;I %<*."+,%&"#'>"!*+]'<.%$*-?.*>'

'

.*"-'`*!%.*'?>,&)'+/*'("$/,&*'

%

All%safety%measures%must%be%observed%at%all%times%when%using%magnetic%core%drills.%

Improper%use%and%carelessness%increase%the%risk%of%accidents.%Read%and%carefully%follow%these%recommendations%in%order%to%improve%your%

own%safety.%%

%

This%machine%is%specifically%designed%for%drilling%holes%in%steel,%expanded%by%the%possibility%of%tapping/reaming/countersinking,%and%must%not%

be%adapted%and/or%used%for%applications%other%than%those%they%were%designed%for,%including%driving%other%apparatus.%%

%

•When%using%electrical%tools,%basic%safety%precautions%should%always%be%followed%to%reduce%the%risk%of%electric%shock,%fire,%and%personal%

injury.%

•Do%NOT%use%in%wet%or%damp%conditions.%Failure%to%do%so%may%result%in%personal%injury.%

•Do%NOT%use%in%the%presence%of%flammable%liquids%or%gasses.%Failure%to%do%so%may%result%in%personal%injury.%

•BEFORE%operating,%the%machine%MUST%be%securely%restrained%to%a%fixed%independent%feature%(by%using%safety%strap%RD4329,%or%other%

means),%to%reduce%the%potential%free%movement%should%the%magnet%become%detached%from%the%work%piece.%Failure%to%do%so%may%

result%in%personal%injury.%

•ALWAYS%wear%eye%and%ear%protectors%when%operating%the%machine.%%Failure%to%do%so%may%result%in%personal%injury.%

•Disconnect%from%power%source%when%changing%cutters%or%working%on%the%machine.%Failure%to%do%so%may%result%in%personal%injury.%

•Cutters%and%swarf%are%sharp,%ALWAYS%ensure%that%hands%are%adequately%protected%when%changing%cutters,%or%removing%swarf.%

•Before%operating,%ALWAYS%ensure%cutter%retaining%screws%are%secured.%%

•Regularly%clear%the%work%area%and%machine%of%swarf%and%dirt,%paying%particular%attention%to%the%underside%of%the%magnet%base.%%

•With%a%gloved%hand,%and%after%switching%off%the%machine,%remove%any%swarf%that%might%have%gathered%around%the%cutter%and%arbor%

before%proceeding%with%cutting.%%

•ALWAYS%remove%your%tie,%rings,%watches%and%any%loose%adornments%that%might%entangle%with%the%rotating%machinery%before%

operating.%%

•Should%the%cutter%become%‘stuck’%in%the%work\piece,%stop%the%motor%immediately%to%prevent%personal%injury.%%Disconnect%from%power%

source%and%turn%arbor%to%and%fro.%%DO%NOT%ATTEMPT%TO%FREE%THE%CUTTER%BY%SWITCHING%THE%MOTOR%ON%AND%OFF.%

•If%the%machine%is%accidentally%dropped,%ALWAYS%thoroughly%examine%the%machine%for%signs%of%damage%and%check%that%it%functions%

correctly%BEFORE%resuming%drilling.%%

•Regularly%inspect%the%machine%and%check%that%nuts%and%screws%are%tight.%%

•ALWAYS%ensure%when%using%the%machine%in%an%inverted%position%that%the%machine%is%securely%restained%in%the%event%of%power%failure.%

Only%use%the%minimum%amount%of%coolant%and%ensure%that%care%is%taken%to%prevent%coolant%entering%the%motor%unit.%%

•Cutting%tools%may%shatter,%ALWAYS%position%the%guard%over%the%cutter%before%activating%the%machine.%Failure%to%do%so%may%result%in%

personal%injury.%

•On%completion%of%the%cut,%a%slug%will%eject.%DO%NOT%operate%the%machine%if%the%slug%has%not%ejected,%as%this%may%cause%injury.%If%

necessary,%use%barriers%to%prevent%unauthorised%access%to%work%area.%

%

6I ("$/,&*'%<*."+,&)',&>+.?$+,%&>'

'

•Keep%the%inside%of%the%cutter%clear%of%swarf.%%It%restricts%the%operating%depth%of%the%cutter.'

•Apply%the%cutting%fluid%to%the%internal%reservoir%via%the%inducement%holes%in%the%arbor.%%It%is%then%“metered%out”%by%the%pilot%during%the%

cutting%cycle%and%is%applied%directly%to%the%cutting%edge.%%Alternatively,%fluid%can%be%applied%directly%onto%the%work\piece%making%

certain%that%it%floods%into%the%groove%formed%by%the%cutter.'

•Occasionally%depress%the%pilot%to%ensure%cutting%fluid%is%being%correctly%metered.'

