Evopower EPW3100-2 User manual

INSTRUCTIONS FOR

7.0HP & 14.0HP Petrol

Pressure Washers

Model #s: EPW3100-2, EPW185-70AR & EPW275-14AR

PLEASE READ THESE INSTRUCTIONS CAREFULLY TO ENSURE THE SAFE AND EFFECTIVE USE

OF THIS PRODUCT.

GENERAL INFORMATION

This manual has been compiled by Genpower Ltd and should be read carefully before operation of your Evopower pressure washer in order to ensure its safe

and correct use. This manual should also be kept safe for future reference. This manual contains information including general safety instructions, how

to assemble the machine and its operation and usage. Whilst every effort has been made to ensure all information supplied in this manual is accurate,

modifications may be made without prior warning.

*EPW185-70AR / EPW275-14AR

2

CONTENTS

Contents/Guarantee..............................................................................................2

Specification.......................................................................................................3-4

General Safety Instructions....................................................................................5

Getting to Know Your Pressure Washer.................................................................6

Assembly...........................................................................................................7-10

Operation and Use..........................................................................................11-19

Maintenance...................................................................................................20-23

Troubleshooting..............................................................................................23-24

Declaration of Conformity....................................................................................25

Contact.................................................................................................................26

GUARANTEE

All Evopower products are carefully checked and tested before being dispatched to the customer to ensure

any problems that may occur are kept to an absolute minimum.

The Evopower pressure washers come with a one year return-to-base guarantee and a two year return-to-

base guarantee on the engine.

However, if we receive any machines back with a non-warranty fault the customer will be charged for

carriage both ways, labour and any parts used. To try and minimise the chances of this happening, please

call and speak to one of our technicians before sending the machine back.

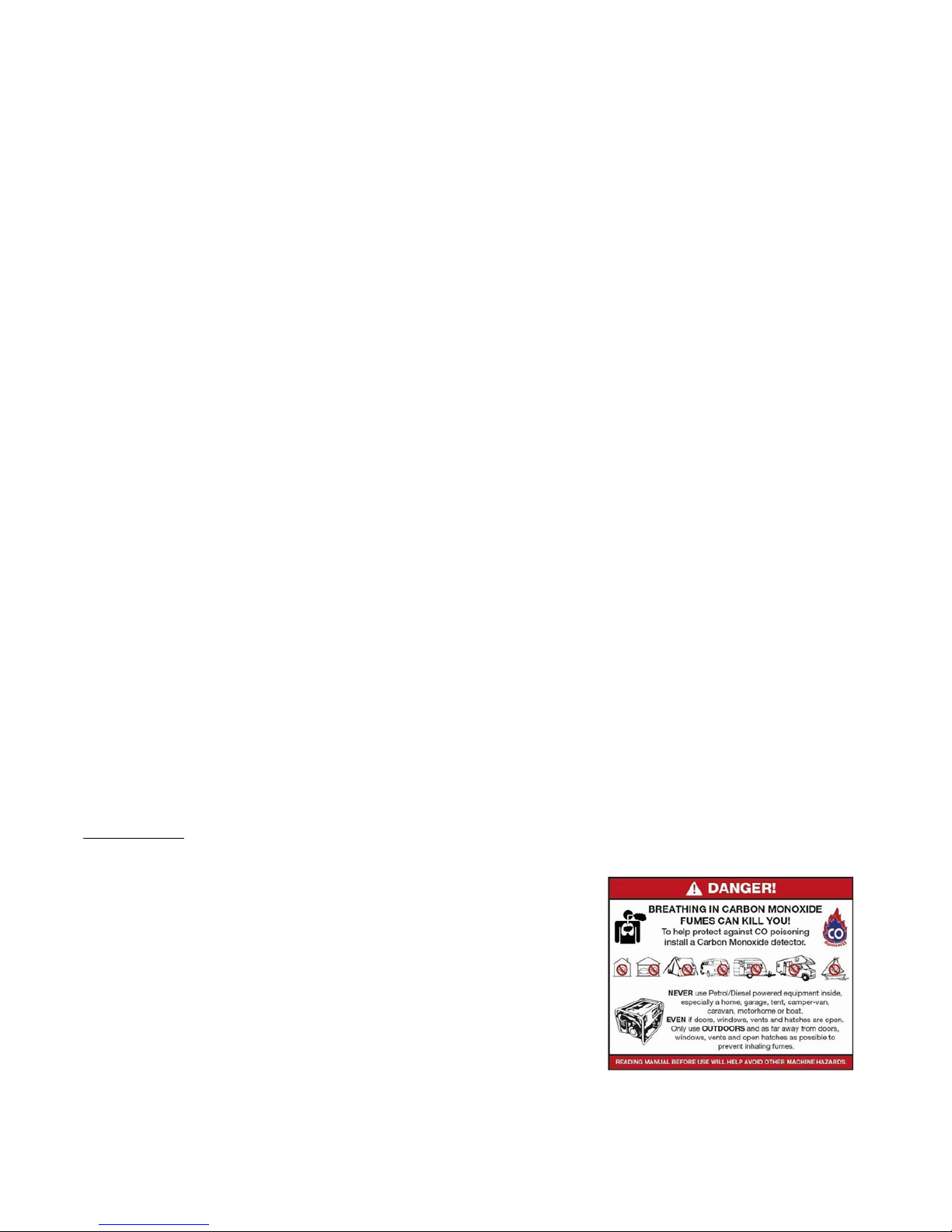

Carbon monoxide.

Carbon monoxide is a colourless and odourless gas. Inhaling this gas can cause death as well as

serious long term health problems such as brain damage.

The symptoms of carbon monoxide poisoning can include but are not limited to the following;

Headaches, dizziness, nausea, breathlessness, collapsing or loss of consciousness.

