5

2.1 The machine is an electrical household appliance, therefore general electric safety rules should be fulfilled

during its operation.

2.2 The appliance is not intended for use by the persons (including children) having lowered physical, sensual or

mental abilities, or if they have no experience or knowledge, if they are not under control or have not been instructed

about the use of the appliance by a person responsible for their safety.

Children must be under control in avoidance of any playing with the appliance.

2.3 By the type of protection from electricity shock the machine is related to class I.

2.4 A double-pole socket having the earthing contact for connection of the machine must be located at a place

accessible for urgent disconnection of the machine from the electrical mains.

2.5 Before connection of the machine to the electrical mains absence of damages of the power supply cord

should visually be checked. The cord must not be twisted and compressed.

When the power supply cord is damaged in order to avoid any danger it must be replaced by the manufacturer

or a service company.

2.6 Safety precautions should be observed during handling and transportation of the machine as it has a big

mass.

2.7 IT IS PROHIBITED to install the machine outside the premise so that not to subject it to atmospheric

impact.

2.8 IT IS PROHIBITED to operate the machine without installation of plugs in accordance with clause 3.1.2.

2.9 When the machine is connected to the cold water supply network only a new filling hose should be used

which is included to a supply set.

2.10 IT IS PROHIBITED to use in the machine the substances containing solvents, as there is a danger of release

of poisonous gases, machine damage, ignition and explosion.

2.11 In the process of washing it is not recommended to touch the machine door glass, as it is heated and may

become the reason of a fire.

