FERREX PLC40 User manual

User Manual

PLASMA CUTTER

Contents

3

Dok./Rev.-Nr. 705680_20200120

AFTER SALES SUPPORT 705680

1300 855 831

MODEL:

PLC40

1

YEAR

WARRANTY

AU

Made in China

FERREX®is a registered trademark of ALDI Stores

DISTRIBUTED BY:

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

www.aldi.com.au

AU

ALDI guarantees that our exclusive brand products are developed to our

stringent quality specifications. If you are not entirely satisfied with this

product, please return it to the nearest ALDI store within 60 days from the

date of purchase, for a full refund or replacement, or take advantage of our

after sales support by calling the supplier’s Customer Service Hotline.

06/2021

1

2

3

4

5

1

DCB

GF

E

A

H

2

Overview ..................................................................................... 3

Package contents/part list .........................................................6

Explanation of Symbols .............................................................. 7

Introduction ................................................................................9

Layout .........................................................................................10

Scope of delivery........................................................................ 11

Intended use ..............................................................................12

Safety regulations......................................................................12

Attachment / Before starting the equipment ......................... 20

Operation....................................................................................21

Cleaning and maintenance....................................................... 23

Technical data ........................................................................... 24

Storage and transport .............................................................. 25

Disposal and recycling .............................................................. 25

Troubleshooting........................................................................ 26

Warranty Details........................................................................ 29

Repair and Refurbished Goods or Parts Notice .......................30

IJ

56

4

Package contents/part

list

1Plasmas cutter, 1x

2Compressed air hose, 1x

3Ground cable with terminal, 1x

4Plasma hose package, 1x

5Hose clamp, 1x

6Nozzle, 3x (1x pre-assembled)

7Electrodes, 3x (1x pre-assembled)