Carbon monoxide poisoning symptoms are similar to flu, food poisoning, viral infections and

simply tiredness. It is quite common for people to mistake this very dangerous poisoning for

something else.

To avoid carbon monoxide poisoning DO NOT use Petrol/Diesel- powered equipment inside any

of the following;

Home, garage, tent, camper van, mobile home, caravan or boat.

This list is not exhaustive and if you are in any doubt contact your dealer.

If you think you have or someone around you has been affected by carbon monoxide poisoning;

Get them fresh air immediately, by leaving the affected area or by opening doors and windows.

If safe and practical to do so make sure that the machine is turned off. DO NOT enter a room

you suspect of having carbon monoxide present – instead call the emergency services.

Contact a doctor immediately or go to hospital - let them know that you suspect carbon

monoxide poisoning.

DO NOT use in an enclosed area or a moving vehicle.

Rev 2

3

SPECIFICATION - EPW3100-2

Part No...................................................................................................EPW3100-2

Engine......................................................................................7.0HP OHV 4-Stroke

Starting Method.......................................................Recoil Start with CDI Ignition

Capacity........................................................................................................212cc

Machine is marked with a 210cc label the cc has just been rounded down.

Max Pressure.................................................................................210bar, 3045psi

Rated Pressure...............................................................................185bar, 2685psi

Litres/Hour.........................................................................................................410

Noise.....................................................................................................70db@7m

Wheels.........................................................Heavy duty single piece wide wheels

Pump....................................................................................BE RX710 Axial Pump

Dimensions...........................................H500mm x W540mm x L570mm (Folded)

Ceramic Pistons................................................................................................Yes

Brass Pump Head..............................................................................................Yes

Thermal Relief Valve.........................................................................................Yes

Adjustable Pressure..........................................................................................Yes

Low Oil Shutdown.............................................................................................Yes

Please ensure that approved eye, ear and foot protection are worn at all times when

machine is in operation.

Rev 2

4

SPECIFICATION - EPW185-70AR

Part No............................................................................................EPW185-70AR

Engine......................................................................................7.0HP OHV 4-Stroke

Starting Method.......................................................Recoil Start with CDI Ignition

Capacity........................................................................................................212cc

Max Pressure................................................................................185bar, 2685psi

Rated Pressure.............................................................................175bar, 2540psi

Litres/Hour.................................................................................................600l/hr

Noise.....................................................................................................70db@7m

Wheels.........................................................Heavy duty single piece wide wheels

Pump.....................................Annovi Reverberi Italian Commercial Triplex Pump

Dimensions.........................................................H940mm x W535mm x L770mm

Ceramic Pistons................................................................................................Yes

Brass Pump Head..............................................................................................Yes

Thermal Relief Valve.........................................................................................Yes

Adjustable Pressure..........................................................................................Yes

Low Oil Shutdown.............................................................................................Yes

Please ensure that approved eye, ear and foot protection are worn at all times when

machine is in operation.

Rev 2

5

SPECIFICATION - EPW275-14AR

Part No............................................................................................EPW275-14AR

Engine.......................................................................14.0HP Loncin OHV 4-Stroke

Starting Method.......................................................Recoil Start with CDI Ignition

Capacity........................................................................................................420cc

Max Pressure................................................................................275bar, 3988psi

Rated Pressure.............................................................................265bar, 3840psi

Litres/Hour.................................................................................................900l/hr

Noise.....................................................................................................70db@7m

Wheels.........................................................Heavy duty single piece wide wheels

Pump.....................................Annovi Reverberi Italian Commercial Triplex Pump

Dimensions.......................................................H1040mm x W595mm x L820mm

Ceramic Pistons................................................................................................Yes

Brass Pump Head..............................................................................................Yes

Thermal Relief Valve.........................................................................................Yes

Adjustable Pressure..........................................................................................Yes

Low Oil Shutdown.............................................................................................Yes

Please ensure that approved eye, ear and foot protection are worn at all times when

machine is in operation.

Rev 2

6

General Safety Instructions

-Please ensure that user instructions have been read carefully

before using the machine to ensure its safe and correct usage.

-The pressure washer has been designed for outdoor use only.

When using outdoors ensure all bystanders are at a safe

distance away to avoid injury.

-Before carrying out any maintenance, adjustments or cleaning

of the Pressure Washer, ensure that the machine is

completely switched off and the engine is cool. Also ensure

that the engine and water supply is turned off after each task.

-This pressure washer has been designed for use with specific

detergents such as neutral shampoo based on biodegradable

anionic surface active detergents. Please check before using

other detergents of chemicals as they may cause damage to

the appliance.

-Take care when using on mechanical parts that contain grease

as it will dissolve and can spread over the ground surrounding

the appliance. To avoid this happening, do not direct the

nozzle towards these parts.

-Ensure a minimum distance of 50cm is kept when cleaning

vehicle tyres due to the high pressure of the machine.

-For safety reasons, do not point the high pressure jets at

animals, people, live electrical parts or the appliance itself.

-Only use accessories such as high pressure hoses and

connections specified by the manufacturer.

-To avoid causing injury or damage to property, do not operate

the appliance until the nozzle is installed securely as high

pressure can cause water to be fired from the lance with

extreme force.

-Coverings such as paint and other surface treatment may be

removed if a high pressure jet is used. Damage may also be

caused to tarmac and grouting between paving slabs.

-Ensure that the machine is switched off completely when

unattended.

-Although the high pressure hose has been manufactured to

withstand high pressures, damage may be caused if used

incorrectly.

-Ensure that the machine is not used by children, persons with

reduced physical, sensory or mental capabilities or those who

lack the experience or knowledge to use the machine safely

and carefully.

-Before using the pressure washer ensure that the high

pressure hose has been unwound completely. Before

unwinding the hose, ensure the machine is switched off

completely.

