Festool CLEANTEX CT 26 E User manual

Other Festool Vacuum Cleaner manuals

Festool

Festool CT 22 E User manual

Festool

Festool CTM 26 E User manual

Festool

Festool CTL 26 E Installation instructions

Festool

Festool CT 33 E User manual

Festool

Festool CTM 22 E SG User manual

Festool

Festool CT 15 E User manual

Festool

Festool CTL 48 E LE EC/B22 Installation instructions

Festool

Festool CTL SYS Installation instructions

Festool

Festool CT 22 E User manual

Festool

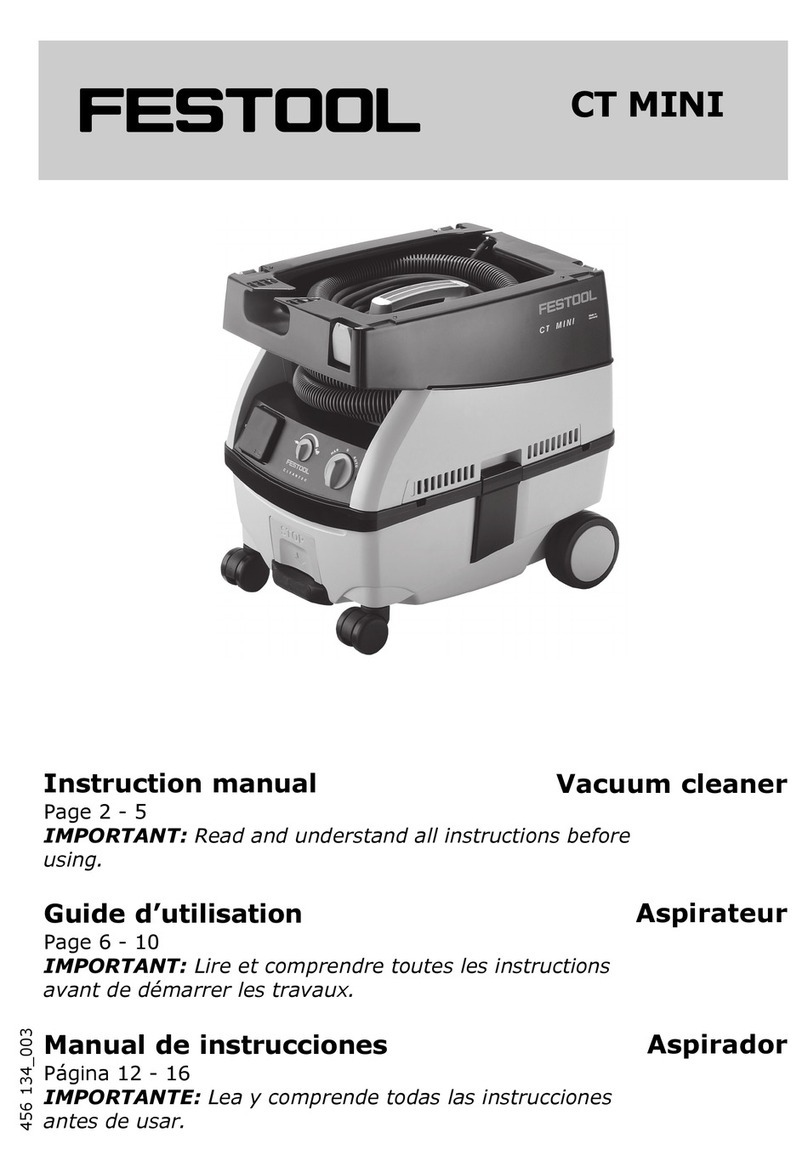

Festool CT MINI User manual

Festool

Festool cleantex ct 17 e User manual

Festool

Festool CTL 26 E User manual

Festool

Festool CLEANTEX CTL Series User manual

Festool

Festool CLEANTEX CT 26 E User manual

Festool

Festool CLEANTEX CT 26 E User manual

Festool

Festool CTM 22 E SG User manual

Festool

Festool CT MINI User manual

Festool

Festool CLEANTEC CT SYS HEPA User manual

Festool

Festool CT 11 E User manual

Festool

Festool CT MINI I HEPA User manual