FERREX HCP3000 User manual

PETROL HIGH PRESSURE CLEANER

HCP3000

CAUTION!: Read the manual carefully before operating this machine!

Vers.No. 220516

Original Instructions

ALDI guarantees that our exclusive brand products are developed to our

stringent quality specifications. If you are not entirely satisfied with this

product, please return it to the nearest ALDI store within 60 days from the

date of purchase, for a full refund or replacement, or take advantage of our

after sales support by calling the supplier’s Customer Service Hotline.

Made in China

FERREX® is a registered trademark of ALDI Stores

DISTRIBUTED BY:

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

www.aldi.com.au

User Manual Contents

Overview 4

Contents of Box 6

Overview 7

Explanation of the symbols on the device 9

Introduction 13

Device description 14

Scope of delivery 15

Proper use 15

Safety instructions 16

Technical data 23

Unpacking 25

Layout 26

Before commissioning 26

Operation 28

Transport 32

Cleaning 33

Maintenance 34

Storage 36

Disposal and recycling 36

Troubleshooting 37

Warranty Details 39

Repair and Refurbished Goods or Parts Notice 40

AFTER SALES SUPPORT 702499

1300 855 831

MODEL:

HCP3000

3

YEARS

WARRANTY

AU

09/2022

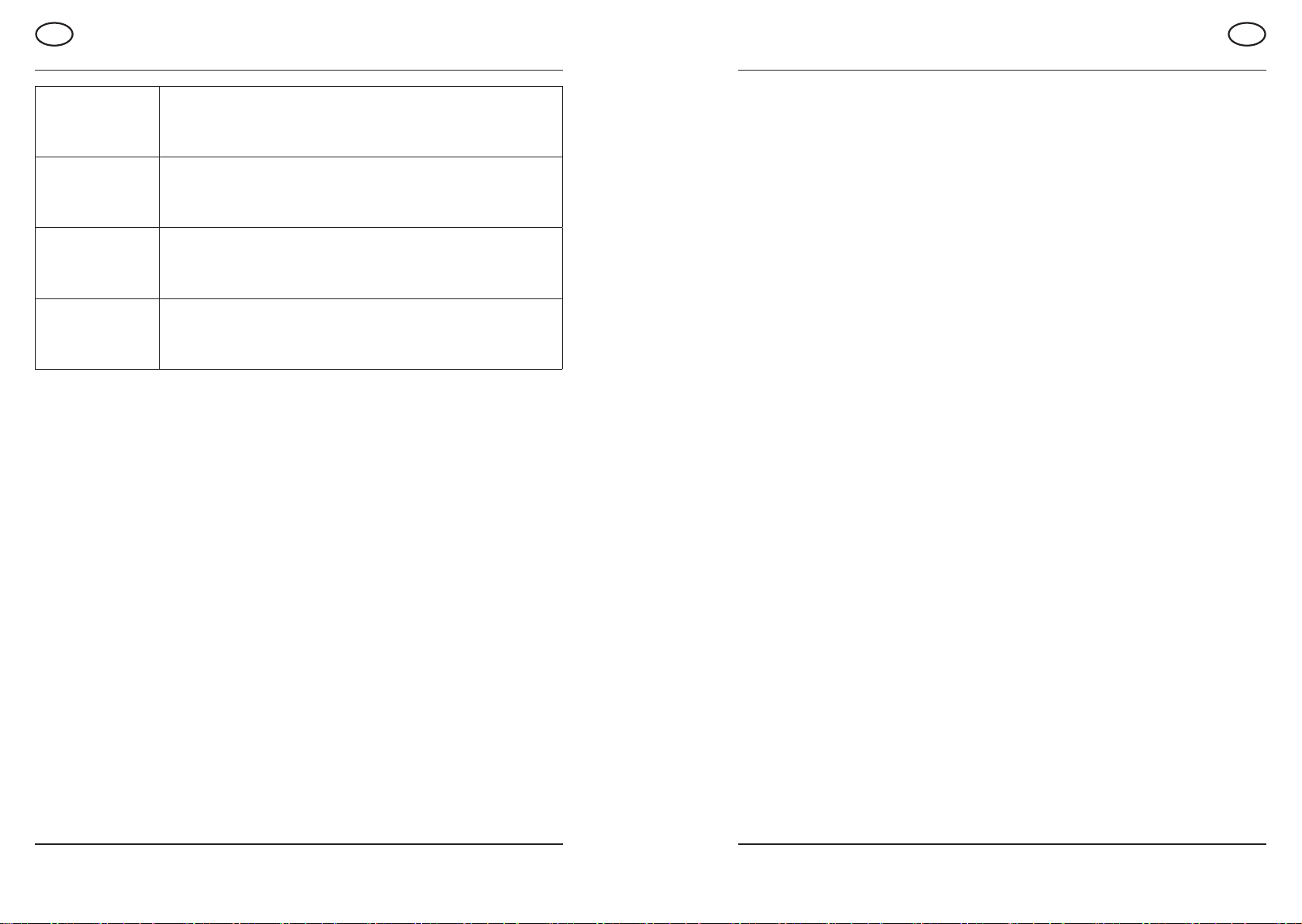

Contents of Box

Wheels (x2)

Axle (x2)

Spring split pin (x2)

High-pressure hose (x1)

Hand spray gun (x1)

Spraying lance (x1)

High pressure nozzles (red, green, white) (x3)

Low pressure nozzle / cleaning nozzle (black) (x1)

Transport bracket (x1)

Filling hose with funnel (x1)

Nozzle cleaner needle (x1)

Spark plug wrench (x1)

Quick connector (x1)

Hose connection adapter (x1)

Assembly material (x1)

Screwdriver (x1)

Operating manual (x1)

OverviewOverview 5Contents of Box

6

4

1

24

25

29

28

WARNING!

1

4

7

5

6

9

12

13

16

15

17

18

20

19

22

4

ASSEMBLY

13

3

6

5

3233 13

76

23

17

8

23

2

17

7

CLICK

3

2

5

35

13

36

5.1

32 33

2

3

4

17

4

3

2

8

10

11

14

21

26

27

23

30

37 38

34

7

40

6.1

AUS

HCP3000

7

AUS

Overview

12

Gasoline

Petrol

11

8

36

9

OIL

10

12

Min

Max

10W30 OIL

Gasolin

Unleaded

e

9

2

28

14

12.1

29

39

31

12.1

13

19

20

11

18

38

Explanation of the symbols on the device

AUSAUS

HCP3000 HCP3000

98

Overview

I. Explanation of the symbols on the device

Symbols are used in this manual to draw your attention to potential hazards. The safety

symbols and the accompanying explanations must be fully understood. The warnings

themselves will not rectify a hazard and cannot replace proper accident prevention

measures.

This symbol is intended to indicate possible dangers.

Follow all safety instructions that follow this symbol to

avoid possible injury or death.

If the instructions in the manual are not read and fol-

lowed, there is a danger of injury or even death, as well

as damage to property.

Running engines emit carbon monoxide, an odour-

less, colourless, poisonous gas. Inhalation of carbon

monoxide can cause nausea, fainting or death. DO NOT

run indoors, even if the windows and doors are open.

