Feider FBT220 User manual

1

ORIGINAL INSTRUCTIONS

PETROL SHREDDER

FBT220

READ THIS INSTRUCTIONS MANUAL BEFORE USE THE TOOL

BUILDER SAS

32, rue Aristide Bergès - ZI 31270 Cugnaux – France

MADE IN PRC

2

Identification

Machine Identification (Pic.1)

A. Hopper

B. Motor

C. Chip Outlet

D. Chipper Funnel

E. Choke

F. Fuel Cock

G. ON/OFF Switch

H. Throttle

I. Fuel Tank Cap

J. Air Cleaner

K. Exhaust

L. Pull Start Handle

Pic.1 Chipper/Shredder Identification

Technical Parameter

Model

FBT220

Chipping Capacity

49.5mm

Blade Speed

2400/min

Engine Type

OHV 4-stroke

Starting System

Recoil

Displacement

212cm3

Engine Power

3.8kW

Engine Speed

3600/min

Fuel Volume

3.6L

Oil Volume

0.6L

Weight

71kg

Noise emission

Sound pressure level LpA:91.8dB(A);

Sound power level: LwA: 105,8dB(A) K=2dB(A)

Guarantee sound power level: 110 dB(A)

Fuel Type

Unleaded Gasoline

Pic.1

3

SECTION 1: SAFETY

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

Safe operating practices

Training

Become familiar with the owner's manual before attempting to operate this equipment.

Preparation

1) Do not allow children to operate this equipment;

2) Do not operate this equipment in the vicinity of bystanders;

3) Do not run engine powered machines in an enclosed area since the exhaust from an engine

contains carbon monoxide, which is colourless, odourless, and tasteless; carbon monoxide can be

extremely dangerous in enclosed areas;

4) Wear ear protection and safety glasses at all times while operating the machine;

5) Avoid wearing clothing that is loose fitting or that has hanging cords or ties;

6) Only operate the machine in open space (e.g. not close to a wall or other fixed object) and on a

firm, level surface;

7) Do not operate the machine on a paved or gravel surface where ejected material could cause

injury;

8) Before starting the machine, check that all screws, nuts, bolts, and other fasteners are properly

secured and that guards and screens are in place. Replace damaged or unreadable labels;

9) Use extra care in handling fuels. They are flammable and the vapours are explosive. The

following points should be observed:

use only an approved container;

Never remove the fuel cap or add fuel with the power source running. Allow engine and exhaust

components to cool before refuelling;

do not smoke;

never refuel the machine indoors;

never store the machine or fuel container inside where there is an open flame, such as a water

heater;

if fuel is spilled, do not attempt to start the power source, but move the machine away from the

area of spillage before starting;

always replace and securely tighten the fuel cap after refuelling;

If the fuel tank is drained, this should be done outdoors.

Operation

1) Before starting the machine, look into the feeding chamber to make certain that it is empty;

2) Keep your face and body away from the feed intake opening;

3) Do not allow hands or any other part of the body or clothing inside the feeding chamber,

discharge chute, or near any moving part;

4) Keep proper balance and footing at all times. Do not overreach. Never stand at a higher level than

the base of the machine when feeding material into it;

5) Always stand clear of the discharge zone when operating this machine;

6) When feeding material into the machine be extremely careful that pieces of metal, rocks, bottles,

cans or other foreign objects are not included;

7) If the cutting mechanism strikes any foreign objects or if the machine should start making any

unusual noise or vibration, shut off the power source and allow the machine to stop. Disconnect the

spark plug wire from the spark plug (electric unit disconnect from supply) and take the following

steps:

inspect for damage;

check for and tighten any loose parts ;

Have any damaged parts replaced or repaired with parts having equivalent specifications.

8) Do not allow processed material to build up in the discharge zone; this may prevent proper

discharge and can result in kickback of material through the feed intake opening;

9) If the machine becomes clogged at the inlet opening or discharge chute shut-off the power source

and disconnect the spark plug wire or remove the ignition key before clearing debris in the inlet

opening or discharge chute. Keep the power source clear of debris and other accumulations to

4

prevent damage to the power source or possible fire. Remember that operating the starting

mechanism on engine powered machines will still cause the cutting means to move;

10) keep all guards and deflectors in place and in good working condition;

11) Do not tamper with the power source governor settings; the governor controls the safe maximum

operating speed and protects the power source and all moving parts from damage caused by over-

speed. Seek authorised service if a problem exists;

12) Do not transport this machine while the power source is running;

13) Shut off the power source and disconnect the spark plug lead (electric unit disconnect from

supply) whenever you leave the work area;

14) Do not tilt the machine while the power source is running.

