TABLE OF CONTENTS

Table of contents

Introduction....................................................................................................................................................................1

Content of the manual..............................................................................................................................................1

Compliance with the rules........................................................................................................................................1

Information on this manual.............................................................................................................................................2

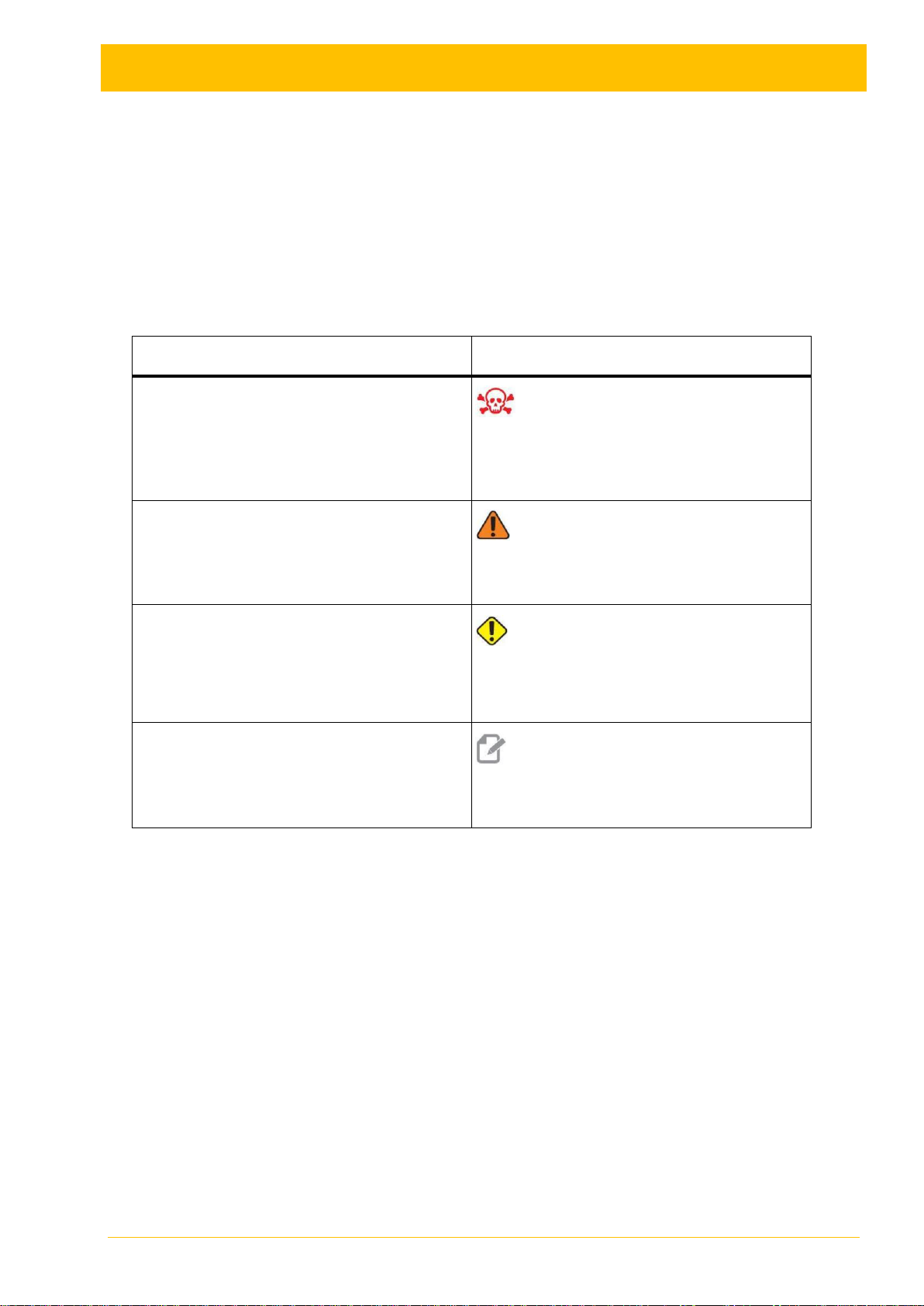

Labelling of warnings................................................................................................................................................2

Safety.............................................................................................................................................................................3

Introduction ..............................................................................................................................................................3

Sources of danger / risks associated with operation ................................................................................................3

Injuries caused by breakage of abrasive product ...............................................................................................3

Fumes, dust and sparks .....................................................................................................................................3