-Ensure that any exhaust emissions are not in the

vicinity of air intakes. The exhaust fumes from petrol

engines contain harmful and hazardous amounts of

Carbon Monoxide, an odourless gas that can kill in

minutes in a poorly ventilated area.

MAINTENANCE

-Never attempt to modify your pressure washer in any

way.

-To keep your pressure washer in working order, ensure

that it is serviced regularly by an authorised service

agent.

-Only use parts in your machine specified by the

manufacturer.

-Use only high quality, clean, fresh oil in your machine

and never use the machine without oil.

-Never refuel your machine near sources of ignition

such as naked flames or sparks.

-Allow engine to cool before refuelling.

-If a spillage occurs, wipe up immediately.

-Ensure a safe distance is kept from the refuelling area

when restarting the engine.

-Ensure fuel is stored for a short time only and is stored

in the correct container away from direct sunlight and

heat.

-Clean the pressure washer thoroughly after each use

and regularly check external nuts and fixings to ensure

they are tight.

Rev 2

7

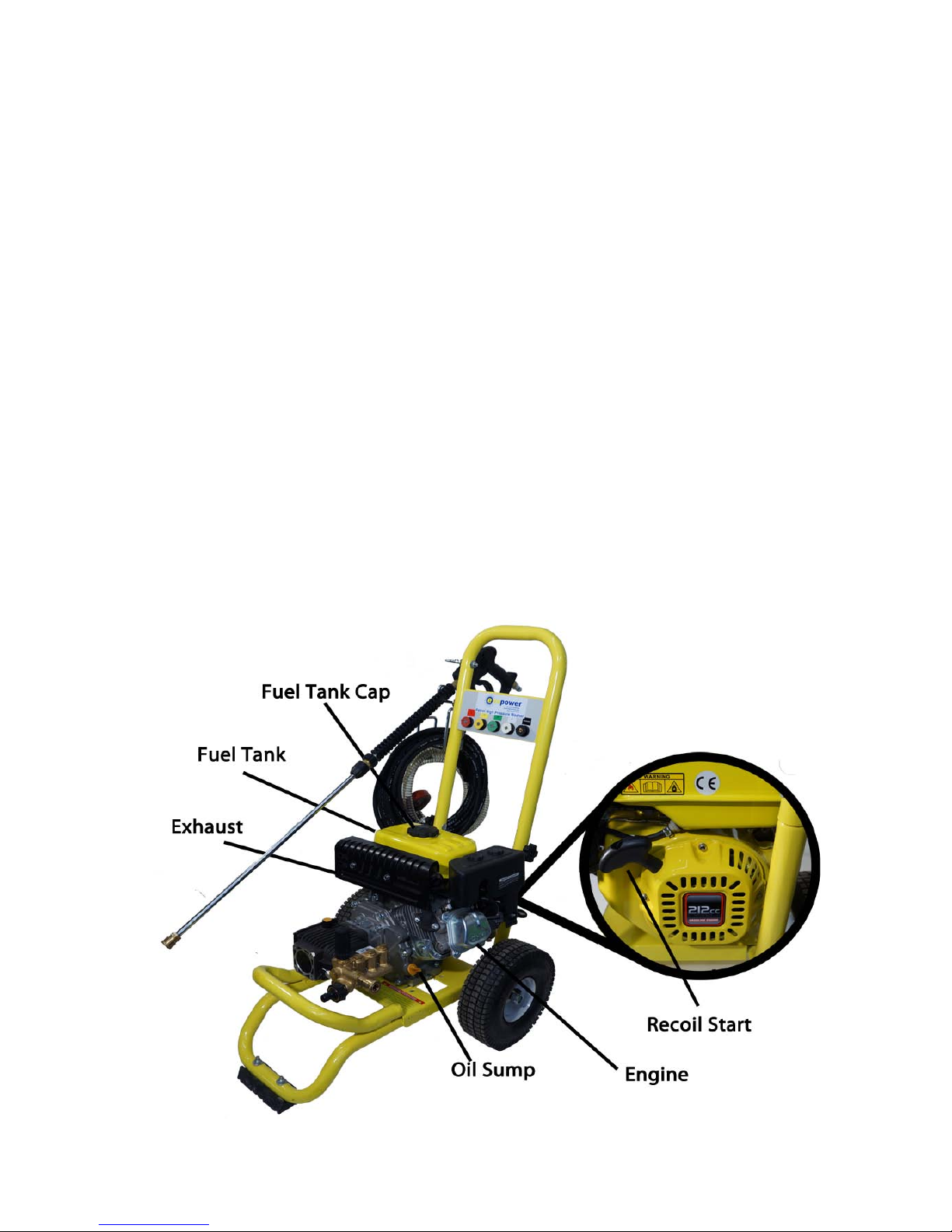

Getting to know your Petrol Pressure Washer

1: Engine

2: Pump

3:Removable Handle

4: Lower Frame

5: Wheels

6: Engine Recoil Start

7: Fuel Tank

8: Air Filter

9: Exhaust Silencer

10: Trigger Gun

11: Lance

12: Quick Release Nozzles

13: High Pressure Hose

14: Pump Outlet High Pressure Fitting

15: Pump Inlet Quick Release Fitting

16: Thermal Relief Valve

17: Engine Oil Filler Cap

18: Pump Oil Filler Cap

19: Suction Hose

UNPACKING: Ensure that all parts of the machine are in perfect condition before using the machine.

If in any doubt please give the manufacturer a call before using item.

Rev 2

8

Fig 1.

Fig 2.

Fig 3.

Fig 4.