Petrol and its vapours are flammable and explosive.

Switch off the engine and let it cool down for at least 2

minutes before refilling.

Risk of explosion: Fuel and its vapours are highly flam-

mable and explosive. DO NOT spray flammable liquids

while the machine is still warm.

Fire, naked flames and smoking prohibited!

Attention: Danger of slipping on damp surfaces.

Attention: Hot surface. Danger of burning!

Wear safety shoes.

15

6

16

41

Explanation of the symbols on the device Explanation of the symbols on the device

AUSAUS

HCP3000 HCP3000

1110

Danger of eye injuries. Water jet can propel objects. Al-

ways wear safety goggles with side shields.

Risk of electric shock! Never spray water on electrical

power sources.

Specification of the sound power level LWA in dB

RUN

CHOKE

ON

OFF

Activate “choke” position (only when the engine is

cold).

Activate “Run” position when the engine is sufficiently

warm.

Wear hearing protection.

Stop! Read all instructions carefully.

Engine delivered without oil:

(10W30 or 10W40)

Fill the engine with the exact amount of oil according to

the scope of delivery.

Always check the oil level of the engine before starting.

Read the operating manual before use.

Fill the tank with fresh, clean petrol. Do not mix oil and

fuel.

Do not use fuel with more than 10% ethanol content.

Fill oil / check oil level

Do not operate the device if there is no oil visible in the

oil tank.

Danger: Exhaust gases are toxic! Do not operate in un-

ventilated areas.

Danger: If the device is operated while refuelling, there

is a risk of fire and explosion!

High-pressure jets can be dangerous when used im-

properly. The jet must not be directed towards any per-

sons, animals, active electrical equipment or the device

itself.

Warning: Device is not suitable for connection to the

drinking water supply system.

Caution: Hot surface. Do not touch the surface below.

3

Warranty Class / 3 Years Warranty

Comply with the Australian norms and directives

Explanation of the symbols on the device Introduction

AUSAUS

HCP3000 HCP3000

1312

II. Introduction

Congratulations on choosing to buy a FERREX® product.

All products brought to you by FERREX® are manufactured to the highest standards of

performance and safety, and as part of our philosophy of customer service and satisfac-

tion, are backed by our comprehensive 3 Years Warranty.

We hope you will enjoy using your purchase for many years to come.

Note:

According to the applicable product liability law the manufacturer of this device is not

liable for damages which arise on or in connection with this device in case of:

• improper handling,

• non-compliance with the instructions for use,

• repairs by third party, non-authorised skilled workers,

• installation and replacement of non-original spare parts,

• improper use.

Recommendations:

Read the entire text of the operating instructions prior to the assembly and operation of

the device.

These operating instructions are intended to make it easier for you to get familiar with

your device and utilise its intended possibilities of use.

The operating instructions contain important notes on how to work safely, properly and

economically with your petrol high pressure cleaner and how to avoid dangers, save re-

pair costs, reduce downtime, and increase the reliability and working life of the petrol

high pressure cleaner .

In addition to the safety regulations contained herein, you must in any case comply with

the applicable regulations of your country with respect to the operation of the petrol high

pressure cleaner .

Put the operating instructions in a clear plastic folder to protect them from dirt and hu-

midity, and store them near the petrol high pressure cleaner. The instructions must be

read and carefully observed by each operator prior to starting the work. Only persons

who have been trained in the use of the petrol high pressure cleaner and have been

informed on the related dangers and risks are allowed to use the petrol high pressure

cleaner. The required minimum age must be met.

In addition to the safety notes contained in the present operating instructions and the

special regulations of your country, the generally recognised technical rules for the oper-

ation of generators must be observed.

DANGER!

Signal word to indicate an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING!

Signal word to indicate a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION! Signal word to indicate a potentially hazardous situation which, if

not avoided, could result in minor or moderate injury.

NOTE Signal word to indicate a possible hazardous situation which, if not

avoided, could result in property damage.

Device description (Fig. 1-16) Scope of delivery

AUSAUS

HCP3000 HCP3000

1514

III. Device description (Fig. 1-16)

1. Bow-type handle

2. High-pressure hose

3. Nozzles (red, green, white, black)

4. Transport bracket

5. Fixing plug

5.1 Sleeve

6. Star grip screws

6.1 Star grip screw screws

7. Tubular frame

8. Tank cover, incl. filter insert

9. Fuel tank

10. Carburettor

11. On/off switch

12. Oil inlet/dipstick

12.1 Oil dipstick

13. Wheel

14. Rubber foot

15. Cleaning agent tank

16. Filler cap for cleaning agent tank

17. Spraying lance

18. Pull cable starter

19. Fuel valve

20. Choke lever

21. Air filter

22. Silencer

23. Hand spray gun

24. Trigger lock

25. Trigger

26. Spray gun holder

27. Hose holder

28. Water outlet

29. Water inlet

30. High-pressure pump

31. Spark plug/Spark plug connector

32. Axle

33. Spring split pin

34. Nozzle cleaning needle

35. Spark plug wrench

36. Filling hose with funnel

37. Quick connector

38. Hose connection adapter

39. Oil drain screw

40. Inlet sieve

41. Petrol drain screw

IV. Scope of delivery

• Wheels (13)

• Axle (32)

• Spring split pin (33)

• High-pressure hose (2)

• Hand spray gun (23)

• Spraying lance (17)

• High pressure nozzles (red, green, white) (3)

• Low pressure nozzle / cleaning nozzle (black) (3)

• Transport bracket (4)

• Filling hose with funnel (36)

• Nozzle cleaner needle (34)

• Spark plug wrench (35)

• Quick connector (37)

• Hose connection adapter (38)

• Assembly material

• Screwdriver

• Operating manual

V. Proper use

This device is intended for cleaning:

Machines, vehicles, structures, tools, facades, terraces, gardening tools, etc.

• for cleaning with the low-pressure jet and cleaning agent (e.g. cleaning of machines,

vehicles, structures, tools)

• for cleaning with a high-pressure jet without cleaning agent (e.g. cleaning facades,

terraces, garden tools)

The machine may only be used for its intended purpose. Any use beyond this is improper.

The user/operator, not the manufacturer, is responsible for damages or injuries of any

type resulting from this.

An element of the proper intended use is also the observance of the safety instructions,

as well as the assembly instructions and operating information in the operating manual.

Persons who operate and maintain the machine must be familiar with this operating

manual and must be informed about potential dangers.

Safety instructions Safety instructions

AUSAUS

HCP3000 HCP3000

1716

In addition, the applicable accident prevention regulations must be strictly observed.

Other general occupational health and safety-related rules and regulations must be ob-

served.

The liability of the manufacturer and resulting damages are excluded in the event of

modifications of the machine.

Please note that our equipment was not designed with the intention of use for commer-

cial or industrial purposes. We assume no guarantee if the device is used in commercial

or industrial applications, or for equivalent work.