Noise ..................................................................................................................................................................4

Vibrations............................................................................................................................................................4

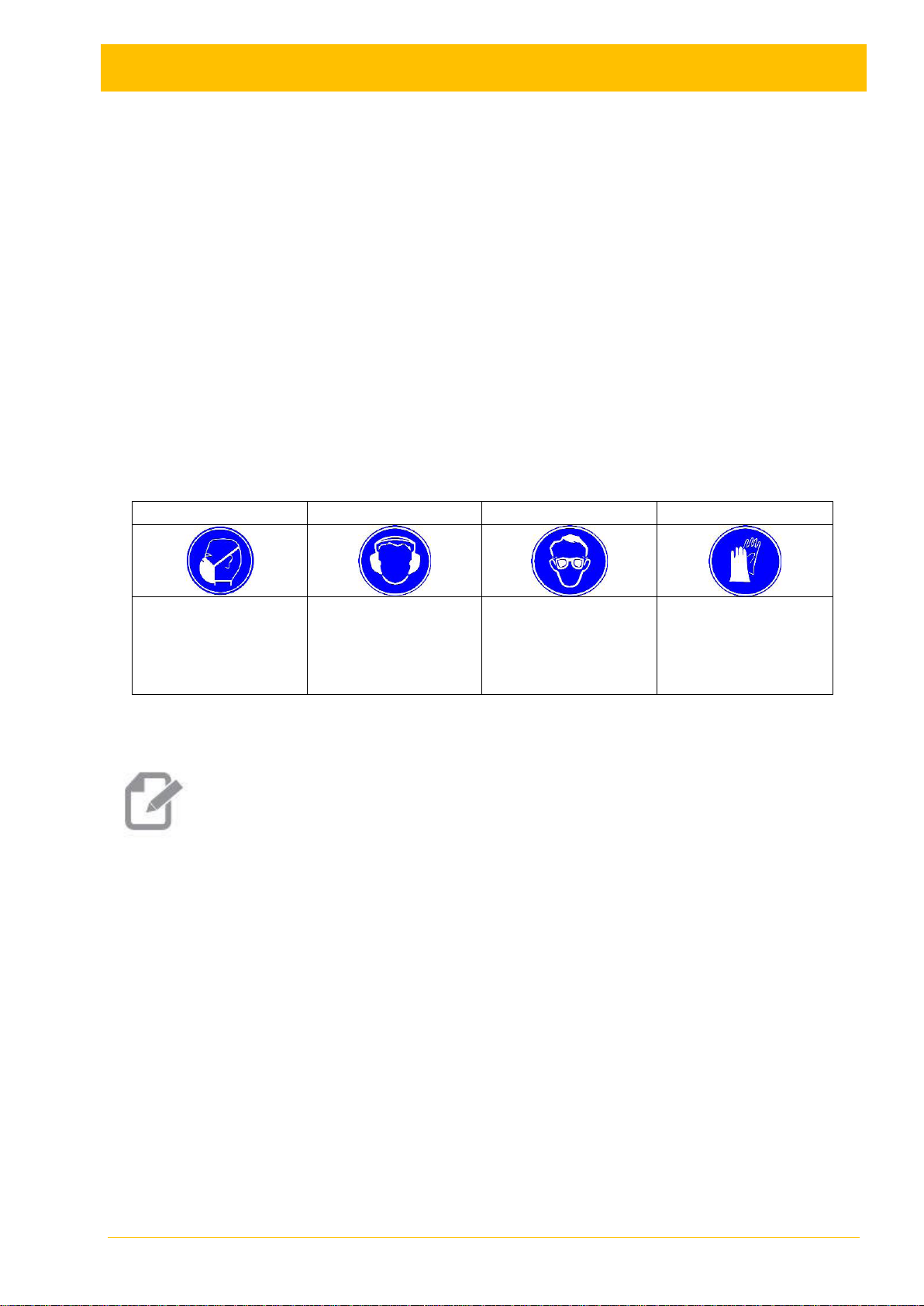

Personal protective equipment required...................................................................................................................4

