FERREX FPB 1500 User manual

ROTARY HAMMER

FPB 1500

User Manual

ID: #05007

m

y

h

a

n

s

e

c

o

n

t

r

o

l

.

c

o

m

M

A

N

U

A

L

D

E

V

E

L

O

P

E

D

I

N

G

E

R

M

A

N

Y

User-friendly

Manual

Original instructions

Package contents................................................................3

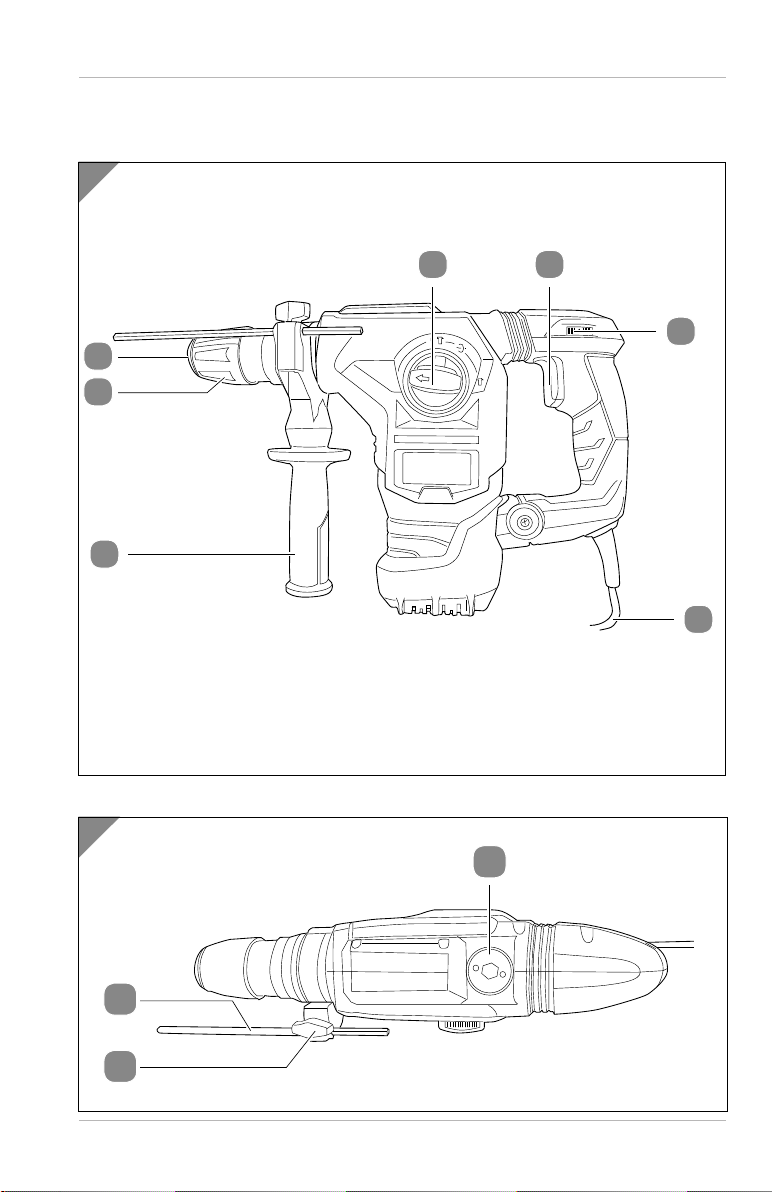

Components ............................................................................. 6

General information............................................................ 7

Reading and storing the user manual ..................................7

Explanation of symbols ...........................................................7

Safety ...................................................................................9

Explanation of notes ............................................................... 9

Proper use................................................................................. 9

Improper use............................................................................ 9

Residual risks...........................................................................10

General power tool safety warnings ....................................11

Special safety instructions for rotary hammer drills......... 14

Supplementary safety instructions..................................... 14

First use...............................................................................17

Checking the rotary hammer drill

and package contents ........................................................... 17

Inserting a tool........................................................................ 17

Removing a tool ......................................................................18

Mounting and adjusting the depth stop.............................18

Setting the extra handle .......................................................18

Operation of the rotary hammer drill .............................. 18

Switching the rotary hammer drill on and off

and adjusting the speed .......................................................19

Switching between the functions....................................... 20

Cleaning and maintenance............................................... 22

Checking the rotary hammer drill........................................22

Cleaning ...................................................................................23