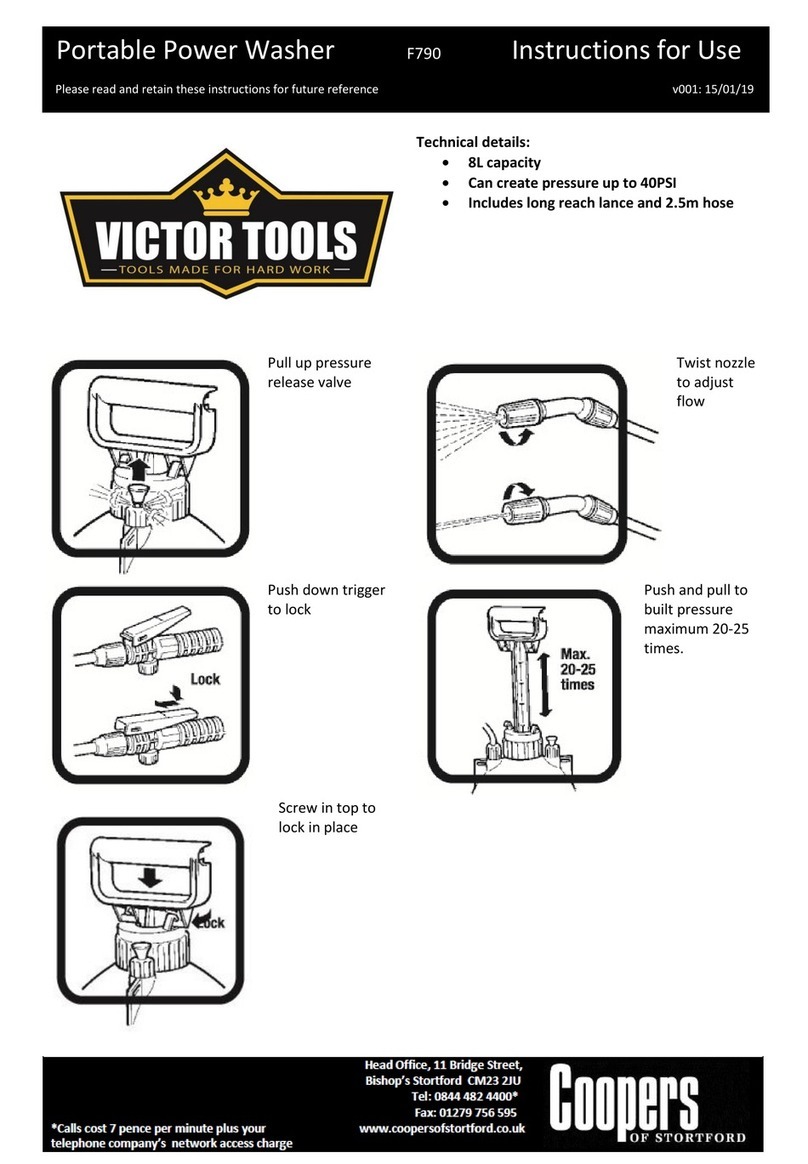

ASSEMBLY

NOTE: There may be a little bit of water

inside the pump assembly due to testing at

the factory.

-LOCATING THE UPPER FRAME (Figs 1-3)

Slide the upper frame over the corresponding uprights of the

lower frame (Fig 1) and secure with the bolts provided.

Secure the hose and lance holders onto the upper frame by

using the nuts and bolts provided. (Fig 2 & 3)

-TO ASSEMBLE THE RUBBER FEET (Fig 4)

To assemble the rubber feet, pass the bolt provided through

the foot and lower bracket located on the base of the machine

and secure in place with washer and nut.

Rev 2

9

Fig 5.

Fig 6.

Fig 7.

Fig 8.