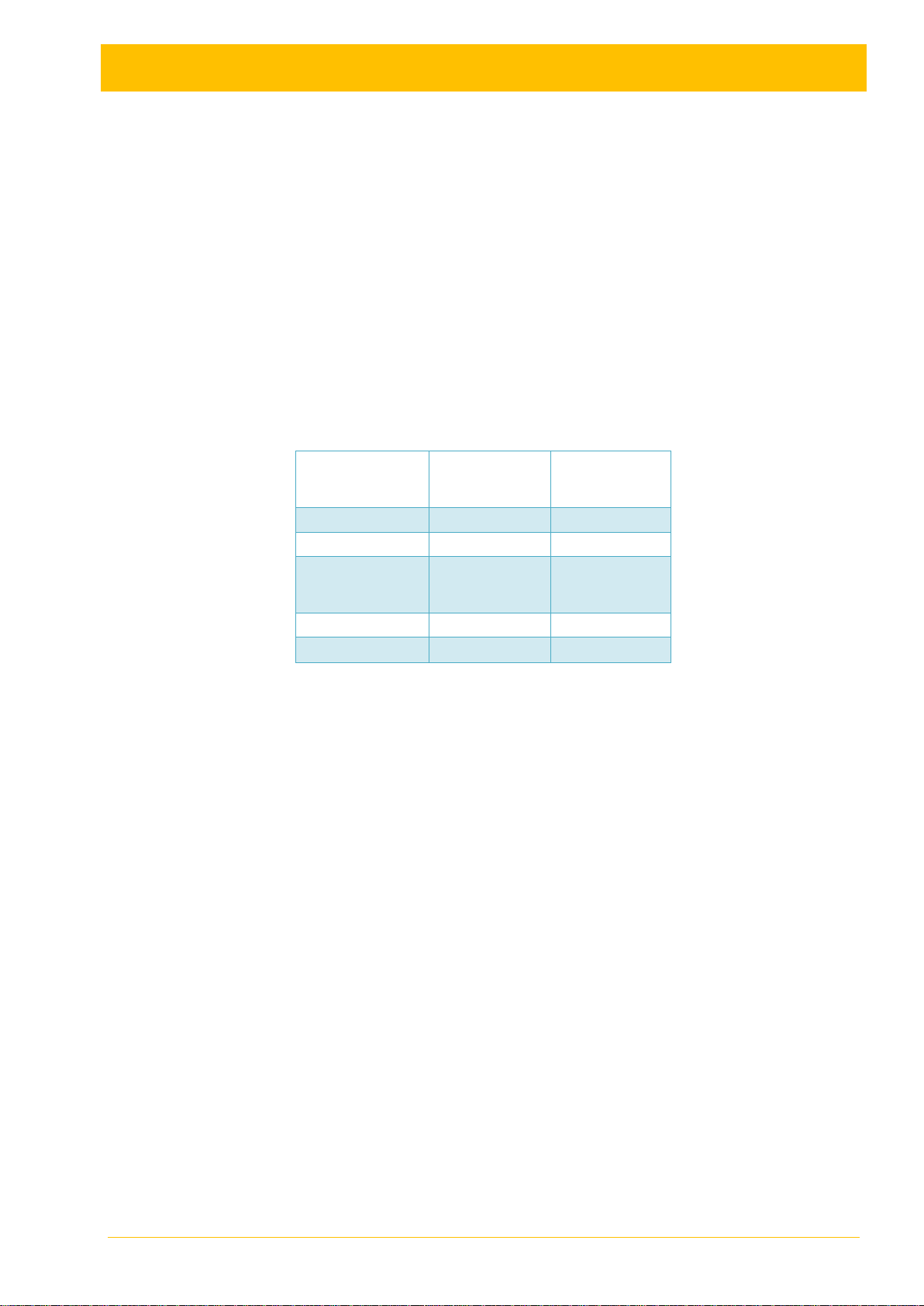

Workplace description..............................................................................................................................................5

Rules for putting machinery into service.............................................................................................................5

Safety and health instructions for the grinder...........................................................................................................5

Conditions for admission to work of a worker .....................................................................................................5

Rules for working with sharpener .......................................................................................................................5

Transport conditions for assembly and disassembly................................................................................................6

Transport work....................................................................................................................................................6

Transport and storage ........................................................................................................................................8

Assembly............................................................................................................................................................8

Stop....................................................................................................................................................................8

Activities before starting work...................................................................................................................................9

Covers................................................................................................................................................................9

Principles and methods of safe working practices..................................................................................................10

It is prohibited to.....................................................................................................................................................10

It's necessary to: ....................................................................................................................................................10

Post-work activities.................................................................................................................................................11

Emergency procedures..........................................................................................................................................11

Remarks.................................................................................................................................................................11

Electrical safety......................................................................................................................................................11

Principles of working with electrical equipment.................................................................................................12