Storage .............................................................................. 23

Transport ........................................................................... 23

Troubleshooting................................................................24

Technical data ................................................................... 25

Noise/vibration information ............................................26

Disposal..............................................................................28

Disposing of the packaging ................................................. 28

Disposing of the rotary hammer drill ................................. 28

Declaration of conformity.................................................29

Contents

3

Package contents

Dok./Rev.-Nr. 197392_20190710

A

1 2

3

5

7

6

4

8

10

9

B

Package contents

4

Package contents

13

12

11

10

C

D

14

15

5

Package contents

NOTICE:

The keyed chuck may only be used

without the hammer function!

Spiral and wood drill bits

are not included in the

package contents.

E

F G

17

16

6

Package contents

Components

1Selector switch “Drilling/Hammer drilling/Set chisel working angle/Chiselling”

2On/Off switch

3Speed control

4Mains cord

5Extra handle (front handle)

6Retaining bush

7Tool holder (SDS plus system chuck)

8Gear grease filler hole

9Wing screw for depth stop

10 Depth stop

11 SDS chisel, 2× (1× flat chisel, 1× pointed chisel)

12 SDS drill bit, 3× (1× 12 mm, 1× 16 mm, 1× 18 mm)

13 Key for the gear grease filler hole

14 Chuck key

15 Keyed chuck with adapter

16 Dust cover

17 Storage case

General information

7

General information

Reading and storing the user manual

This user manual accompanies this rotary hammer FPB 1500 (hereinafter

referred to only as the “rotary hammer drill”). It contains important

information about safety, usage and care.

Read this user manual carefully before using the rotary hammer drill. Pay

particular attention to the safety instructions and warnings. Failure to comply with the

instructions in this user manual may result in severe injury or damage to the rotary

hammer drill.

Comply with all applicable local or national regulations concerning the use of this

rotary hammer drill. Keep this user manual in a safe place for future reference. If you

pass the rotary hammer drill on to third parties, please be absolutely sure to include

this user manual.