VI. Safety instructions

6.1 Danger levels

ATTENTION

Note on a potentially dangerous situation that can lead to property dam-

age.

mCAUTION

Note on a potentially dangerous situation that can lead to minor injuries.

mWARNING

Information on a potentially dangerous situation that can lead to severe

personal injury or death.

mDANGER

Information on an imminent danger that will lead to severe personal in-

jury or death.

6.2 General safety instructions

IMPORTANT!

Before using your device for the first time, read these safety instruc-

tions and act accordingly. Store these safety instructions for later use

or for subsequent owners.

• Before start-up, read the operating manual for your device and pay par-

ticular attention to the safety instructions.

• Warning and information labels attached to the device provide impor-

tant information for safe operation.

• In addition to the information in the operating manual, the general

safety and accident prevention regulations of the legislature must be

followed.

• Observe the relevant national regulations of the legislator for liquid

emitters.

• Observe the relevant national regulations of the legislator for accident

prevention. Liquid emitters must be tested regularly and the result of

the test must be recorded in writing.

The machines must not be used by children. Children should be super-

vised in order to ensure that they do not play with the device.

This machine is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

mWARNING

This machine is designed to use the cleaning agents supplied or recom-

mended by the manufacturer. The use of other cleaning agents or chemi-

cals may affect the safety of the machine.

mWARNING

High pressure jets can be dangerous when used improperly. The jet must

not be directed towards any persons, pets, active electrical equipment or

the machine itself.

mWARNING

Do not use this machine within range of other people unless they are

wearing protective clothing.

mWARNING

Do not direct the jet at yourself or others to clean clothing or footwear.

mWARNING

Risk of explosion: Do not spray flammable liquids.

mWARNING

High pressure cleaners shall not be operated by children or untrained

persons.

Safety instructions Safety instructions

AUSAUS

HCP3000 HCP3000

1918

mWARNING

High-pressure hoses, fixtures and couplings are important for machine

safety. Only use high-pressure hoses, fixtures and couplings recommend-

ed by the manufacturer.

mWARNING

To ensure machine safety, only use original spare parts from the manu-

facturer or spare parts approved by the manufacturer.

mWARNING

Water that has flowed through the backflow prevention device is consid-

ered non-potable.

mWARNING

Do not use the machine if a connection cable or important parts of the ma-

chine are damaged, e.g. safety devices, high-pressure hoses, spray gun.

mWARNING

Machines powered by an internal combustion engine must not be used

indoors without adequate ventilation systems approved by the relevant

national health and safety authorities.

mWARNING

Make sure that there are no exhaust emissions near air intakes.

6.3 Water connection

mDANGER

• The high-pressure hose must not be damaged. A damaged high-pres-

sure hose must be replaced immediately. Only hoses and connections

recommended by the manufacturer may be used. For the order no.,

please refer to the operating manual.

• The screw connection of all connection hoses must be tight.

ATTENTION

• Observe the regulations of your water supply company.

6.4 Operation

mDANGER

• The device with the working equipment must be checked for proper

condition and operational safety before use.

Do not use the device if a connection cable or important parts of the de-

vice are damaged, e.g. safety devices, high-pressure hoses, hand spray

guns.

• Never inject liquids containing solvents or undiluted acids and solvents!

These include, for example, petrol, paint thinner or heating oil. The spray

mist is highly flammable, explosive and poisonous. Do not use acetone,

undiluted acids and solvents as they can damage the materials used on

the device.

• When using the device in danger zones (e.g. petrol stations), the rele-

vant safety regulations must be observed. Do not operate the device in

explosive environments.

• All live parts in the work area must be protected from water jets.

• The trigger of the hand spray gun must not be jammed during opera-

tion.

ATTENTION

• Do not use acetone, undiluted acids or solvents as they corrode the ma-

terials used on the device.

• The device must have a level, stable base.

• Do not operate the device at temperatures below 5° C.

mWARNING

• When using cleaning agents, the safety data sheet of the cleaning agent

manufacturer must be observed, especially the instructions on person-

al protective equipment.

• Only cleaning agents approved by the device manufacturer may be

used. This device has been developed for the use of cleaning agents that

are supplied or recommended by the manufacturer. The use of cleaning

agents or chemicals may affect the safety of the device.

• Keep cleaning agents out of the reach of children.

• Do not open the cover while the device is in operation.

• In case of longer breaks in operation, switch off the device at the main

switch / device switch.

mWARNING

• Asbestos-containing materials and other materials containing sub-

stances hazardous to health must not be sprayed off.

• Before cleaning, a risk assessment of the surfaces to be cleaned must be

carried out to identify health and safety requirements. The necessary

protective measures must be taken accordingly.

Safety instructions Safety instructions

AUSAUS

HCP3000 HCP3000

2120

• With short spraying lances there is a danger of injury as a hand may ac-

cidentally come into contact with the high-pressure jet. If the spraying

lance used is shorter than 75 cm, do not use a spot spraying nozzle or

rotor nozzle.

ATTENTION

• Vehicle tyres/tyre valves may only be cleaned with a minimum spraying

distance of 30 cm. Otherwise the vehicle tyre/tyre valve may be dam-

aged by the high-pressure jet. The first sign of damage is the discolour-

ation of the tyre. Damaged vehicle tyres are a source of danger.

mCAUTION

• If the operating manual of the unit (technical data) specifies a sound

pressure above 80 dB(A), wear hearing protection.

• Wear suitable protective clothing and safety goggles to protect against

splashing water or dirt.

• The recommended cleaning agents must not be used undiluted. The

products are safe to operate as they do not contain any environmentally

harmful substances.

In case of contact of cleaning agent with eyes, immediately rinse thor-

oughly with plenty of water and consult a doctor immediately if swal-

lowed.

• Allow the hoses to cool down after hot water operation or operate the

device briefly in cold water mode.

6.4.1 For units with a hand-arm vibration value >2.5 m/s² (see tech-

nical data)

mDANGER

• Prolonged use of the device may lead to vibration-induced circulatory

problems in the hands. A generally valid duration for use cannot be de-

termined because it depends on several influencing factors:

-Personal predisposition to poor circulation (often cold fingers, finger

tingling).

-Low ambient temperature. Wear warm gloves to protect your hands.

-Tight grasping worsens the blood circulation.

-Uninterrupted operation is worse than operation interrupted by

breaks.

• In case of regular, long-term use of the device and repeated occurrence

of corresponding signs (for example, finger tingling, cold fingers), we

recommend a medical examination.

6.5 Operation

mWARNING

• For petrol or oil-powered machines, it is important to provide adequate

ventilation and ensure that exhaust gases are properly discharged.

mDANGER

• The operator must use the device as intended. It must take the local con-

ditions into account and pay attention to third parties, especially chil-

dren, when working with the device.

• The device must never be left unattended while it is in operation.

• The device may only be used by persons who have been instructed in its

handling or who have demonstrated their ability to operate it and have

been expressly instructed to use it. The device must not be operated by

children or untrained persons.

• Always wear suitable gloves when working on the device.

• The water jet coming out of the spraying lance creates a recoil force. Due

to the angled spraying lance, a force acts upwards. Hold the gun and

spraying lance firmly.