Mandedintenance and storage

a) When the machine is stopped for servicing, inspection, or storage, or to change an accessory,

shut off the power source, disconnect the spark plug wire from the spark plug, make sure that all

moving parts have come to a complete stop and, where a key is fitted remove the key. Allow the

machine to cool before making any inspections, adjustments, etc.

b) Store the machine where fuel vapour will not reach an open flame or spark. For extended storage

periods, run the unit dry of fuel. Always allow the machine to cool before storing;

c) When servicing the cutting means be aware that, even though the power source will not start due

to the interlock feature of the guard, the cutting means can still be moved by a manual starting

mechanism.

Additional safety instructions for units with bagging attachments

a) shut-off the power unit before attaching or removing the bag.

.

Explain symbols

Read operator's manual

Keep bystanders away

Danger - Rotating blades. Keep hands and feet out of openings while machine is

running

Wear eye and ear protection

Do not use as a step

5

SECTION 2: SET UP

Set Up Safety

This machine presents serious injury hazards to untrained users. Read through

this entire manual to become familiar with the controls and operations before

starting the machine!

Location

Site Considerations

The chipper/shredder must be placed on a firm, flat, grass or dirt surface to prevent the

machine from tipping. DO NOT place the machine on concrete, asphalt, or other hard

surfaces. The chips could bounce up from the hard surface and cause injury.

Working Clearances

Consider the length of the material to be processed through the machine and make sure

that there is enough height above the chipper/shredder to accommodate the material.

Make sure the unit is located close to the area where the chips are going to be used to

reduce carrying.

Stay clear of the discharge area. Make sure all bystanders, children, pets, or objects that

you do not want damaged or covered in chips, are clear of the discharge area.

6

Assembly

The major components of this chipper/shredder have been assembled at the factory.

Some minor assembly is required. The assembly process will use all the parts and

hardware listed in the inventory.

DO NOT attempt to start this machine until all assembly has been completed. Serious

personal injury and damage to the machine could occur.

To assemble the chipper/shredder:

1.

Tip the chipper/shredder over and remove the bolts shown in Pic.2. DO NOT turn the

chipper/shredder over once it is full of oil and gas. The oil and gas will spill out.

For fixing the leg: 3pcs Bolt M8x20, 1pc Bolt M8x200, 1pc Support Tube, 3pcs

Washer Ø8, 3pcs Locknut M8.

For fixing the wheel assembly: 2pcs Bolt M8x200, 2pcs Support Tube, 2pcs Washer

Ø8, 2pcs Locknut M8.

Pic.2 Attaching the leg

2.

Attach the wheel assembly and the leg with the bolts that were removed in Step 1.

3.

Place the handle on the hopper and line up all of the holes. Secure it with flat

washer(Ø8, 4pcs), spring washer(Ø8, 4pcs) and bolt(M8x20, 4pcs). (See Pic.3)

Pic.3 Installing the handle

4.

Place the funnel over the studs in the side of the chipper/shredder and secure it with

flat washer(Ø8, 3pcs), spring washer(Ø8, 3pcs) and locknut(M8, 3pcs). (See Pic.4)

Pic.4 Funnel installation

7

This chipper/shredder does not have oil in the motor when shipped. Add oil

before operating the chipper/shredder, or the motor will seize.

Pic.5 Fence netting installation

6.

Before operating, fill the motor with oil and gas according to the instructions.

Filling the engine oil

Place the machine on a level surface and remove the oil filler cap (Pic.5)(5.1).

Add engine oil up to the upper level of the dipstick (Pic.6)(6.1).

Filling the fuel tank

The chipper/shredder is powered by a four-stroke engine, which uses unleaded gasoline

fuel. Use a suitable funnel to transfer the fuel to the engines fuel tank, taking care not to

spill any fuel or over fill the fuel tank. The fuel tank should not be filled above the top of the

fuel filter as shown in Pic.7

5. Fit

the fence netting use the 4screws and 4 nuts. (See Pic.5)

8

Loose hair and clothing could get caught in machinery and cause serious

personal injury. Keep loose clothing and long hair away from moving machinery.

If you have never used this type of machine or equipment before, WE STRONGLY

RECOMMEND that you read books, trade magazines, or get formal training

before beginning any projects.

This chipper/shredder does not have oil in the motor when shipped. Add oil

before operating the chipper/shredder, or the motor will seize.

SECTION 3: OPERATIONS

Operation Safety

Damage to your eyes, hands, and ears could result from using this machine

without proper protective gear. Always wear safety glasses, hearing protection,

and leather gloves when operating this machine.

Chipping/Shredding

Understand and follow all of the safety precautions listed in SECTION 1: SAFETY before

operation.

This chipper/shredder is intended for mulching garden and pruning waste such as green

branches, twigs, brush, vines, and long grasses. DO NOT use this chipper/shredder for

chipping construction debris, plastic, paper products, rope or twine, or any material that

may contain metal.

Note: Remove any nails, rope, twine, or rocks that may be imbedded in roots, before

inserting material into the chipper/shredder.