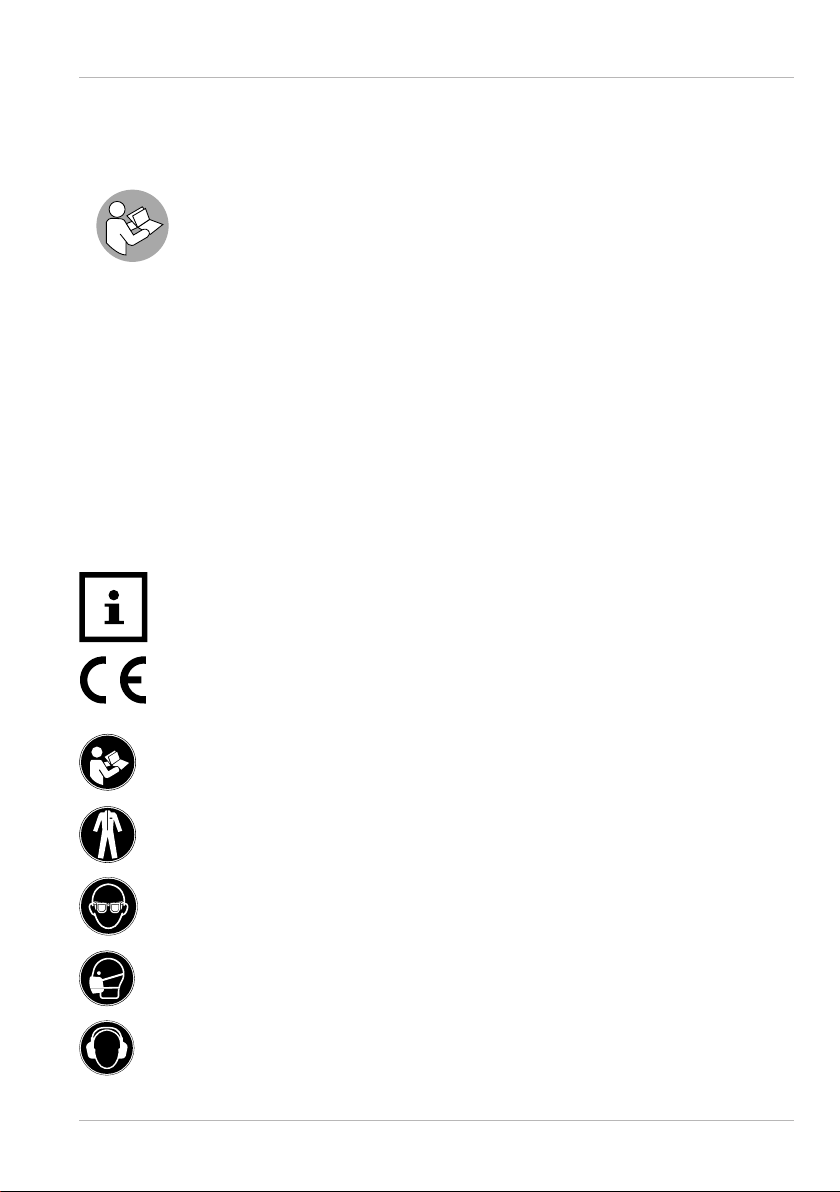

Explanation of symbols

The following symbols are used in this user manual, on the rotary hammer drill or on

the packaging.

This symbol provides you with useful supplementary information about

the use.

Declaration of conformity (see “Declaration of conformity” section):

Products marked with this symbol meet all applicable Community

regulations for the European Economic Area.

Read the user manual.

Wear suitable, tight fitting clothing.

Wear protective goggles.

Wear a dust mask.

Wear ear protection.

General information

8

Wear suitable secure footwear.

Wear suitable protective gloves.

Protection class II

Drilling in wood and metal without the hammer function

Hammer drilling in concrete and masonry

Setting the working angle

sorgung muss mit den Angaben auf

dem Typenschild der Maschine übe

r- Chiselling in tiles and masonry

Safety

9

Safety

Explanation of notes

The following symbols and signal words are used in this user manual.

WARNING!

Indicates a hazardous situation that, if not

avoided, could result in death or serious injury.

CAUTION!

Designates a dangerous situation that may result

in minor or moderate injury if not avoided.

NOTICE!

Warns of possible damage to property.

Proper use

The rotary hammer drill is only designed for drilling and hammer drilling in concrete,

rock and masonry as well as for minor chiselling tasks. With the keyed chuck, the

rotary hammer drill can also be used for drilling without the hammer function in

wood and metal. It is only intended for private use and is not suitable for commercial

use.

The tool holder is suitable for tools corresponding to the SDS plus system.

Any other applications are expressly prohibited and are deemed improper use.

Improper use

All applications with the device, which are not specified in the chapter “Proper use”

are deemed improper use.

Neither the manufacturer nor the retailer can accept any responsibility for injury, loss

or damage caused by misuse of this product of any kind.

Examples of misuse are given in the following non-exhaustive list:

• using the rotary hammer drill for other than the intended purposes. This can

result in hazards and injuries;

• use of accessories that are not especially intended for this rotary hammer drill.

Even if the accessories can be mounted on your rotary hammer drill, this is no

guarantee for safe use.

The warranty offered by the manufacturer is forfeited if different or non-original

parts are used on the machine.

Safety

10

• changes to the rotary hammer drill;

• commercial or industrial use of the rotary hammer drill as well as in connection

with the trades;

• use of the rotary hammer drill by persons under the age of 16;

• operation or maintenance of the rotary hammer drill by persons not familiar with

how to handle the rotary hammer drill and/or who are not aware of the related

risks;

• failure to observe the safety instructions and warnings as well as the assembly,

operating, maintenance and cleaning instructions contained in this user manual;

• failure to comply with any regulations relating to accident prevention,

occupational medicine or safety, which specifically and/or generally apply to the

use of this rotary hammer drill;

• repairs of the rotary hammer drill performed by parties other than the

manufacturer or a qualified professional;

• use of fitted tools whose permissible speed is not at least as high as the

maximum speed specified for the rotary hammer drill. Accessories that rotate

faster than permissible may break and be projected. There is a risk of injury.

The user of the device is liable for all damage to property and injury to persons

incurred due to incorrect use.

Residual risks

Despite proper use, inconspicuous residual risks cannot be completely ruled out.

The following risks may arise due to the nature of the use:

• injury if long hair, articles of clothing or jewellery are caught by rotating parts or

fitted tools;

• injury caused by projected workpieces or parts of work pieces;

• fire hazard if the motor is not sufficiently ventilated;

• injury to health attributed to hand-arm vibrations if the rotary hammer drill is

used for a prolonged period of time or if the rotary hammer drill is not guided

and maintained properly;

• lung injury if a suitable dust mask is not worn;

• hearing loss if suitable ear protection is not worn;

• eye injury caused by flying materials or parts thereof if no suitable eye protection

is worn.

