FEDERAL PACIFIC PMDF Series User guide

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 1

TYPE PMDF

INSTRUCTIONS FOR INSTALLATION AND OPERATION

15kV • 25kV • 35kV

QUALIFIED PERSONS ..........................................1

SAFETY ......................................................2

Safety Information ..........................................2

Following Safety Instructions .................................2

Safety Precaution ...........................................2

INTRODUCTION ...............................................3

Receiving ..................................................3

Handling ...................................................3

Storage ....................................................3

GENERAL DESCRIPTION .......................................3

SECURITY FEATURES ..........................................3

INSTALLATION ................................................4

Placement of Unit ...........................................4

Customer Cable Connections .................................4

BUSHING WELLS AND BUSHINGS ..............................5

Bushing Wells ..............................................5

Bushings ...................................................6

REMOVAL OF LOADBREAK ELBOWS .............................6

INSTALLATION OF METERING TRANSFORMERS ..................7

TYPICAL DIMENSIONS.........................................8

DOOR SYSTEM................................................9

Door-Latch Features .........................................9

MAINTENANCE ..............................................10

OPTIONAL FEATURES .........................................10

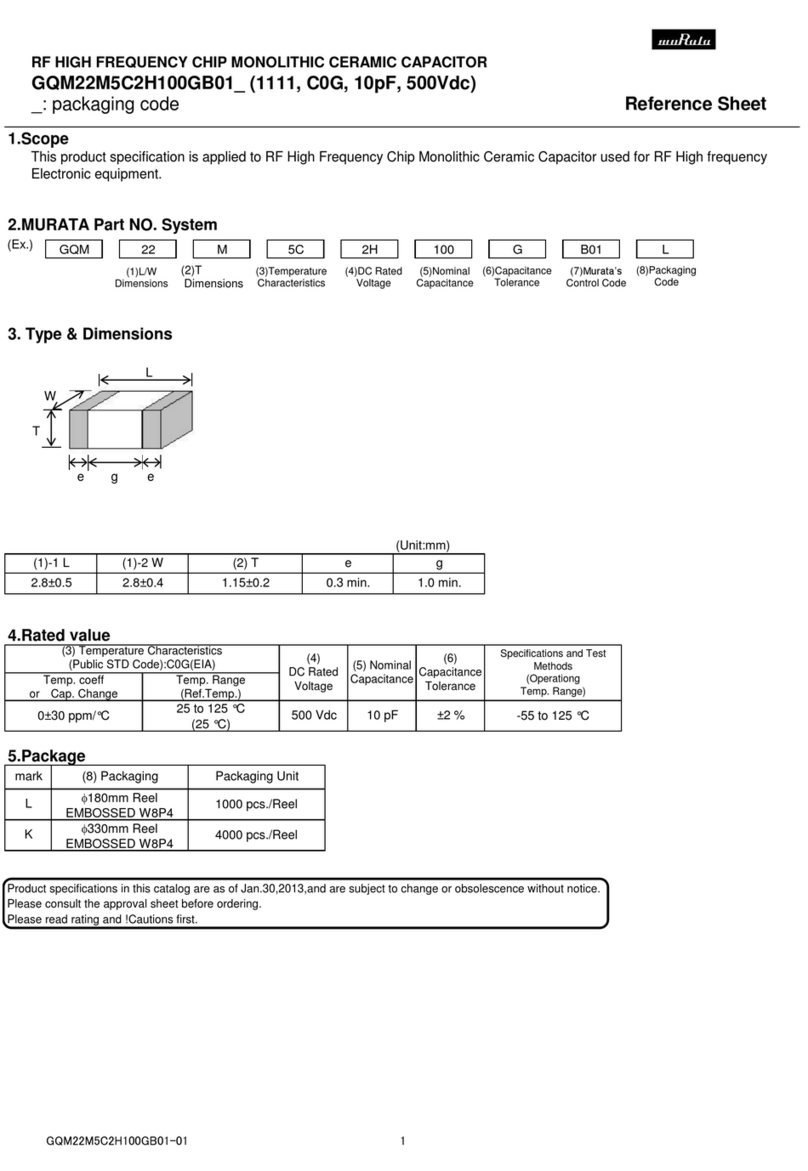

Figure 1. External views of PMDF Pad-Mounted Switchgear with optional

KWH meter mounted in an isolated low-voltage compartment attached to unit.

Federal Pacific PMDF models meet applicable industry standards, which are

ANSI 386 and IEEE C57.12.28.

© 2014 Electro-Mechanical Corporation

Qualified Persons

The equipment covered by this publication must be selected for a spe-

cific application and it must be operated and maintained by Qualified

Persons who are thoroughly trained and knowledgeable in the instal-

lation, operation, and maintenance of underground power distribution

equipment along with the associated hazards that may be involved. This

publication is written only for such qualified persons and is not intended

to be a substitute for adequate training and experience in safety proce-

dures for this type of equipment. Proper installation is the responsibility

of the operating and construction personnel and the utility performing

and authorizing the work. Completion of these instructions implies no

further warranty by the manufacturer.

A Qualified Person is defined in the National Electrical Code (NEC/

NFPA-70) as:

One who has skills and knowledge related to the construction and op-

eration of the electrical equipment and installations and has received

safety training to recognize and avoid the hazards involved.

The specific electrical safety training requirements to be considered a

qualified person are detailed in NFPA-70E, Article 110.1(D), Employee

Training. Some of the requirements from the 2012 edition are shown

below. For the specific detailed training requirements for a Qualified

Person make certain to refer to the most recent applicable edition.

These training requirements would include, but are not limited, to the

following key points:

• The skills and techniques necessary to distinguish exposed energized

parts from other parts of electrical equipment.

• The skills and techniques necessary to determine the proper approach

distances corresponding to the voltages to which the qualified person

will be exposed.

• The proper use of the special precautionary techniques, personal pro-

tectiveequipment,insulatingandshieldingmaterials, and insulatedtools

for working on or near exposed energized parts of electrical equipment.

• Tasks performed less often than once per year have additional training

requirements.

These instructions are intended only for such qualified persons. They

are not intended to be a substitute for adequate training and experience

in safety procedures for this type of equipment. Additionally, the recom-

mendations in this instruction bulletin are not intended to supersede or

to take the place of established utility safety guidelines and established

practices. If there is any question, consult with your foreman or supervi-

sor, as appropriate.

Please refer to OSHA 29 CFR 1910.399 and NFPA 70E Articles 100 and 110.

WARNING

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 2

SAFETY INFORMATION

Understanding Safety-Alert Messages

There are several types of safety-alert messages which may

appear throughout this instruction bulletin as well as on labels

attached to the pad-mounted switchgear. Familiarize yourself

with these types of messages and the importance of the various

signal words, as explained below.

If you do not understand any portion of this instruction bulletin

and need assistance, contact the Switchgear Division of Federal

Pacific at 276-669-4084.

Replacement Instructions & Labels

If you need additional copies of this instruction bulletin, contact

Federal Pacific at 276-669-4084.

It is important that any missing, damaged, or faded labels on the

equipment be replaced immediately. Replacement labels are

available by contacting Federal Pacific.

SAFETY PRECAUTION

FOLLOWING SAFETY INSTRUCTIONS

NOTICE

Thoroughly and carefully read this instruction

bulletin before installation of the pad-mounted

switchgear, before switching with elbows or

installingoraccessingthemeteringtransformers

in this equipment, and before performing any

maintenance on the equipment.

......

DANGER

Federal Pacific Fuse Mountings in conjunction with appropri-

ate fuses are designed to protect equipment and to disconnect

faulted equipment from the system. The fuses cannot protect

personnel from injury or electrocution if contact is made with

energized circuits or hardware.

NOTICE

NOTICE is used to address practices not related to physical

injury.