ASSEMBLY

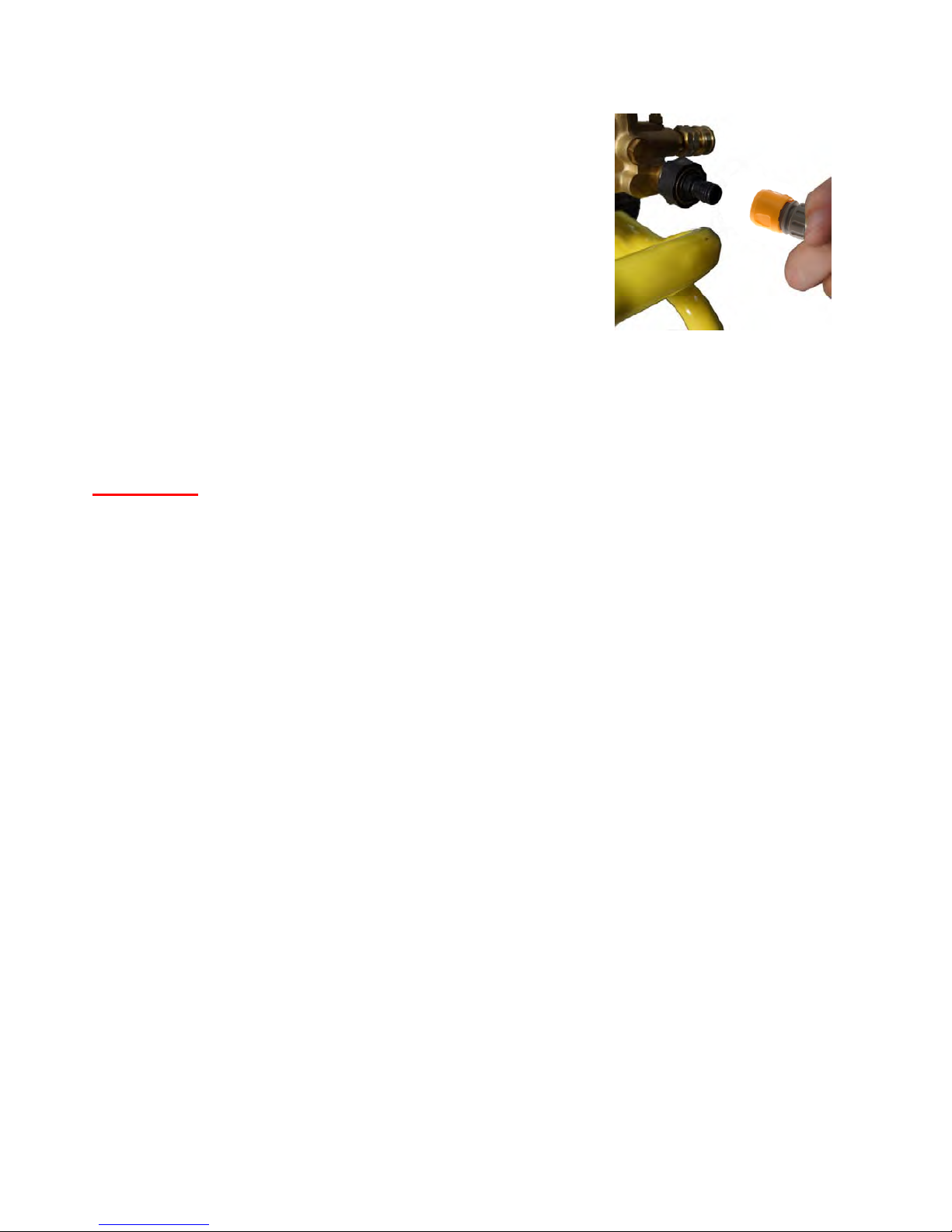

- FITTING THE HOSE CONNECTOR ONTO THE

WATER INLET (Fig 5)

In order for a garden hose to be connected easily,

screw the quick release hose connector onto the

thread of the water inlet connector and tigthten

then push the female garden hose connector firmly in

place.

- ENGINE OIL (Fig 6-7)

WARNING:

BEFORE staring the machine, the engine must be

filled with clean, high quality oil. Use SAE15

W40 petrol engine oil in both the pump and the

engine. This is not supplied with the machine.

Ensure that the oil is filled to the top of the filler

neck and then replace the oil filler cap.

For the high pressure pump (Not on the

EPW3100-2), fill through the pump oil filler plug

(Fig 8A.) to halfway up the pump body using

the oil level gauge (Fig 8B.) as a reference.

Use SAE15 W40 oil for this process.

NOTE:

For important environmental reasons, do not deposit

oil containers in the bin or in the ground. Instead

take to recycling station where itcanbe sorted properly.

Rev 2

10

Fig 9.

Fig 10.

Fig 11.

Fig 12.

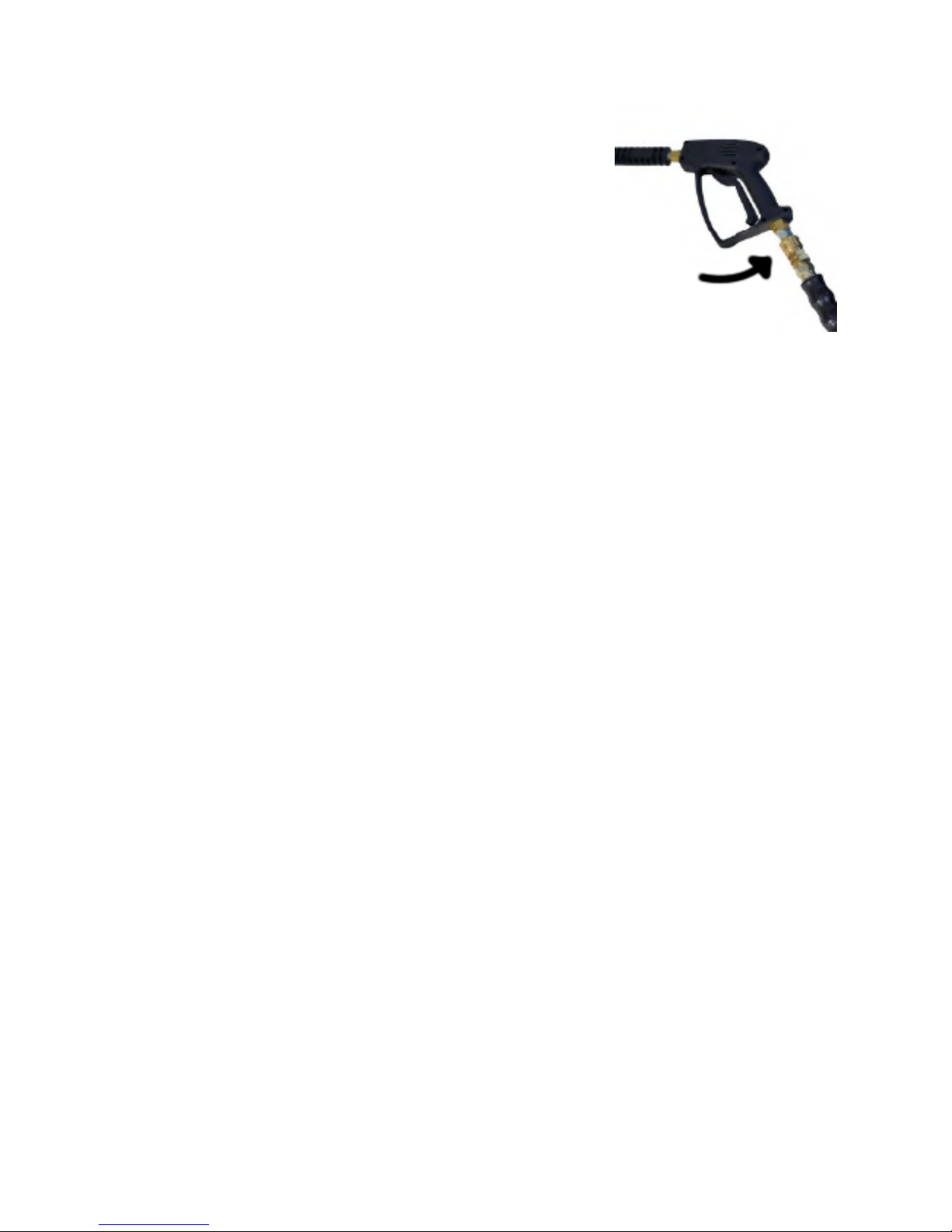

-HIGH PRESSURE CONNECTION (Figs 9-14)

Connect the high pressure hose to the high pressure outlet.