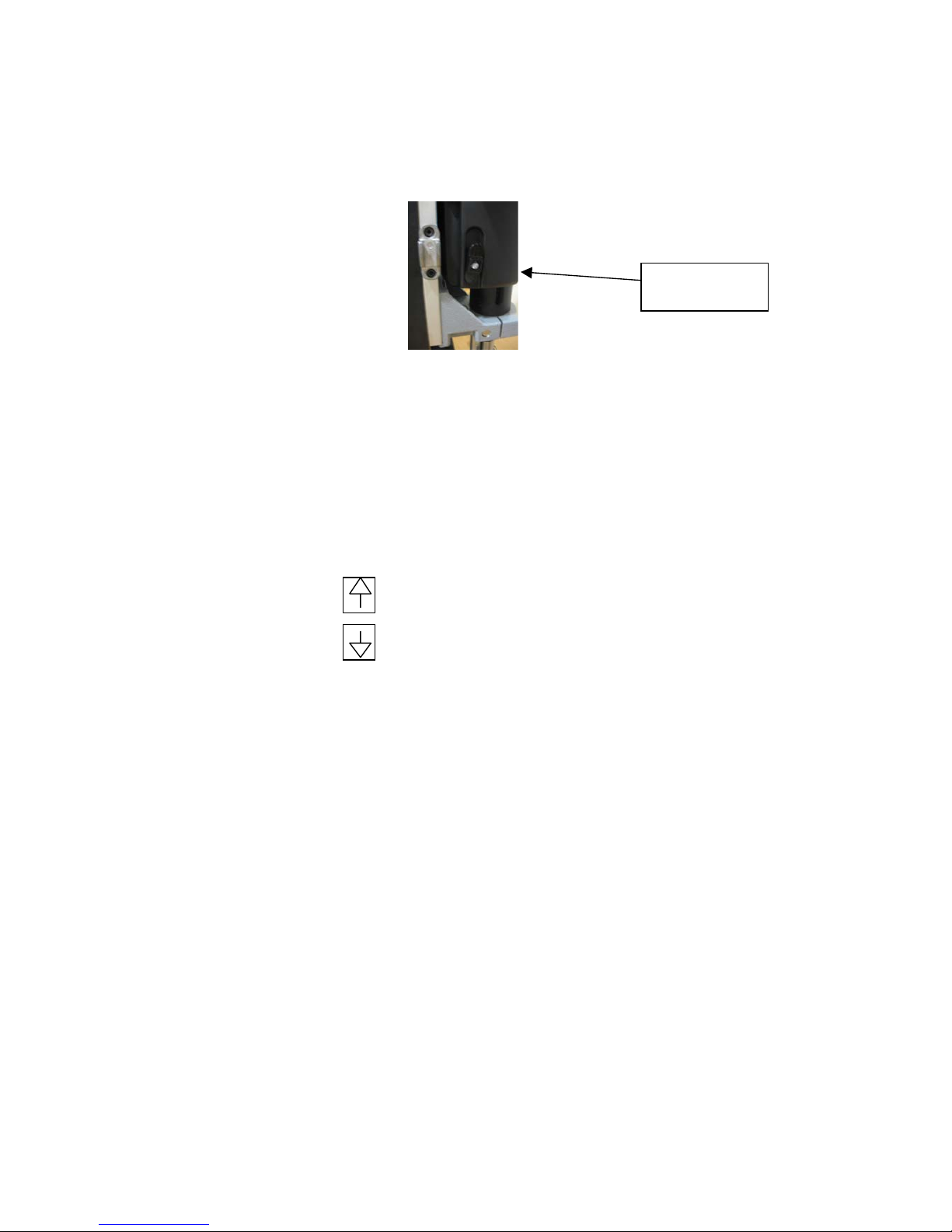

•To%start%the%machine,%first%switch%on%the%magnet%by%depressing%the%single%red%button.%%Ensure%that%the%rotary%switch%is%set%to%R,%%then%

start%the%motor%by%depressing%the%GREEN%%(I)%start%button.'

•ALWAYS%switch%off%the%motor%by%depressing%the%RED%(O)%stop%button.%%DO%NOT%switch%off%the%motor%by%switching%the%magnet%off.'

•Apply%light%pressure%when%commencing%to%cut%a%hole%into%the%work%surface.%%Pressure%can%then%be%increased%sufficiently%to%load%the%

motor.%Excessive%pressure%is%undesirable%when%using%the%Rotabroach™%“FALCON”%machine.%It%does%not%increase%the%rate%of%

penetration%and%may%result%in%damage%to%the%machine%and%cutter.'

•Always%ensure%that%the%slug%has%been%ejected%from%the%previous%hole%before%commencing%to%cut%the%next.'