To operate the chipper/shredder:

1.

Place the chipper/shredder on a flat, firm, dirt or grass surface and point the outlet in

a safe direction.

2.

Check the oil and gas levels before starting the motor.

3.

Place the bag over the chute and tie it securely in place.

4.

Make sure the hopper and funnel are empty before starting the engine. If there is

material in the hopper or funnel, the pull start cord may stop suddenly causing the

chipper/shredder to fall over, or causing injury to your hand or arm.

5.

Put on eye and ear protection, and gloves, start the chipper/shredder as instructed in the

manual, then set the throttle to fast.

9

6.

Stand to the side of the hopper and make sure you have a stable stance and firm

footing.

To start the chipper/shredder:

Turn the fuel lever to the ON position (Pic.8)(8.1).

Set the choke lever to the ON position (Pic.9)(9.1).

Turn the engine ON/OFF switch to the ON position (Pic.10)(10.1).

Hold down the engine firmly with one hand on the frame. With the other hand grip the

recoil starter cord handle and pull slowly until resistance is felt indicating that the recoil

starter is engaged. When resistance is felt pull the cord sharply (Pic.11). Continue this

procedure until the engine starts.

When the engine has been successfully started and is running smoothly return the choke

lever to the OFF position (Pic.12)(12.1).

When the engine is running, the speed can be adjusted by moving the throttle control

lever (Pic.13)(13.1) to the high (indicated by a hare), medium or low position (indicated by

a tortoise).

10

To stop the chipper/shredder:

To stop the engine, turn the engine ON/OFF switch to the OFF position (Pic.14)(14.1).

When the engine has stopped and before storage, turn the fuel lever to the OFF position

as shown in Pic.15 (15.1).

To shred twigs, leaves, and brush:

1.

Slowly pour the material into the hopper. DO NOT try to stuff too much material in at

one time or the machine will jam.

2.

Use a 1" diameter branch to push the material into the hopper if necessary (see

Pic.16). DO NOT use your hands!

Pic.16 Shredding leaves

Note: Move the throttle to the idle position, or turn the chipper/shredder OFF, when not

actively shredding or chipping.

3.

Turn OFF the machine, allow all moving parts to completely stop, and disconnect the

spark plug wire before moving the machine, emptying the bag, unclogging the inlets

or outlets, filling the gas tank, or performing maintenance and repairs.

Shredding Tips:

Feed material into the chipper/shredder slowly. If the motor begins to bog down, you

are feeding too fast.

Roots and dirty material will dull or damage the blades.

11

Remove the chips often. Allowing the chips to pile up to the outlet will cause the outlet

to clog.

Avoid shredding wet leaves or brush to reduce clogging. If you must shred wet material,

alternate wet and dry material.

To chip branches:

1.

Stand to the side of the hopper and make sure you have a stable stance and firm

footing.

2.

Remove twigs and smaller branches from the branch if they might catch on the edges

of the funnel and prevent the branch from going in.

3.

Place branches into the funnel, thick end first, and allow the blades to draw the

branch into the funnel (see Pic.17).

Pic.17 Chipping branches

4.

When finished chipping, turn OFF the machine, allow all moving parts to come to a

complete stop, and disconnect the spark plug wire before moving the machine,

emptying the bag, unclogging the inlets or outlets, filling the gas tank, or performing

maintenance and repairs.

Chipping Tips:

DO NOT feed material in excess of the diameter indicated on the funnel cover into the

funnel. Large branches will cause the motor to stall.

Chipping wood when it is green is easier on the machine. The blades will stay sharper

longer.

The chipper/shredder will work best if the blades are sharp. Rotate, sharpen, or replace

the blades as soon as chipper/shredder performance begins to deteriorate.

12

Turn OFF the machine, allow all moving parts to come to a complete stop, and

disconnect the spark plug wire before moving the machine, emptying the bag,

unclogging the inlets or outlets, filling the gas tank, or performing maintenance

and repairs.

SECTION 4: MAINTENANCE

Visual Inspection

Before and after using the chipper/shredder, closely inspect the machine for loose parts

and damage.

Check the hopper, hopper guard, and funnel for cracks, holes, and loose bolts.

Check the box frame for cracks or damage.

Check the entire machine for loose bolts or screws.

Check the blades and hammers for cracks and dings.

Check the engine oil level.

Cleaning

Clean the machine after each use. Allow the motor to cool and remove the spark plug wire.

Brush off or vacuum wood chips and wipe off the remaining dust from the exterior of the

machine with a dry cloth. DO NOT rinse off the chipper/ shredder with water. Remove any

chips or debris from the hopper and the discharge chute.

It is much harder to clean the machine if you allow it to sit for a while after use. You may

need to use an engine cleaner to remove the built up resins from the motor. Engine

cleaners are available at most auto parts stores.