8Diffuser, 2x

9Ceramic cap, 2x

10 Warranty card

11 Operatiing instructions

1

2

3

5

4

6

7

8

9

10

11

1315 141618

22

23

24

25

28

31

38

34

35

33

32

30

20

29

21 19

37

1217

36

27

26

1

12

11

10

9

6

8

7

315

16

10a

14

13

11a

4

5

9a

515 16

13

14

6

19

20

8

18 17 16 15

7

24

21

22

19

19a

23

9

21

22

10

11 12

Kapitelüberschrift

7

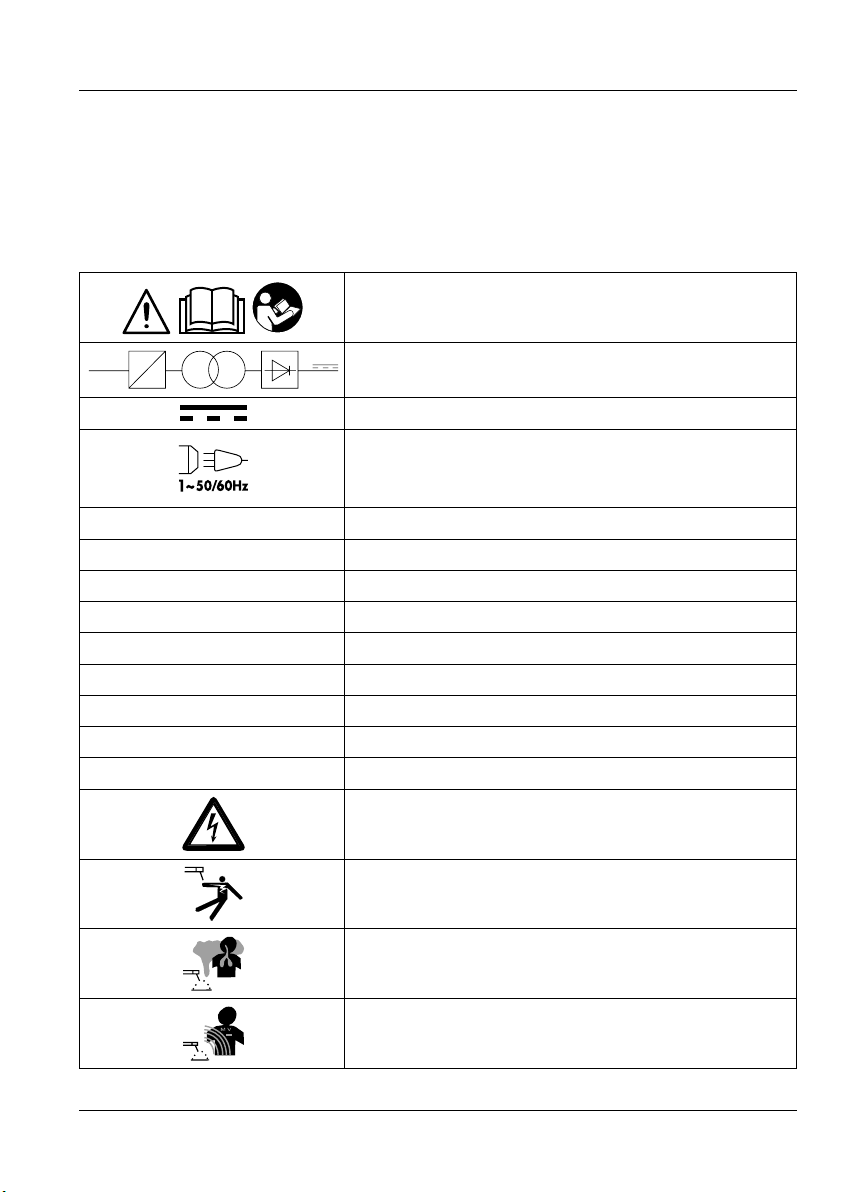

Explanation of Symbols

The use of symbols in this manual is intended to draw your attention to possible risks.

The safety symbols and the explanations that accompany them must be perfectly un-

derstood. The warnings in themselves do not remove the risks and cannot replace

correct actions for preventing accidents.

Caution - Read the operating instructions to

reduce the risk of injury

1~ f1

f2

Single-phase static frequency converter trans-

former rectifier

Direct current

Power input; phase number, as well as

Alternating current symbol and rated value of the

frequency

U0Rated idling voltage

U1Mains voltage

XDuty cycle

l2Cutting current

U2Operating voltage [V]

lmax Rated maximum mains current

le Effective value of the highest line current [A]

IP21S Protection type

HInsulation class

Caution! Risk of electric shock!

Electric shock from the welding electrode can be

fatal

Inhaling welding smoke can be hazardous to

your health.

Electromagnetic fields can interfere with the

functionality of pacemakers.

Explanation of symbols

Kapitelüberschrift

8

Welding sparks can cause an explosion or fire.

Arc rays can damage the eyes and injure the

skin.

Electromagnetic compatibility is not guaranteed

in residential areas. Therefore, the device can

only be used for occasional, smaller welding

work!

Do not use the device outdoors and never in

rain!

Cutting with the plasma cutter.

Suitable for welding with an increased electric

risk.

Connection – Ground terminal plug

Connection – plasma burner - Power plug

Connection – plasma burner

Work light

Overheat protection indicator lamp

12

1Warranty period

Warranty class

m Attention! In this operating manual, we have used this sign

to mark all sections that concern your safety.

Explanation of symbols

Kapitelüberschrift

9

Introduction

Congratulations on choosing to buy a FERREX®product.

All products brought to you by FERREX®are manufactured to the highest standards

of performance and safety, and as part of our philosophy of customer service and

satisfaction, are backed by our comprehensive 1 Year Warranty.

We hope you will enjoy using your purchase for many years to come.

Note:

According to the applicable product liability law the manufacturer of this device is

not liable for damages which arise on or in connection with this device in case of:

• improper handling,

• non-compliance with the instructions for use,

• repairs by third party, non-authorised skilled workers,

• installation and replacement of non-original spare parts,

• improper use.

Recommendations:

Read the entire text of the operating instructions prior to the assembly and operation

of the device.

These operating instructions are intended to make it easier for you to get familiar

with your device and utilise its intended possibilities of use.

The operating instructions contain important notes on how to work safely, properly

and economically with your machine and how to avoid dangers, save repair costs,

reduce downtime, and increase the reliability and working life of the machine.

In addition to the safety regulations contained herein, you must in any case comply

with the applicable regulations of your country with respect to the operation of the

machine.

Keep the operating instructions in a clear plastic folder to protect them from dirt and

humidity; store them near the machine. The instructions should be read and careful-

ly understood by each operator prior to using the machine. Only persons who have

been trained in the use of the machine and are aware of the related dangers and

risks should be allowed to use the machine. The local required minimum age must

be met.

In addition to the safety notes contained in these operating instructions and any

specific regulations in your country, the generally recognised technical rules for the

operation of identically constructed machines must be observed.