SAFETY

INSTRUCTIONS

SafetyInstructions (orequivalent)signs indicatespecific safety-

related instructions or procedures.

DANGERindicates a hazardoussituationwhich, if notavoided,

will result in death or serious injury.

DANGER

WARNING

WARNINGindicatesahazardoussituationwhich, ifnotavoided,

could result in death or serous injury.

CAUTION

CAUTIONindicatesa hazardoussituationwhich,ifnot avoided,

could result in minor or moderate injury.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 3

Introduction

PMDF pad-mounted switchgear is designed to provide depend-

able on-the-line service and to make installation, operation

and maintenance as simple as possible. Federal Pacific PMDF

models meet applicable industry standards, which are ANSI 386

and IEEE C57.12.28.

High quality materials and careful workmanship have been com-

binedtoprovidethebestswitchgearavailable. Theswitchgearhas

been thoroughly inspected and adjusted at the factory. However,

successful operation depends on proper installation and care.

This manual has been written to assist you in obtaining long and

economical service from your switchgear.

Readthismanualbeforeinstallingandoperatingyourswitchgear.

Receiving

Upon receipt of the switchgear, check each item received for

shipping damage. Each item should be checked against the ship-

ping manifest to assure that the proper number of items were

received. Should any shortage or damage exist, note it on the

shipping papers. A claim should be filed at once with the carrier

and the Federal Pacific agent or sales office should be notified.

The carrier is responsible for all damage occurring during tran-

sit. Receiving personnel must note all damage to equipment on

shipping papers so that claims can be processed.

Handling

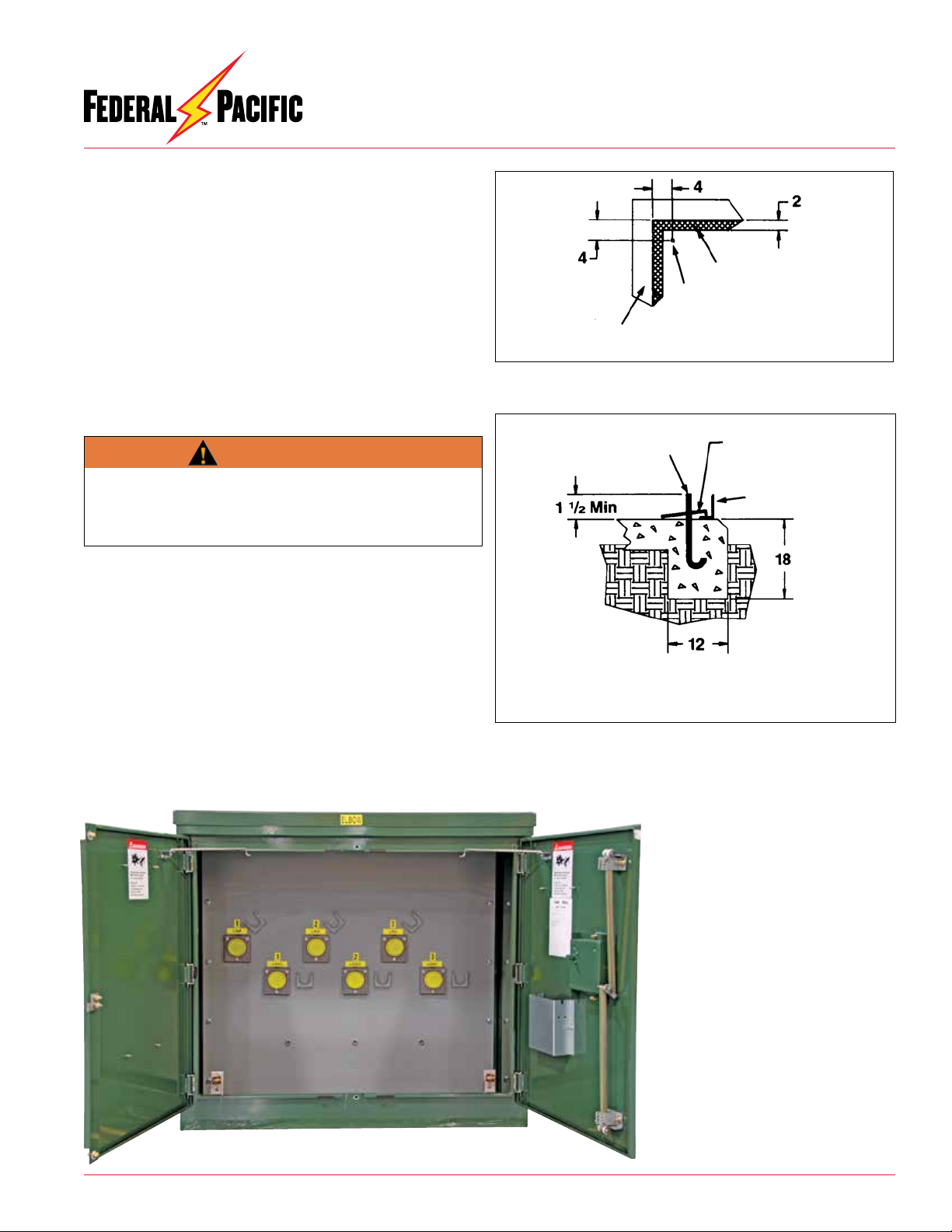

Removable lifting plates are provided to allow the use of hooks to

lift the complete enclosure. The lifting device should be arranged

to evenly distribute the lifting force between the lifting plates.

Do not lift at an angle less than 60° from the horizontal. See

Figure 2. A spreader bar may be required to maintain the proper

minimum angles. Failure to comply with this requirement may

result in damage to the equipment.

The switchgear is securely mounted to a sturdy shipping pallet

with provisions for forklift use. The use of a forklift truck is not

recommended, but if this method is used the forks must extend

completely through the skid to avoid damaging the equipment.

Storage

The switchgear as received may be wrapped in a protective

plastic film, which must be removed for storage.

To avoid damage to the enclosure finish, the protective film

must be removed for outdoor storage of unit.

Export or special packing is available as an option based on

customer’s requirements and special conditions. Separate in-

structions are available for these situations.

Figure 2. Lifting Method

General Description

PMDF dead-front pad-mounted

switchgear consists of one or more

single-pole 200 ampere bushing

wells to accommodate 200 ampere

loadbreak (or non-loadbreak) in-

serts and elbows. Alternately, the

unit may be optionally equipped

with

600 ampere bushings to ac-

commodate 600 ampere elbow

connectors. When used with 200

ampere bushing wells and load-

break inserts and elbows, and

other protectivedevices, thePMDF

switchgear provides a secure and

efficient means of single-pole

switching with elbows on the in-

coming lines.

In addition, the unit may be furnished with metering transformers

(voltage transformers and current transformers), or provisions

only for metering transformers, and with optional meter socket

(mounted on the enclosure or in a low-voltage compartment)

and associated wiring. When the unit is provided with “Mount-

ing Provisions only for Metering Transformers, the customer is

responsible for providing, installing, wiring, and connecting all

metering transformer and associated secondary components.

Security Features

PMDF pad-mounted switchgear meets the security require-

ments in IEEE C57.12.28 and incorporates a number of security

features to minimize hazards to operating personnel.

1. Rugged 11-gauge steel, using all welded construction of the

enclosure, with a bolted roof, and hinged and bolted doors

assures a tamper-resistant design.

2. Padlockable doors with security bolts provide customer-

controlled access.

3. 200 ampere bushing wells of cycloaliphatic epoxy and with

removable studs.

NOTICE

NOTICE

4. Hazard-alert signs and labels, both external and internal,

indicate potential hazards to personnel.

5. Full-width fiberglass barriers (or optional clear polycarbonate

barriers) behind doors on fuse compartment.

6. Wind brace to secure enclosure door open and a cable-

connected clip to secure inner barriers open.