Maintenance of engine

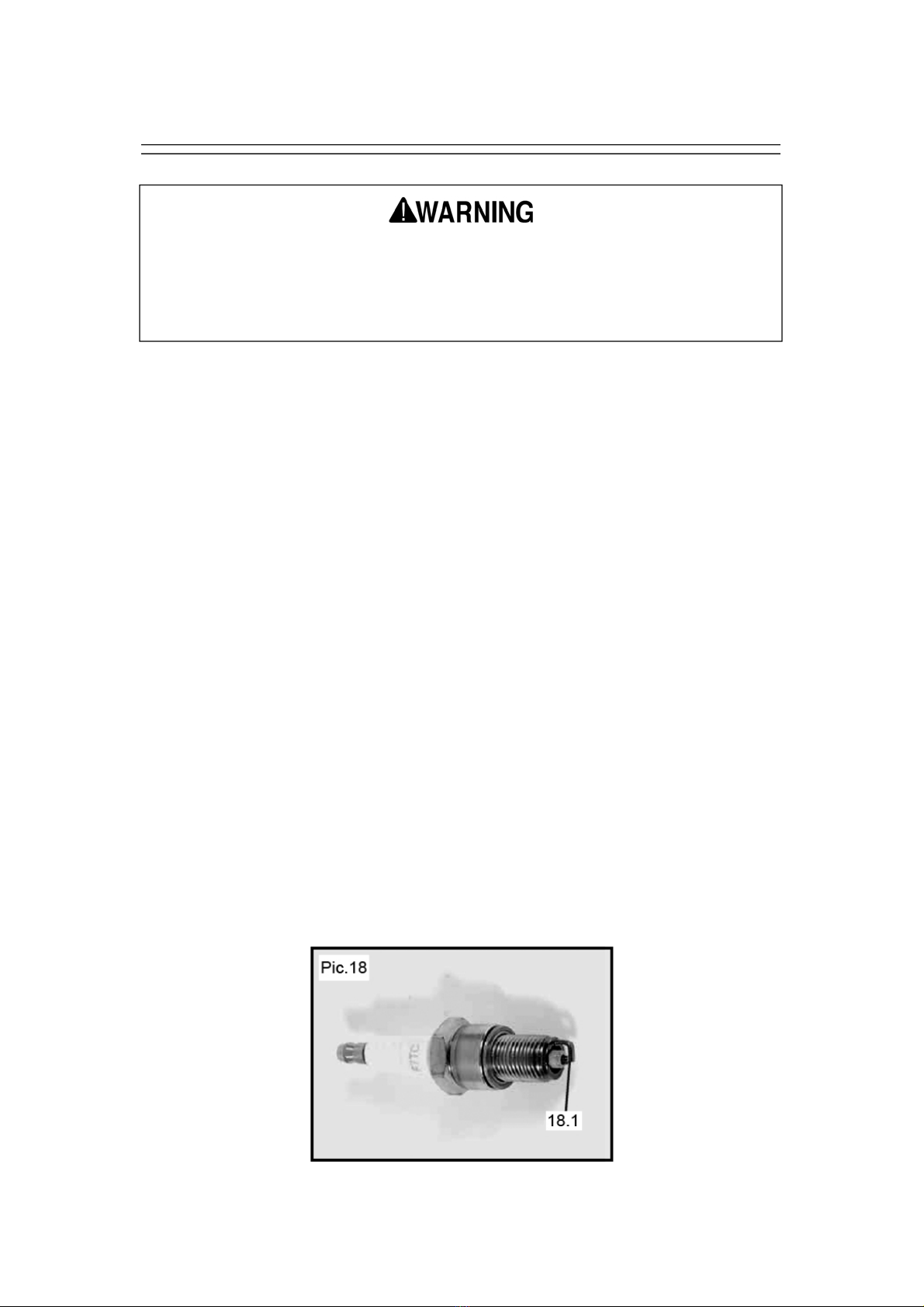

Spark Plug

After every 50 hours of running the spark plug should be removed. Check the color of the

deposits on the end of the spark plug it should be a “Tan” color. Remove all deposits using

a stiff brush a brass wire brush is ideal. Check the spark plug gap (Pic.18)(18.1) and adjust

if required. The correct gap should be 0.7 to 0.8mm.

13

Engine oil replacement

Place the machine on a level surface and warm up the engine for several minutes. Then

stop the engine.

Remove the oil filler cap (Pic.5)(5.1).

Place an oil pan under the engine. Remove the oil drain plug (Pic.5)(5.2) so that the oil

can be completely drained. You will need to use a tube or other similar device to prevent

the oil leaking onto the frame of the chipper/shredder.

Check the oil drain plug, gasket, oil filler cap and O-ring and if damaged replace.

Reinstall the oil drain plug.

Add engine oil up to the upper level of the dipstick (Pic.6)(6.1).

