ORDERING INFORMATION:

You may order MK Diamond products through your local MK Diamond distributor or, you may order direct

from MK Diamond.

NOTE: There is a $25.00 minimum order when ordering direct from MK Diamond. All purchases must be

made using VISA or MasterCard.

When ordering direct from MK Diamond, please have the following information ready before calling:

•The Model Number of the saw

•The Serial Number of the saw

•Where the saw was purchased and when

•The Part Number for the part(s) being ordered

•The Part Description for the part(s) being ordered

All parts may be ordered by calling toll free to – 800 421-5830 or 310 539-5221 and asking for Customer

Service. For technical questions, call – 800 474-5594.

RETURN MATERIALS POLICY:

To expedite the service relative to the return of a product purchased through MK Diamond, please observe

the following:

NOTE: When returning all items, they must have been purchased within the previous twelve (12) months.

•Have the Model Number of the saw

•Have the Serial Number of the saw

•Have the location of where the saw was purchased

•Have the date when the saw was purchased

•Contact Customer Service for approval to return the item(s)

•Obtain a Returned Goods Number (RGA) authorizing the return

•Follow the packaging instructions in the following section

•Ensure your item(s) are prepaid to the destination

For returned items, call toll free to – 800 421-5830 or 310 539-5221 and ask for Customer Service. For

technical questions, call – 800 474-5594 or 310 257-2845.

PACKAGING INSTRUCTIONS:

•Remove the Blade guard and Support Angle Assembly

•Dry the saw before shipping

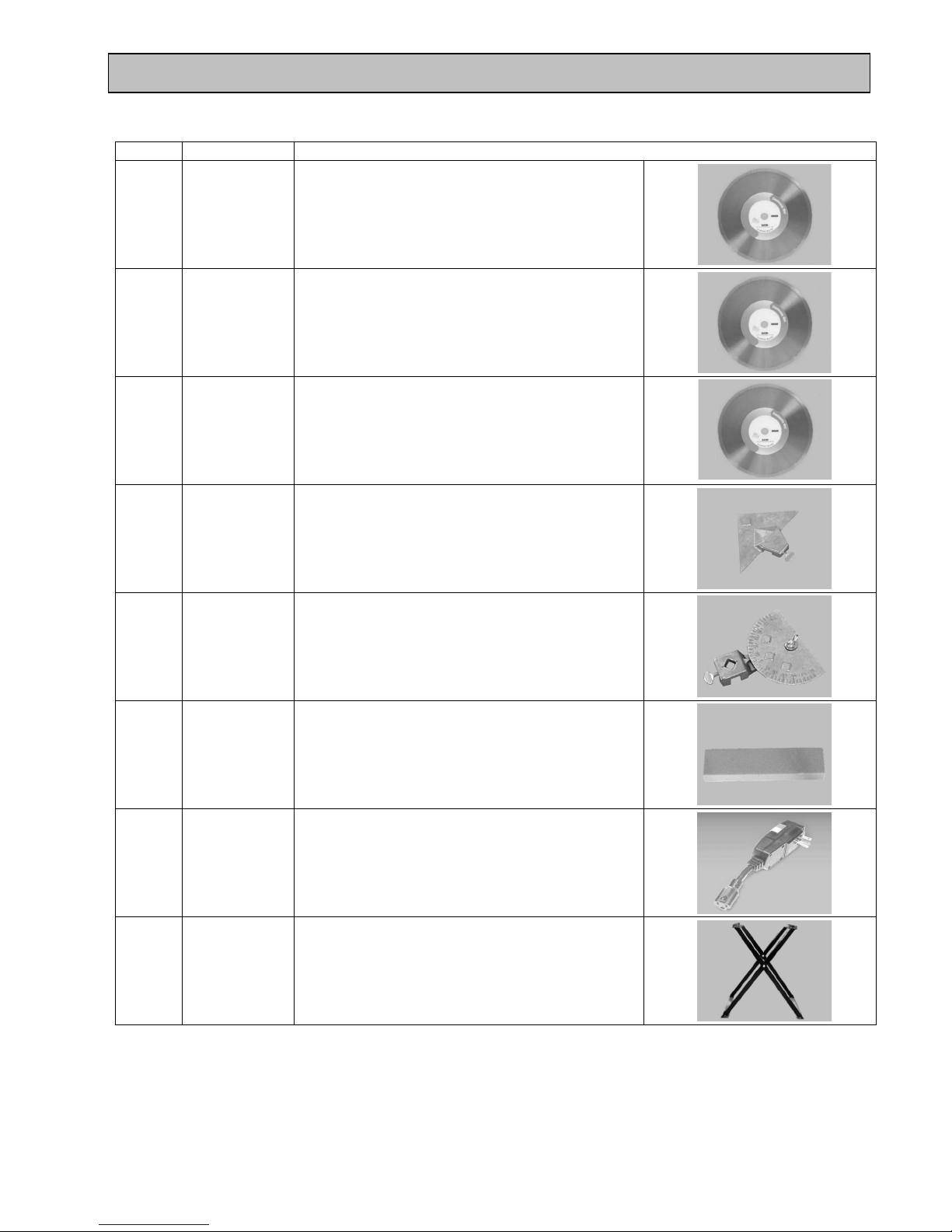

•When packing, include the following: MK-770, Diamond Blade, Blade guard and Support Angle Assembly

and Adjustable Cutting Guide (Other Accessories are not required)

•Package the unit in its original container or one of comparable size (do not ship the unit partially exposed)

•Ensure all parts are secured in the packaging to prevent moving

AUTHORIZED SERVICE CENTERS:

For quicker repair time, you may contact MK Diamond Customer Service, toll free, at – 800 421-5830 or 310

539-5221 for the Authorized Service Center closest too you. For technical questions, call – 800 474-5594.