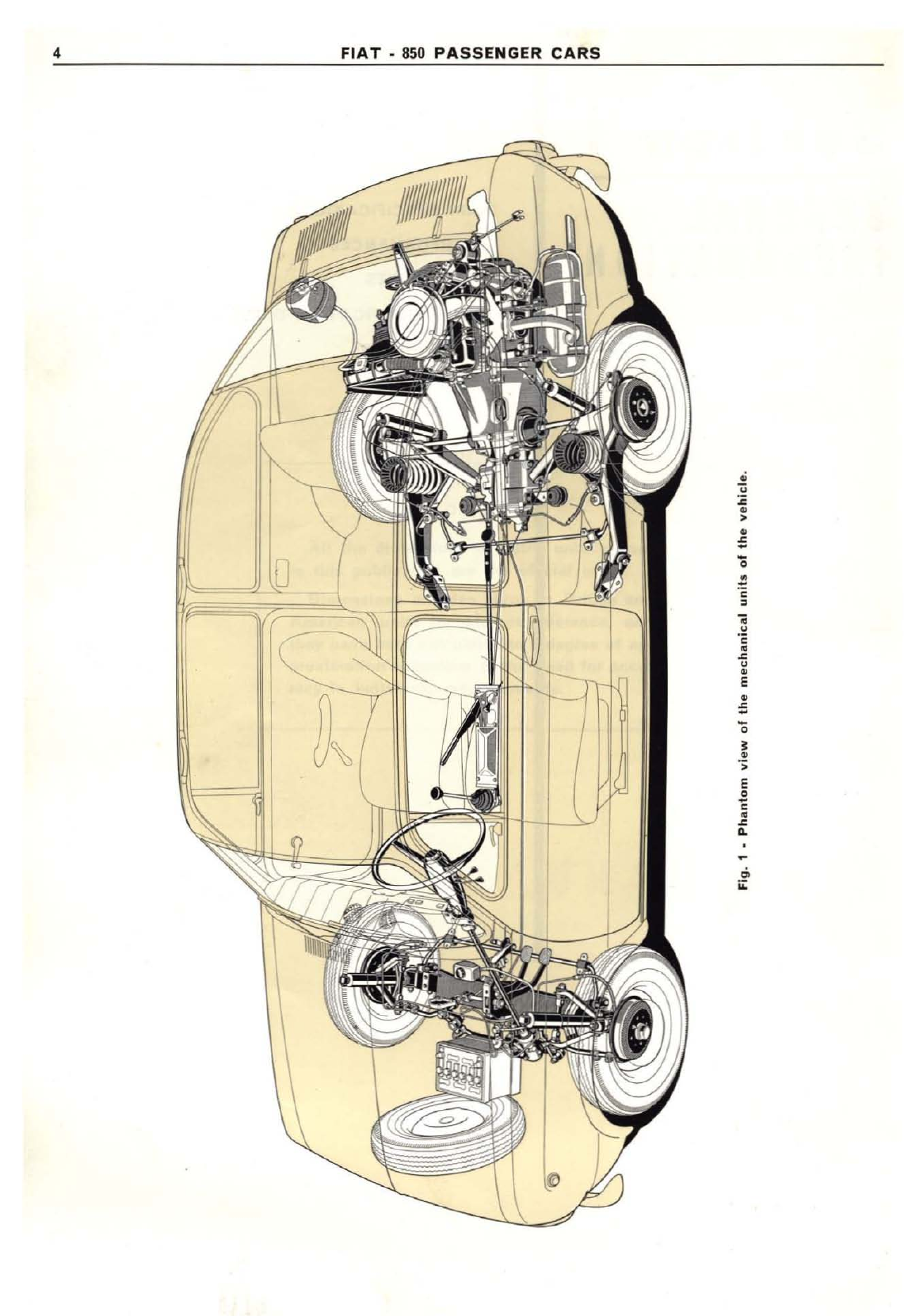

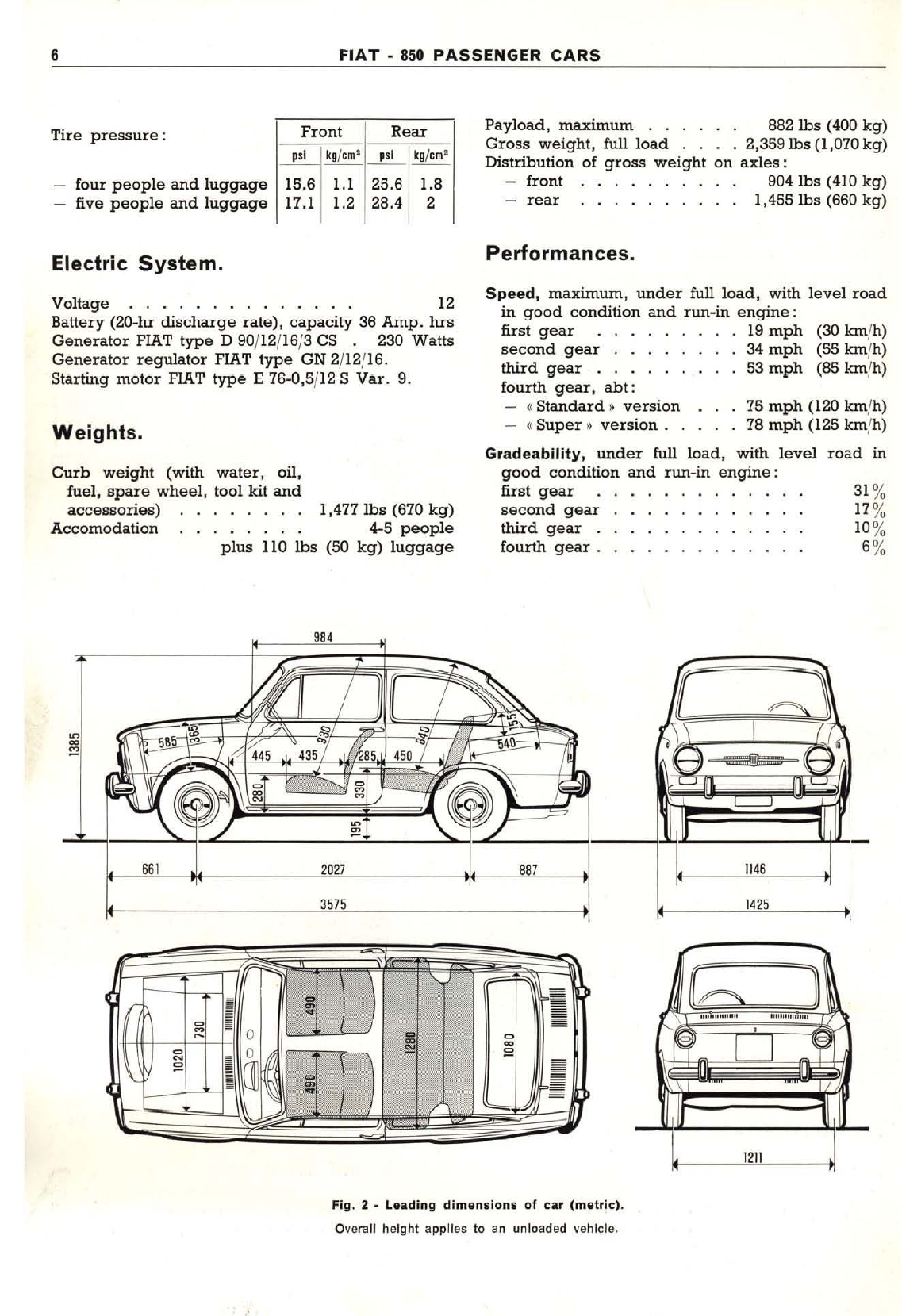

Fiat 850 Sedan 1968 Install guide

Other Fiat Automobile manuals

Fiat

Fiat 124 Spider 2019 User manual

Fiat

Fiat 500L User manual

Fiat

Fiat PANDA User guide

Fiat

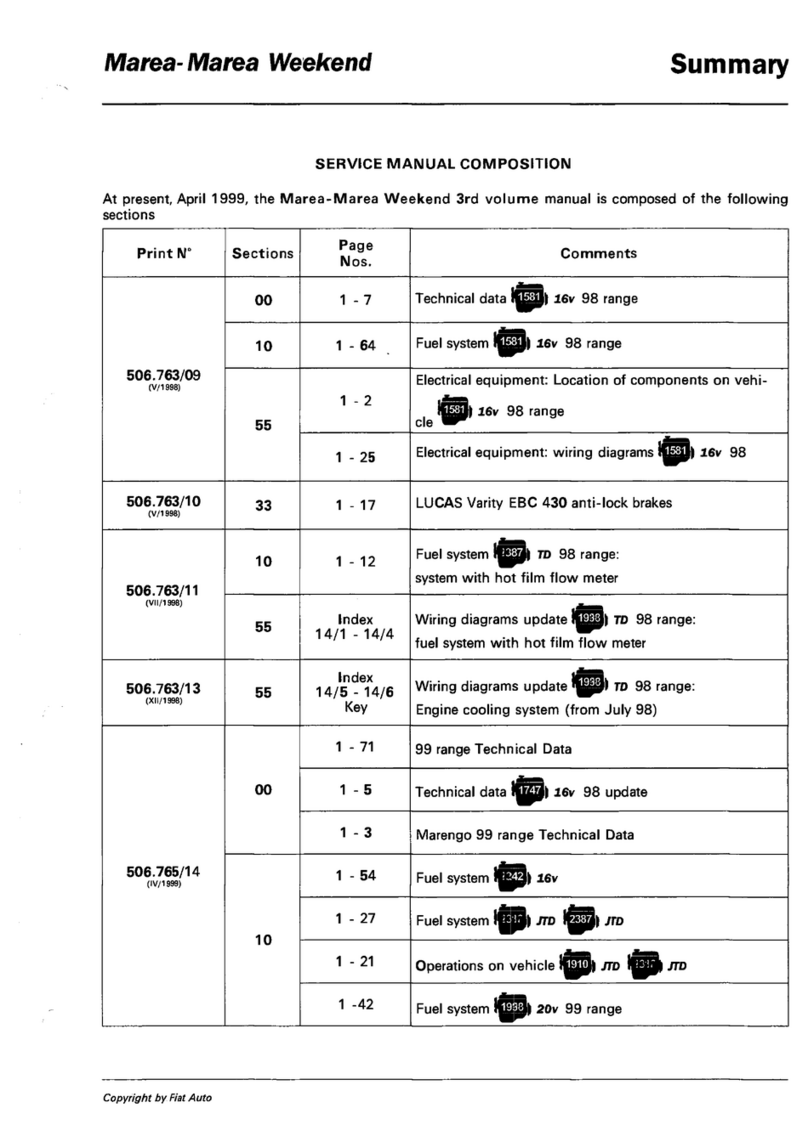

Fiat 1998 Marea Weekend User manual

Fiat

Fiat 500e User manual

Fiat

Fiat 1986 Panda Van User manual

Fiat

Fiat 1995 Bravo User manual

Fiat

Fiat 500 ABARTH 2017 User manual

Fiat

Fiat Marea Weekend Instruction manual

Fiat

Fiat 124 SPIDER 2020 User manual

Fiat

Fiat 500 Abarth User guide

Fiat

Fiat 1995 Bravo User guide

Fiat

Fiat 500L 2018 User manual

Fiat

Fiat 2015 500e User manual

Fiat

Fiat Spider 124 1975 User manual

Fiat

Fiat 479 cc Instruction manual

Fiat

Fiat 1986 Panda Van Product guide

Fiat

Fiat Barchetta 2000 User manual

Fiat

Fiat Spider-2000 User manual

Fiat

Fiat PUNTO User guide