FiberLabs EDFA-1550 Series Installation and maintenance instructions

Technical passport / EDFA-1550

12-2016-v4

1550nm Optical Amplifier

EDFA-1550/24 (4×17)

Technical passport / EDFA-1550

12-2016-v4

2

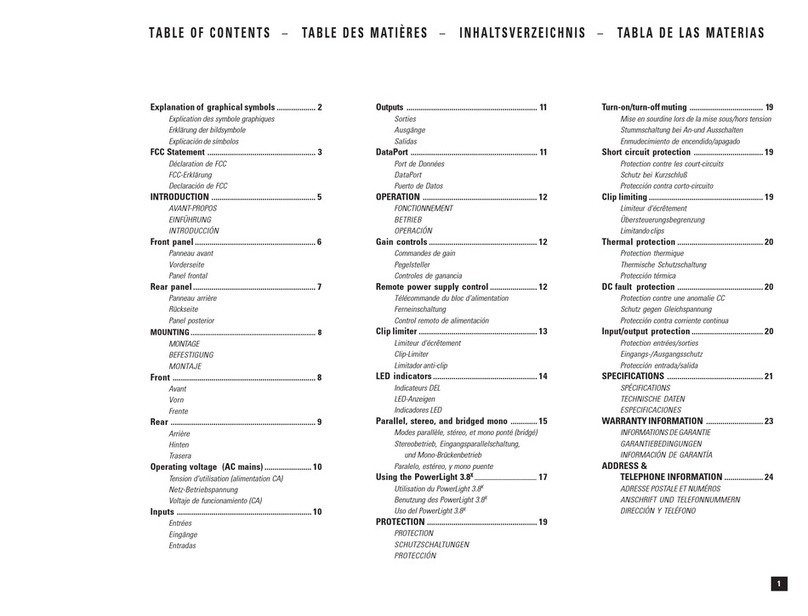

Table of contents

TABLE OF CONTENTS.............................................................................................2

FOREWORD................................................................................................................3

1. PRODUCT SUMMARY..........................................................................................3

2. PERFORMANCE CHARACTERISTICS ............................................................4

3. BLOCK DIAGRAM ................................................................................................4

4. TECHNIQUE PARAMETER.................................................................................4

4.1 Link test conditions ..............................................................................................4

4.2 Technique Parameters .......................................................................................... 5

5. EXTERNAL FUNCTION DESCRIPTION...........................................................6

5.1 Front Panel Description........................................................................................ 6

5.2 Rear Panel Description .........................................................................................7

5.3 Displayed Parameter description..........................................................................8

6. NETWORK MANAGEMENT DESCRIPTION.................................................11

6.1 Interface description ...........................................................................................12

6.2 Set up the super terminal ....................................................................................13

6.3 Operating Parameter Configuration ................................................................... 14

6.4 WEB Network Management ..............................................................................16

7. INSTALLATION DEBUGGING .........................................................................18

7.1 Unpack and Check.............................................................................................. 18

7.2 Instruments and Tools ........................................................................................ 19

7.3 Installation Steps ................................................................................................19

8. CLEAN AND MAINTENANCE METHOD OF THE OPTICAL FIBER ACTIVE

CONNECTOR............................................................................................................19

Technical passport / EDFA-1550

12-2016-v4

3

Foreword

This manual applies to EDFA-1550 series Fiber Amplifiers. It mainly describes the performance

characteristics, technical parameters, installation and debugging, common troubleshooting, and other

related content of the product. In order to ensure that the equipment can be successfully installed and

safely operated, please read this manual carefully before installing and debugging the equipment. And the

installation and debugging should be strictly according to the specified steps on the manual to avoid

unnecessary damage to equipment or accident harm to the operator. Any questions, please contact with us

in time.

Special Tips:

1)Er-doped Fiber Amplifier is high end professional equipment, and its installation and debugging must

be operated by special technician. Read this manual carefully before operating to avoid damage to

equipment caused by fault operation or accident harm to the operator.

2)While the fiber amplifier is working, there is an invisible laser beam from the optical output adapter

on the front panel. Avoiding permanent harm to the body and eye, the optical output should not aim at

the human body and human should not look directly at the optical output with the naked eye!

3)Please make sure that the ground terminal of the case and power outlet has been reliably grounding

before turning on the power (Grounding resistance should be < 4Ω) to prevent the static damage the

pump laser device and harm to human because of case charged.

4)To ensure the equipment can work stable over a long time in voltage unsteady or poor voltage wave

region, it´s recommend to the customer that he equips special AC regulated power supply, or even AC

uninterrupted power supply (UPS) system for conditional regions. In the region with large

temperature variation environment (The equipment's ideal work environment temperature is 25°C) or

bad room environment it´s recommend to the customer that he equips special air-condition system to

improve the work environment.