Introduction

Kapitelüberschrift

10

Layout

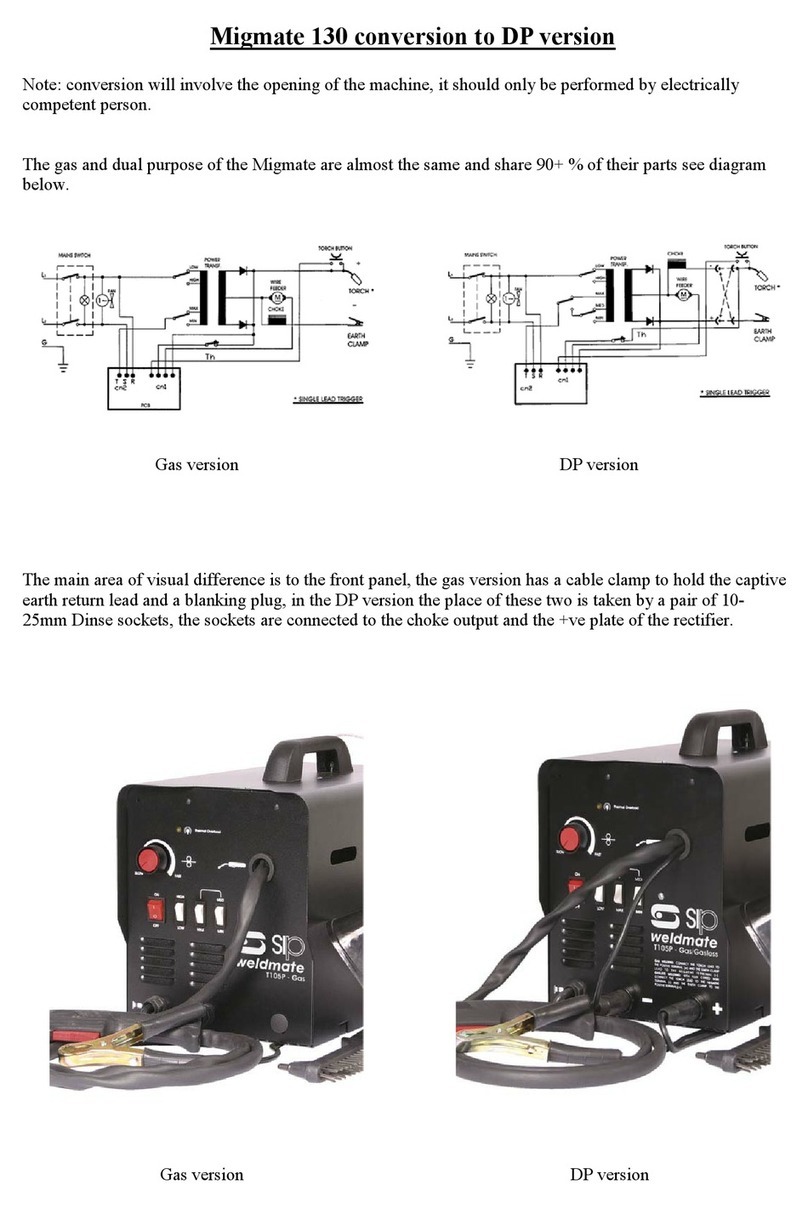

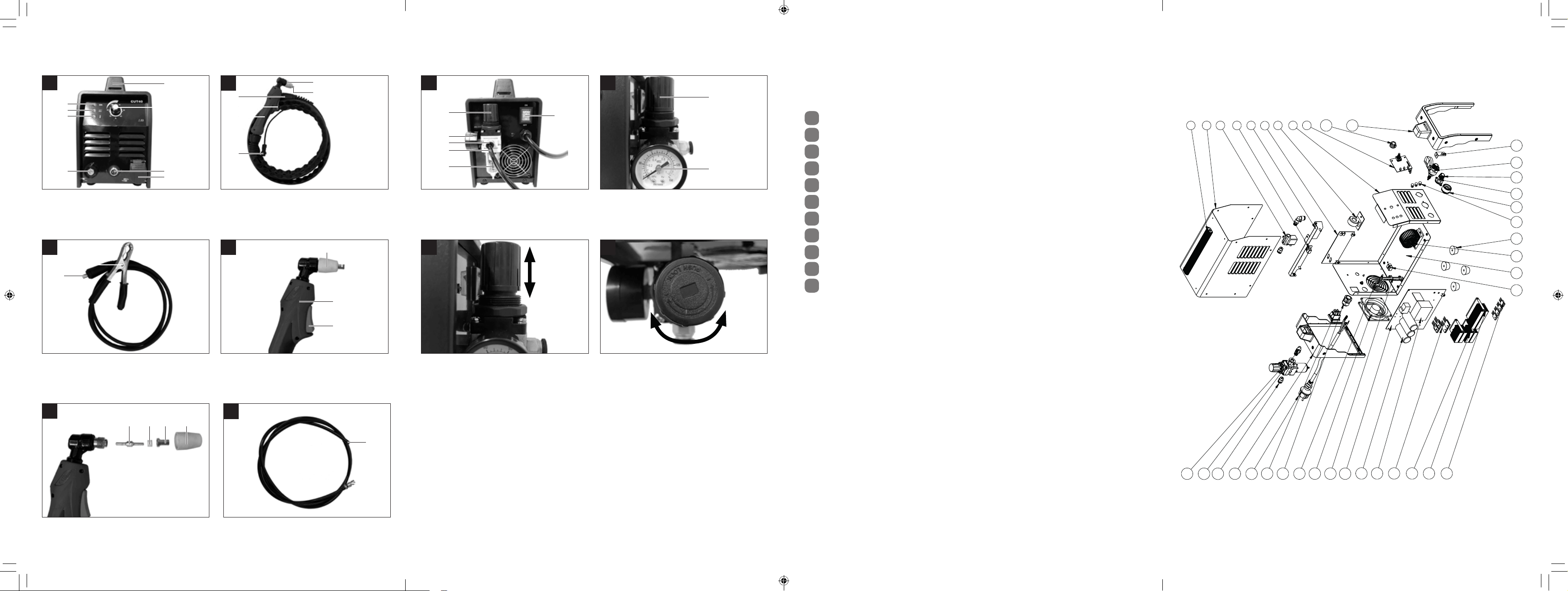

Layout (Fig. 1, 3, 4, 5, 7, 8, 9)