(Fig 9.)

Assemble the trigger gun and lance. Next, connect the high

pressure hose to the trigger gun. (Fig 10.)

-INSERTING A NOZZLE:

Pull back the locking collar, found at the end of the lance,

insert the nozzle and release the collar. This will lock the

nozzle firmly in place. (Fig 10.)

To prevent injury to yourself or others, ensure that the

nozzle is fitted correctly so it does not come lose and fly off

during use.

Connect the supply hose to the units water inlet connector

and turn the water on fully. (Fig 11.)

Rev 2

11

Fig 13.

Fig 14.

Before starting your pressure washer, pull the trigger

(Fig

13.) to get rid of any trapped air and wait for a steady flow

of water to emerge from the nozzle. This primes the pump

and ensures there is no air left in the system.

NOTE:

We recommend that when pull starting the machine, the

trigger is squeezed to prevent the build up of pressure. This

will aid starting.

The pressure washer features a locking facility to prevent

accidental operation. (Fig 14.)

Rev 2

12

OPERATION AND USE

WARNING:

ENGINE OIL IS NOT PROVIDED WITH THIS MACHINE. PLEASE ENSURE THE ENGINE IS FILLED WITH CLEAN,

HIGH QUALITY OIL BEFORE USE.

-This engine features a low oil level shutdown, however it is important not to run the engine with a

high or low oil level as this may cause damage. To avoid this problem, check the oil level before

starting the engine.

-Check that the pump oil level is correct.

STARTING UP:

Water Supply Connection:

-CAUTION! It is important to use clean or filtered water for intake only. Ensure that the water intake

is sufficient to match the flow of the pump.

-Keep the pressure washer as close to the water supply as possible.

-Water can also been used from the main supply. To do this, simply connect a supply hose to the

water inlet of the unit and to the desired water supply. Turn on the water supply. Ensure that the

hose used is at least 13mm and that it is an reinforced hose pipe.

-Do not operate the appliance for more than 2 minutes whilst the spray gun is in the closed position

as this will over heat the pump. (N.B. All Evopower pressure washers are fitted with thermal relief

valves to prevent any instance of overheating, however it is good practice to switch the engine off

when not pressure washing.)

-Do not operate the pressure washer with a pulsing action. Pulsing is the repeated on and off

operation of the trigger.

-Water can also be used from an open container. To do this, unscrew the coupling part of the water

inlet. Next, screw the suction hose (with filter) onto the water connection of the unit. Hang the filter

up in the container and vent the unit before usage. Unscrew the high pressure line at the high

pressure outlet of the unit. Turn the unit on and let it run until there are no longer bubbles present

at the high pressure outlet. Turn the unit off again and screw on the high pressure hose again.

-If the above conditions are not followed correctly, serious damage can be cause to the machine.

Rev 2

13

Fig 15.

Fig 16.

Fig 17.

Fig 18.

-STARTING THE ENGINE (FIG 15-20)

Move the fuel lever to the right- the ON position.

After doing this, move the choke lever to the left in order

to close the choke for initial start-up. YOU MAY NOT NEED TO

USE THE CHOKE IF THE ENGINE OR AIR IS WARM.

Next, turn thered engine switch (Fig 17.) ON by

turning clockwise.

Slowly pull the starting handle until you start to feel a

slight resistance andthen pull quickly andsharply.

NOTE:

In order to prevent damage to the starter assembly, return

the startingrope handle gently. Do not pull the rope all of the

way out.

Rev 2

14

Fig 19.

Fig 29.

Fig 21.

Fig 22

Let the engine idle for a few seconds before turning the choke

lever to the right.

The speed of the machine can be adjusted when in operation

by moving the throttle to the high position. Do not force the

stop bracket on the throttle as it can damage the engine.

-STOPPING THE ENGINE (FIGS 21-22)

To stop the pressure washer take the following steps:

-Turn the engine switch to the OFF position.

-Push the fuel lever to the OFF position (right).

CAUTION:

Always turn the machine off when not in use and always

discharge the pressure by pressing the trigger in.

Rev 2

15

Fig 23.

-ADJUSTING THE SPRAY PATTERN (FIG 23)

Your Evopower Pressure Washer comes complete with five

colour-coded nozzles and a turbo nozzle, each giving a different

spray pattern. Each nozzle does as follows.

RED: 0⁰NOZZLE

This nozzle gives an extremely powerful pinpoint stream. It covers

only a small area and due to its power should only be used on

materials such as metal or concrete. DO NOT USE ON WOOD.

YELLOW: 15⁰ NOZZLE

This nozzle delivers a powerful spray pattern, making it ideal for

cleaning small areas. As with the red nozzle, this nozzle should only be

used on areas which can withstand this high pressure.

WHITE: 40⁰ NOZZLE

This nozzle gives a less powerful stream than the first two nozzles.

This means that it can cover a much larger area meaning that it can

be used for a wide range of cleaning jobs.

GREEN: 40⁰ NOZZLE

This nozzle gives a less powerful stream than the first two nozzles.

This means that it can cover a much larger area meaning that it can

be used for a wide range of cleaning jobs.