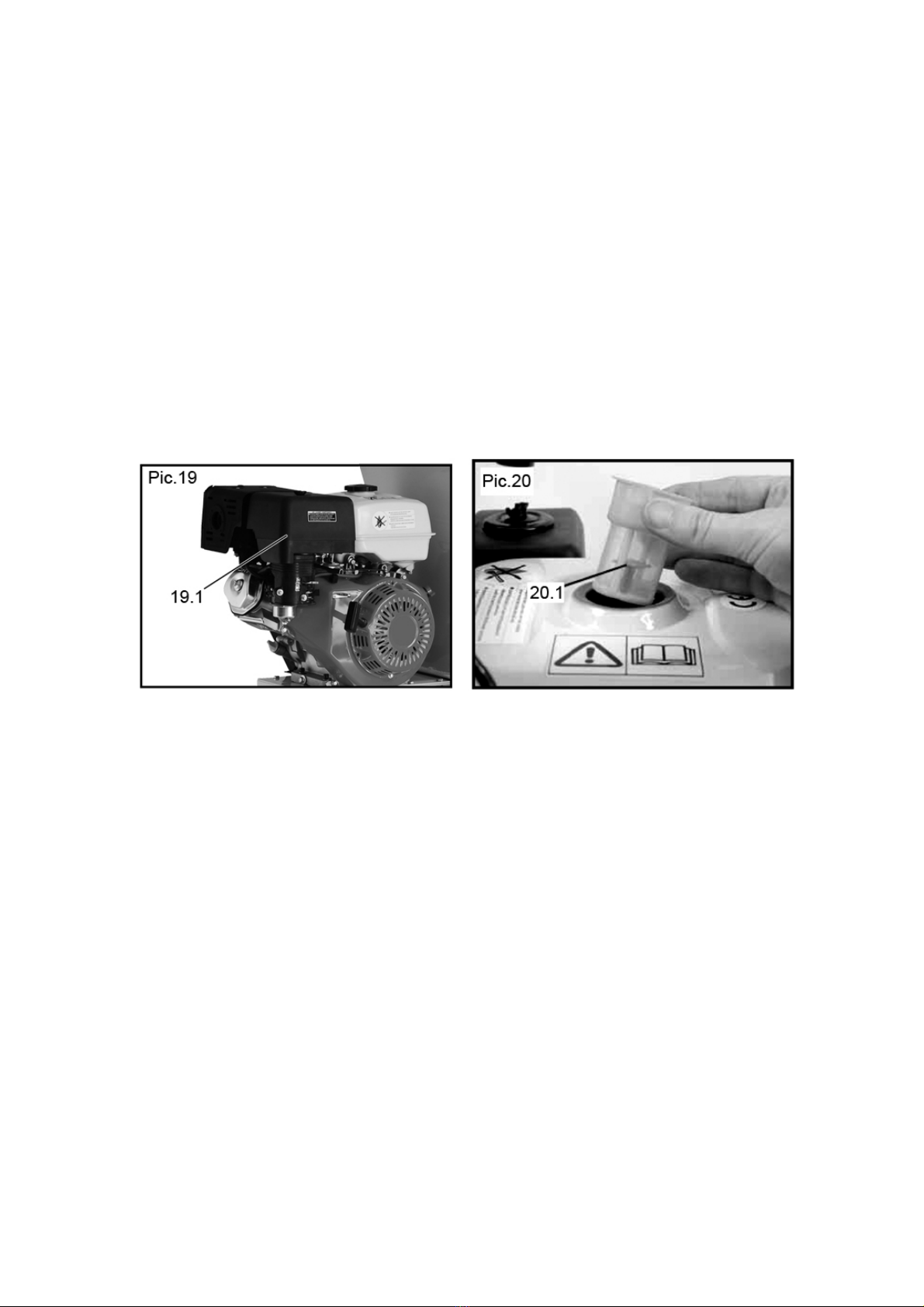

Air Filter

After every 100 hours of running or every month, the air filter (Pic.19)(19.1) should be

removed, examined for deterioration and cleaned. Clean the air filter thoroughly using

environmentally friendly water based degreasing agent. Allow to dry fully then replace the

air filter. Warning! Never run the engine without the air filter fitted.

Fuel tank filter

After every 150 hours of running or every three months the fuel tank filter (Pic.20)(20.1)

should be removed and cleaned. Remove the fuel tank filler cap and the filter, clean the

filter thoroughly using environmentally friendly water based degreasing agent and re-fit.