1. Handle

2. Plasma cutter

3. Mains plug

4. Plasma hose package

5. Ground terminal clamp

6. Mains indicator lamp

7. Work light

8. Overheat protection indicator lamp

9. Ground terminal connection socket

9a. Ground terminal plug

10. Plasma burner connection socket

10a. Plasma burner plug

11. Plasma burner power socket

11a. Plasma burner power plug

12. Current controller

13. Plasma burner

14. Plasma burner trigger

15. Ceramic cap

16. Nozzle

17. Diffuser

18. Electrode

19. Compressed air hose

19a. Compressed air connection

20. Quick connector compressed air hose

21. Rotary knob to regulate the pressure

22. Manometer

23. Condensation water tank

24. On/off switch

Kapitelüberschrift

11

Scope of delivery (Fig. 2)

Position Part Quantity

A Plasma cutter 1x

B Compressed air hose 1x

C Ground cable with terminal 1x

D Plasma hose package 1x

E Hose clamp 1x

F Nozzle 3x (1x pre-assembled)

G Electrodes 3x (1x pre-assembled)

H Operating instructions 1x

I Diffuser 2x

J Ceramic cap 2x

• Open the packaging and take out the equipment with care.

• Remove the packaging material.

• Check that all listed contents are present.

• Inspect the equipment and parts for any damage. Please contact the helpline if

anything is missing.

• If possible, keep the packaging until the end of the guarantee period.

• Read the operating instructions fully to familiarise yourself with the tool prior to

using it.

• Only use original accessories and spare parts. Spare parts are available by

contacting the helpline.

• Specify the part numbers when you contact the helpline.

m ATTENTION!

The device and packaging materials are not toys!

Children must not be allowed to play with plastic bags, film and small parts!

There is a risk of swallowing and suffocation!

Scope of delivery

Kapitelüberschrift

12

Intended use/Safety regulations

Intended use

The device is intended for compressed-air plasma cutting of all electrically conduc-

tive metals. Observing the safety instructions and assembly instructions and operat-

ing information in the instructions for use is also a component of the intended use.

This device is designed for domestic DIY use only and is not designed for commercial,

trade or industrial use

It is imperative to adhere to the applicable accident prevention regulations. The de-

vice must not be used:

• in insufficiently ventilated rooms,

• in moist or wet environments,

• in explosive environments,

• to defrost pipes,

• in close proximity to people with cardiac pacemakers and

• in close proximity to easily flammable materials.

Use the product only as described and only for the specific applications as stated.

Keep these instructions in a safe place. Ensure you hand over all documentation

when passing the product on to anyone else. Any use that differs to the intended use

as stated above is prohibited and potentially dangerous.

Damage or injury caused by misuse or disregarding the above warning is not cove-

red by the warranty or any liability on the part of the manufacturer. The device is not

intended for commercial use. Commercial use will void the guarantee.

Safety regulations

mWARNING! Please read through the operating instructions carefully

before use. Familiarise yourself with the device, its proper use and the

safety notes based on these operating instructions. These form part of

the product and must be available at all times.

mWARNING! RISK OF SERIOUS INJURY OR DEATH FOR INFANTS AND

CHILDREN! Never leave children unsupervised near packaging materi-

al. There is a risk of suffocation.

• This device may be used by children aged 16 years and older, and by

Kapitelüberschrift

13

persons with reduced physical, sensory or mental capacities, or a lack

of experience and knowledge, if they are supervised or have been in-

structed in how to use the device safely and understand the dangers

that may arise when using it. Do not allow children to play with the

device. Cleaning and day-today maintenance must not be performed

by children without supervision.

• Repairs or/and maintenance work must only be carried out by quali-

fied electricians.

• Only use the cutting cable provided in the scope of delivery.

• During operation, the device should not be positioned directly on the

wall, covered or jammed between other devices so that sufficient air

can be absorbed through the ventilation slats. Makes sure that the

device is correctly connected to the supply voltage. Avoid any form of

tensile stress of the power cable. Disconnect the plug from the socket

prior to setting up the device in another location.

