoint.: 0°C

►Core probe temp. setpoint.: 3°C

+

SORING CYCLE

►Setpoint Temp. room: 2°C

HARD - Chapetr 9.2.5

a) 1st phase

►Room temp. setpoint.: -20°C

►Core probe temp. setpoint.: 15°C

a) 2nd phase

►Room temp. setpoint.: 0°C

►Core probe temp. setpoint.: 3°C

+

STORAGE CYCLE

►Room temp. setpoint.: 2°C

POSITIVE TIME-BASED CHILLING

SOFT - Chapetr 9.2.6

100% of time Soft chilling

►Room temp. setpoint.: 0°C

+

STORAGE CYCLE

►Room temp. setpoint.: 2°C

HARD - Chapetr 9.2.7

60% of time Hard chilling

►Room temp. setpoint.: -20°C

40% of time Soft chilling

►Room temp. setpoint.: 0°C

+

STORAGE CYCLE

►Room temp. setpoint.: 2°C

FREEZING WITH CORE PROBE

SOFT - Chapetr 9.2.9

a) 1st phase

►Room temp. setpoint.: 0°C

►Core probe temp. setpoint.: +3°C

a) 2nd phase

►Room temp. setpoint.: -40°C

►Core probe temp. setpoint.: -18°C

+

STORAGE CYCLE

►Room temp setpoint: -20°C

HARD - Chapetr 9.2.8

►Room temp setpoint: -40°C

►Core probe temp. setpoint: -18°C

+

STORAGE CYCLE

►Room temp. setpoint.: -20°C

TIME-BASED FREEZING

SOFT - Chapetr 9.2.11

60% of time Soft chilling

►Room temp. setpoint.: 0°C

40% of time Hard chilling

►Room temp. setpoint.: -40°C

+

STORAGE CYCLE

►Room temp. setpoint.: -20°C

HARD - Chapetr 9.2.10

100% of time Hard chilling

►Room temp. setpoint.: -40°C

+

STORAGE CYCLE

►Room temp. setpoint.: -20°C

13

ENGLISH

9.2.4 POSITIVE SOFT CHILLING with core probe and subsequent storage

The time-based chilling and storage cycle consists in two phases:

►1st phase: Soft chilling cycle (Room temp. setpoint 0°C; Core probe temp. setpoint 3°C)

►2nd phase: Storage (Room temp. setpoint 2°C)

- Make sure the blast chiller is in “

ON/STAND-BY

” mode, that the keyboard is not locked (chapter 11) and

that no procedures are being carried out.

► Press and release the key: the icon starts ashing

The display shows the room’s temperature setpoint.

► It is possible to use the keys to modify this value.

► Press and release the key within 20

seconds:

and icons remain on, and a one-

minute test is carried out, to make sure the core

probe has been correctly inserted:

►If the test has a positive outcome, the chilling

cycle with core probe does not stop.

►If the test has a negative outcome (e.g. core

probe not inserted), the acoustic buzzer warns

us 3 times (each 10 seconds) that the core probe

has not been inserted. In this case there is no

need to press any keys, after 30 seconds a time-

based cycle automatically begins.

During the chilling cycle a temperature, the display shows the temperature detected by the

core probe, and the icon is on.

► It is possible to display the room’s temperature in any moment, pressing and releasing the

key.

►To restore the standard display mode, press and release the same key or do not operate for

15 seconds.

►Once the chilling cycle has been carried out, the blast chiller automatically switches to a

storage cycle.

►During the storage, the display shows the temperature detected by the room probe and the

icon is on.

► To stop any cycle, press the key.

NB: If the required temperature is not reached within the scheduled time (positive chilling: 90 min,

freezing: 240 min), a recursive beep is issued as warning.

The blast chiller keeps chilling / freezing until reaching the scheduled temperature. Failure to reach

the temperature within the scheduled time may take place when introducing products which are

bigger in size or weight compared with the standard ones or products with higher temperature of the

maximum allowed.

14

ENGLISH

9.2.5 POSITIVE HARD CHILLING WITH CORE PROBE and subsequent storage

The chilling cycle with core probe and subsequent storage consists in three phases:

►1st phase: Hard chilling cycle (Room temp. setpoint -20°C; Core probe temp. setpoint 15°C)

►2nd phase: Soft chilling cycle (Room temp. setpoint 0°C; Core probe temp. setpoint 3°C)

►3nd phase: Storage (Room temp. setpoint 2°C)

After completing a phase, the blast chiller automatically switches to the next one.

- Make sure the blast chiller is in “ON/STAND-BY” mode, that the keyboard is not locked (chapter

11) and that no procedures are being carried out.

► Press and release the key the icon starts ashing.

