- 3 -

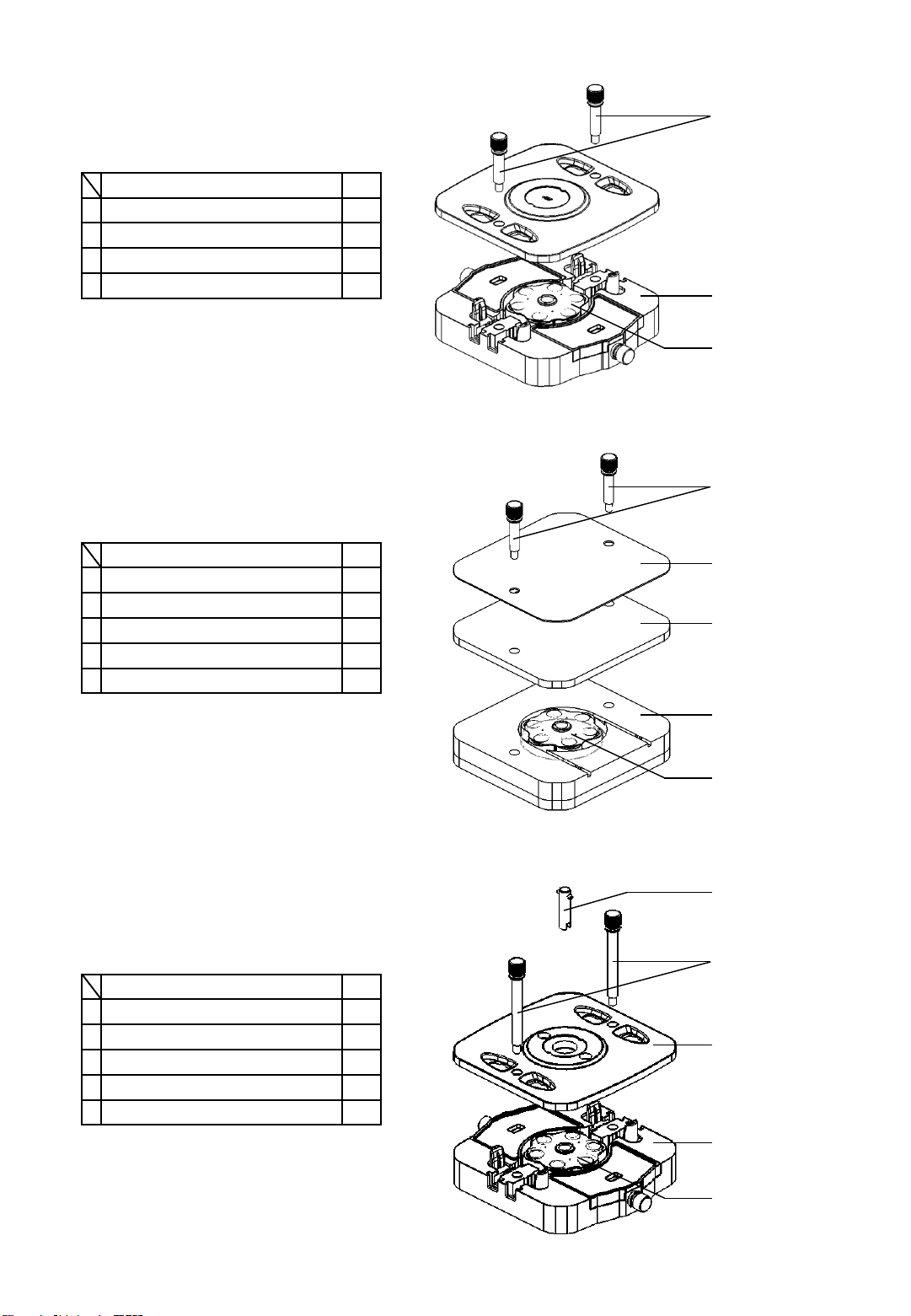

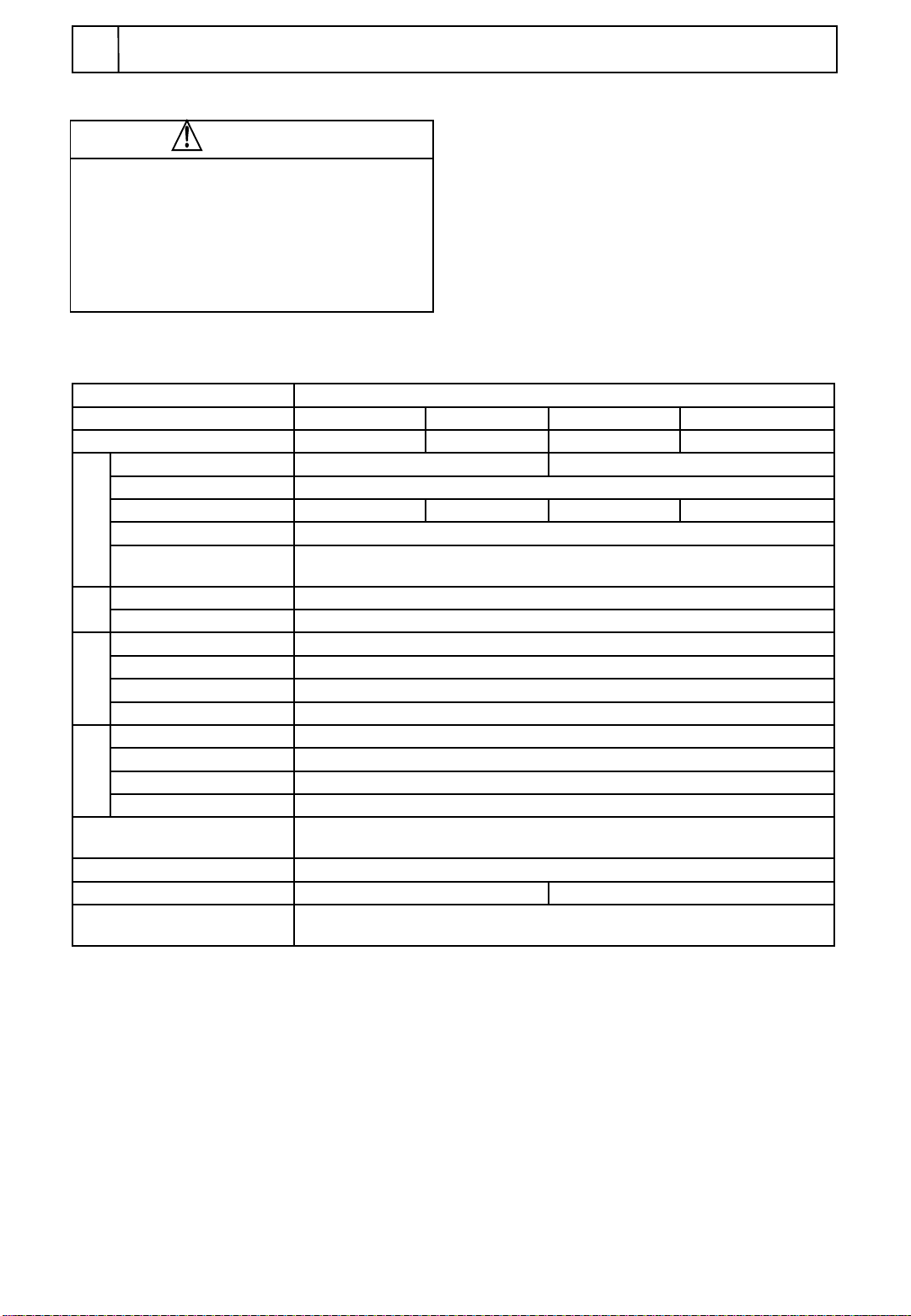

Product name Constant volume fluid supply pump(Peristaltic tube pump)

Model MP-2000A MP-2010A MP-2000B MP-2010B

Tube holding system Groove with a fixed width

Performance

Flow range 10~180 mL/h 0.5~9.0 mL/h 80~1450 mL/h 5.0~72.5 mL/h

Flow precision ±2% (Repetition precision: within ±1%)

Max. discharge pressure 147kPa(1.5kg/cm2)

Max. suction pressure 9.8kPa(0.1kg/cm2)

Viscosity and temperature

of solution Max.2Pa・s (2000cP) 0~60℃(Non-freezing)

Func-

tion

Rotation setting Volume setting

Fluid supply direction Normal/Reverse selectable

Configuration

Motor AC speed control & induction motor output: 15W

Driving circuit Speed feedback control

Tube case PVC resin

Safety function Thermal protector and fuse

Standards

Number of tubes to hook 1 tube

Number of tube case stages 1 stage

Usable tube material Silicon, Tygon® , Fluran® , PharMed®

Usable tube dia. I.D.:1.15mm×O.D.:3.2mm I.D.:3.7mm×O.D.:6.1mm

Operating environmental

temperature range 0~40℃(Non-condensing)

Ext. size[mm] ※1 120(137)W×130(152)D×177(190)H

Mass Approx.3.2kg

Power input and rated power

supply AC100V 50/60Hz 0.4A 40VA

※Performance has been measured at: room temperature of 20℃, rated source voltage, clean water, liquid

temperature of 20℃, back pressure of 0, a silicon tube(s) is used.

※Flow, flow precision, discharge pressure and other pressures will differ depending on the tube used.

※Discharge amount may be less when the viscosity of the solution exceeds 0.1Pa・s(100cp).

※1 Figures in ( ) shows a size including protrusions such as screws and knobs.