• If the device is not in operation, always switch it off by pressing the

ON/OFF switch. Place the electrode holder on an insulated surface

and only remove it from the holder after allowing it to cool down for

15 minutes.

• Hot metal and sparks are blown off from the cutting arch. The flying

sparks, hot metal as well as hot objects and hot device equipment can

cause fires or burns. Check the working environment and make sure

the workplace is suitable prior to using the device.

• Remove all flammable material within 10 m of the plasma cutter. If this

is not possible, cover the objects meticulously using suitable covers.

• Do not make cuts in places where flying sparks could come into con-

tact with flammable material.

• Protect yourself and others from flying sparks and hot metal.

• Please be careful because sparks and hot materials can easily fall

through small gaps and openings while cutting and land on adjacent

areas.

• Please be aware that cutting on a ceiling, floor or a partition can cause

a fire on the opposite side that is not visible.

• Connect the power cable using the shortest route with a socket sit-

uated close to the workplace to prevent the power cable from being

spread across the whole room and located on a surface which could

cause an electric shock, sparks or fire outbreak.

Safety regulations

Kapitelüberschrift

14

Safety regulations

• Do not use the plasma cutter to defrost frozen tubes.

Risk of electric shock

mWARNING! Electric shock from the cutting electrode can be fatal.

• Do not use the plasma cutter when it is raining or snowing.

• Wear dry insulating gloves.

• Do not touch the electrodes with bare hands.

• Do not wear wet or damaged gloves.

• Protect yourself from electric shock with insulation against the work-

piece.

• Do not open the device housing.

• Additional protection against a shock from the mains power in the

event a fault can be provided by using a fault-circuit interrupter,

which is operated with a leakage current of no more than 30 mA and

covers all mains-powered devices in close proximity. The fault-circuit

interrupter must be suitable for all types of current.

• There must be means of rapid electrical isolation of the cutting pow-

er source or the cutting circuit (e.g. emergency stop device) which are

easily accessible.

Danger from smoke emission when plasma cutting:

• Inhalation of fumes which result from plasma cutting can endanger

health.

• Do not keep your head in the fumes.

• Use the device in open areas.

• Only use the device in well-ventilated spaces.

Danger from flying sparks when plasma cutting:

• Cutting sparks can cause an explosion or fire.

• Keep flammable substances away from the cutting location.

• Do not use the plasma cutter near flammable substances.

• Cutting sparks can cause fires.

• Keep a fire extinguisher close by and an observer should be present

to be able to use it immediately.

• Do not carry out plasma cutting on drums or any other closed con-

tainers. Danger from arc beams:

• Arc beams can damage your eyes and injure your skin.

Kapitelüberschrift

15

• Wear a hat and safety goggles.

• Wear hearing protection and high, closed shirt collars.

• Use a welding safety helmet and make sure that the filter setting is

correct.

• Wear complete body protection. Danger from electromagnetic fields:

• Cutting current generates electromagnetic fields.

• Do not use if you have a medical implant.

• Never wrap the cutting cable around your body.

• Guide cutting cables together. Welding shield-specific safety instruc-

tions

• With the help of a bright light source (e.g. lighter) examine the prop-

er functioning of the welding shield prior to starting with any cutting

work.

• Cut spatters can damage the protective screen. Immediately replace

damaged or scratched protective screens.

• Immediately replace damaged or highly contaminated or splattered

components.

• The device must only be operated by people over the age of 16.

• Please familiarise yourself with the cutting safety instructions. To that

end, you must also observe the safety instructions of your plasma

cutter.

• Always wear a welding helmet while welding and plasma cutting. If it

is not used, you could sustain severe lesions to the retina.

• Always wear protective clothing during welding and plasma cutting

operations.

• Never use the welding shield without the protective screen because

this could damage the optical unit. There is a risk of damage to the

eyes!

• Regularly replace the protective screen to ensure good visibility and

fatigue proof work.

Environment with increased electrical hazard

Environments with increased electrical hazard may be encountered, for

example:

• In workplaces where the space for movement is restricted, such that

the operator is working in a forced posture (e.g.: kneeling, sitting, ly-

ing) and is touching electrically conductive parts;

Safety regulations

Kapitelüberschrift

16

Safety regulations

• In workplaces which are restricted completely or in part in terms of

electrical conductivity and where there is a high risk through avoida-

ble or accidental touching by the operator;

• In wet, humid or hot workplaces where the air humidity or weld sig-

nificantly reduces the resistance of human skin and the insulating

properties or effect of protective equipment.

• Even a metal conductor or scaffolding can create an environment

with increased electrical hazard.

• When using plasma cutters under electrically dangerous conditions,

the output voltage of the plasma cutter must be greater than 48 volt

when idling (effective value).

• The plasma cutter may not be used in these cases due to the output

voltage.

