3

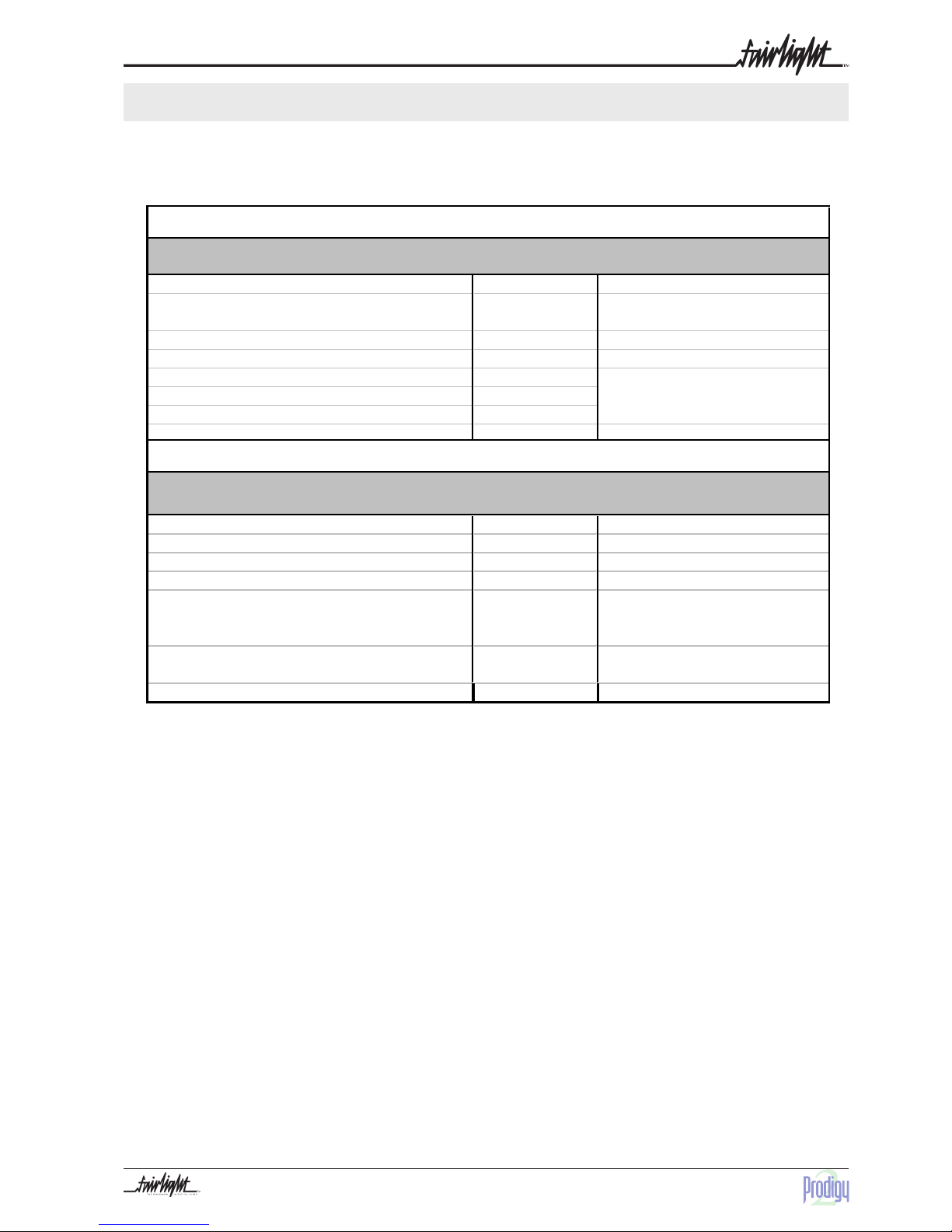

TABLE OF CONTENTS

IMPORTANT NOTICE ......................................... 2

CERTIFICATES & COMPLIANCES ........................... 5

CC EMISSION CONTROL .................................. 5

SAFETY SYMBOLS ............................................ 6

MAINS PLUGS & MAINS POWER CORDS .............. 7

OBTAINING TECHNICAL SUPPORT ........................ 8

SECTION 1 - INTRODUCTION ............................. 9

1.1 Product Description .............................. 9

1.2 Manual Summary ................................. 9

1.3 System Overview ............................... 10

1.4 Unpacking .......................................... 11

1.5 Equipment Supplied ............................ 11

1.6 System Overview ............................... 12

1.6.1 Prodigy 2 Engine ........................ 12

1.6.2 Prodigy 2 Control Surface .......... 12

1.6.3 Monitor Box ............................... 12

1.6.4 Audio I/O .................................... 12

1.7 Prodigy 2 Control Cable..........................

Interconnections ....................................... 13

1.8 Static Precautions ............................... 14

1.9 Environment........................................ 14

SECTION 2 - PHYSICAL INSTALLATION - ENGINE .... 15

2.1 Mechanical Installation ...................... 15

2.2 Electrical Installation .......................... 16

2.3 Engine Rear Panel Connections .......... 17

2.4 Cabling ............................................... 18

2.5 External Cable Length Considerations 18

2.5.1 SONY 9-PIN CABLE ....................... 18

2.5.2 VGA CABLE ............................... 18

2.5.3 AUDIO CABLE .............................. 18

2.5.4 DIGITAL AUDIO CABLES ................. 18

2.6 Connecting The Various Engine...............

Components .............................................. 19

SECTION 3 PHYSICAL INSTALLATION - CONTROL .......

SURFACE ..................................................... 20

3.1 Introduction......................................... 20

3.2 Mechanical Installation ...................... 20

3.3 Connecting The Various Prodigy 2 Surface

Components .............................................. 21

............................................................ 21

3.4 Surround Monitor and Remote Mic Amp

Setup. ........................................................ 22

3.5 Electrical Installation .......................... 23

3.5.1 Safety ......................................... 23

3.5.2 Mains input voltage .................... 23

3.5.3 Mains connection ....................... 23

3.5.4 Fuses ......................................... 24

3.6 Internal and External SCSI Devices.... 25

SECTION 4 - SYSTEM CONFIGURATION ............... 26

4.1 Introduction......................................... 26

4.2 Switching on the Equipment ............ 26

4.2.1 Engine .............................................. 26

4.2.2 Prodigy 2 Console ...................... 28

4.3 Prodigy 2 Engine Boot up.................... 29

4.4 Engine Software Installation ............... 31

4.7.1 Installing Software From Exabyte31

SECTION 5 - CONFIGURING DISK DRIVES .......... 32

5.1 External Hard Disk Drives ................. 32

5.1.1 Wide Based Disk Drives ............ 32

5.1.2 Narrow Based Disk Drives ........ 32

5.1.2 Configuring The Engine For Narrow

Use ...................................................... 33

5.1.3 Mixing Wide And Narrow Disk

Drives ................................................. 34

5.2 Checking for Newly Installed SCSI ........

Devices ................................................... 35

5.3 Setting Up Removable Media Devices35

SECTION 6 - BISCUIT PC CONFIGURATION ......... 36

6.2 BIOS Settings ...................................... 37

6.3 Software Installation for Prodigy 2 ..........

Surface..................................................... 38