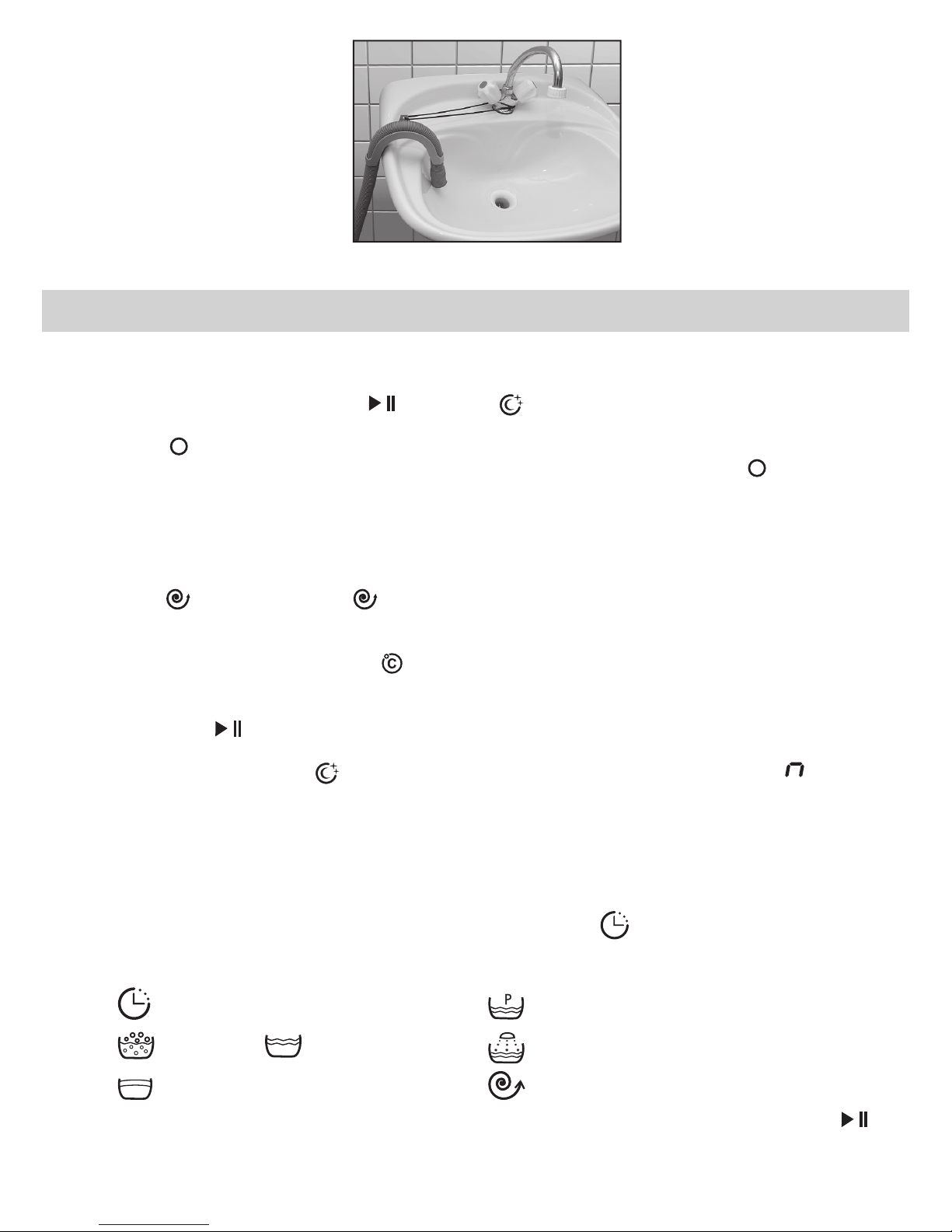

2.12 After the end of a washing the machine is to be switched off, disconnected from the electrical mains, the

plug is to be pulled out of the socket, and the water supply cock is to be closed (see fig. 8).

2.13 For provision of electrical and fire safety the following IS PROHIBITED:

— to connect the machine to the electrical circuit having malfunctioned protection from current overloads;

— to use a socket without an earthing contact for machine connection;

— to use adapters, multi-seat (having two or more points of connection) sockets and elongation cords for

machine connection to the electrical mains;

— to disconnect the machine from the electrical mains by pulling the supply cord;

— to insert and pull out the power supply plug from the socket, as well as to touch the operating machine

with wet hands;;

— to wash the machine under a water jet;

— to independently repair and introduce amendments to the machine design, as well as to its water and electric

power supply. This may result in serious damages of the machine and deprive of the warranty repair. The repair must

only be performed by a qualified mechanical expert of a service company.

2.14 If any malfunction is found in machine operation related to electrical crackling, smoking, etc. The machine

should immediately be disconnected from the electrical mains, by pulling the plug from the socket, the water supply

cock should be closed, and a mechanical expert of a service company should be called.

In case of a fire the machine should immediately be disconnected from the electrical mains, the water supply

cock should be closed, measures are to be taken for fire extinguishing and a fire brigade is to be called.

3.1.1 Packaging materials (polyethylene film, foamed polystyrene parts) are to be removed from the machine.

The protecting film is to be removed from the display.