• When using angled spraying equipment, the recoil forces and twisting

forces may change.

mWARNING

• Aerosols can develop when using high pressure cleaners. Inhaling aer-

osols can cause damage to your health. Respiratory protection masks

of class FFP2 or higher are suitable for protection against aqueous aer-

osols.

6.6 Transport

mDANGER

• When transporting the device, the engine must be shut down, the spark

plug connector removed and the device securely fastened.

6.7 Maintenance

mDANGER

• Before cleaning and servicing the device and replacing parts, switch off

the device.

• Depressurize the high-pressure system before working on the device

and accessories.

• The spark plug connector must be removed.

• Repairs may only be carried out by approved service centres or by spe-

cialists in this field who are familiar with all relevant safety regulations.

Safety instructions Technical data

AUSAUS

HCP3000 HCP3000

2322

6.8 Accessories and spare parts

mDANGER

• To avoid hazards, repairs and the installation of spare parts may only be

carried out by authorised customer service.

• Only accessories and spare parts approved by the manufacturer may be

used. Original accessories and original spare parts provide the guaran-

tee that the device can be operated safely and without malfunctions.

6.9 Hot water and petrol engine devices

mDANGER

• Only the fuel specified in the operating manual may be used. There is a

risk of explosion with unsuitable fuels.

• When refuelling devices with petrol engines, make sure that no fuel gets

onto hot surfaces.

• Please always observe the special safety instructions in the operating

manual for devices with petrol engines.

• When operating the device indoors, ensure that there is sufficient venti-

lation and that the exhaust gases are discharged. (Danger of poisoning)

• The flue opening must not be closed.

mWARNING

• Danger of burning! Do not bend over or touch the flue opening.

6.10 Handling fuel

mDANGER

• Do not operate the high pressure cleaner if fuel has been spilled, move

the device to another location and avoid any spark formation.

• Do not store, spill or use fuel near open flames or equipment such as

stoves, boilers, water heaters, etc. that have a pilot light or produce

sparks.

• Keep highly flammable objects and substances away from the silencer

(at least 2 m).

• Do not operate the engine without the silencer and check it regularly,

clean it and replace it if necessary.

• Do not use the engine on wooded, bushy or grassy terrain without the

exhaust pipe being fitted with a spark arrester.

• Except when making adjustments, do not run the engine with the air

filter removed or without the cover over the intake manifold.

• Do not make any adjustments to governor springs, governor rods or

other parts that may cause an increase in engine speed.

• Danger of burning! Do not touch hot silencers, cylinders or cooling fins.

• Never bring hands and feet close to moving or rotating parts.

• Danger of poisoning! Device must not be operated in closed rooms.

• Do not use unsuitable fuels as they can be dangerous.

6.11 Safety devices

Safety devices serve to protect the user and must not be overridden or

converted.

6.11.1 Overpressure valve

• When the hand spray gun is closed, the pressure relief valve opens and

the high-pressure pump returns the water to the pump suction side.

This prevents the permitted working pressure from being exceeded.

• The pressure relief valve is set and sealed at the factory. Adjustments

can only be made by the customer service.

6.11.2 Thermal valve

• The thermal valve protects the high-pressure pump against non-per-

mitted heating in circuit operation when the hand spray gun is closed.

• The thermal valve opens when the water temperature exceeds 55 - 60°C

and discharges the hot water to the outside.

6.12 Residual risks

mCAUTION

Despite intended use, non-obvious residual risks cannot be completely

excluded.

• Injuries due to slipping on sewage

• Injuries or material damage caused by the high-pressure water jet

VII. Technical data

Engine

Type DHP212

Displacement 212 cm³

Rated output at 4.3 (5.8) kW (hp)

Nominal speed 3600 min-1

Fuel tank 3.6 l

Fuel Petrol, unleaded

Oil quantity - engine 0.6 l

Oil type - engine SAE10W30 or SAE10W40

Technical data Unpacking

AUSAUS

HCP3000 HCP3000

2524

Spark plug F7RTC

Water connection

Hose diameter 13 mm

Max. supply temperature 40 °C

Max. supply pressure 0.5 (5) MPa (bar)

Pump

Rated pressure 22.1 (221) MPa (bar)

Max. allowable pressure 24.1 (241) MPa (bar)

Rated flow 9.5 l/min

Max. flow rate 10 l/min

Thermal valve opening

temperature

55 - 60 °C

Input connection G 3/4 (EU)

Output connection M22x1.5

Cleaning agents Only use cleaning agents approved for high pressure

cleaners.

Weight 30kg

Noise emission

Measured value for noise determined according to EN 60335-2-79. The A-weighted noise

level is typically:

Sound pressure level LpA.................... 90 dB(A)

Uncertainty KpA ............................................ 3 dB

Sound power level LWA ......................105 dB(A)

Uncertainty KWA............................................ 3 dB

Wear hearing protection to avoid hearing damage!

Vibration emission values (vector sum of three directions) determined per EN 60335-2-79:

Hand spray gun handle

Vibration value................................. 0.828 m/s2

Hand spray gun, centre

Vibration value................................ 2.068 m/s²

Uncertainty K ......................................0.85 m/s²

Note:

The vibration level specified in this instruction has been measured based on a measure-

ment procedure standardised in EN 60335-2-79 and can be used for unit comparison. The

specified vibration emission value can also be used for an initial estimation of the expo-

sure.

mWARNING

• The vibration level will vary depending on the use and may in some cases be high-

er than the value specified in these instructions. The vibration load could be under-

estimated if the device is regularly used in such a way. For an accurate estimation of

the vibration exposure during a given working period, the times when the device is

switched off or running but not actually in use should also be taken into account.

• This can significantly reduce the vibration load over the entire working period.

VIII. Unpacking

• Open the packaging and carefully remove the device.

• Remove the packaging material, as well as the packaging and transport safety devices

(if present).

• Check whether the scope of delivery is complete.

• Check the device and accessory parts for transport damage. In the event of complaints

the carrier must be informed immediately. Later claims will not be recognised.

• If possible, keep the packaging until the expiry of the warranty period.

• Familiarise yourself with the product by means of the operating instructions before

using for the first time.

• With accessories as well as wearing parts and replacement parts use only original

parts. Replacement parts can be obtained from your dealer.

• When ordering please provide our article number as well as type and year of manufac-

ture for your equipment.

mDANGER

The device and the packaging are not children‘s toys! Do not let children play with plastic

bags, films or small parts! There is a danger of choking or suffocating!

mWARNING

• During unpacking, transport and storage, bear in mind the high dead weight of the

machine. These activities should be carried out by two people.

• Make sure the device is level on a flat surface during unpacking, installation and stor-

age, operation, testing, maintenance and when not in use.

Layout Before commissioning

AUSAUS

HCP3000 HCP3000

2726

IX. Layout

9.1 Installing the bow-type handle (Fig. 3)

1. Fold the bow-type handle (1) onto the base frame of the device.

2. Tighten the star grip screw (6) using the existing screws (6.1).

9.2 Fitting the spraying nozzle unit (Fig. 1)

1. Position the spraying nozzle unit so that the holes provided for it are on top of each

other.