WARNING

Before energizing the switchgear, remove all yellow and red

shipping caps on bushings and bushing wells, and replace

them with a suitable system of insulated separable connectors

(elbows), insulating protective covers, or plugs, as appropriate.

Failure to replace the shipping caps may result in flashover,

equipment damage, serious personal injury, or death.

CAUTION

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 4

Customer Cable Connections

1. Make up the primary cable connections per user’s standard

URDoperatingprocedures,cable manufacturer instructions, and

elbow terminator manufacturer instructions.

Installation

Each unit is shipped with this instruction bulletin which is located

inside one of the compartment doors. These instructions should

be reviewed prior to placing unit on pad.

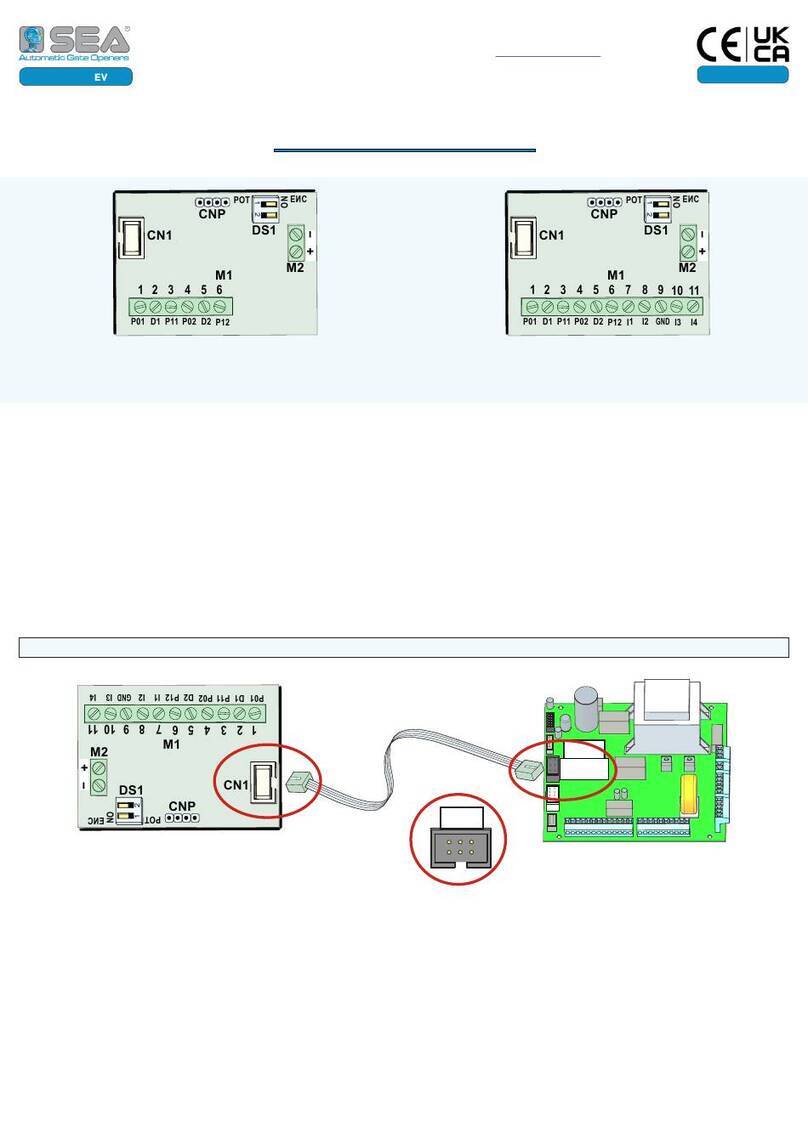

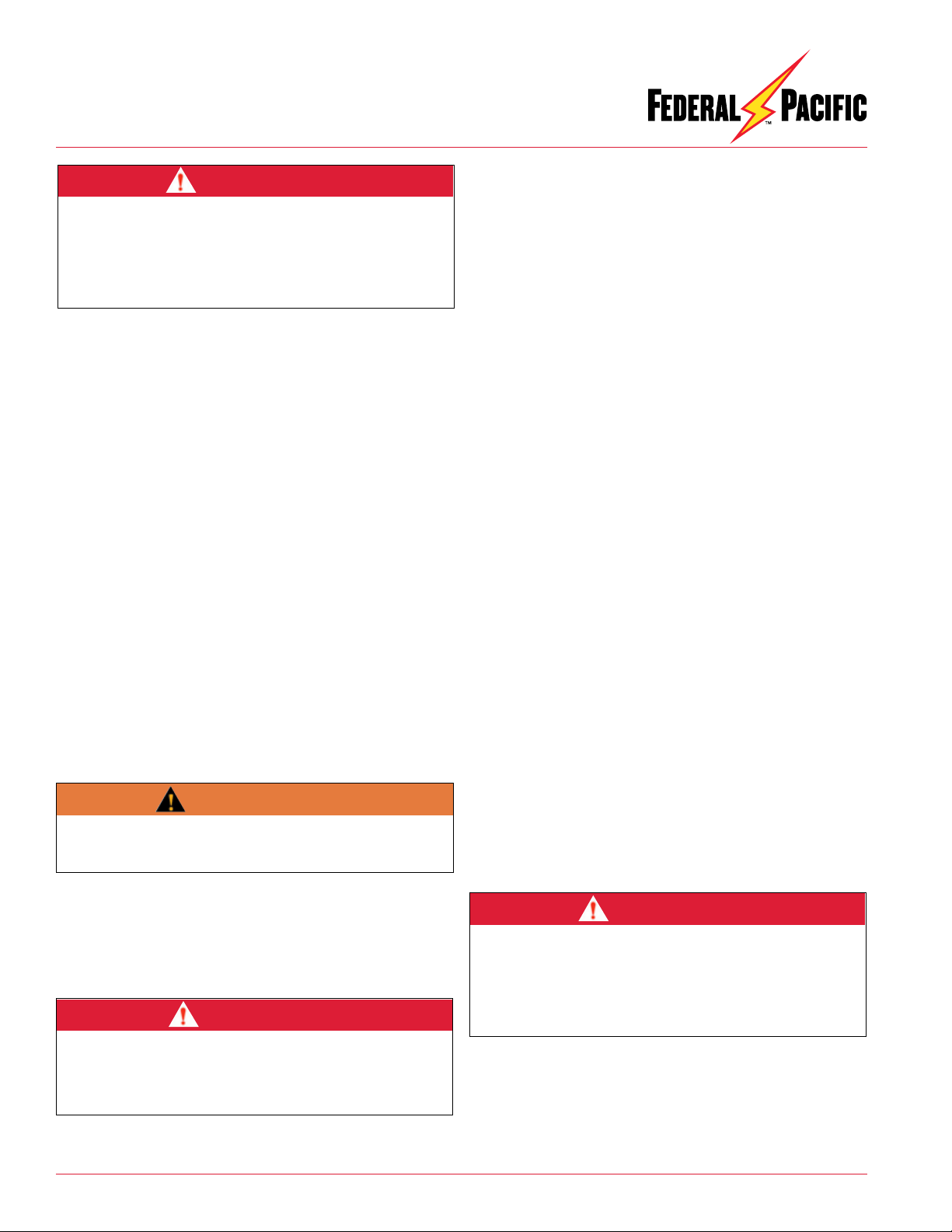

Placement of Unit

Remove unit from shipping pallet per handling procedures on

Page 3 (see Figure 2). When unit has been correctly oriented and

placed on pad (see Figure 3), verify that unit is level and shim if

necessary between unit base and pad. Secure unit to pad using

four (4) tie-down clips as furnished (see Figures 3, 4 and 5). Check

compartment door operation for any binding due to enclosure

distortion and re-shim if necessary. A recessed grouting should

then be applied between unit base and pad to prevent entry of

foreign objects, vegetation, insects, animals, and moisture.