► Press and release the key the HARD and icon ash

The display shows the working setpoint during the chilling.

► It is possible to use the keys to modify this value.

► Press and release the key within 20

seconds

the , HARD and icon remain

on, and a one-minute test is carried out, to

make sure the core probe has been correctly

inserted:

►If the test has a positive outcome, the chilling

cycle with core probe starts.

►If the test has a negative outcome (e.g. core

probe not inserted), the acoustic buzzer warns

us 3 times (each 10 seconds) that the core

probe has not been inserted. In this case there

is no need to press any keys, after 30 seconds

automatically begins a time-based cycle.

During the chilling cycle, the display shows the temperature detected by the core probe, and

the icon is on.

► It is possible to display the room’s temperature in any moment, pressing and releasing the

key.

► To restore the standard display mode, press and release the same key or do not operate for

15 seconds.

► Once the chilling cycle has been carried out, the blast chiller automatically switches to a

storage cycle.

► During the storage, the display shows the temperature detected by the room probe and the

icon is on.

► To stop the cycle, press the key.

15

ENGLISH

NB: If the required temperature is not reached within the scheduled time (positive chilling: 90 min,

freezing: 240 min), the control board emits a repeated loud bleep as a warning.

The blast chiller keeps chilling / freezing until reaching the scheduled temperature. Failure of reaching

the temperature within the scheduled time may take place when introducing products which are

bigger in size or weight compared with the standard ones or products with higher temperature of the

maximum allowed.

9.2.6 SOFT TIME-BASED CHILLING and subsequent storage

In order to select a time-based chilling cycle, you just need to make sure not to insert the core probe.

The Soft time-based and storage cycle consists in two phases:

►1st phase:Soft chilling cycle (Room temp. setpoint 0°C during the whole cycle)

►2nd phase: Storage phase (Room temp. setpoint 2°C)

- Make sure the core probe is not inserted.

- Make sure the blast chiller is in “ON/STAND-BY” mode, that the keyboard is not locked (chapter

11) and that no procedures are being carried out.

► Press and release the key the icon starts ashing

The display shows the working setpoint during chilling.

► It is possible to use the keys to modify this value and modify the values with the same keys

► Press and release the key within 20

seconds:

The icons remain on and the cycle

starts

► The control board carries out a one-minute test, to make sure the core probe has been cor-

rectly inserted, the icon ashes during the whole test, and turns off at the end of it.

► If the core probe has not been correctly inserted, the acoustic buzzer warns us 3 times (each

10 seconds).

► There is no need to press any keys, a time-based cycle will automatically begin.

During the chilling, the display shows the temperature detected by the room probe and the

and min icons remain on.

► It is possible to modify the duration of the cycle by pressing the keys.

► To display the room’s temperature, press and release the . To restore the standard

display mode, press and release the same key or do not operate for 15 seconds.

►Once the chilling has been completed, according to the scheduled duration, the blast chiller

automatically switches to storage.

-During storage, the display shows the temperature detected by the probe, and the icon is on

.

►To stop the cycle, press the key.