1. Product Summary

EDFA-1550 series 1550nm optical fiber amplifier is the important optical relay transmission equipment in

1550nm optical fiber communication system. It mainly used for the long distance optical fiber

transmission of TV image signal, digital television signal, telephone voice signal and data (or compressed

data) signal. This product uses the high-performance erbium doped fiber and low noise pump laser, and

built-in perfect embedded automatic monitoring system, to ensure the excellent performance indicators.

Technical passport / EDFA-1550

12-2016-v4

2. Performance Characteristics

Automatic control the output optical power.

The output optical power is adjustable, attenuation range is 0-3dB.

Adopt high-performance erbium doped fiber, high efficiency energy conversion.

Adopt advanced 32 bit processor, coordinate with perfect automatic monitoring systemic circuit. It

can timely and accurately monitor optical output power and various work status of the pump laser,

ensures the stable optical output power and can effectively extend the working life of the pump laser.

Built-in blue screen 160×32 dot matrix LCD monitor on the front panel, accurately showing all

working status parameters.

19″1U height standard rack mount, equipped standard IEEE802.3 10Base-T Ethernet interface and

RS232 interface, can expediently realizes network management monitoring.

3. Block diagram

4. Technique Parameter

4.1 Link test conditions

Special instructions: The performance parameters of this manual according to the measuring method of

GY/T 184-2002 < CATV system analog optical fiber amplifier technical requirements and measuring

method>, and tested in the following conditions.

Test condition: With standard optical fiber and standard optical receiver composed the test link. Set 59

PAL-D analog TV channel signal at 550MHz frequency range under the specified link loss. Transmit

digital modulation signal at range of 550 MHz ~ 862MHz, the digital modulation signal level (in 8 MHz

bandwidth) is 10dB lower than analog signal carrier level. When the input optical power of optical

receiver is -1dBm, measure the C/CTB, C/CSO and C/N.

4

Technical passport / EDFA-1550

12-2016-v4

5

4.2 Technique Parameters

Item Unit Technique parameter Remark

Operating bandwidth nm 1535 - 1565

Input optical power

range dBm -3 - +10

Total optical output

power dBm 24 Optional

One way optical output

power dBm 17

Output power stability dBm ±0.5

Noise figure dB ≤5.0 Input optical

power 0dBm

Input dB ≥45

Return loss Output dB ≥45

Input dBm ≤-30Pump leakage

power Output dBm ≤-30

Optical connector type SC/APC

Power supply voltage V AC160V - 250V(50 Hz)

Consumption W < 30

Operating Temperature

Range °C -5 - +55

Maximum operating

relative humidity % Max 95% No Condensation

Storage Temperature

Range °C -30 - +70

Maximum storage

relative humidity % Max 95% No Condensation

Dimension mm 483(W)×340(D)× 44(H)

Technical passport / EDFA-1550

12-2016-v4

5. External Function Description

5.1 Front Panel Description

Schematic diagram of the front panel

1) Power indicator: Switching power supply one power working – yellow; dual powers working –

green.

2) Input optical power indicator:The input optical power is lower than the given threshold – red;

normal – green.

3) Pump working status indicator: Red light means the pump is not working, but the machine

parameters are normal; flashing red light means the machine has broken down, related fault reason

see the alarm menu of the display menu; Green light means the pump is working normal.

4) Output optical power indicator: This light turns on when the output optical power is large than

+10dBm.

5) 160×32 Dot-matrix LCD screen: used to display all the parameters of the machine.

6) Display the exit or cancel key of the setup menu.

7) Display the up or increase key of the setup menu.

8) Display the down or decrease key of the setup menu.

9) Display the enter key of the setup menu.

10) Pump laser switching key: used to control the working status of pump laser. “ON” means the pump

laser is open and “OFF” means the pump laser is closed. Ensure the key is on “OFF” position before

power on. After passing self-test, rotate the key to “ON” position according to the displayed message.

11-14)Optical signal output: This interface is the optical signal output port of the device. The default

connector type is SC/APC. There is invisible laser beam from this port after normal operating. So

the port should not be aligned to the human body or the naked eyes to avoid accidental injury.

15)Optical signal input: The connector type is SC/APC.

6

Technical passport / EDFA-1550

12-2016-v4

5.2 Rear Panel Description

Schematic diagram of the rear panel

1) Ground stud of the chassis: used for the connection of the device and ground wire.

2) Fan outlet

3) RS232 interface: Used for configuring the network management parameters.

4) LAN interface: correspond to IEEE802.3 10Base-T interface, used for network management.

5) AC power input of power supply 1.

6) The fuse of power supply 1.

7) The switch of power supply 1.

8) AC power input of power supply 2.

9) The fuse of power supply 2.