Figure 3. Typical pad layout and associated circuit diagram for one particular PMDF design. DO NOT USE FOR CONSTRUCTION PURPOSES.

2. Connect the concentric neutral wires to the enclosure ground

pads inside the enclosure to facilitate ground system conforming

to user’s grounding procedures.

The maximum momentary rating of the switchgear must

be considered when selecting cable size for connecting

switchgear to system ground. Refer to unit rating sheet on

inside of doors.

3. Install fault indicators, if applicable in accordance with the

manufacturer’s instructions.

ONE LINE DIAGRAM

LINE LOAD LOAD

"CT" AND "PT"

8

46

8

54

5462 45 3/4

30 1/2

20

8

8

15

4

4

RECOMMENDED PAD LAYOUT

COMPARTMENT

METERING

SEE CORNER DETAIL

ELBOW

COMPARTMENT

ANCHOR BOLT

LOCATIONS

CUSTOMERS

EQUIPMENT

BASE

PAD

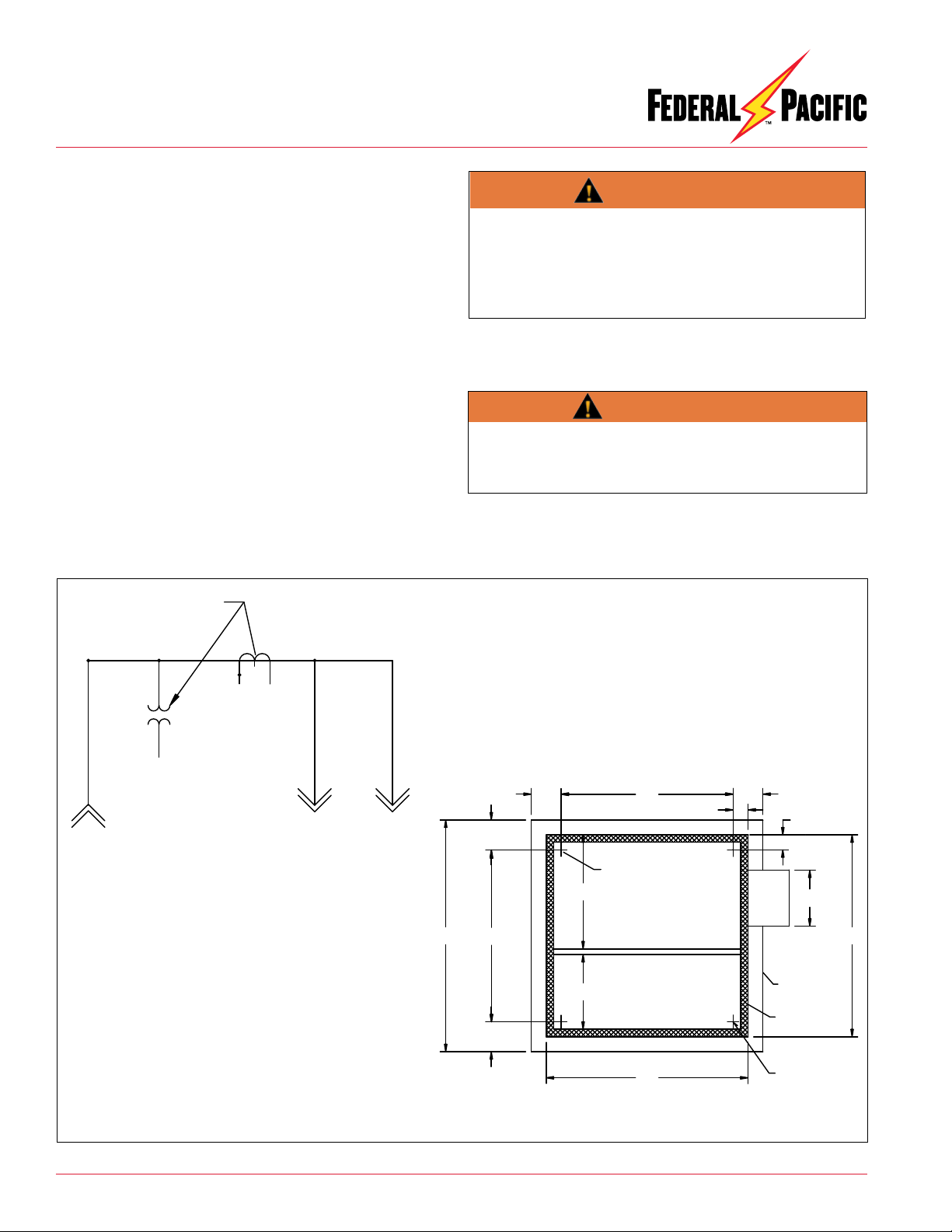

WARNING

WARNING

Before energizing the switchgear, remove all yellow and red

shipping caps on bushings and bushing wells, and replace

them with a suitable system of insulated separable connectors

(elbows), insulating protective covers, or plugs, as appropriate.

Failure to replace the shipping caps may result in flashover,

equipment damage, serious personal injury, or death.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 5