Plasma cutting in tight spaces

• When welding and plasma cutting in tight spaces this may pose a haz-

ard through toxic gases (risk of suffocation). In tight spaces the device

may only be operated if there are trained individuals in the immedi-

ate vicinity who can intervene if necessary. In this case, before start-

ing to use the plasma cutter, an expert must carry out an assessment

in order to determine what steps are necessary, in order to guaran-

tee safety at work and which precautionary measures should be tak-

en during the actual cutting procedure.

Total of open circuit voltages

• When more than one plasma power source is operated at the same

time, their open circuit voltages may add up and lead to an increased

electrical hazard. The plasma power sources must be clearly marked

with their individual control units and connections, in order to be able

to identify which device belongs to which circuit.

Using shoulder straps

• The plasma cutter must not be used if the device is being carried e.g.

with a shoulder strap (not included).

This is intended to prevent:

• The risk of losing your balance if the lines or hoses which are connect-

ed are pulled.

Kapitelüberschrift

17

• The increased risk of an electric shock as the operator comes into con-

tact with the earth if he/she is using a Class I plasma cutter, the hous-

ing of which is earthed through its conductor.

Protective clothing

• At work, the operator must protect his/her whole body by using ap-

propriate clothing and face protection against radiations and burns.

The following steps must be observed:

• Wear protective clothing prior to cutting work.

• Wear gloves.

• Open windows to guarantee air supply.

• Wear protective goggles.

• Gauntlet gloves made of a suitable material (leather) must be worn

on both hands. They must be in perfect condition.

• A suitable apron must be worn to protect clothing from flying sparks

and burns. When specific work, e.g. overhead cutting, is required, a

protective suit must be worn and, if necessary, even head protection.

Protection against rays and burns

• Warn of the danger to the eyes by hanging up a sign saying “Caution!

Do not look into flames!”. The workplaces must be shielded so that the

persons in the vicinity are protected. Unauthorised persons must be

kept away from cutting work.

• The walls in the immediate vicinity of fixed workplaces should neither

be bright coloured or shiny. Windows up to head height must be pro-

tected to prevent rays being transmitted or reflecting through them,

e.g. by using suitable paint.

EMC Device Classification

• According to standard IEC 60974-10, it has to do with a plasma cut-

ter with class A electromagnetic compatibility. Thus, it meets the ap-

propriate requirements in the industrial and residential area. In res-

idential areas, it can be connected to the public low-voltage supply

network. Even if the plasma cutter complies with the emission level

as per the standard, the plasma cutter can still result in electromag-

netic disturbances in sensitive systems and devices. The operator is

responsible for malfunctions that occur through the arc while plasma

Safety regulations

Kapitelüberschrift

18

Safety regulations

cutting and must take suitable protective measures. In doing so, the

operator must consider the following:

• Power cables, control, signal and telecommunication lines

• Computer and other microprocessor controlled devices.

• Television, radio and other playback devices

• Electronic and electrical safety equipment

• Persons with cardiac pacemakers or hearing aids

• Measurement and calibration devices

• Noise immunity of other devices in the vicinity

• The time of day at which the cutting work is performed.

The following is recommended to reduce possible interference ra-

diation:

• The plasma cutter must be regularly maintained and kept in a good

condition

• Cutting cables should be completely unwound and installed parallel

on the floor, if possible

• Devices and systems at risk of interference radiation must be re-

moved from the cutting area if possible, or shielded.

General plasma explanations

• Plasma cutters are operated by pushing pressurised gas, e.g. air,

through a small pipe. In the centre of the pipe, there is a negative-

ly charged electrode that is directly above the nozzle. The vortex ring

causes the plasma to rotate quickly. If you supply the negative elec-

trode with current and make the tip of the nozzle touch the metal, this

connection creates a closed, electrical circuit.

A powerful spark occurs between the electrode and the metal. While

the gas flows into the pipe, the spark heats up the gas until it has

reached the plasma condition. This reaction causes a current from

the controlled plasma with a temperature of 17.000 ºC or more that

moves at speed of 6.096 m/sec and the metal transforms into steam

and molten discharge. The plasma itself conducts electrical current.

The working circuit that allows the arc to occur remains as long as cur-

rent is supplied to the electrode and the plasma remains in contact

with the metal to be processed. The cutting nozzle has a range of fur-

ther channels. These channels generate a constant flow of protective

Kapitelüberschrift

19

gas around the cutting area. The pressure of the gas flow controls the

radius of the plasma jet.

Please note!

This machine is only designed to use compressed air as “gas”.

Installation environment

Make sure that working area is sufficiently ventilated. If the device is

used without sufficient cooling, the power-on time reduces and it can

result in overheating. Additional protection can be required for this

purpose:

• The device must be free-standing with a distance of at least 0.5 m all

around.

• Ventilation slots must not be blocked or covered.

• The device must not be used a storage place and tools or other items

must not be placed on the device. It must be operated in a dry and

well ventilated working environment.