2. Now fix the unit with four sleeves (5.1) and the fixing plugs (5).

3. To do this, first press the sleeves (5.1) into the holes provided and then secure them

with the fixing plugs (5).

9.3 Fix the transport holder to the bow-type handle (Fig. 4)

1. Slide the transport bracket (4) from above into the already pre-assembled mounting

on the tubular frame (7).

9.4 Fitting the wheels (Fig. 5)

1. Slide the axle (32) through the wheel (13) from the outside.

2. Now guide the axle (32) with wheel (13) from the outside into the tubular frame (7) and

secure it with the spring split pin (33).

3. Repeat the process on the opposite side.

9.5 Fitting the hand spray gun, spraying lance (Fig. 6, 7, 8, 9)

mDANGER

• Danger of injury! The device, supply lines, high-pressure hose and connections must be

in perfect condition. If their condition is not perfect, the device must not be operated.

• Always tighten the fixing by hand! A too loose connection can lead to disconnection and

cause injury.

1. Connect the spraying lance (17) to the hand spray gun (23).

2. Hand-tighten the screwed connection of the spraying lance (17).

3. Fit the high-pressure hose (2) to the hand spray gun (23).

4. Attach the high-pressure hose (2) to the water outlet (28) by turning the fixing.

X. Before commissioning

10.1 Filling/checking the engine oil (Fig.10)

ATTENTION

• The engine oil must be filled before the first use!

• Check the oil level before each start-up.

• Do not operate the device if no oil is visible on the oil dipstick (12.1).

• Do not overfill the engine oil. Too high an oil level can lead to engine damage.

• Refill the oil if necessary. Only use engine oil (SAE10W30 or SAE10W40).

1. Place the device on a flat, even surface and remove any dirt from the area around the

oil inlet/dipstick (12)/oil tank cover with oil dipstick (12.1).

2. Open and remove the oil tank cover with oil dipstick (12.1) by turning anti-clockwise.

3. Fill the system with max. 400 ml four-stroke engine oil (SAE10W30 or SAE10W40) as

required.

4. Check the oil level using the marks on the oil dipstick (12.1).

5. Place on the oil tank cover with oil dipstick (12.1) and close by turning clockwise.

10.2 Filling in fuel (Fig. 11)

mDANGER

Risk of fire and explosion!

• Use standard unleaded petrol with max. 10% bioethanol component.

• Never refuel the device in enclosed spaces, with the engine running or hot.

• Do not smoke when refuelling.

• Do not use a two-stroke mixture.

• Do not refuel near naked flames or sparks.

• Do not spill fuel. Use funnel.

• Wipe up spilled fuel.

• After refuelling, close the canister and tank properly.

1. Open and remove the fuel tank cover (8) by turning anti-clockwise.

2. Place a filling hose with funnel (36) in the opening of the fuel tank (9).

3. Fill the fuel tank (9) with fuel up to max. 3-4 cm below the top edge.

4. Replace the fuel tank cover (8) and close the fuel tank (9) by turning clockwise.

10.3 Connecting the water supply (external) to the pump (Fig. 12)

mWARNING

• If the inlet sieve is missing or damaged, do not operate the high pressure cleaner. Parti-

cles in the high-pressure jet can cause injury.

• The maximum water inlet pressure must not exceed 0.5 MPA.

ATTENTION

• The length of the free garden hose must be at least 3m between the inlet of the high

pressure cleaner and a shut-off device, such as a Y shut-off coupling or other suitable

shut-off valve.

• Do not operate the high pressure cleaner without a water supply. If the high pressure

cleaner is operated without water, the high pressure cleaner will be damaged.

1. Before connecting the garden hose (NOT included in the scope of delivery) to the water

inlet (29), check the inlet sieve (40). Clean a contaminated inlet sieve (40), replace a

damaged inlet sieve (40, Fig. 2).

Operation Operation

AUSAUS

HCP3000 HCP3000

2928

2. To remove all impurities, run water through the garden hose for 30 seconds. Shut off

the water. Important: Do not suction stagnant water for the water supply. Only use

water up to max. 40° C.

3. Fit the hose connection adapter (38) on the water inlet (29).

4. The garden hose (NOT included in the scope of delivery) can be equipped with the

enclosed quick connector (37).

5. Connect the garden hose (NOT included in the scope of delivery) to the water inlet (29).

The hose must not be longer than 15 m.

6. Check that the hose is tightly fitted.

10.4 Self-suction from open tanks/containers and natural bodies of water

mDANGER

• Never suck up water from a drinking water tank.

• Never suck up liquids containing solvents such as paint thinner, petrol or oil. Solvent

spray is highly flammable, explosive and toxic.

Use the self-priming accessories (not included in scope of delivery) consisting of:

• Suction filter

• 3 m reinforced vacuum hose

With this accessory, the device can take in water max. 0.5 m above the water level. This

can last about 1 minute.

1. Submerge the 3 m vacuum hose completely under water to displace the air.

2. Connect the vacuum hose to the device and ensure that the suction filter remains

under water.

3. Run the device with the hand spray gun removed until water flows evenly from the

high-pressure hose.

4. If water does not come out after 1 minute, switch off the device and check all

connections. Once the water is flowing, turn off the device and connect the hand spray

gun and spraying lance to start work.

It is important that the hose and couplers are of good quality, connected tightly and that

the seals are undamaged and inserted straight. Leaky connections can hinder suction.

XI. Operation

Check the device to make sure that all of the following steps have been performed:

1. Before commissioning the device, read and understand the operating manual

completely.

2. Check that the bow-type handle (1) is tightly fitted.

3. Check that oil has been poured into the oil inlet/dipstick to the specified level.

4. Pour the specified type of petrol into the fuel tank (9).

5. Check that the hose connections are tightly fitted.

6. Check that the high-pressure hose (2) has no kinks, cracks or other damage.

7. Have a suitable water connection with sufficient flow ready.

8. Ensure the device is level.

9. Switch on the water supply.

ATTENTION

• Do not switch on the pump if the water supply is not connected or switched on.

• Select the required nozzle (3) and insert it in the spraying lance (17). (Fig. 7)

11.1 Starting the engine

ATTENTION

• At initial start-up, oil level (SAE10W30 or SAE10W40) and fuel (unleaded regular petrol)

must be filled in.

1. Check fuel level and engine oil, top up if necessary.

2. Ensure the device has sufficient ventilation.

3. Make sure that the spark plug / spark plug connector (31) is secured.

mCAUTION

• When starting with the pull cable starter (18), injuries to the hand can occur due to sud-

den kick-back.

11.1.1 Cold start (Fig. 13)

1. Set the choke lever (20) to the “Choke” position.

2. Set the on/off switch (11) to the “I/ON” position.

3. Open the fuel valve (19).

4. Start the engine with the pull cable starter (18). Pull the handle strongly for this. If the

engine does not start, pull the handle again.

5. After starting the engine, let the machine run for a few seconds and then set the choke

lever (20) to “Run”.