16

ENGLISH

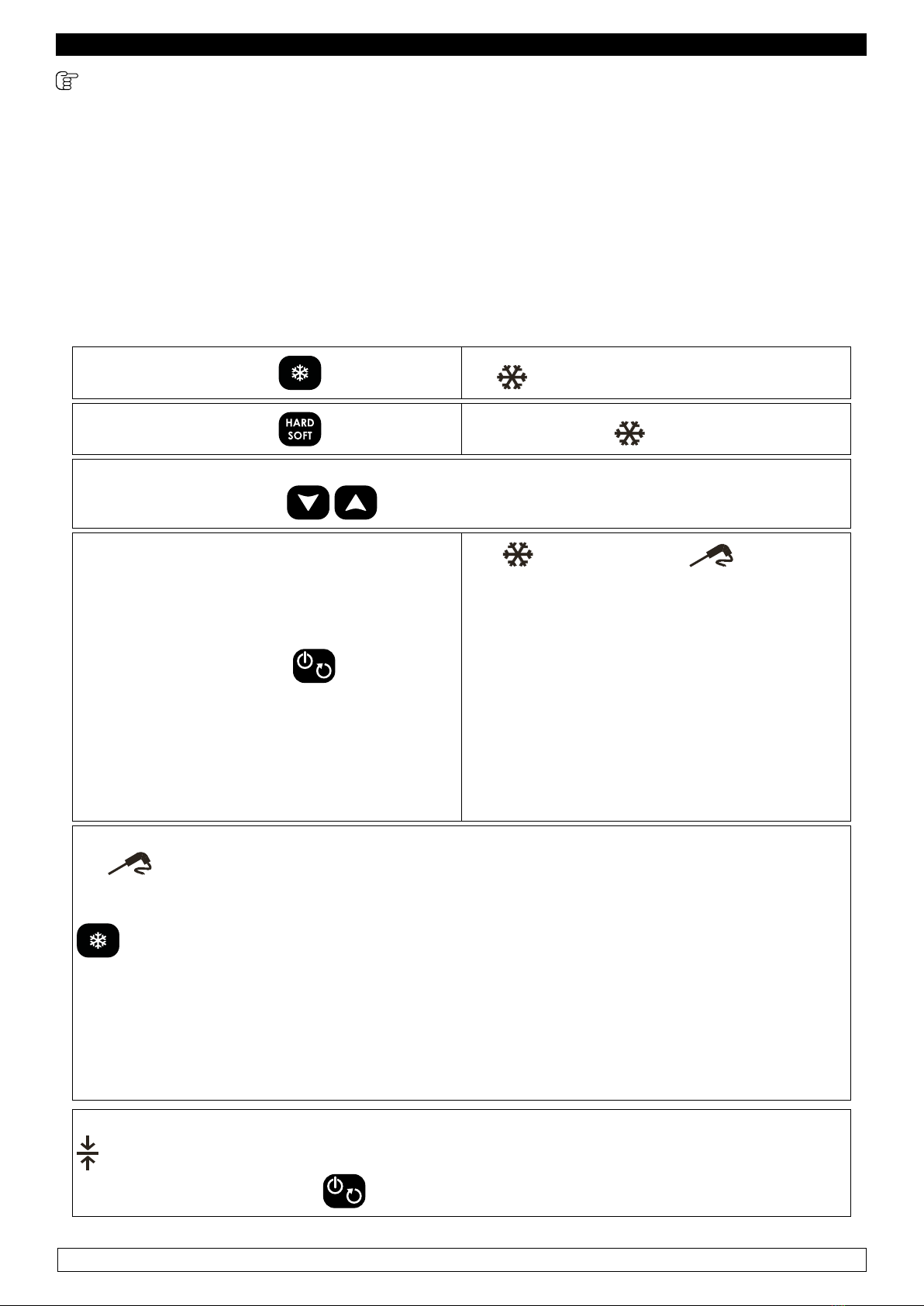

9.2.7 HARD TIME-BASED CHILLING and subsequent storage

In order to select a time-based chilling cycle, you just need to make sure not to insert the core

probe.

The Soft time-based and storage cycle consists in three phases:

►1st phase: Hard chilling cycle (60% of the whole duration of the cycle; Room temp. setpoint -20°C)

►2nd phase: Soft chilling cycle (40% of the whole duration of the cycle; Room temp. setpoint -0°C)

►3nd phase: Storage cycle (Room temp. setpoint: 2°C)

After completing a phase, the blast chiller automatically switches to the next one.

- Make sure the core probe is not inserted

- Make sure the blast chiller is in “ON/STAND-BY” mode, that the keyboard is not locked (chapter

11) and that no procedures are being carried out.

► Press and release the key: the icon starts ashing

► Press and release the key the HARD icon starts ashing

The display shows the working setpoint during the chilling.

It is possible to use the keys to modify this value

► Press and release the key within 20

seconds:

The ,HARD and icon remain on

and the cycle starts

► The control board carries out a one-minute test, to make sure the core probe has been cor-

rectly inserted, the icon ashes during the whole test, and turns off at the end of it.

If the core probe has not been correctly inserted, the acoustic buzzer warns us 3 times (each

10 seconds). There is no need to press any keys, a time-based cycle will automatically begin.

► During the chilling, the display shows the time remaining before the end of the cycle.

► The ’icon turns off, while the and min icons remain on.

► It is possible to modify the duration of the cycle by pressing the keys.

► To display the room’s temperature, press and release the key.

► To restore the standard display mode, press and release the same key or do not operate

for 15 seconds.

17

ENGLISH

►Once the Hard chilling has been completed, according to the scheduled duration, the blast

chiller automatically switches to chilling SOFT.

►display shows the time remaining before the end of the chilling, the

, and min remain on

► Once the chilling has been completed, according to the scheduled duration, the blast chiller

automatically switches to storage.

► During storage, the display shows the temperature detected by the probe, and the icon

is on.

► To stop the cycle, press the key.

9.2.8 HARD FREEZING WITH CORE PROBE and subsequent storage

The freezing time-based and storage cycle consists in two phases:

►1st phase:Hard freezing cycle (Room temp. setpoint -40°C; Core probe temp. setpoint -18°C)

►2nd phase: Storage cycle (Room temp. setpoint -20°C)

- Make sure the blast chiller is in “ON” mode, that the keyboard is not locked (chapter 11) and that

no procedures are being carried out.