Safety

11

General power tool safety warnings

WARNING Read all the safety notes, instructions, illustrations and

technical details supplied with this power tool. Failure to follow the safety

notices and instructions may result in an electric shock, fire and/or severe

injury.

Save all warnings and instructions for future reference.

The term “power tool” used in the safety instructions refers to mains-operated

power tools (corded) and battery-powered power tools (cordless).

Work area safety

a) Keep your work area clean and well lit.

Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust.

Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power

tool.

If you are distracted, you could lose control of the power tool.

Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in

any way. Do not use any adapter plugs with earthed (grounded)

power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as

pipes, radiators, ranges and refrigerators.

There is an increased

risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water

entering a power tool will increase the risk of electric shock.

d) Do not use the cord for improper purposes such as for carrying

the power tool, for hanging it up or for pulling or unplugging

it from the socket. Keep cord away from heat, oil, sharp edges

and moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use only extension cords

that are suitable for outdoor use.

Use of a cord suitable for outdoor

use reduces the risk of electric shock.

Safety

12

f) If operating a power tool in a damp location is unavoidable, use

a residual current device (RCD) protected supply.

Use of an RCD

reduces the risk of electric shock.

Personal safety

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Wearing personal protective equipment (such as a dust mask, non-

slip safety shoes, a hard hat or ear protection) as appropriate to the

tool and to your application can reduce the risk of injury.

c) Prevent unintentional starting. Ensure the switch is in the off-

position before connecting to your power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with

your finger on the switch or connecting the power tool to a power

supply while the switch is set to “on” may lead to accidents.

d) Remove any adjusting key or wrench before turning the power

tool on.

A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all

times.

This enables better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair and clothing away from moving parts.

Loose clothes,

jewellery or long hair can be caught in moving parts.

g) If there is an option for installing dust suction devices and dust

containers, these should be attached and used correctly.

Use of

dust collection can reduce dust-related hazards.

h) Do not be lulled into a false sense of security and ignore the

safety rules for power tools, even if you are well acquainted with

power tools, having used them frequently.

Using power tools

without due care and attention can cause serious injuries in a split

second.

Safety

13

Power tool use and care

a) Do not overload the power tool. Use the correct power tool for

your application.

The correct power tool will do the job better and

more safely at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and

off.

Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the

rechargeable battery from the power tool before making any

adjustments, changing insertion tools or storing the power tool.

Such preventive safety measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach of children. Do not let any

individual who is not familiar with the power tool or who has not

read these instructions operate this power tool.

Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools and insertion tools with care. Check for

misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s operation.

If any parts of the power tool are damaged, have them repaired

before use.

Many accidents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories, insertion tools etc. in accordance

with these instructions. taking into account the working

conditions and the work to be performed.

Use of the power tool for

operations different from those intended could result in a hazardous

situation.

h) Keep handles and handle surfaces dry, clean and free from oil

and grease.

Slippery handles and handle surfaces will prevent you

from operating and controlling the power tools safely in unforeseen

situations.

Safety

14

Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts.

This will ensure that the safety of

the power tool is maintained.

Special safety instructions for rotary hammer drills

a) Wear ear protection.

Noise may cause hearing loss.

b) Use the extra handles shipped with the device.

Loss of control may

cause injury.

c) Hold the device by the insulated gripping surfaces when

performing work where the fitted tool may come into contact

with hidden power lines or its own mains cord.

Cutting accessory

contacting a “live” wire may make exposed metal parts of the power

tool “live” and could give the operator an electric shock.

Supplementary safety instructions

WARNING!

Risk of electric shock!

A faulty electrical installation or excessive mains voltage may result in an electric

shock.

− Only connect the rotary hammer drill if the mains voltage of the socket

corresponds to the data on the rating plate.

− Only connect the rotary hammer drill to an easily accessible socket so that

you can quickly disconnect it from the power supply in the event of a fault.

− Never touch the rotary hammer drill or the mains plug with damp hands.

− Lay the mains cord so that it does not pose a tripping hazard.

− Do not kink the mains cord and do not lay it over sharp edges.