Remaining hazards

The machine has been built using modern technology in accordance

with recognized safety rules. Some remaining hazards, however, may

still exist.

• Injury through electric current if incorrect electric connection leads

are used.

• Even when all safety measures are taken, some remaining hazards

which are not yet evident may still be present.

• Remaining hazards can be minimized by following the safety instruc-

tions as well as the instructions in the chapter Authorized use and in

the entire operating manual.

• Health hazard due to electrical power, with the use of improper elec-

trical connection cables.

• Release the handle button and switch off the machine prior to any op-

erations.

• Avoid accidental starts of the machine: Do not press the start button

while inserting the plug into the socket.

• Use the tools recommended in this manual to obtain the best results

from your machine.

Safety regulations

Kapitelüberschrift

20

Safety regulations/Attachment/Before starting the equipment

• Always keep hands away from the work area when the machine is

running.

• Eye injuries due to glare,

• Touching hot parts of the device or workpiece (burn injury),

• In case of improper protection risk of accident and fire through sparks

and slag particles,

• Harmful emissions from smoke and gases if there is a lack of air or if

closed rooms are insufficiently extracted.

Warning! This electric tool generates an electromagnetic field during

operation. This field can impair active or passive medical implants un-

der certain conditions. In order to prevent the risk of serious or dead-

ly injuries, we recommend that persons with medical implants consult

with their physician and the manufacturer of the medical implant prior

to operating the electric tool.

Attachment / Before starting the equipment

Connecting the cutting torch

• Insert the plasma burner plug (10a) into the plasma burner connection socket (10)

and tighten the union nut hand-tight (see Fig. 1,3 + 4).

• Insert the plasma burner power plug (11a) into the plasma burner power socket (11)

and tighten the union nut hand-tight (see Fig. 1,3 + 4).

Connecting the ground cable

• Connect the ground terminal plug (9a) with the ground terminal connection socket

(9). Make sure that the connecting shaft is first connected and then turned. The

connecting shaft must face upwards when plugging in the ground terminal plug

(9a). After plugging in, the connecting shaft must be rotated in a clockwise direc-

tion until it reaches the stop, in order to lock it in place (see Fig. 1,3 + 5). This does

not require force!

Connect the compressed air hose

• Connect the compressed air hose (19) on the back of the plasma cutter to the com-

pressed air connection (19a). To do so, insert the side of the compressed air hose

into the compressed air connection (19a) of the plasma cutter without a quick con-

nector (see Fig. 9).

Kapitelüberschrift

21

• The pressure can be set via the rotary knob to regulate the pressure (21) on the

condensate separator (see Fig. 9 - 12). Select a pressure of 4–4.5 bar.

• In order to release the compressed air hose (19), you must press the locking mech-

anism of the compressed air connection (19a) and pull out the compressed air hose

(19) at the same time.

The compressed air source (not included) must have a filter and regulator.

mIMPORTANT!

You must fully assemble the appliance before using it for the first time!

mATTENTION!

The ceramic cap (15) must only be screwed on to the plasma burner (13) once it

has been equipped with the electrode (18), the diffuser (17) and the nozzle (16).

If these parts are missing, the device may malfunction and it may create a haz-

ard for the operating personnel.

Operation

1. Set the plasma cutter up in a dry and well ventilated area in the vicinity of the

workpiece.

2. Clamp the ground terminal clamp (5) to the workpiece to be cut and make sure

that there is a good electrical contact.

3. Turn the compressed air supply on.

4. Press the On/off switch (24) to position I.

5. Set the cutting current on the current controller (12). If the arc beam is interrupt-

ed, the cutting current must be set higher if necessary. If the electrode burns

through frequently, then the cutting current must be set lower.

6. To cut in the manual cutting mode, pull the plasma burner (13) across the work-

piece while maintaining a constant speed.

7. To achieve the perfect cut, it is important for the material thickness to comply

with the correct cutting speed. If the cutting speed is too low, the cutting edge

will be blunt due to the severe heat input. The optimal cutting speed is achieved

once the cutting jet is slightly inclined towards the rear while cutting.

8. If the plasma burner trigger(14) is released, the plasma jet goes out and the pow-

er source switches off. The gas continues to flow for approx. 5 seconds in order

to cool the burner. The same process is followed when the workpiece is pulled

out with a pressed plasma burner trigger (14). During the gas post-flow time, the

Attachment/Before starting the equipment/Operation

Kapitelüberschrift

22

Operation

plasma cutter must not be switched off to avoid damaging the plasma burner (13)

as a result of overheating.

Electrical connection

The electrical motor installed is connected and ready for operation. The connection

complies with the applicable VDE and DIN provisions.

The customer‘s mains connection as well as the extension cable used must also com-

ply with these regulations.

Damaged electrical connection cable

The insulation on electrical connection cables is often damaged.

This may have the following causes:

• Passage points, where connection cables are passed through windows or doors.