► Press and release the key

The , and HARD icons starts

ashing

The display shows the temperature setpoint during the chilling.

► It is possible to use the keys to modify this value

► Press and release the key within 20

seconds:

The , , HARD and icon

remain on.

A test is carried out, to make sure the core

probe has been correctly inserted:

►If the test has a positive outcome, the

storing cycle with core probe is activated.

►If the test has a negative outcome, a time-

based chilling cycle is activated.

►During freezing, the display shows the temperature detected by the probe, and the

icon is on.

18

ENGLISH

► To display the room’s temperature, press and release the key. To restore the standard

display mode, press and release the same key or do not operate for 15 seconds.

► Once the freezing has been completed, the blast chiller automatically switches to storage.

► During storage, the display shows the temperature detected by the probe, and the icon

is on.

► To stop the cycle, press the key.

NB: If the required temperature is not reached within the scheduled time (positive chilling: 90 min,

freezing: 240 min), the control board emits a repeated loud bleep as a warning.

The blast chiller keeps chilling / freezing until reaching the scheduled temperature.

Failure to reach the temperature within the scheduled time may take place when introducing

products which are bigger in size or weight compared with the standard ones of the maximum

allowed.

9.2.9 SOFT FREEZING WITH CORE PROBE and subsequent storage

The Sorf temperature-based freezing and storage cycle consists in three phases:

►1st phase: Soft freezing cycle (Room temp. setpoint 0°C; Core probe temp. setpoint +3°C)

►2nd phase: Hard Freezing cycle (Room temp. setpoint -40°C; Core probe temp. setpoint -18°C)

►3nd phase: Storage cycle (Room temp. setpoint -20°C)

After completing a phase, the blast chiller automatically switches to the next one.

- Make sure the blast chiller is in “ON” mode, that the keyboard is not locked (chapter 11) and that

no procedures are being carried out.

►

Press and release the key The , and HARD icon starts

ashing

►

Press and release the key the HARD icon turns off

The display shows the temperature setpoint during the freezing.

►

It is possible to use the keys to modify this value

► Once the values have been modied, press and

release the

key

The , and icons remain on

and a test is carried out to make sure the probe

has been correctly inserted.

►

If the test has a positive outcome, the

temperature-based freezing cycle is activated.

►

If the test has a negative outcome, a time-

based chilling cycle is activated.

19

ENGLISH

► During the Soft freezing phase, the display shows the temperature detected by the probe, and the

icon is on.

►

To display the room’s temperature, press and release the key. To restore the standard

display mode, press and release the same key or do not operate for 15 seconds.

►

Once the Soft freezing phase has been completed, the blast chiller automatically switches to

freezing.

►

During the freezing phase, the display shows the temperature detected by the probe, and the

icon is on.

Once the freezing phase has been completed, too, the blast chiller automatically switches to the storage

phase.

►During the storage phase, the display shows the temperature detected by the probe, and the

icon is on.

► To stop the cycle, press the

key

NB: If the required temperature is not reached within the scheduled time (positive chilling: 90 min,

freezing: 240 min), the control board emits a repeated loud bleep as a warning.

The blast chiller keeps chilling / freezing until reaching the scheduled temperature.

Failure to reach the temperature within the scheduled time may take place when introducing products

which are bigger in size or weight compared with the standard ones of the maximum allowed.

9.2.10 HARD TIME-BASED FREEZING and subsequent storage

In order to select a HARD time-based freezing cycle, you just need to make sure not to insert the

core probe

The time-based freezing and storage cycle consists in two phases:

►1st phase: Hard Freezing cycle (Room temp. setpoint -40°C during the whole cycle)

►2nd phase: Storage cycle (Room temp. setpoint -20°C)

- Make sure the core probe is not inserted.

- Make sure the blast chiller is in “ON” mode, that the keyboard is not locked (chapter 11) and that

no procedures are being carried out.

►

Press and release the key:

The , and HARD icons starts

ashing

The display shows the working setpoint during the freezing.

►

It is possible to use the keys to modify this value.

This manual suits for next models

10

Table of contents

Other Everlasting Freezer manuals

Popular Freezer manuals by other brands

Electrolux

Electrolux ERN29801 user manual

montpellier

montpellier MIFF730FF Installation and operating instructions

Zanussi

Zanussi ZFG06400WA user manual

Electrolux

Electrolux E32AF75FPS - Icon - Refrigerator Dimension Guide

Zanussi

Zanussi ZV280P Instruction booklet

montpellier

montpellier MTTF32W Installation and operating instructions