Figure 5. Bolting Units to Pad

Cabinet

5/8-11 Anchor

Bolts (by others) 4 Tie Down

Plates Provided With

Unit

Recommended

Pad Section

Figure 4. Typical Anchor Bolt Location

Corner Detail

Anchor Bolt

Enclosure Flange

Customers

Box Pad

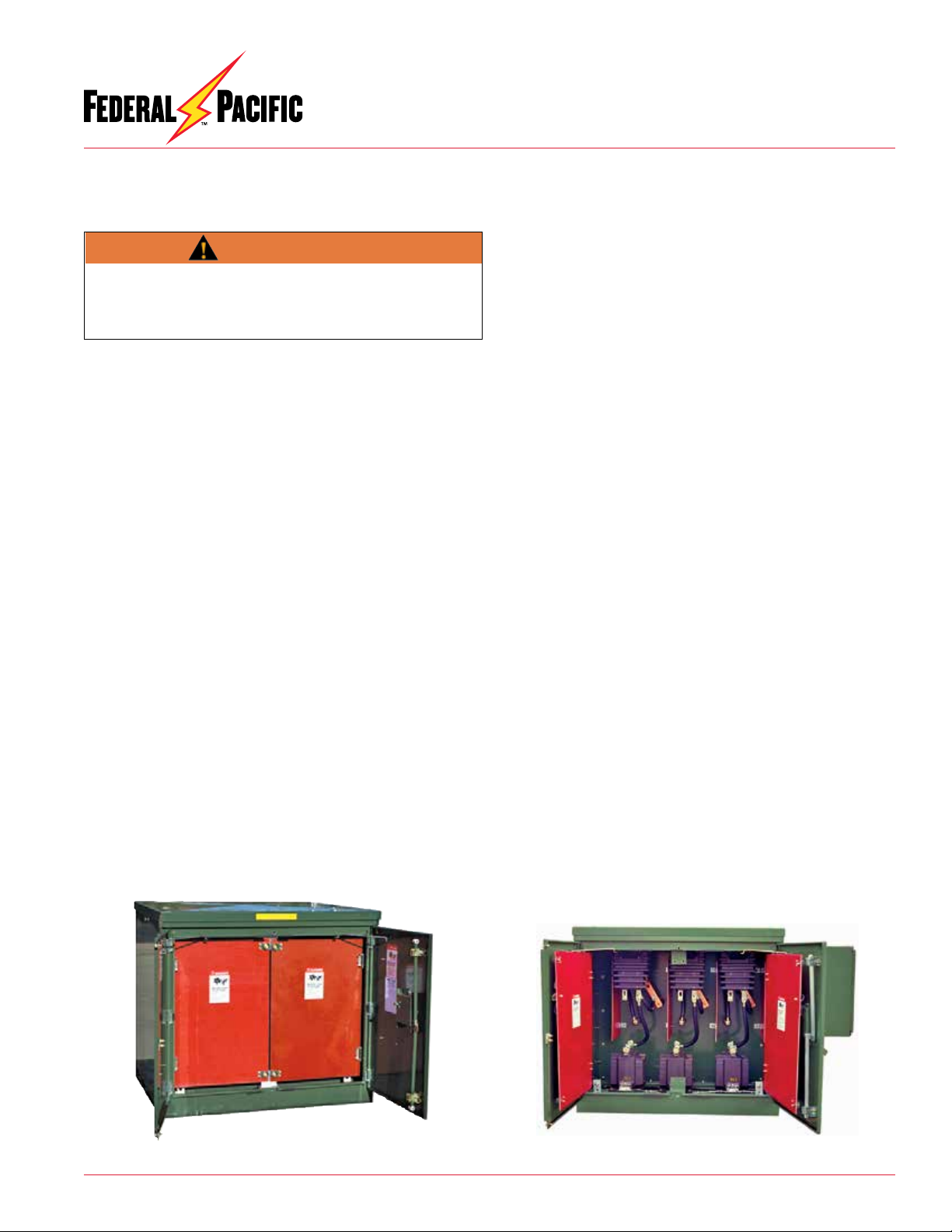

Figure 6. View of PMDF elbow-compartment

side with doors open to show customer selected

bushing wells (pictured) or, if specified optional

600 ampere bushings. The 200 ampere bushing

wells accommodate loadbreak inserts and

elbow connectors. Dust covers (yellow discs)

must be removed from all unused positions and

replaced with protective insulating bushing-

well plugs (or insulating bushing covers when

furnished with 600 ampere bushings, which

have red dust covers).

Bushing Wells and Bushings

Federal Pacific PMDF Pad-Mounted Switchgear is furnished

with a choice of either 200 ampere bushing wells or 600 ampere

bushings on the line side or load side. The bushing wells and

bushings meet ANSI 386 standard requirements.

Bushing Wells

The 200 ampere bushing wells accommodate 200 ampere elbow

(separableinsulated)loadbreakconnectors and accessories. The

units are shipped with a yellow dust cover over each bushing well

to preventcontamination. Dust covers are NOT capable of

provid-

ing any electricalinsulationat medium voltage levels.Therefore,

if an elbow is not to be connected to a bushing well, prior to

energization the dust cover MUST be removed and replaced

with an insulating protective bushing-well plug. See Figure 6.

Install load-break inserts following the insert manufacturer’s

instructions supplied therewith. Terminate cables and install 200

ampereloadbreakelbowsandaccessoriesfollowinginstructions

provided by the cable manufacturer and the elbow manufacturer.

The 200 ampere elbows are a loadbreak device and, if standard

system operating practices and conditions permit, may be re-

moved when the equipment is energized, providing single-pole

loadbreak live switching is performed using insulated shotgun

clamp sticks. Before performing any live-switching with elbows,

install insulating feed-through standoff bushings on the parking

stand adjacent to the loadbreak elbow to be switched.

WARNING

For all un-terminated phase positions, failure to remove dust

covers and replace with a protective insulating bushing-well

plug prior to energization may result in equipment damage,

personal injury or death.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 6

Terminate cables and install 600 ampere elbows and accessories

following instructions provided by the cable manufacturer and

the elbow manufacturer. The 600 ampere elbows are a dead-

break device and must NOT be removed when the equipment

is energized.

Always follow user’s and manufacturer’s standard operating

procedureswhen installing, maintainingor removing 200 ampere

loadbreak elbow connectors and accessories. Such procedures

should always include:

1. Verifying the correct circuit is being maneuvered,

2. Installing portable feed-through standoff bushings on the

parkingstandadjacenttotheloadbreakelbow tobe switched,

3. Recognizing that the unit may be subject to back feed and

taking necessary precautions to isolate the equipment from

such possibility before maneuvering 200 amp elbows when

dead-break procedures are to be followed,

4. Testing for voltage, and

5. Grounding the circuits before any other work is attempted.

Bushings

The 600 ampere bushings accommodate 600 ampere elbow

(separable insulated) connectors and accessories. The units

are shipped with a red dust cover over each bushing to prevent

contamination. Dust covers are NOT capable of providing any

electrical insulation at medium voltage levels. Therefore, if an

elbow is not to be connected to a bushing, prior to energization

the dust cover MUST be removed and replaced with an insulating

protective bushing cover.

Always follow user’s and manufacturer’s standard operating

procedureswheninstalling,maintainingorremoving600 ampere

elbow connectors. Such procedures should always include:

1. Opening adjacent load-interrupting devices to completely de-

energize the unit,

2. Recognizing that the unit may be subject to back feed and tak-

ing necessary precautions to isolate the equipment from such

possibility before maneuvering 600 amp elbows,

3. Testing for voltage to verify circuit is de-energized before

maneuvering 600 amp elbows, and

4. Grounding the circuits before any other work is attempted.

Removal of Load-Break Elbows

1. Remove the padlock and fully loosen the penta-head bolt. Pull

and lower the door handle cover to open the active elbow-

compartmentdoorandsecurewiththewindbrace. SeeFigures

7 through 14.

2. Loosenthetwo pentaheadboltsthatsecurethepassiveelbow

compartment door and secure it open using the windbrace.

3. System operating practices may allow loadbreak elbows to

be switched while the associated cable is energized. Follow

loadbreak elbow manufacturer’s procedures for proper tech-

nique whenlive switchingisto beperformedusing theelbows.

If live switching is not permitted with elbows, appropriately

rated voltage testers should be used to verify that the circuit

is completely de-energized.

4. Using the shotgun clamp stick, install and secure the feed-

through standoff bushing on the parking stand.

5. If live switching of elbows is not permitted for operating

circumstances of the system, test the elbow to be moved for

voltage. After verifying that voltage is not present, or if live

switching is permitted, use the shotgun clamp stick to remove

the elbow connector from the appropriate bushing well, fol-

lowing standard system operating procedures and the elbow

manufacturer’s instructions. Move the elbow connector onto

a standard feed-thru standoff bushing that is placed in the

parking stand.

WARNING

Failure to remove dust covers and replace with a protective

insulating bushing cover prior to energization may result in

equipment damage, personal injury or death.

DANGER

Do not attempt to remove 600 ampere elbows (separable

insulated) connectors when the equipment is energized. Any

attempt to remove 600 ampere elbows while the equipment

is energized will result in equipment damage, personal injury

or death.

DANGER

When removing energized 200 ampere elbows (separable

insulated) connectors, do not allow the elbow probe to

touch any grounded surface. Before working on any cables

or circuits, test for voltage and ground the circuit. Failure to

follow proper procedures while the equipment is energized

will result in equipment damage, personal injury or death.

DANGER

When removing energized 200 ampere elbows (separable

insulated) connectors, do not allow the elbow probe to

touch any grounded surface. Before working on any cables

or circuits, test for voltage and ground the circuit. Failure to

follow proper procedures while the equipment is energized

will result in equipment damage, personal injury or death.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 7

6. Install an insulating protective cover on the exposed 200

amp bushing-well insert following grounding-elbow manu-

facturer’sinstructions.Connecttheground-clampconnector

of the grounding elbows to the enclosure ground rod.

Before installing grounding elbows, test for voltage. Failure

to properly test for voltage to establish that the circuit is de-

energized before installing grounding elbow may result in

equipment damage, personal injury or death.

7. If appropriate for operating circumstances of the system,

test the remaining feed-through standoff bushings for volt-

age and, after confirming that voltage is not present, then

install a grounding elbow on the remaining bushing.

8. Repeattheabove proceduresfor each200 ampere loadbreak

elbow that is to be moved.

9. Aftercompletingthework tobeperformed,the groundelbows

are to be removed. First, remove the grounding elbow from

the feed-thru bushing. Then, remove the ground connector

from the ground rod.