11.1.2 Warm start (Fig. 13)

1. Set the choke lever (20) to the “Run” position.

2. Set the on/off switch (11) to the “I/ON” position.

3. Start the engine with the pull cable starter (18). Pull the handle strongly for this.

11.1.3 After starting the engine (Fig.1)

1. Flip the trigger lock (24) on the hand spray gun (23).

2. Hold the hand spray gun (23) in a safe direction and pull the trigger (25). This cleans

the pump system of air and impurities.

11.2 Switch off the engine (Fig. 13)

1. Allow the device to run for a short time without load before switching it off so that the

device can “cool down”.

2. Set the on/off switch (11) to the “0/OFF” position.

Operation Operation

AUSAUS

HCP3000 HCP3000

3130

3. Close the fuel valve (19).

11.2.1 After shutting off the engine

1. Connect the water supply.

2. Pull the trigger (25) until the device is depressurized.

11.3 Setting the working pressure and flow rate

With this device, the working pressure and flow rate are fixed and cannot be adjusted.

11.4 Changing the nozzle (Fig. 7)

mDANGER

1. Before changing the nozzle, switch off the device and pull the trigger (25) until the

device is depressurized.

11.4.1 Using the spray nozzles (Fig. 7)

The quick-release connector on the spraying lance (17) can be used to switch between

four nozzles (3).

Proceed as follows to change the nozzles (3):

1. Pull back the ring of the quick-release connector and pull off the nozzle (3).

2. Select the required nozzle (3):

3. Soft jet: 40° (white) or 25° (green)

4. Hard jet: 0° (red)

5. Cleaning agent: black

6. Pull the ring back, insert the selected nozzle (3) and release the ring. Pull on the nozzle

(3) to check the tight fit.

7. The best cleaning results are achieved when the nozzle (3) is held at a distance of 20 to

60 cm from the surface to be cleaned. If the distance is too short, the sprayed surface

can be damaged.

8. When cleaning car tyres, maintain a distance of at least 30 cm.

11.5 Operation with cleaning agents

mWARNING

1. Switch off the device before carrying out any setting or maintenance work.

ATTENTION

Unsuitable cleaning agents can damage the device and the object to be cleaned.

• Only use recommended cleaning agents that are suitable for high pressure cleaners.

This device is intended for use with cleaning agents recommended by the manufacturer.

The use of other cleaning agents or chemicals may have a negative effect on the safety

of the machine.

• Recommended cleaning agents are primarily agents that are suitable for use with high

pressure cleaners. These are available in DIY and car accessories stores, among others.

ATTENTION

Cleaning agents can be harmful to the environment.

• Observe the manufacturer‘s instructions when using and disposing of the cleaning

agent and waste water.

Proceed as follows to work with cleaning agents:

1. Prepare the cleaning agent solution according to the manufacturer‘s instructions.

2. Read the instructions for using the nozzles (3) (see 11.4.1).

3. Check that the nozzle (3) for cleaning agent (black) has been inserted.

4. Open the filler cap for the cleaning agent tank (16).

5. Fill the cleaning agent tank (15) with cleaning agent.

ATTENTION

• Cleaning agent must not be applied with the high-pressure nozzles (3) (white, green or

red).

1. Check that the garden hose is also connected to the water inlet (29) (see 10.3).

2. Check whether the high-pressure hose (2) is connected to the hand spray gun (23) and the

water outlet (28) (see 9.5).

3. Insert nozzle (3) for cleaning agent (black) on spraying lance (17) (see 11.4.1).

4. Then start the engine (see 11.1).

11.5.1 Recommended cleaning method

1. Loosen dirt: Spray on cleaning agent sparingly and leave to act for 1 - 5 minutes, but do

not allow to dry.

2. Remove dirt: Rinse off loosened dirt with a high-pressure jet.

11.5.2 After operation with cleaning agent

1. After operating with cleaning agent, clean the cleaning agent tank (15) and the con-

nected hoses.

ATTENTION

Do not leave the cleaning agent in the cleaning agent tank (15)!

• Empty the cleaning agent tank (15) after operation.

To clean the cleaning agent tank (15) and the high-pressure pump (30), proceed as fol-

lows:

1. Pull the trigger (25) of the hand spray gun (23) until the cleaning agent tank (15) is

empty.

2. Fill the cleaning agent tank (15) with clear water.

3. Insert the cleaning agent nozzle (3) (black) on the spraying lance (17).

Transport Cleaning

AUSAUS

HCP3000 HCP3000

3332

4. Start up the high pressure cleaner as described in chapter 10.

5. Rinse the high pressure cleaner with clear water for several minutes.

11.6 Interrupting operation

• Release the trigger (25) of the hand spray gun (23).

Note:

When the trigger (25) of the hand spray gun (23) is released, the engine continues to idle.

1. Switch off the engine during longer interruptions (several minutes) (see 11.2).

2. Pull the trigger (25) until the device is depressurized.

3. Secure the hand spray gun (23) with the trigger lock (24) against unintentional

opening.

11.7 Finishing work

1. Switch off the engine at the end of work (see 11.2).

2. Shut off the water supply to the high pressure cleaner.

3. Pull the trigger (25) until the device is depressurized.

4. Securethehand spray gun (23) withthetrigger lock (24) against unintentional opening.

5. Unscrew the water supply hose from the device.

XII. Transport

mCAUTION

Risk of injury and damage!

• Note the weight of the device during transport.

12.1 Preparation for transport

Note:

Dispose of petrol in an environmentally friendly manner!

1. Empty the fuel tank (9) with a fuel suction pump (not included in the scope of

delivery).

2. To ensure that no petrol remains in the carburettor (10), the remaining petrol in

the carburettor (10) must be drained out. To do this, place a suitable container (not

included in the scope of delivery) under the carburettor (10) and open the petrol

drain screw (41). Fig.16

3. Drain the engine oil from the warm engine (as described).

4. Remove the spark plug connector (31) from the spark plug.

5. Wind up the high-pressure hose (2) and place it in the hose holder (27).

6. Insert the spraying lance (17) into the transport bracket (4) and hang the hand spray

gun (23) into the transport bracket (4).

7. Slide the device by the bow-type handle (1).

8. When transporting the device in vehicles, secure it against rolling away, slipping and

tipping, for example with tension straps, in accordance with the applicable directives.

XIII. Cleaning

mDANGER

Danger of injury due to unintentional start-up of the device.

• Before working on the device, turn the engine switch to “0/Off” and remove the spark

plug connector.

Danger of burning

• Do not touch hot silencers, cylinders or cooling fins.

mWARNING

• Switch off the device before carrying out any setting or maintenance work.

• Remove the spark plug connector (31).

ATTENTION

• Switch off the device immediately and contact your customer service:

-In the event of unusual vibrations or noises.

-If the engine seems overloaded or misfires.

• Keep protective devices, air vents and the engine housing as free of dust and dirt as

possible. Rub the device clean with a dry cloth or blow it off with compressed air at low

pressure.

• We recommend that you clean the device directly after every use.

• Clean the device at regular intervals using a damp cloth and a little soft soap. Do not

use chemical cleaning agents or solvents. These could damage the plastic parts of the

device. Make sure that no water penetrates the device interior.