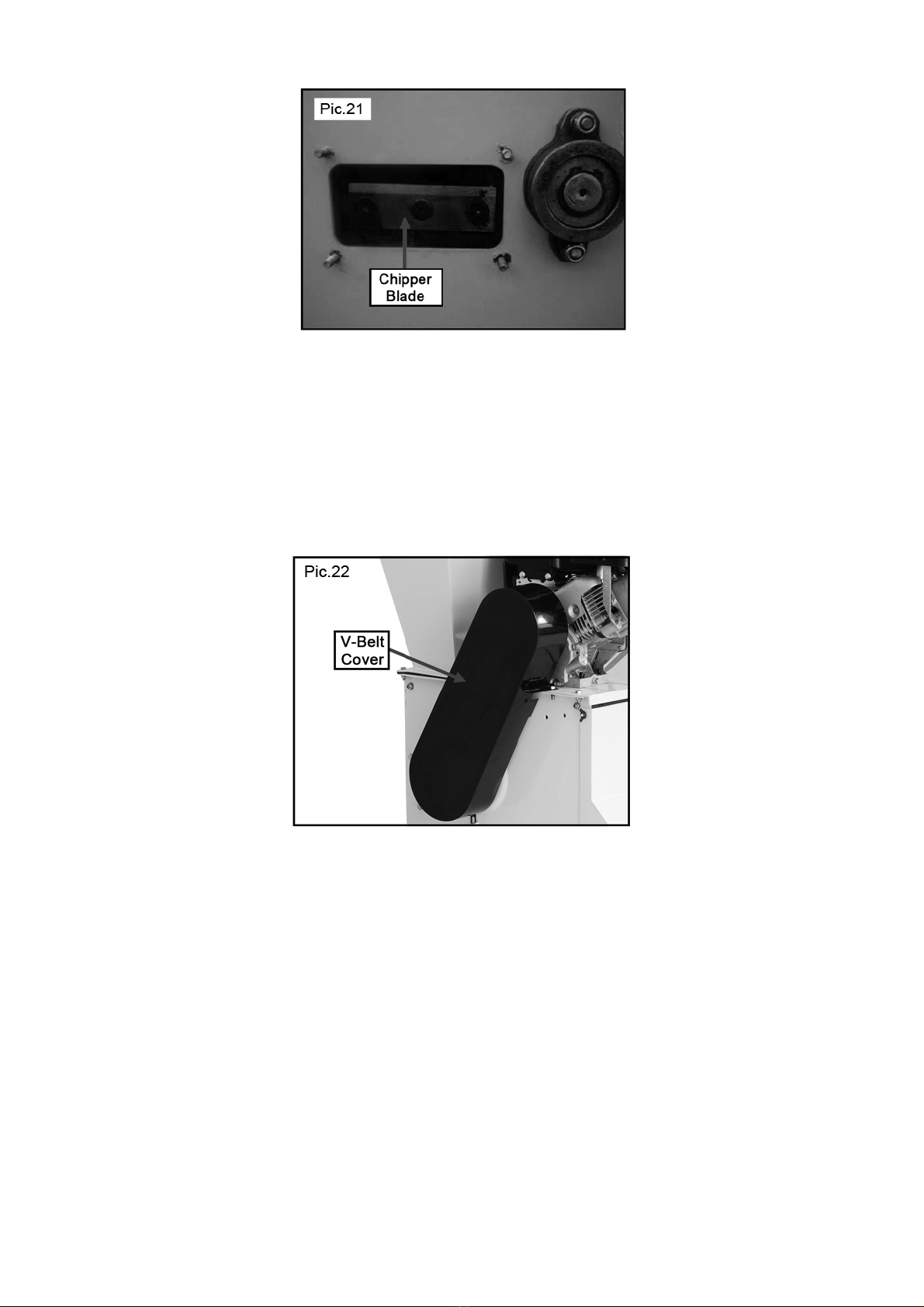

Replacing Blades

Sharpen or replace the blades as soon as the chipping performance begins to deteriorate,

or if you notice dings, chips, or cracks.

To perform this procedure:

1.

TURN OFF THE MACHINE, ALLOW ALL MOVING PARTS TO COME TO A

COMPLETE STOP, AND DISCONNECT THE SPARK PLUG WIRE!

2.

Remove the side cover plate to expose the blades. (See Pic.21)

3.

Remove one blade, rotate the impeller, and remove the second blade.

4.

Have the original blades professionally sharpened, or order a replacement set, then

re-install the blades.

5.

Replace the side cover plate and re-attach the spark plug wire.

14

Pic.21 Chipper blade

Replacing V-Belt

Replace or tighten the V-belt if you notice the motor running and the chipper blades

are not spinning.

To perform this procedure:

1.

TURN OFF THE MACHINE, ALLOW ALL MOVING PARTS TO COME TO A

COMPLETE STOP, AND DISCONNECT THE SPARK PLUG WIRE!

2.

Remove the V-belt cover as shown in Pic.22.

3.

Roll the belt off of the pulleys and install the new belt.

4.

Replace the V-belt cover and re-attach the spark plug wire.

Storage

Follow these guidelines when storing your chipper/shredder.

Remove the spark plug wire to prevent unauthorized starting.

Empty the bag before storing to keep the mulch from rotting in the bag.