• Kinks where the connection cable has been improperly fastened or routed.

• Places where the connection cables have been cut due to being driven over.

• Insulation damage due to being ripped out of the wall outlet.

• Cracks due to the insulation ageing.

Such damaged electrical connection cables must not be used and are life-threaten-

ing due to the insulation damage.

Check the electrical connection cables for damage regularly. Make sure that the con-

nection cable does not hang on the power network during the inspection.

Electrical connection cables must comply with the applicable VDE and DIN provisions.

Only use connection cables with the marking „H07RN“.

The printing of the type designation on the connection cable is mandatory.

For single-phase AC motors, we recommend a fuse rating of 16A (C) or 16A (K) for ma-

chines with a high starting current (starting from 3000 watts)!

Kapitelüberschrift

23

Cleaning and maintenance

Cleaning:

• Switch off the main power supply and the main switch of the device prior to carry-

ing out maintenance or repair work on the plasma cutter.

• Regularly clean the outside of the plasma cutter and its accessories. Use com-

pressed air, cotton waste or a brush to remove dirt and dust.

• In case of a defect or a necessary replacement of equipment parts, please contact

the appropriate qualified personnel.

Maintenance:

mATTENTION!

Pull out the power plug before carrying out any maintenance work on the equip-

ment.

Let hot parts cool down before touching.

• The parts displayed in Figure 7 are the electrode (18), the diffuser (17) and the noz-

zle (16). They can be replaced once the ceramic cap (15) has been unscrewed.

• The electrode (18) must be replaced if there is a crater of approximately 1.5 mm

depth in the centre.

• The nozzle (16) must be placed if the central bore is damaged or if it has expanded

in comparison to a drilling of a new nozzle. If the electrode (18) or the nozzle (16) are

replaced too late, this can result in an overheating of the parts. This can reduce the

lift cycle of the diffuser (17).

mATTENTION!

• The ceramic cap (15) must only be screwed on to the plasma burner (13) once it has

been equipped with the electrode (18), the diffuser (17) and the nozzle (16).

If these parts are missing, the device may malfunction and it may create a haz-

ard for the operating personnel.

The plasma cutter must be regularly maintained for perfect function and to comply

with the safety requirements. Improper and wrong operation may cause failures and

damage to the device. Have repairs only conducted by qualified specialists.

Connections and repairs

Connections and repairs of electrical equipment may only be carried out by an elec-

trician.

Cleaning and maintenance

Kapitelüberschrift

24

Cleaning and maintenance/Technical data

Please provide the following information in the event of any enquiries:

• Machine data - type plate

Service information

Please note that the following parts of this product are subject to normal or natural

wear and that the following parts are therefore also required for use as consuma-

bles.

Wear parts*: electrode, diffuser, nozzle

* Not necessarily included in the scope of delivery!

Technical data

Mains connection 230 V~ / 50/60 Hz

Output 15 - 40 A

On-load factor*35% at 40A (25°C)

20% at 40A (40°C)

Working pressure 4 - 4.5 bar / 58 - 65 PSI

Insulation class H

Cutting capacity 0.1 mm - 12 mm

( depending on the material)

Material

Copper: 1 - 4 mm

Stainless steel: 1 - 8 mm

Aluminium: 1 - 8 mm

Iron: 1 - 10 mm

Steel: 1 - 12 mm

Dimensions L x W x H 375 x 169 x 250 mm

Weight 6 kg

Subject to technical changes!

On-load factor*= is the percentage of the operating time, in which the machine can

be used continuously under normal temperature conditions. In relation to a 10-min-

ute time period this means, for example, that with a duty cycle of 20%, that it can be

used for 2 minutes and then there should be a break of 8 minutes. If you exceed the

duty cycle values then this will trigger the overheating protection which will bring

the device to a stop until it has cooled down to the normal working temperature. Ex-

ceeding the duty cycle values continuously can damage the device.

Table of contents

Popular Welding System manuals by other brands

Hwayuan Electric

Hwayuan Electric ZDE7-1200HD Manual instruction

Ter Welding

Ter Welding Multi 250 instruction manual

Thermal Arc

Thermal Arc Raider 10 owner's manual

Lincoln Electric

Lincoln Electric RANGER IM834-B Operator's manual

Chicago Electric

Chicago Electric 98870 Set up and operating instructions

Buffalo

Buffalo MMIG125 Assembly & operating instructions

Top Gun

Top Gun SYN 2500 PULSE user manual

Lincoln Electric

Lincoln Electric POWER FEED IM916 Operator's manual

Hypertherm

Hypertherm HT4100 instruction manual

Thermal Dynamics

Thermal Dynamics 35C DRAG-GUN PLUS operating manual

Amada

Amada Thin-Line TL-080B Series Operation manual

Lincoln Electric

Lincoln Electric SPEEDTEC 215C AUS Operator's manual