10. If applicable, remove the insulating protective cover from

the bushing-well insert.

11. Following elbow manufacturer’s proper procedure for posi-

tioning, removal and closing circuit using elbows, move the

elbow connector from the feed-through standoff bushing

and secure it onto the 200 ampere bushing-well insert.

12. Remove the feed-through standoff bushing.

13. Remove and store the windbrace.

14. Close and secure the passive door by fully tightening both

the top and bottom penta-head bolts.

15. Close and padlock the main doors before leaving the gear.

Installation of Metering Transformers

1. Remove the padlock and fully loosen the penta-head bolt. Pull

and lower the door handle cover to open the active elbow-

compartmentdoorandsecurewiththewindbrace. SeeFigures

7 through 14.

2. Loosenthetwopentaheadboltsthatsecure thepassiveelbow

compartment door and secure it open using the windbrace.

3. Loosen the penta-head bolts on each inner barrier and secure

them open using the pin proved on the door inserted into the

clip on the top edge of the barrier.

4. Installthevoltagetransformers(alsoknownaspotentialtrans-

formers or PTs) and current transformers (CTs) in accordance

with the manufacturer’s instructions and the user’s standard

operatingpractice. Makecertainthatthecurrenttransformers

are installed and oriented in the proper polarity.

5. The voltage transformer incoming connections must be in-

stalled on the line (or source) side of the current transformer

connections.

6. Make the connections for the voltage transformers with ap-

propriately sized copper bus or insulated copper cable.

7. Make the connections for the wound (or bar) type current

transformerswiththeappropriatelysizedcopperbusorcopper

cable.

8. Install and wire a shorting-type terminal block on the sec-

ondary side of the current transformers in accordance with

applicable manufacturer’s instructions and user’s standard

practice instructions.

9. Install and wire a terminal block on the secondary side of

the voltage transformer in accordance with the applicable

manufacturer’s instructions and the user’s standard practice

instructions.

10. Make appropriately protected secondary connections from

the voltage transformer’s and current transformers to the

kilowatt-hour meter in accordance with the applicable

manufacturer’sinstructionsand theuser’sstandard practice

instructions.

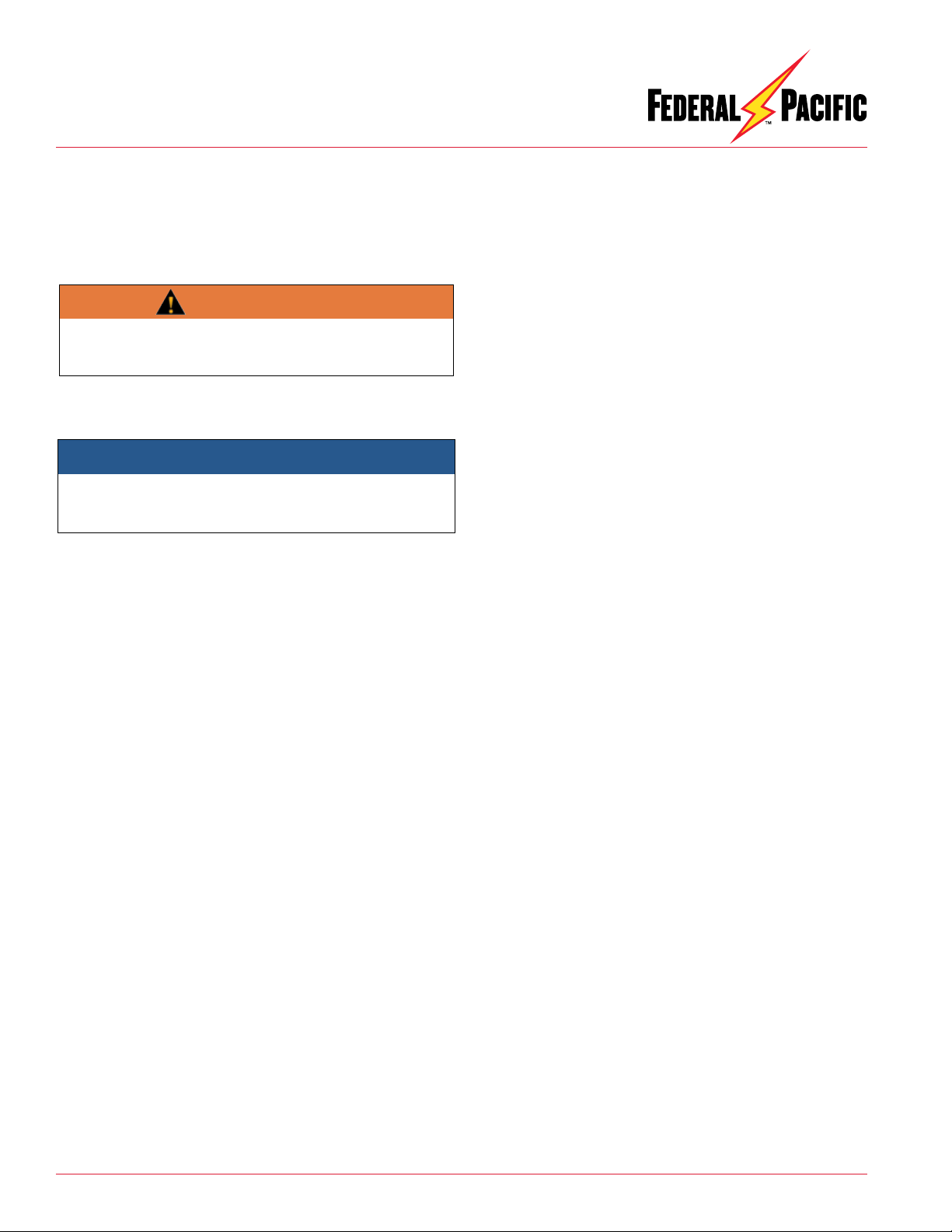

Figure 8. Open door view of metering transformers with

fiberglass inner barriers secured open.

Figure 7. Open door view of PMDF with inner

barriers bolted in place.

WARNING

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 8

Catalog

Number

Volt

Nom.

kV

BIL

Dimensions - Inches*

A B C D E F G H J K L M N P R

PMDF-315-R6-200 15 95 54 54 51 22 28 14 14 7 NA NA 22 62 62 46 46

PMDF-315-L9-200 15 95 54 54 51 22 28 14 14 7 5 8-5/8 22 62 62 46 46

PMDF-325-R6-200 25 125 66 66 51 24-1/2 30-1/2 17-1/2 16 8-1/2 NA NA 24 74 74 58 58

PMDF-325-L9-200 25 125 66 66 51 24-1/2 30-1/2 17-1/2 16 8-1/2 6 8-3/8 24 74 74 58 58

PMDF-335-R6-200 35 150 76 66 53 24-1/2 33 22-1/2

18-5/16

12-9/16

5-5/8 8-1/2 24 74 84 68 58

34.5 kV designed to customer specifications.

Typical Dimensions*

*Do not use these dimensions for construction purposes.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 9

Door System

The door latching feature furnished on the main doors provides

ease in opening and closing of the doors.

Door-Latch Features

Features of the door-latch system are:

• Three-point latching of doors. See Figure 12.

• After unlatching on opening, the door is secured open with

a windbrace. Hinged inner barriers are secured open with

a cable-connected pin on the door and inserted into a clip

on the top edge of the barrier. See Figure 12. For closing, the

door is manually latched, bolted closed and padlocked.

• Unlatching is only accomplished by first rotating (in counter-

clockwise direction) the captive penta-head (or hex-head)

bolt through several revolutions and then lowering the door

handle. See Figures 8 through 10.

Figure 13. Padlock cannot be inserted until

penta-head bolt is fully tightened.

Figure 14. Always close, latch and padlock

the enclosure door before leaving the unit or

when working on the opposite side.