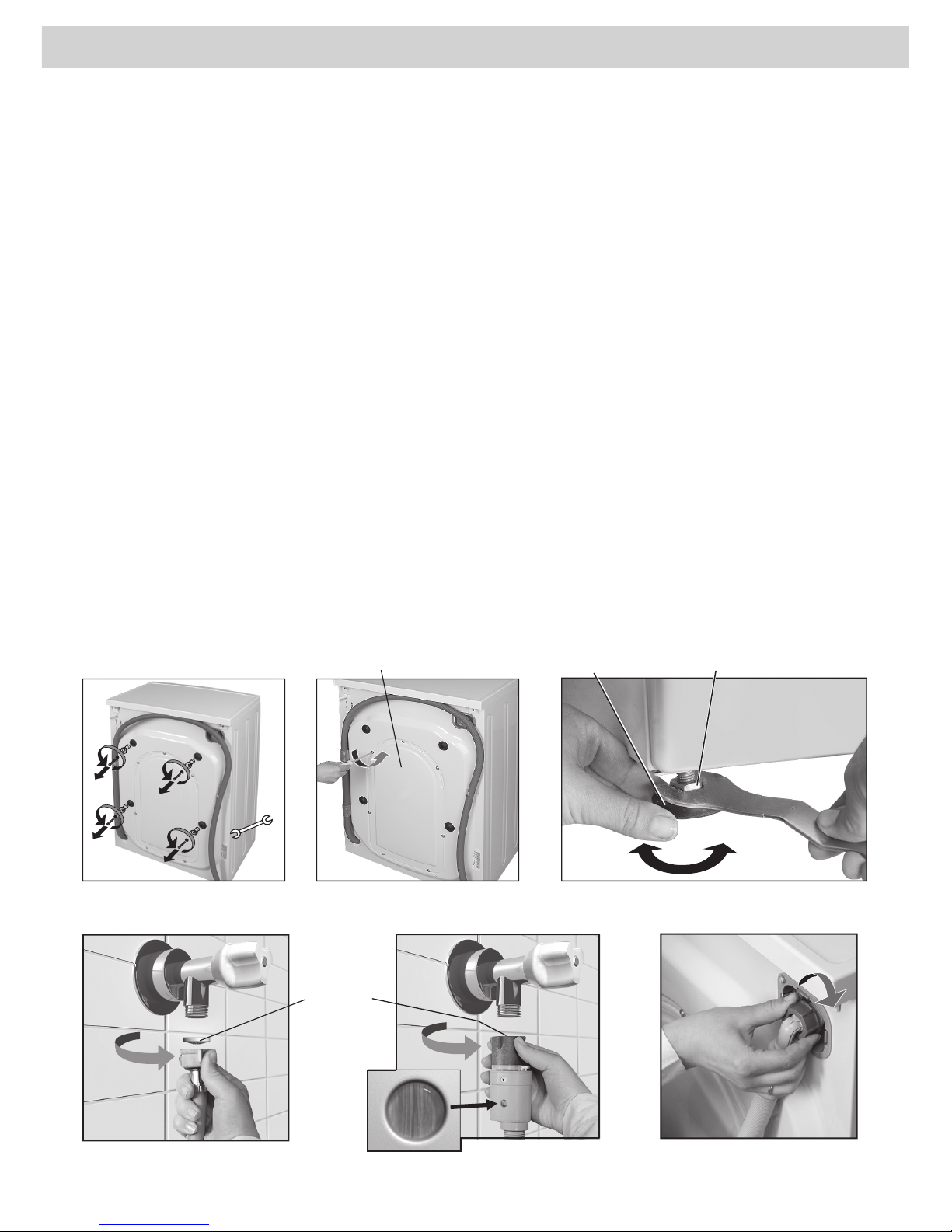

Four screws should be turned out with the aid of a spanner and rubber and plastic sleeved are to be removed

in accordance with figure 2. If the sleeves are left inside the machine and they could not be removed, the rear panel

should be taken out in accordance with fig. 3 with the aid of a cross screw driver and the sleeves should be removed.

The panel is to be reinstalled. Holes are to be closed with plastic plugs included to a supply set.

Screws and sleeves are to be kept for possible machine transportation in future.

3.2.1 The machine must be installed onto a strong, even and dry surface.

The soft floor cover (a carpet, coating based on foamed polyurethane, etc.) is not suitable for installation, as it

contributes to vibration and worsening of machine ventilation.

The machine should be installed on a wooden floor by preliminarily strongly fixing a slab made of wooden

materials to the floor having thickness at least 15 mm. It is recommended to install it in a premise corner on the

wooden floor in the process of operation for better machine stability.