BLACK: LOW PRESSURE NOZZLE

This nozzle has the lowest pressure and is perfect for applying

chemicals or cleaning solutions.

TURBO NOZZLE (EPW185-70AR / EPW275-14AR)

This nozzle produces a spiral spray of water, and provides up to twice

the effective cleaning power.

NOTE:

It is vital to test a small area first when cleaning items such as paving slabs to

ensure that damage will not be caused. Connect the nozzle to the lance using

the quick release coupling. In order to connect a nozzle, slide the collar back

towards the gun and push the nozzle into the end of the lance. Release the

collar to lock the nozzle into position. To disconnect, slide the collar back in

the direction of the gun.

Rev 2

16

-USING THE DETERGENT FACILITY

We strongly recommend using a high quality pressure washer detergent OR a traffic film remover (TFR)

with this machine.

NOTE:

Please note that thick detergents may not flow freely from the tank and so may cause a blockage in the

flow system.

To avoid this problem from occurring, flush the detergent facility out with a generous amount of water

after use. In order to activate the detergent delivery, fit the black nozzle onto the lance and completely

submerge the end of the detergent pick up pipe in the container of detergent. If an extended high

pressure hose is used, the detergent function may not work.

-CLEARING A BLOCKAGE

A blockage may be the problem if the flow rate reduces splutters or becomes inconsistent. To solve,

release the trigger and switch the machine off. Next, squeeze the trigger to relieve any pressure and

carefully check the jet in the end of the lance for any blockage that may have occurred. If this is the case,

use a thin piece of wire to clean the nozzle.

Rev 2

17

SAFETY INSTRUCTIONS FOR THE ENGINE

-To reduce the chances of injury or

damage to the machine, ensure that

you read the engine instruction

manual carefully before use.

-Keep the machine at least one metre

away from all buildings and other

equipment when in use. Ensure to

run in a well ventilated area.

-Keep away from other flammable

substances such as petrol.

-When refuelling, keep away from

sparks and naked flames and only do

so when the machine is completely

switched off.

The main parts of the machine are located as follows. Fig 24.

-Make sure that you do not overfill

the fuel tank. If a spillage occurs,

clean up immediately in a safe and

appropriate manner.

-

Make sure fuel cap is attached

securely.

-Please note that the

engine and

exhaust

will remain hot for some

time after use.

-

Before transporting or storing the

machine, ensure that it has fully

cooled down.

Rev 2

18

Fig 25.

PRE-OPERATION INSPECTION

CAUTION:

In relation to the engines performance, engine oil is a key

factor. Only use high quality, clean oil with no additives. Do not

use 2-stroke gasoline engine oil. Using unsuitable oil will

shorten the engines service life.

RECOMMENDED OIL: SAE15W40 (for pump and engine)

-Make sure the engine is on level ground. Check the oil level

by fir

stly removing and cleaning the dipstick. Reinsert the

dipstick into the oil filler. If the oil level is too low, fill to the

recommended mark.

CAUTION:

Running the pressure washer with an insufficient supply of

engine oil may cause serious damage to the engine.

-ENGINE OIL REPLACEMENT

Ensure the machine is located on a level surface and allow the

engine to warm up for several minutes. After this, turn the

engine off and remove the oil filler cap. Carefully place an oil

pan under the engine and completely drain the machine of oil

by removing the oil drain plug. Alternatively, the oil can be

sucked out of the oil filler neck using an oil suction device.

-Check that no damage has been caused to the oil drain plug,

gasket, oil filler cap and O-ring. If damage has been caused

replace immediately.

-Replace oil drain plug.

-Add engine oil to the top of the oil filler neck.