13.1 Nozzle cleaning

If there is a pulsating sensation when the trigger (25) is pressed, the nozzle (3) is poten-

tially dirty or clogged and should be cleaned immediately.

1. To clean the nozzle (3), switch off the engine and stop the water supply.

2. Depressurize the device (see 11.6).

3. Remove the nozzle (3) from the spraying lance (17). Make sure that the nozzle (3)

points away from you in a safe direction.

4. Use the nozzle cleaner needle (34) or a small paper clip to remove debris from the

nozzle (3).

5. Rinse the nozzle (3) with clear water.

6. Refit the nozzle (3) to the spraying lance (17).

7. Start the water supply and start the device.

Maintenance Maintenance

AUSAUS

HCP3000 HCP3000

3534

13.2 Draining water

ATTENTION

Risk of damage!

• Freezing water in the device can destroy parts of the device.

In winter, store the device preferably in a heated room.

When storing in an unheated room, proceed as follows:

1. Unscrew the water supply hose and high-pressure hose (2).

2. Let the device run for max. 1 minute until the pump and lines are empty.

XIV. Maintenance

mWARNING

• Switch off the device before carrying out any setting or maintenance work.

• Remove the spark plug connector (31).

mDANGER

Danger of injury due to unintentional start-up of the device.

• Before working on the device, turn the engine switch to “0/Off” and remove the spark

plug connector.

Danger of burning

• Do not touch hot silencers, cylinders or cooling fins.

14.1 Maintenance intervals

Before commissioning:

1. Check the oil level on the oil tank cover with oil dipstick (12.1).

2. If the oil is milky (water in the oil), contact customer service immediately.

3. Check the high-pressure hose (2) for damage (danger of bursting). Replace a

damaged high-pressure hose (2) immediately.

Every 25 operating hours:

1. Check the oil level on the oil tank cover with oil dipstick (12.1).

2. If the oil is milky (water in the oil), contact customer service immediately.

Every 50 operating hours:

1. Check the oil level on the oil tank cover with oil dipstick (12.1).

2. If the oil is milky (water in the oil), contact customer service immediately.

3. Clean the air filter.

4. Check the fasteners between the engine and the frame for cracks and have cracked

fasteners replaced by customer service.

14.2 Maintenance work

14.2.1 Changing the engine oil (Fig. 10/14)

Note:

Dispose of used oil in an environmentally friendly manner!

The engine oil change should be carried out while the engine is at operating tem-

perature.

1. Provide a collecting container for approx. 1 litre of oil.

2. Place the device on a suitable surface.

3. Open the oil drain screw (39) (Fig. 14).

4. Drain the engine oil into the collection container provided.

5. To speed up the draining of the engine oil, you can open the oil tank cover with oil

dipstick (12.1).

6. After the used oil has drained out, close the oil drain screw (39) and put the device

back on level ground.

7. Fill engine oil up to the top marking on the oil dipstick (12.1).

For oil type and filling quantity, see Technical Data.

ATTENTION

• To check the oil level, do not screw in the oil tank cover with oil dipstick (12.1), but only

insert it up to the thread.

14.2.2 Air filter (Fig. 1)

Clean the air filter (21) regularly, replace if necessary.

1. Remove the air filter cover. Pull carefully on the edges of the air filter (21).

2. Remove the contaminated filter element.

3. Knock out the contaminated filter element or blow it out with compressed air at low

pressure.

4. Replace the filter element and the air filter cover.

14.2.3 Spark plug (Fig. 14)

Check the spark plug / spark plug connector (31) for contamination for the first time after

20 operating hours and clean it with a copper wire brush if necessary. Then service the

spark plug every 50 operating hours.

1. Remove the spark plug connector (31) from the spark plug by turning it.

2. Remove the spark plug with the enclosed spark plug wrench (35).

3. The re-assembly takes place in reverse order.

14.3 Service information

With this product, it is necessary to note that the following parts are subject to natural or

usage-related wear, or that the following parts are required as consumables.

Storage Troubleshooting

AUSAUS

HCP3000 HCP3000

3736

Wearing parts*: Spark plug, high-pressure hose, spraying lance, nozzles, air filter

* may not be included in the scope of supply!

XV. Storage

mCAUTION

Risk of injury and damage!

• Note the weight of the device during transport.

Store the device and its accessories in a dark, dry and frost-free place that is inaccessible

to children. The optimum storage temperature is between 5 and 30˚C.

Cover the device to protect it from dust or moisture.

Store the operating manual with the device.

15.1 Preparation for storage

Note:

Dispose of petrol in an environmentally friendly manner!

1. Empty the fuel tank (9) with a fuel suction pump (not included in the scope of delivery).

2. To ensure that no petrol remains in the carburettor, the remaining petrol in the

carburettor must be drained out. To do this, place a suitable container (not included

in the scope of delivery) under the carburettor and open the petrol drain screw (41).

Fig.16:

3. Change the oil at the end of every season. To do so, remove the used engine oil from a

warm engine and refill with fresh oil.

4. Remove the spark plug. Fill approx. 20 ml of oil into the cylinder using an oil can (not

included in scope of delivery). Pull the pull cable starter (18) slowly so that the oil coats

the inside of the cylinder. Attach the spark plug again.

5. Open the star grip screws (6) and fold the device in (Fig. 15).

6. Store the device in a well-ventilated place or area.

XVI. Disposal and recycling

The device is supplied in packaging to avoid transport damages. This packaging is raw

material and can thus be used again or can be reintegrated into the raw material cycle.

The device and its accessories are made of different materials, such as metals and plas-

tics. Take defective components to special waste disposal sites.

Check with your specialist dealer or municipal administration!

XVII. Troubleshooting

mWARNING

Danger of injury due to unintentional start-up of the device!

• Before working on the device, turn the on/off switch (11) to the “Off” position and remove

the spark plug connector (31).

mWARNING

Danger of burning!

• Do not touch hot silencers, cylinders or cooling fins.

ATTENTION

• If the fault cannot be rectified, the device must be checked by customer service.