Figure 10. Door handle cover is secured

closed by a penta-head (or hex-head) bolt.

Turn socket counter-clockwise to loosen

bolt.

Figure 9. Door handle is stainless steel. Figure 11. With penta-head bolt fully

loosened, handle can be pivoted down to

unlatch the door.

Figure 12. Three-point door latch

mechanism. Enclosure door is

secured open by windbrace. Inner

barrier is secured open by a pin on

the door inserted into a clip on the

barrier.

• The door padlocking provision prevents unlatching the door-

latch cover until the padlock has been removed. Padlocking

also secures the door to the cabinet enclosure. See Figures

13 and 14.

• The protective door-latch cover is stainless steel. Also, ac-

cess to the penta-head bolt is only possible after the padlock

has been removed.

• A closed, latched and padlocked door can successfully

withstand a "pull" greater than 600 pounds at any point on

the door.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 10

Maintenance

FederalPacificswitchgeardoesnotrequireroutine mechanical or

electrical maintenance. However, the following are some recom-

mendations for enhancing continued service of the equipment.

1. Yearly mechanical exercising of the loadbreak elbows is

recommended.

The switchgear must be completely de-energized from all

sources before any attempt is made to enter the metering

transformer compartment of the switchgear.

2. Check for cleanliness generally, but particularly for accumula-

tion of any foreign material on insulators, barriers and metering

transformers.

Barriersand insulatorscan be cleanedwith anon-alcoholbased

cleaner that does not leave any residue when dry. Residue

must be removed.

Optional Features

Standard options can be supplied that best serve the customer's

needs and operating practices. These are listed below with the

applicable catalog number suffix.

Base Spacer-Non-compartmented or compartmented suffix

beginning with letter “-A” — followed by a number, or “-AS”

followed by a number when of stainless steel.

Finish Color and Special Cabinet Material

Fault Indicators

Copper Bus (-C)

Strip Heaters

Stainless Steel (-F4)

600 Ampere Bushings in lieu of 200 ampere bushing wells

(-600)

NOTICE

WARNING

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 11

This Page Intentionally Left Blank

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2D-700

INSTALLATION & OPERATION INSTRUCTIONS

PMDF PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017 VER. 2.1

PAGE 12

This Page Intentionally Left Blank

Every effort is made to ensure that customers receive an up-to-date instruction manual on the use of Federal Pacific

products; however, from time to time, modifications to our products may without notice make the information contained

herein subject to alteration.