Rev 2

19

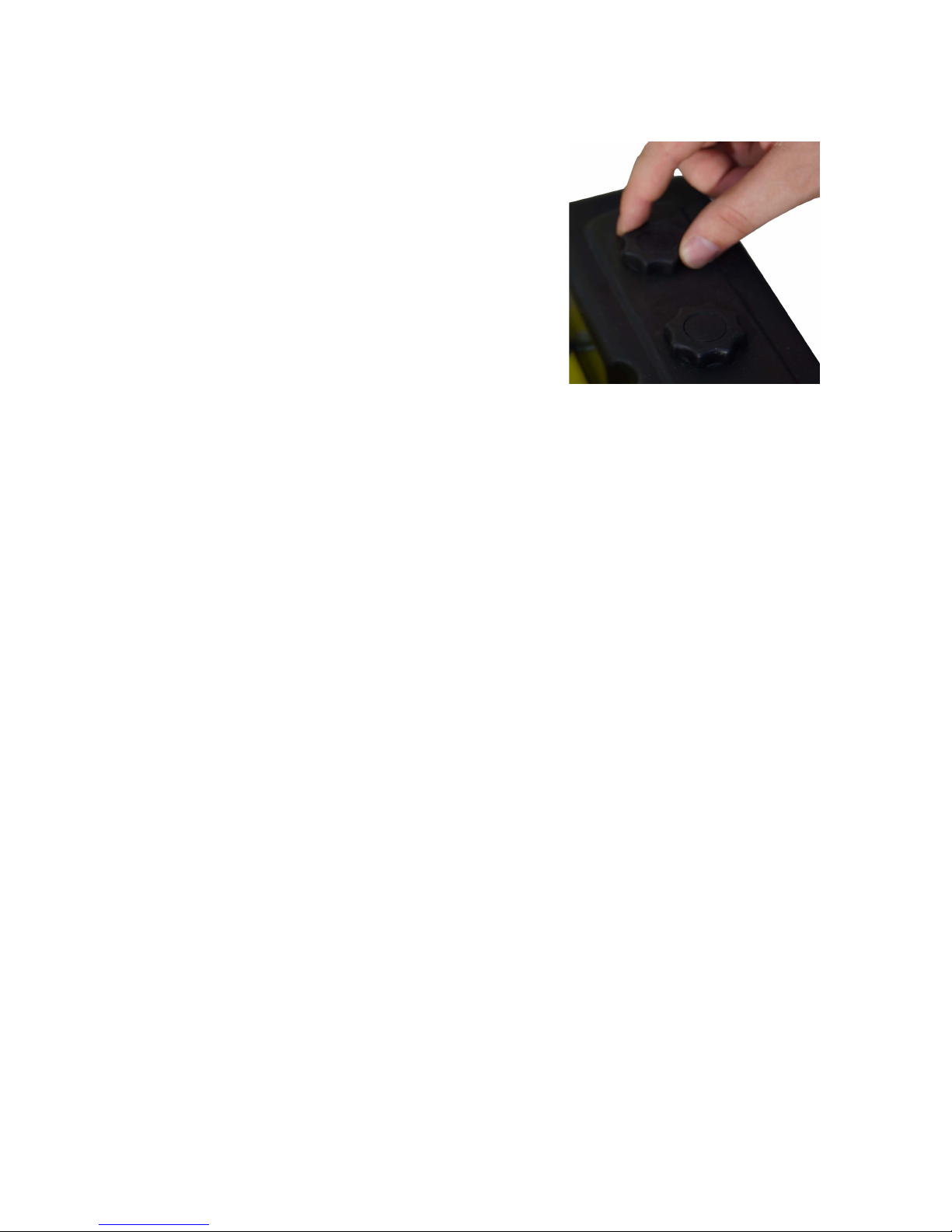

-FUEL AND FUEL TANK:

FUEL

Ensure that only fresh, clean unleaded petrol is used. This will decrease the chance of producing a

carbon deposit and will prolong the engines service life. Also, ensure that old or polluted fuel is

never used as this may cause damage to the engine, and make it difficult to start.

-CAUTION:

Fuel must be handled carefully as itcan cause extensive damage to plastic orpainted surfaces.

Before use, check the fuel level. Ifthe fuel level istoo low, refuel the tank. Remember not tofill

over the fuel filter shoulder. N.B Modern unleaded petrol has a short shelf life. Ifleft for more

than two months, itmay start todeteriorate.

-WARNING:

It isimportant toremember that petrol isanextremely flammable and potentially explosive fuel.

For this reason, refuel ina well ventilated area when the engine has been completely stopped. Do

not allow any flames orsparks near the refuelling area. Ensure that the fuel cap isfastened

securely after use. Any accidental spillages should be cleaned up immediately in a safe

manner. Keep out of the reach of children.

-FUEL TANK FILTER (FIG 26.)

The fuel tank filter should be removed and cleaned every 150 hours ofrunning time orevery

three months, whichever comes sooner. Todothis, remove the fuel tank filler cap and the filter

and clean the filter thoroughly.

-LOW ENGINE OILSHUT DOWN:

NOTE:

Once the oil level is too low, the engine low oil shutdown will stall the engine automatically to

avoid damage whilst the engine is still on. Insufficient oil will cause damage tothe engine. If the

engine oil level istoo low, the engine will not run.

Fig 26.

Rev 2

20

-AIR FILTER (FIG 27.)

The air filter should be removed, examined and cleaned

every 100 hours of running time or every month, whichever

comes sooner. The air filter should be cleaned with an

environmentally friendly water based degreasing agent. The

air filter should then be left the dry before replacing it back

into the machine and adding a few drops of engine oil,

squeezed into the foam filter. Do not run the pressure

washer without the air filter correctly fitted (Foam air filter

only).

- STORAGE

The following storage rules should be followed if the pressure washer will not be used or is to be

stored for more than one month.

Drain all fuel from both the fuel tank and carburettor. Next, remove the spark plug and pour in

around one tablespoon of clean engine oil into the spark plug hole. Make sure the ignition is

turned off, and then gently pull on the recoil starter cord several times. Replace the spark plug

and continue to pull the recoil starter cord until the piston is on the compression stroke then

stop pulling.

When storing the pressure washer, make sure you do so in a dry and well ventilated place under

cover.

-PREPARATION FOR WINTER AND LONG TERM STORAGE

Different preparation is required if the pressure washer is not going to be used for over

three months or if it is to be stored over the winter months where frost and cold weather is

likely. Mix a solution of automotive antifreeze as recommended on the packaging in order to

protect the pump unit. When the solution has completely drained out of the outlet seal with a

cork or other bung. Then continue to decant the antifreeze solution into the inlet until the

pump is full and then carefully seal the inlet.

When using the pressure washer for the first time after a lengthy time in storage, ensure that all

antifreeze is flushed thoroughly out of the pump, hose and lance. Small leaks may occur from

the pump when the pressure washer is first started, however these will disappear after a short

time.

Fig 27.

Rev 2

This manual suits for next models

2

Table of contents

Other Evopower Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Bosch

Bosch UniversalAquatak 1900 Operating/safety instructions

AR Blue Clean

AR Blue Clean MAXX 2100 Assembly, care and use instructions

Vax

Vax PowerPlus VPW2C manual

SNOWJOE

SNOWJOE SUNJOE SPX2005P-RM Operator's manual

Power Stroke

Power Stroke PS80544D Operator's manual

Watts

Watts LF909 Installation, maintenance & repair

Graco

Graco Hydra-Clean 4040 Instructions- Instructions-parts list

Xstream

Xstream HW152EMD Operation manual

Bosch

Bosch GST Professional 150 CE Original instructions

Porter-Cable

Porter-Cable A08058-0412-0 instruction manual

Kärcher

Kärcher HD 5/12 C manual

Interpump Group

Interpump Group TX 10.130 operating instructions