23. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of dust

collection can reduce dust-related hazards.

24.Safety Warnings for Chop and Plunge Saw Kit

a) Never stand on the power tool. Serious injuries can

occur when the power tool tips over or when

inadvertently coming into contact with the saw blade.

b) Never remove cutting remainders, wood chips,

etc. from the sawing area while the machine is

running. Always guide the tool arm back to the neutral

position first and then switch the machine off.

c) Guide the saw blade against the workpiece only

when the machine is switched on. Otherwise there is

damage of kickback, when the saw blade becomes

wedged in the workpiece.

d) Keep handles dry, clean, and free from oil and

grease. Greasy, oily handles are slippery causing loss

of control.

e) Operate the power tool only when the work area

to the workpiece is clear of any adjusting tools,

wood chips, etc. Small pieces of wood or other objects

that come in contact with the rotating saw blade can

strike the operator with high speed.

f) Keep the floor free of wood chips and material

remainders. You could slip or trip.

g) Use the machine only for cutting the materials

listed under Intended use. Otherwise, the machine

can be subject to overload.

h) If the saw blade should become jammed, switch

the machine off and hold the workpiece until the

saw blade comes to a complete stop. To prevent

kickback, the workpiece may not be moved until

after the machine has come to a complete stop.

Correct the cause for the jamming of the saw blade

before restarting the machine.

i) Do not use dull, cracked, bent or damaged saw

blades. Unsharpened or improperly set saw blades

produce narrow kerf causing excessive friction, blade

binding and kickback.

j) Always use saw blades with correct size and

shape (diamond versus round) of bore. Saw blades

that do not match the mounting hardware of the saw

will run eccentrically, causing loss of control.

k) Do not touch the saw blade after working before

it has cooled. The saw blade becomes very hot while

working.

l) Check the cable regularly and have a damaged

cable repaired only through an authorised

customer service agent. Replace damaged

extension cables. This will ensure that the safety of

the power tool is maintained.

m) Store the machine in a safe manner when not

being used. The storage location must be dry and

lockable. This prevents the machine from storage

damage, and from being operated by untrained

persons.

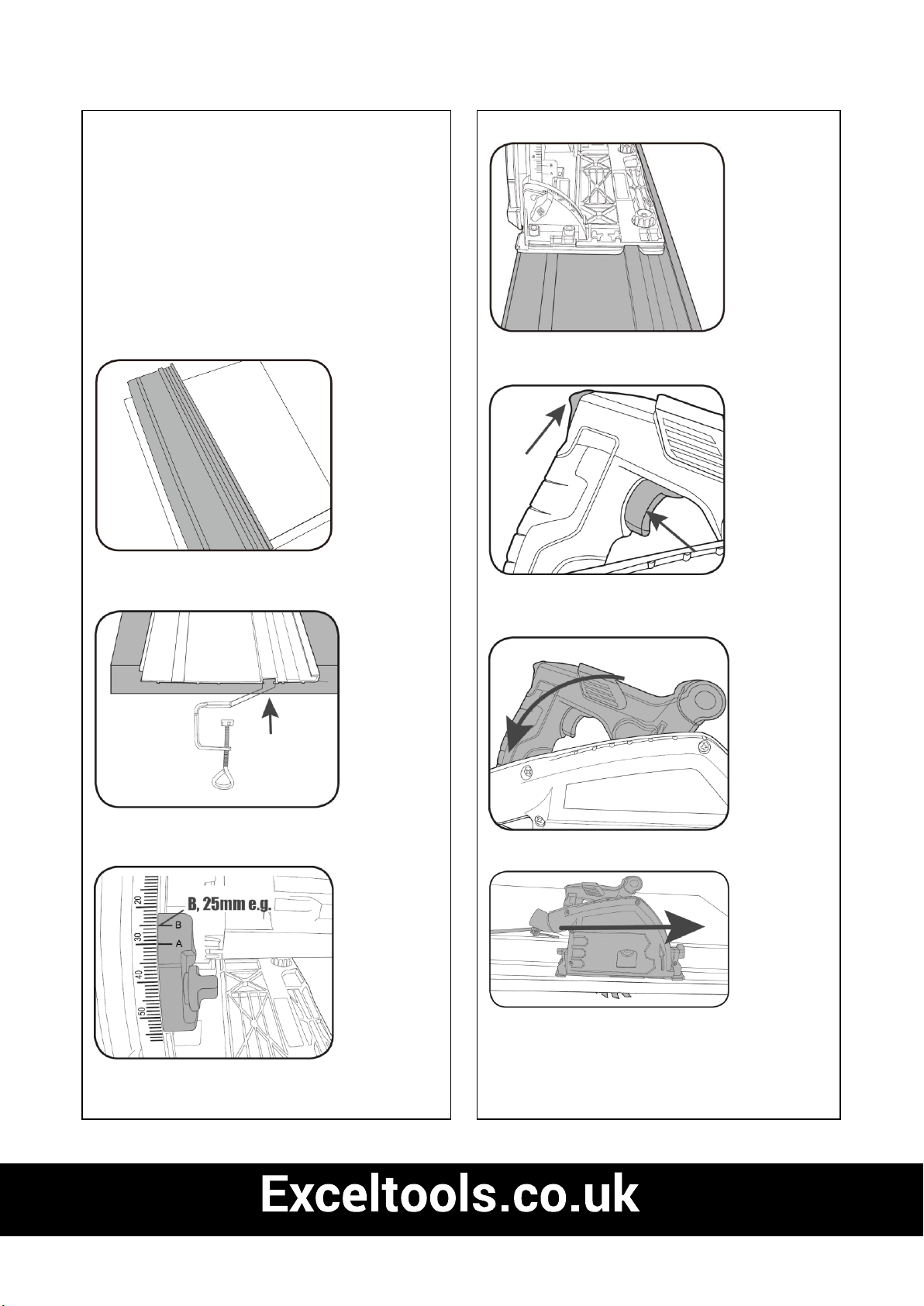

n) Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than

by hand.

o) Never leave the machine before it has come to a

complete stop. Cutting tools that are still running can

cause injuries.

p) Never use the machine with a damaged cable. Do

not touch the damaged cable and pull the mains

plug when the cable is damaged while working.

Damaged cables increase the risk of an electric

shock.

q) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool‟s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

r) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account

the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.