− If the connection line is damaged, you must – in order to avoid risks – have

it replaced by the manufacturer or its customer service representative.

− Before beginning work, check the work area for hidden power, water or

gas lines. If necessary, use a pipe detector.

− Secure the workpiece with a suitable clamping device. This will ensure

that it is more securely held than it would be with your hand.

Safety

15

− Immediately switch the rotary hammer drill off if the fitted tool jams. A tool

that jams can trigger kickback.

− Never use the rotary hammer drill as a screwdriver when hammer drilling.

It is prohibited to tighten and loosen screws, nuts and the like when

hammer drilling.

WARNING!

Risk of injury!

Failure to follow the warning notes can result in injury.

− Store the rotary hammer drill in an area that is not accessible for children.

− Wear suitable protective clothing! Wear protective goggles and a

protective helmet to protect yourself against airborne particles and

splintered debris.

− Set up partitioning walls to protect nearby persons from airborne particles

and splintered debris.

− Wear work gloves to prevent your fingers from being crushed and to

prevent skin abrasions.

− Only connect the rotary hammer drill to the power supply after it has been

switched off.

− Make sure that the rotary hammer drill’s switch is set to the position that

corresponds to the type of work you intend to perform.

− Only start the rotary hammer drill when it is pressed against a workpiece

(wall, ceiling etc.).

− Disconnect the rotary hammer drill from the mains once you have finished

work.

− Never touch the outer casing directly after drilling. It becomes very hot

when drilling.

− Before performing work, always check whether the chisel or the drill bit

are correctly secured in the tool holder.

− Check the tool holder regularly for wear or damage.

− Never remove dust, chips or splinters while the motor is running.

− Secure small workpieces so that they are not pulled along by the drill bit

when drilling.

Safety

16

NOTICE!

Risk of damage!

Improper handling of the rotary hammer drill may result in damage to the

rotary hammer drill or the fitted tools.

− Only place the rotary hammer drill on an easily accessible, flat, dry, heat-

resistant and sufficiently stable work surface.

− Do not place the rotary hammer drill on the edge of the work surface.

− Never place the rotary hammer drill on or near hot surfaces (stovetops

etc.).

− Ensure that the mains cord does not come into contact with hot parts.

− Never expose the rotary hammer drill to high temperatures (heaters etc.)

or to effects of the weather (rain etc.).

− Never attempt to clean the rotary hammer drill by immersing it in water

and do not use a steam cleaner to clean it. Otherwise you could damage

the rotary hammer drill.

− Do not use aggressive solvents to clean the rotary hammer drill.

− Stop using the rotary hammer drill if its plastic parts exhibit cracks

or breaks or are deformed. Only have a qualified workshop replace

damaged parts with corresponding original spare parts.

− Operate the selector switch “Drilling/Hammer drilling/Set chisel working

angle/Chiselling” only when the motor is not running. Switching when the

motor is running can damage the gears.

− Always keep the connector cord away from your sphere of action by

moving it back away from the rotary hammer drill.

− Avoid the motor from coming to a stop under load when drilling and

screw driving.

First use

17

First use

Checking the rotary hammer drill and package contents

NOTICE!

Risk of damage!

If you are not cautious when opening the packaging with a sharp knife or other

pointed objects, you may quickly damage the rotary hammer drill.

− Be very careful when opening.

1. Lift the rotary hammer drill out of the packaging with both hands.

2. Place the rotary hammer drill on a level, stable surface, e.g. on a workbench.

3. Remove the packaging material and all protective foils.

4. Check whether the rotary hammer drill or the individual parts exhibit damage.

If this is the case, do not use the rotary hammer. Contact the manufacturer at the

service address specified on the warranty card.

5. Check to make sure that the delivery is complete (see Fig. A, B, C, D, F, G).

The tool holder is suitable for tools in accordance with the SDS plus

system.

Inserting a tool

The drill bit and chisel with a shaft corresponding to the SDS plus system can be

inserted directly into the tool holder 7.

1. If necessary, clean the end of the drill bit 12 or the chisel 11 to be inserted and

grease it lightly with drilling grease (not included in the package contents).

2. Point the tool holder up.

3. Insert the lightly greased end of the drill bit and turn it to the locking point with

gentle pressure. It is not necessary to push the retaining bush 6down in the

process.

In case of drill bits for wood or metal, you must first mount the additional keyed chuck

with adapter 15 (see chapter “Drilling without the hammer function”).