© 2014 Electro-Mechanical Corporation

This manual suits for next models

5

Table of contents

Popular Industrial Electrical manuals by other brands

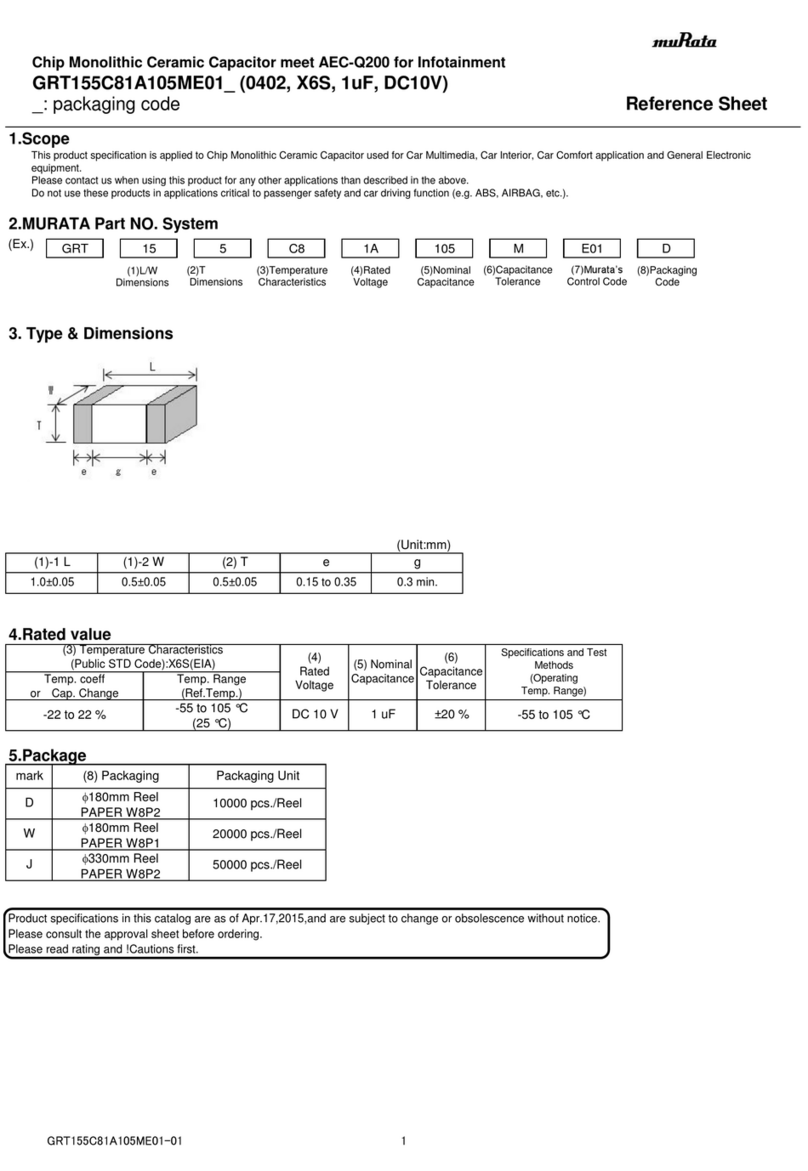

Murata

Murata GRT155C81A105ME01 Series Reference sheet

Murata

Murata GQM22M5C2H220GB01 Series Reference sheet

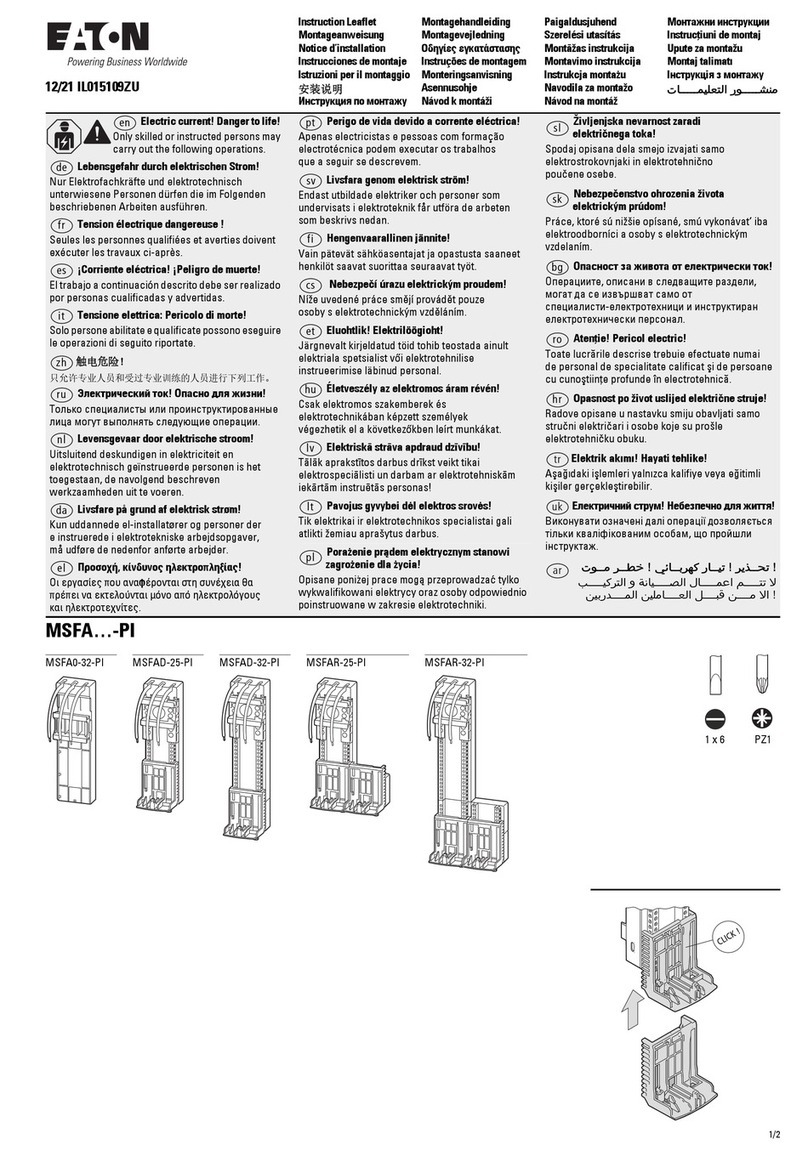

Eaton

Eaton Power Defense NZM-XBZ225 Instruction leaflet

Eaton

Eaton MSFA-PI Series Instruction leaflet

ION Optix

ION Optix C-Pace EP Manual for installation

Eaton

Eaton Cutler-Hammer Ampgard SC9000 instructions

Biometra

Biometra TGRADIENT 48 manual

Murata

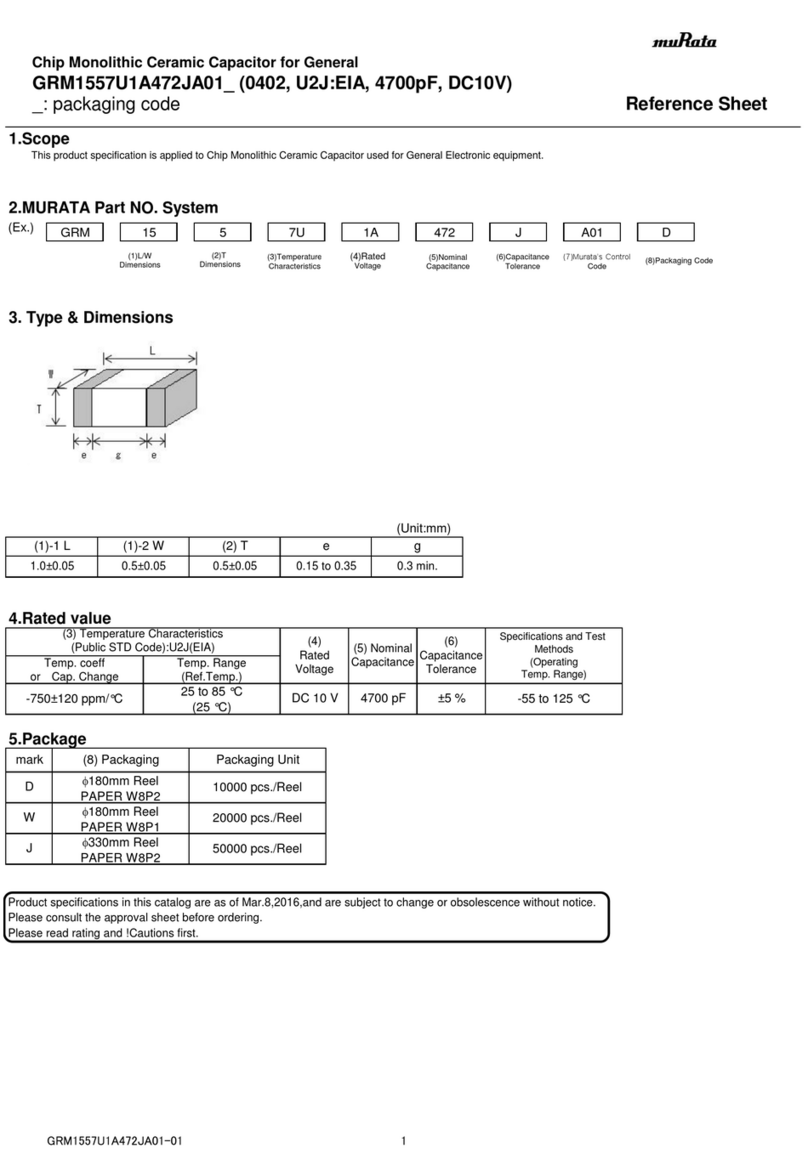

Murata GRM0225C1E5R2BA03 Series Reference sheet

Murata

Murata GRM1557U1A472JA01 Series Reference sheet

Murata

Murata GRM1885C2A4R0CA01 Series Reference sheet

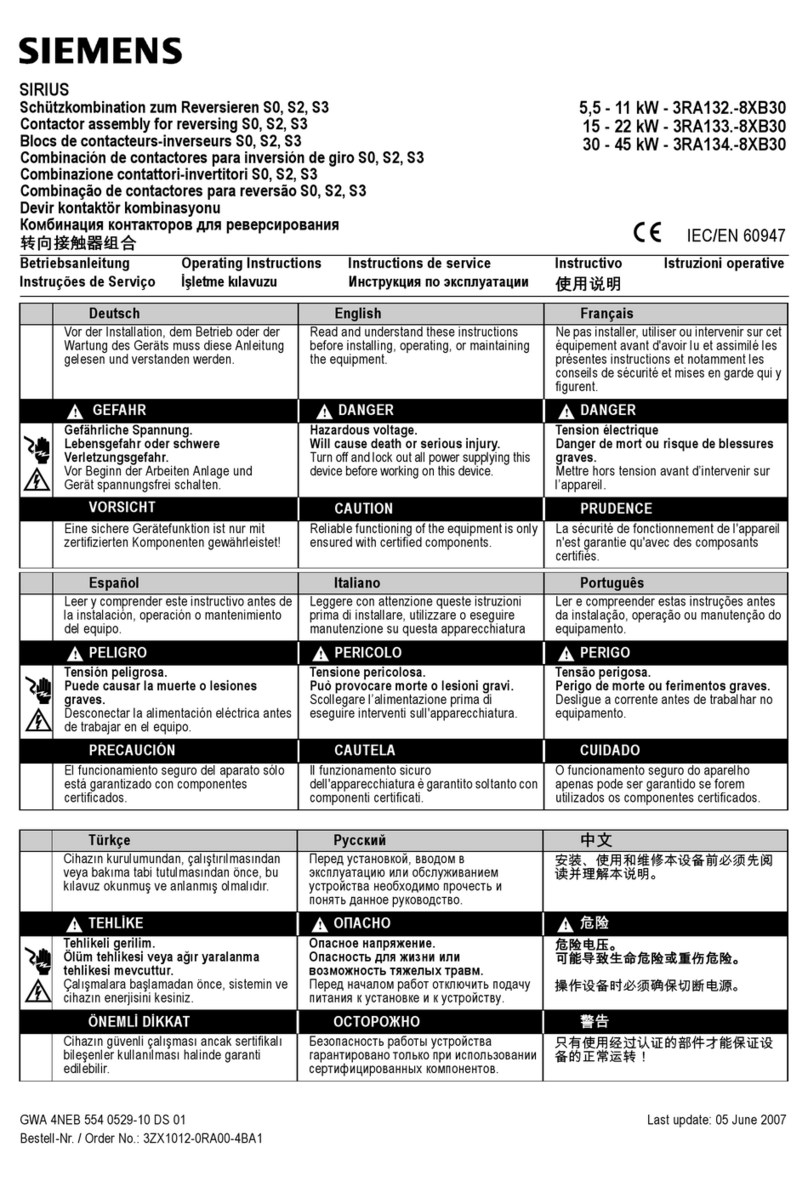

Siemens

Siemens SIRIUS 3RA132.-8XB30 operating instructions

Crossbow Technology

Crossbow Technology AHRS500GA Series Operator's manual