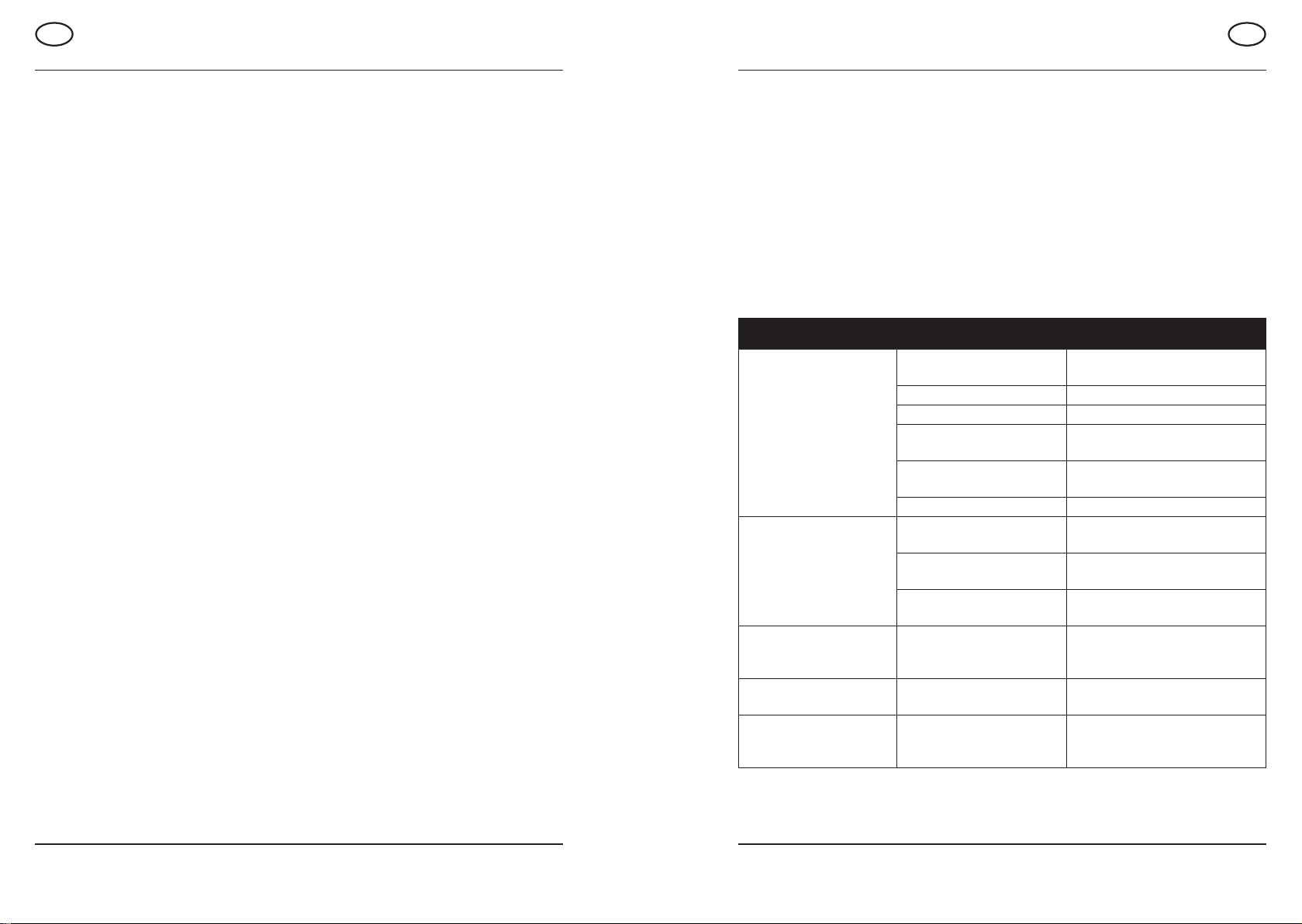

Fault Possible cause Remedy

Engine cannot be

started

Automatic oil cut-off

starts.

Check oil level, fill with engine

oil.

Spark plug sooty Clean or replace spark plug.

No fuel Top up with fuel.

Spark plug connector is

disconnected

Connect the spark plug con-

nector to the spark plug.

Spark plug connector is

damaged

Contact customer service.

Ignition does not work Contact customer service.

Engine is difficult to start Out-of-date fuel or water

in fuel

Drain fuel and fill with new fuel.

Spark plug does not pro-

duce an ignition spark

Contact customer service.

Carburettor incorrectly

adjusted

Contact customer service.

Engine has too little

power and vibrates

excessively

Contaminated air filter Clean the air filter.

Engine dies during

operation

No fuel Top up with fuel.

Engine loses power

during operation

Engine speed is too low Operate the trigger slower. If

the fault persists, contact Cus-

tomer Service.

Troubleshooting

AUS

HCP3000

38

Device does not build up

pressure

Nominal speed of the

engine too slow

Check the nominal speed of

the engine; contact customer

service.

Low-pressure nozzle fitted Fit the high-pressure nozzle.

Nozzle clogged / washed

out

Clean / renew nozzle

Suction filter clogged Clean the suction filter.

Air in the system Bleed the device (see “Before

commissioning”).

Water supply volume too

low

Check the water supply volume.

Supply line to the

high-pressure pump leak-

ing or clogged

Check all supply lines to the

high-pressure pump. Contact

customer service.

Pump is defective Contact customer service.

Device leaks, water drips

from the bottom of the

device

The high-pressure pump

leaks

A maximum of 3 drops / minute

is permissible. In case of severe

leakage, have the device

checked by customer service.

Cleaning agent is not

sucked in

High-pressure nozzle

fitted

Fit the low-pressure nozzle.

Cleaning agent hose leak-

ing or blocked

Check or clean the cleaning

agent hose

Petrol high pressure cleaner

Warranty Details

The product is guaranteed to be free from defects in workmanship and parts for a period of 36

months from the date of purchase. Defects that occur within this warranty period, under normal

use and care, will be repaired, replaced or refunded at our discretion. The benets conferred by this

warranty are in addition to all rights and remedies in respect of the product that the consumer has

under the Competition and Consumer Act 2010 and similar state and territory laws.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and for compensation for any other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced

if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

3

YEARS

WARRANTY

REGISTER YOUR PURCHASE AT www.aldi.com.au/en/about-aldi/product-registration/ TO KEEP UP-TO-DATE WITH IMPORTANT PRODUCT INFORMATION

AFTER SALES SUPPORT

1300 855 831 support@scheppach.com.au

AUS Hotline Costs: Local rate for landline calls*

*Charges may var y dependent upon net work operator or mobile network provider. MODEL: HCP3000 PRODUCT CODE: 702499 09/2022

Petrol high pressure cleaner

Repair and Refurbished Goods

or Parts Notice

Unfortunately, from time to time, faulty products are manufactured which need to be returned to

the Supplier for repair.

Please be aware that if your product is capable of retaining user-generated data (such asles stored

on a computer hard drive, telephone numbers stored on a mobile telephone, songs stored on a

portable media player, games saved on a games console or les stored on a USB memory stick)

during the process of repair, some or all of your stored data may be lost.

We recommend you save this data elsewhere prior to sending the product for repair.

You should also be aware that rather than repairing goods, we may replace them withrefurbished

goods of the same type or use refurbished parts in the repair process.

Please be assured though, refurbished parts or replacements are only used where they meet

ALDI’s stringent quality specications.

If at any time you feel your repair is being handled unsatisfactorily, you may escalate your com-

plaint. Please telephone us onSUPPLIER TELEPHONE or write to us at:

RossMac Pty. Ltd.

Unit 6, 4 Ovata Drive, Tullamarine, Victoria, 3043

Telephone: 1300 855 831 (Monday - Friday 8:00am-6:00pm)

Email: [email protected]om.au

AFTER SALES SUPPORT

1300 855 831 support@scheppach.com.au

AUS Hotline Costs: Local rate for landline calls*

*Charges may var y dependent upon net work operator or mobile network provider. MODEL: HCP3000 PRODUCT CODE: 702499 09/2022

3

YEARS

WARRANTY

Table of contents

Other FERREX Pressure Washer manuals