Place the chipper/shredder in a dry, level area. If the chipper/shredder is tipped it may

leak oil and gas.

DO NOT store the chipper/shredder near an ignition source, such as a wood stove, gas

or electric heater, or an appliance or heater with a pilot light.

Store the chipper/shredder in a well ventilated area. DO NOT store the

chipper/shredder in an area that will allow toxic gas fumes into areas inhabited by

humans or animals.

15

Close the discharge chute deflector and place the covers over the hopper and the

funnel to prevent objects or critters from getting into the machine.

If the engine is not to be used or is to be stored for more than one month the following

storage procedure should be carried out. Drain all the fuel from the fuel tank and the

carburetor ensure that all the fuel has been removed. Remove the spark plug and

pour approximately one tablespoon full of clean engine oil into the spark plug hole.

With the ignition turned OFF gently pull on the recoil starter cord several times. Re-fit

the spark plug continue to pull the recoil starter cord until the piston is on the

compression stroke (when resistance is felt) then stop pulling.

16

SECTION 5: SERVICE

Review the troubleshooting and procedures in this section to fix your machine if a problem

develops.

Troubleshooting

Symptom

Possible Cause

Possible Solution

Engine will not start.

1.

Control levers are not in correct

positions for starting.

2.

Spark plug wire is not connected

to the spark plug, or the spark plug

is bad.

3.

No gas, or gas is old and stale.

4.

Air filter is dirty.

5.

Engine oil is low.

6.

Blocked fuel line.

1. Make sure the ON/OFF switch is ON, the

fuel shut-off valve is open, and the choke and

throttle controls are in the start position.

.2. Connect the spark plug wire or replace the

spark plug.

3.

If empty, fill the tank. If full, drain the gas,

then fill the tank with fresh gas.

4.

Clean out the air filter.

5.

Add oil to the engine.

6.

Clean out the fuel line.

Engine does not

run smoothly.

1.

Engine is warm, and the choke is

still in the CHOKE position.

2.

Air filter is dirty.

3.

Stale fuel, water or dirt in fuel,

blocked fuel line.

1.

Move the choke to the RUN position.

2.

Clean the air filter.

3.

Drain the fuel tank, clean out the fuel line,

and fill the tank with fresh gas.

Engine overheats.

1.

Chips and sawdust around the

motor.

2.

Dirty air filter.

1.

Clean off the motor.

2.

Clean out the air filter.

Machine vibrates or

makes unusual noises.

1.

Loose or damaged parts.

2.

Impeller or blades have woody

residue or chunks stuck to them.

1.

Check the blades, hammers, impeller, and

all connections. Tighten, repair, or replace

any loose or damaged parts.

2.

Clean the impeller and blades.

Chipper/shredder no

longer chips or shreds

well.

1.

Dull or damaged blades and

hammers.

2.

Loose, worn, or damaged V-belt.

1.

Sharpen or replace blades and check the

hammers for damage.

2.

Replace or tighten V-belt.

Chips do not come out

of the discharge chute

or come out slowly.

1.

Discharge chute or hopper is

clogged.

2.

Insufficient motor RPM's.

1. Turn OFF the motor, disconnect the spark

plug, then clean out the machine

2. Move the throttle to FAST.

Turn OFF the machine, allow all moving parts to come to a complete stop, and

disconnect the spark plug wire before moving the machine, emptying the bag,

unclogging the inlets or outlets, filling the gas tank, or performing maintenance

and repairs.

17

SECTION 6: CE DECLARATION

BUILDER SAS

32 rue Aristide Berges -Z1 31270 Cugnaux - France

Tel: +33 (0) 5.34.508.508 Fax: +33 (0) 5.34.508.509

Declares that the machinery designated below:

PETROL SHREDDER

FBT220

Serial number: 20210454963-20210454982

20210640968-20210640987

Is in conformity with the requirements of the Directive Machine 2006/42/EC and to the followings

Europeans Directives: EMC Directive 2014/30/EU

Directive 2000/14/CE Annex VI, 2005/88/EC

Emission directive (EU) 2016/1628 & 2018/989/EU

This tool is also in conformity with the following these standards:

EN 13683:2003+A2:2011, EN 55012:2007+A1:2009, EN 61000-6-1:2007

Sound power level: LwA: 105,8dB(A)

K=2dB(A)

Guarantee sound power level: 110 dB(A)

Responsible of the technical file: Olivier PATRIARCA

Cugnaux, 19/04/2021

Philippe MARIE / PDG

WARRANTY

The manufacturer guarantees the product against defects in material and workmanship for a period of 2

years from the date of the original purchase. The warranty only applies if the product is for household use.

The warranty does not cover breakdowns due to normal wear and tear.

The manufacturer agrees to replace parts identied as defective by the designated distributor. The

manufacturer does not accept responsibility for the replacement of the machine, in whole or in part , and/or

ensuing damage.