•If%the%slug%sticks%in%the%cutter,%move%the%machine%to%a%flat%surface,%switch%on%the%magnet%only,%and%gently%bring%the%cutter%down%to%

make%contact%with%the%surface.%%This%will%usually%straighten%a%cocked%slug%and%allow%it%to%eject%normally.%

•Apply%a%small%amount%of%light%oil%lubricant%regularly%to%the%slide%and%arbor%support%bearing.%

•Insecure%anchorage,%a%loosely%fitting%slide,%or%a%worn%bearing%in%the%arbor%support%bracket%usually%causes%cutter%breakage.%%

%

*b+*&>,%&'$"`#*'>*#*$+,%&'

•The%machines%are%factory%fitted%with%a%3%metre%length% of% cable% having% three,%1.5mm²%conductors,%LIVE,%NEUTRAL%and%EARTH.%%%If%it%

becomes%necessary%to%fit%an%extension%cable%from%the%power%source,%care%must%be%taken%in%using%a%cable%of%adequate%capacity.%%Failure%

to%do%so%will%result%in%a%loss%of%traction%by%the%magnet%and%a%reduction%of%power%from%the%motor.%%

%

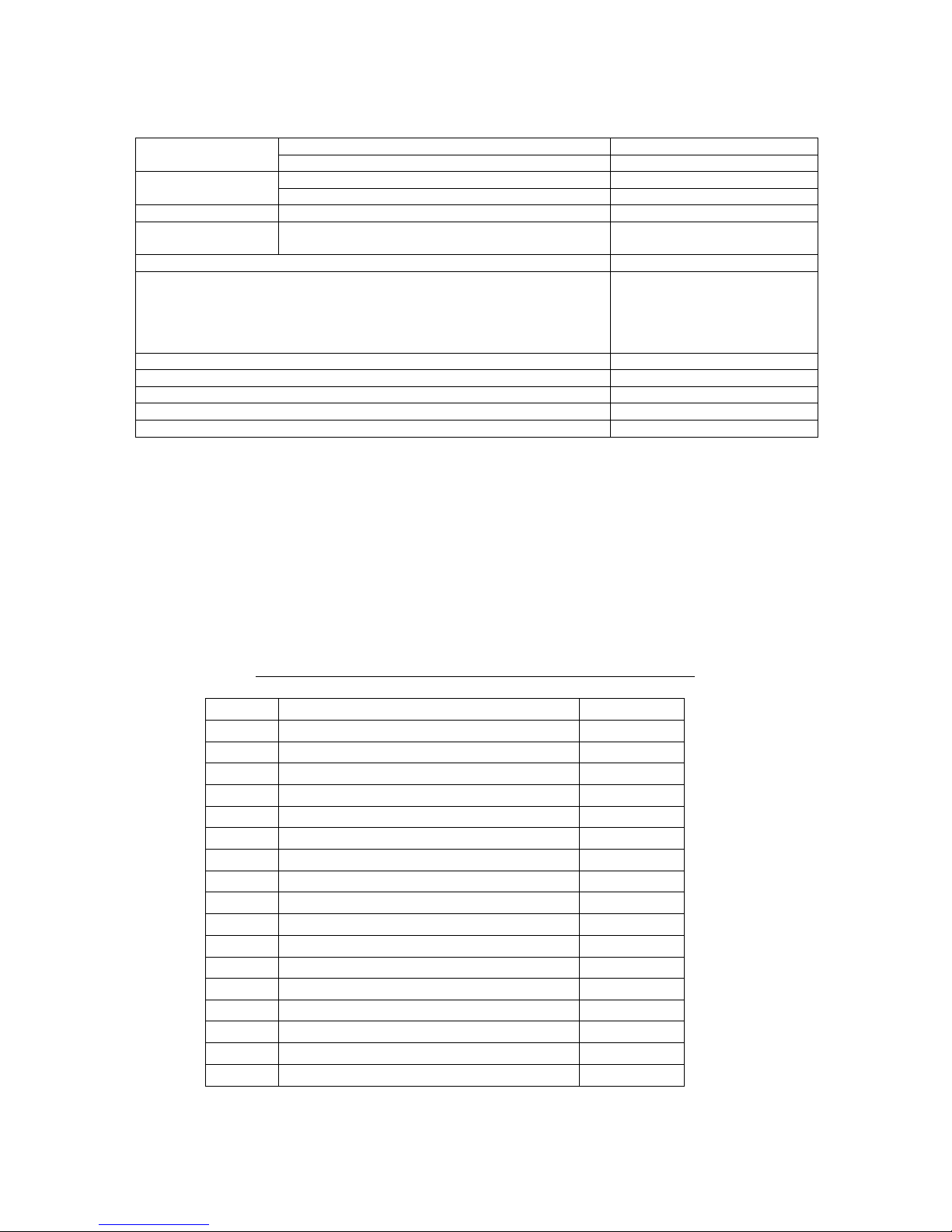

•Assuming%a%normal%AC%supply%of%the%correct%voltage,%it%is%recommended%that%the%following%extension%lengths%shall%not%be%exceeded:%

%

!0C'997^'4QXX3VF';P8M2@C24'0W';'D0C2'K'9P8MMc'

%

!0C'J;7^'4QXX3V:% JL'M2@C24'0W';'D0C2'K'9P8MM²%%