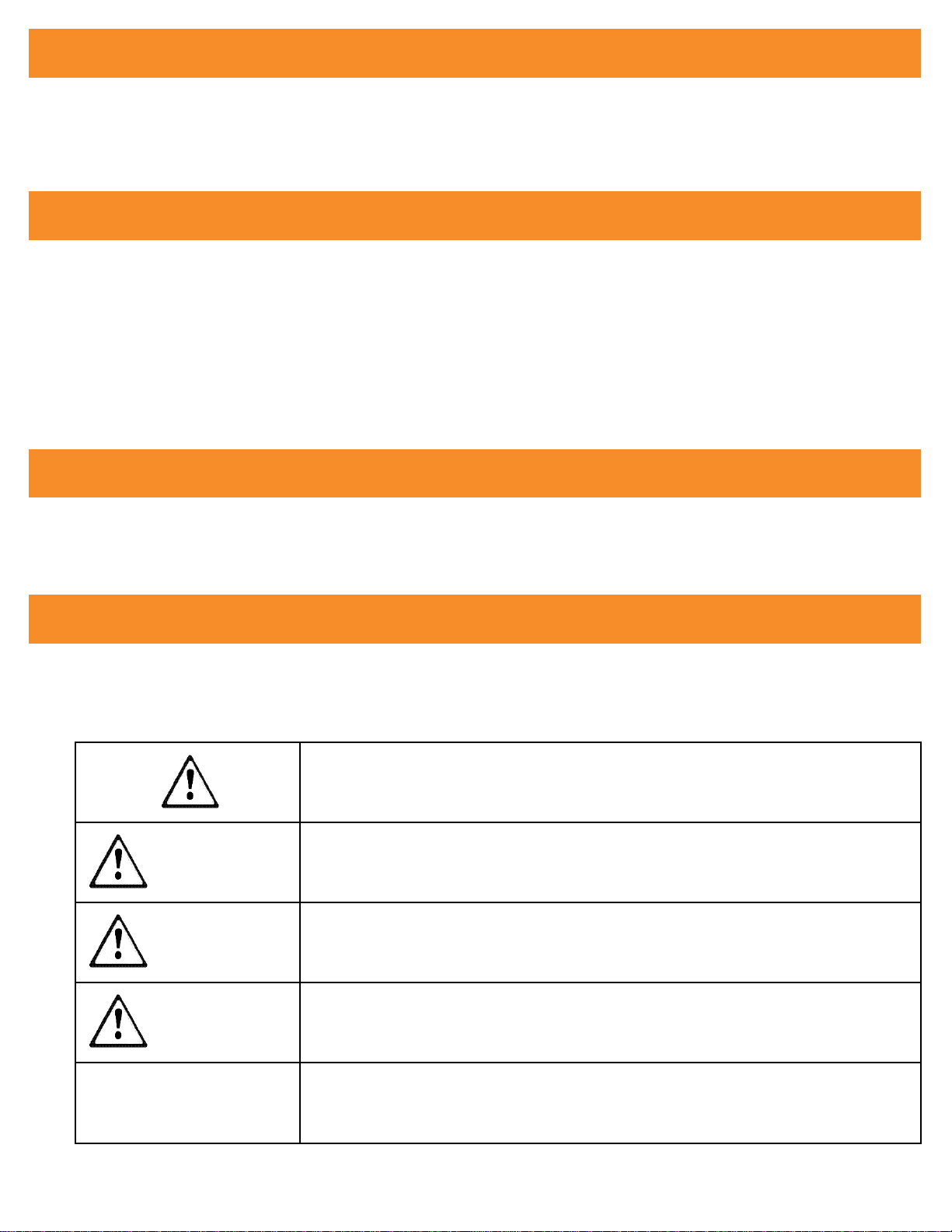

This symbol, either used alone or with a signal word, is used to call your attention

to instructions involving your safety and/or the safety of others. Failure to follow

these instructions will likely result in personal injury or death.

DANGER This signal word is used to identify a hazard which, if not avoided, will result in

death or serious injury.

WARNING This signal word is used to identify a hazard which, if not avoided, could result in

death or serious injury.

CAUTION This signal word is used to identify a hazard which, if not avoided, could result in

minor or moderate injury.

NOTICE

This signal word is used to identify a hazard which, if not avoided, could result in

property or equipment damage. It also may be used for special instructions

related to performance, maintenance or general items.

INTRODUCTION

Congratulations on purchasing one of the nest pieces of masonry equipment on the market today!

If this is your rst EZG Manufacturing product, you will not be disappointed. If you have previously

owned an EZG Manufacturing product, you will nd the same high quality and dependability that you

have come to expect from EZG Manufacturing.

The purpose of this manual is to inform the owner/employer/and the operator, how to safely operate

this piece of equipment, and make them aware of any hazards. It also contains important information

regarding assembly, set up, operation, and maintenance. It is the Owner/Employer’s responsibility

to make sure that anyone who operates this machine understands all safety warnings. If you do not

understand any items in this manual, please contact the dealer where this product was purchased, or

the manufacturer at the number listed throughout this manual. If you have any suggestions about how

to make this manual easier to understand, contact the manufacturer. Keep this manual available for

reference wherever this piece of equipment is being used and make it available to any operators.

Illustrations in this manual may show details or components that may not be the same as your

machine. Continuing improvements to the design of this machine may have caused changes that are

not included in this manual. The information in this document is subject to change without notice.

The following safety symbols and signal words will be used throughout this manual and on the

product, for your safety and the safety of others, please become familiar with their meaning and heed

their warnings.

ABOUT THIS MANUAL

GENERAL INFORMATION

SAFETY INFORMATION

EZG Manufacturing 1-800-417-9272

Revision Number-013 02/22/2022-Present 3