The warranty does not cover breakdowns due to:

• insucient maintenance.

• abnormal assembly, adjustment or operations of the product.

• parts subject to normal wear and tear.

The warranty does not extend to:

• shipping and packaging costs.

• using the tool for a purpose other than that for which it was designed.

• the use and maintenance of the machine done in a manner not described in the user manual.

Due to our policy of continuous product improvement, we reserve the right to alter or change specications

without notice. Consequently, the product may be dierent from the information contained therein, but a

modication will be undertaken without notice if it is recognized as an improvement of the preceding

characteristic.

READ THE MANUAL CAREFULLY BEFORE USING THE MACHINE.

When ordering spare parts, please indicate the part number or code, you can nd this in the spare parts list

in this manual. Keep the purchase receipt; without it, the warranty is invalid. To help you with your product,

we invite you to contact us by phone or via our website:

• +33 (0)9.70.75.30.30

• https://services.swap-europe.com/contact

You must create a "ticket" via the web platform.

• Register or create your account.

• Indicate the reference of the tool.

• Choose the subject of your request.

• Describe your problem.

• Attach these les: invoice or sales receipt, photo

of the identication plate (serial number), photo

of the part you need (for example: pins on the

transformer plug which are broken).

18

SECTION7:WARRANTY

WHAT TO DO IF MY MACHINE BREAKS DOWN?

the repairer will refuse the machine.

Go to the store with the complete machine and with the receipt or invoice.

the repairer will refuse the machine.

c) Create a SWAP-Europe service ticket on the site: https://services.swap-europe.com When making the

request on SWAP-Europe, you must attach the invoice and the photo of the nameplate (serial number).

d) Contact the repair station to make sure it is available before dropping o the machine.

Go to the repair station with the complete machine packed, accompanied by the purchase invoice and the

station support sheet downloadable after the service request is completed on the SWAP-Europe site

For machines with engine failure from manufacturers BRIGGS & STRATTON, HONDA and RATO, please

refer to the following instructions.

Repairs will be done by approved engine manufacturers of these manufacturers, see their site:

• http://www.briggsandstratton.com/eu/fr

• http://www.honda-engines-eu.com/fr/service-network-page;jsessionid=5EE8456CF39CD572AA2AEEDFD

290CDAE

• https://www.rato-europe.com/it/service-network

Please keep your original packaging to allow for after-sales service returns or pack your machine

with a similar cardboard box of the same dimensions.

For any question concerning our after-sales service you can make a request on our website https://

services.swap-europe.com

Our hotline remains available at +33 (9) 70 75 30 30.

If you bought your product in a store:

a) Empty the fuel tank if your product has one.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

If you bought your product on a website:

a) Empty the fuel tankif your product has one.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

SECTION8: PRODUCT FAILURE

19

THE WARRANTY DOES NOT COVER:

• Start-up and setting up of the product.

• Damage resulting from normal wear and tear of the product.

• Damage resulting from improper use of the product.

• Damage resulting from assembly or start-up not in accordance with the user manual.

• Breakdowns related to carburetion beyond 90 days and fouling of carburetors.

• Periodic and standard maintenance events.

• Actions of modication and dismantling that directly void the warranty.

• Products whose original authentication marking (brand, serial number) has been degraded, altered or

withdrawn.

• Replacement of consumables.

• The use of non-original parts.

• Breakage of parts following impacts or projections.

• Accessories breakdowns.

• Defects and their consequences linked to any external cause.

• Loss of components and loss due to insucient screwing.

• Cutting components and any damage related to the loosening of parts.

• Overload or overheating.

• Poor power supply quality: faulty voltage, voltage error, etc.

• Damages resulting from the deprivation of enjoyment of the product during the time necessary for repairs

and more generally the costs related to the immobilization of the product.

• The costs of a second opinion established by a third party following an estimate by a SWAP-Europe repair

station

• The use of a product which would show a defect or a breakage which was not the subject of an immediate

report and/or repair with the services of SWAP-Europe.

• Deterioration linked to transport and storage*.

• Launchers beyond 90 days.

• Oil, petrol, grease.

• Damages related to the use of non-compliant fuels or lubricants.

* In accordance with transport legislation, damage related to transport must be declared to carriers within 48

hours maximum after observation by registered letter with acknowledgement of receipt.

This document is a supplement to your notice, a non-exhaustive list.

Attention: all orders must be checked in the presence of the delivery person. In case of refusal by the

delivery person, it you must simply refuse the delivery and notify your refusal.

Reminder: the reserves do not exclude the notication by registered letter with acknowledgement within 72

hours.

Information:

Thermal devices must be wintered each season (service available on the SWAP-Europe site). Batteries must

be charged before being stored.

SECTION9: WARRANTY EXCLUSIONS

20

Table of contents

Other Feider Paper Shredder manuals