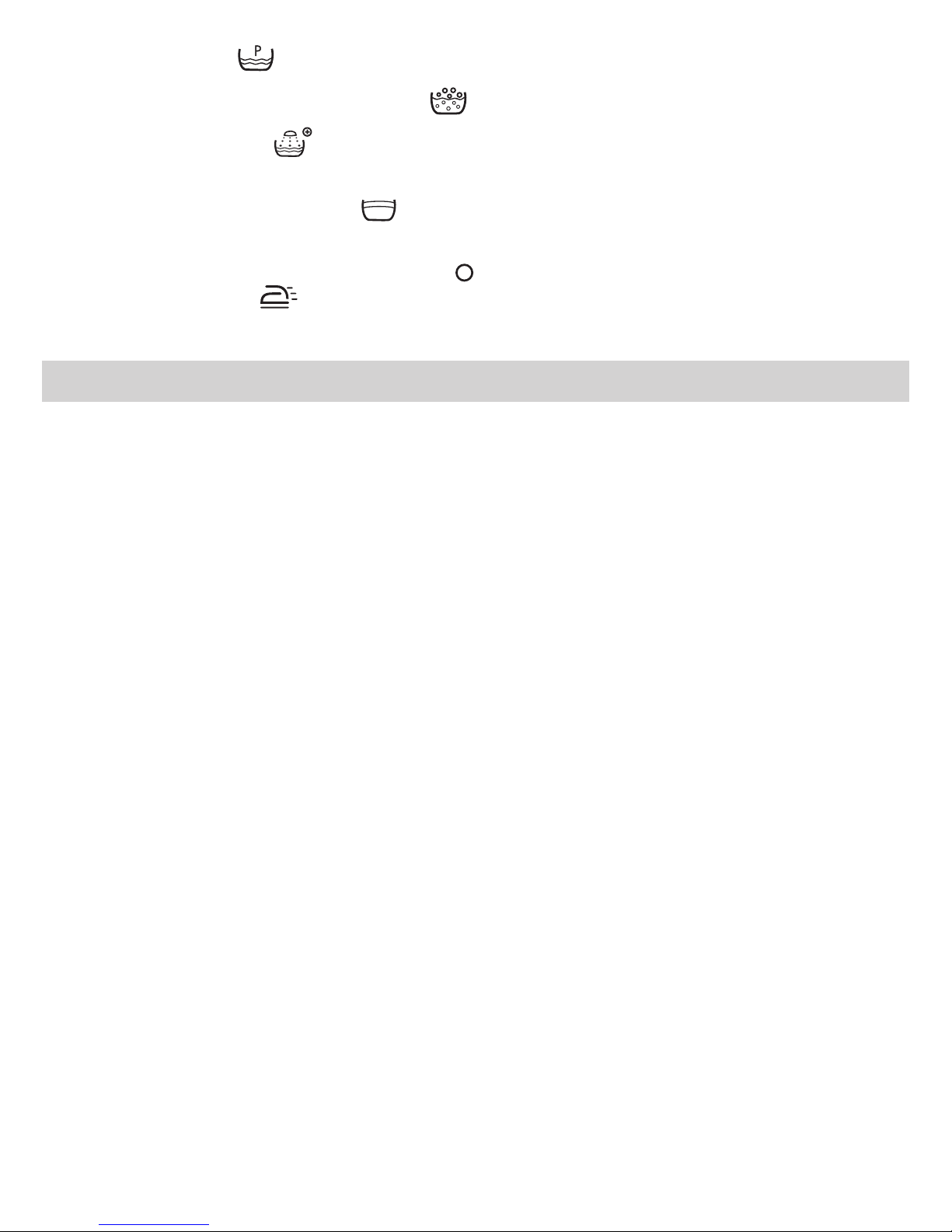

3.2.2 The machine is to leveled strictly horizontally in relation to the floor by screwing the adjustable supports in

and out in accordance with figure 4: counter-nuts are to be released at supports with the aid of a spanner, height of

supports is to be adjusted, counter-nuts are to be tightened. Wrong leveling of the machine or insufficient tightening

of counter-nuts may become a source of vibration and increased noise during machine operation.