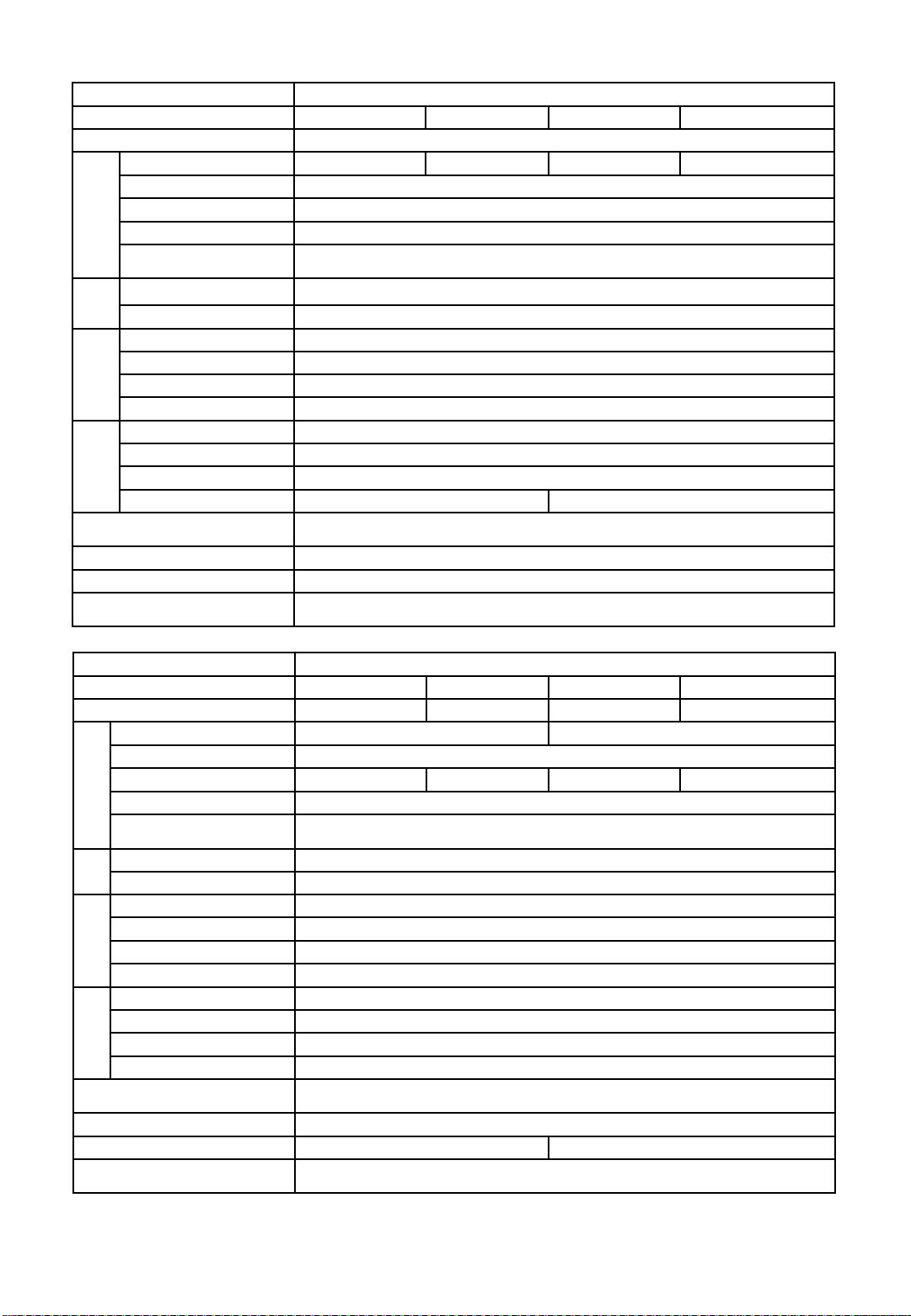

Product name Constant volume fluid supply pump(Peristaltic tube pump)

Model MP-2100 MP-2101 MP-2110 MP-2111

Tube holding system Screw-adjustable Spring type Screw-adjustable Spring type

Performance

Flow range 10~1450 mL/h×4 0.5~72.5 mL/h×4

Flow precision ±2% (Repetition precision: within ±1%)

Max. discharge pressure 196kPa(2kg/cm2) 98kPa(1kg/cm2) 196kPa(2kg/cm2) 98kPa(1kg/cm2)

Max. suction pressure 9.8kPa(0.1kg/cm2)

Viscosity and temperature of

solution Max.2Pa・s (2000cP) 0~60℃(Non-freezing)

Func-

tion

Rotation setting Volume setting

Fluid supply direction Normal/Reverse selectable

Configuration

Motor AC speed control & induction motor output: 15W

Driving circuit Speed feedback control

Tube case PET resin

Safety function Thermal protector and fuse

Standards

Number of tubes to hook 4 tubes

Number of tube case stages 2 stages

Usable tube material Silicon, Tygon® , Fluran® , PharMed®

Usable tube dia. O.D.: 3~6.1mm

Operating environmental

temperature range 0~40℃(Non-condensing)

Ext. size[mm] ※1 127(166)W×130(152)D×206(219)H

Mass Approx. 3.3kg Approx.3.4kg

Power input and rated power

supply AC100V 50/60Hz 0.4A 40VA