1. Insert the keyed chuck with adapter into the tool holder.

2. Insert a suitable drill bit into the keyed chuck and secure it with the chuck key 14 .

NOTICE: The keyed chuck may only be used without the hammer function!

Operation of the rotary hammer drill

18

Removing a tool

1. Tool without keyed chuck 15 :

Push the retaining bush 6back to remove the tool.

2. Tool with keyed chuck:

Use the chuck key 14 to open the keyed chuck and remove the tool. Push the

retaining bush 6back to remove the keyed chuck.

Mounting and adjusting the depth stop

1. Loosen the wing screw 9on the extra handle 5until the depth stop 10 can

be inserted in the clamping opening.

2. Pull the depth stop up to the tip of the inserted drill bit 12 .

3. Push the tip of the drill bit and depth stop up against a flat surface and push the

depth stop back by the desired drilling depth.

4. Fix the setting by tightening the wing screw. The front end of the depth stop will

come into contact with the respective base once the set drilling depth is reached.

5. Drill a test hole if necessary.

Setting the extra handle

1. Loosen the extra handle 5by turning it anticlockwise and turn it around the drill

axis to a convenient lateral working position.

2. Turn the front handle clockwise to fix it in place.

Operation of the rotary hammer drill

WARNING!

Risk of accident and injury!

There is a risk of accident and injury in the event of accidental activation/

deactivation when inserting and removing tools as well as when transporting

and cleaning the rotary hammer drill.

− Before inserting and removing tools, pull the mains plug to prevent the

rotary hammer drill from accidentally activating.

− Never touch the inserted tool while it is still rotating.

Operation of the rotary hammer drill

19

NOTICE!

Risk of damage!

When performing overhead work, dust and other contaminants may penetrate

the chuck and damage it.

− Before inserting the tool, push the dust cover over the tool shaft so that it

collects the drill dust.

− Place the dust cover on the tool shaft so that the keyhole of the dust cover

points towards the tip of the tool.

Switching the rotary hammer drill on and off and

adjusting the speed

WARNING!

Risk of accident and injury!

Drilling into brick masonry could damage power lines, gas lines and water lines.

There is a risk of electrocution, gas emission and water damage.

− Before drilling into walls and masonry, check that they do not contain

power, gas or water lines.

− Always use both hands to hold the rotary hammer drill by the insulated

handles to protect yourself against an electric shock.

1. Use the speed control 3to set the motor to the desired speed.

“6” indicates the maximum speed.

Observe the speed recommendations of the accessory manufacturer with respect

to working carefully with materials.

2. Push the On/Off switch 2.

The rotary hammer drill will operate at the preselected speed.

3. Release the On/Off switch to switch off the rotary hammer drill.

This rotary hammer drill has a vibration damper to reduce vibrations.

Operation of the rotary hammer drill

20

Switching between the functions

CAUTION!

Risk of injury!

When hammer drilling, chiselling and drilling, rock splinters, airborne dust,

borings and sparks may be produced.

− Wear protective goggles and ear protection when hammer drilling,

chiselling or drilling.

− Also wear a dust mask when drilling in a material with a loose structure,

slabs or concrete and masonry or when hammer drilling.

NOTICE!

Risk of damage!

Improper handling may damage the rotary hammer drill.

− Only switch between hammer drilling and normal drilling if the rotary

hammer drill and the inserted tool have come to a stop.

− Only use the keyed chuck without the hammer function.

WARNING!

Risk of accident and injury!

Flat chisels do not have guiding cutting edges. Therefore, they cannot be used

for drilling. The flat cutting edge also produces strong kickback forces when it

is rotated.

− Always switch tool rotation off when working with a chisel tool.

Drilling without the hammer function

NOTICE!

Risk of damage!

Improper handling may damage the rotary hammer drill.

− Always push the release button before you turn the selector switch.

Table of contents

Popular Rotary Hammer manuals by other brands

Dexter Laundry

Dexter Laundry 1500RH2-50.5 Legal and Safety Instructions

Hitachi Koki

Hitachi Koki Instruction ManualDH 22PG Handling instructions

Bosch

Bosch GBH 4-32 DFR Professional Repair instructions

Metabo

Metabo BHE 2444 operating instructions

Bosch

Bosch GBH 2-24 DS Repair instructions

Hitachi

Hitachi DH 25DL Handling instructions