10) The switch of power supply 2.

7

Technical passport / EDFA-1550

12-2016-v4

8

5.3 Displayed Parameter description

Name display discription

xxxxxxx Display vendor logo.

xxxxxxx Display model number.

System Starting xxxxxxx Start countdown / lock status.

Suspend Page In: xx.x out: xx.x

Unit: dBm Display the input / output optical power

1.Disp Parameters Entry of parameter display menu

2.Set Parameters Entry of parameter setting menu

Main Page

3.Alarm Status Entry of alarm information menu

Input Power: xx.x dBm Input power, accurate to 0.1 dBm

Output Power: xx.x dBm Output power, accurate to 0.1 dBm

Output ATT: x.x dBm Output power ATT, accurate to 0.1 dBm

Pump1 Bias: x mA Bias current of pump1, accurate to 1mA

Pump1 Temper: xx.x°C Temperature of pump1, accurate to 0.1°C

Pump1 Tec: x.xx A Cooling current of pump1, accurate to 0.01 A

Pump2 Bias: x mA Bias current of pump2, accurate to 1m A

Pump2 Temper: xx.x °C Temperature of pump2, accurate to 0.1 °C

Pump2 Tec: x.xx A Cooling current of pump2, accurate to 0.01 A

+5V Read: x.x V +5V power supply voltage , accurate to 0.1 V

-5V Read: -x.x V -5V power supply voltage , accurate to 0.1 V

System Temper: xx.x °C Chassis temperature, accurate to 0.1 °C

Serial NO.: xxxxxxxx Device serial number

IP Addr: xxx.xxx.xxx.xxx IP address

Mask: xxx.xxx.xxx.xxx Subnet mask

Gateway: xxx.xxx.xxx.xxx Gateway

Mac: xxxxxxxxxxxx Physical address

Trap Addr1:

xxx.xxx.xxx.xxx trap1 address

Trap Addr2:

xxx.xxx.xxx.xxx trap2 address

1.Disp

Parameters

Firmware Ver: Vx.xx Firmware Version number

Technical passport / EDFA-1550

12-2016-v4

9

Set Low Input Threshold Set the input optical power low alarm

threshold, range -10.0~9.9dBm

Set High Input Threshold Set the input optical power high alarm

threshold , range -10.0~10.0dBm

Set APC MODE Set the constant optical power output

function, on or off

Set Output ATT Set the output optical power attenuation,range

-4.0~0.5dBm

IP Addr Set IP address

Mask Set subnet mask

Gateway Set gateway

Trap Addr1 Set trap1

Trap Addr2 Set trap2

Buzzer Switch Set the switch of beeper

2.Set

Parameters

Restore Factory config Restore the factory configuration,set

content as shown above

xxx= LOLOW:

Very low input optical power alarm

xxx= LOW:

Low input optical power alarm

xxx= HIGH:

High input optical power alarm

Input Status: xxx

Xxx= HIHIGH:

Very high input optical power alarm

xxx= LOLOW:

Very low output optical power alarm

xxx= LOW:

Low output optical power alarm

xxx= HIGH:

High output optical power alarm

Output Status: xxx

Xxx= HIHIGH:

Very High output optical power alarm

xxx= LOLOW:

Very low bias current of pump1 alarm

xxx= LOW:

Low bias current of pump1 alarm

xxx= HIGH:

High bias current of pump1 alarm

3.Alarm Status

Pump1 Bias: xxx

Xxx= HIHIGH:

Very high bias current of pump1 alarm

Technical passport / EDFA-1550

12-2016-v4

10

xxx= LOLOW:

Very low temperature of pump1 alarm

xxx= LOW:

Low temperature of pump1 alarm

xxx= HIGH:

High temperature of pump1 alarm

Pump1 Temper: xxx

Xxx= HIHIGH:

Very high temperature of pump1 alarm

xxx= LOLOW:

Very low cooling current of pump1 alarm

xxx= LOW:

Low cooling current of pump1 alarm

xxx= HIGH:

High cooling current of pump1 alarm

Pump1 Tec: xxx

Xxx= HIHIGH:

Very high cooling current of pump1 alarm

xxx= LOLOW:

Very low bias current of pump2 alarm

xxx= LOW:

Low bias current of pump2 alarm

xxx= HIGH:

High bias current of pump2 alarm

Pump2 Bias: xxx

Xxx= HIHIGH:

Very high bias current of pump2 alarm

xxx= LOLOW:

Very low temperature of pump2 alarm

xxx= LOW:

Low temperature of pump2 alarm

xxx= HIGH:

High temperature of pump2 alarm

Pump2 Temper: xxx

Xxx= HIHIGH:

Very high temperature of pump2 alarm

xxx= LOLOW:

Very low cooling current of pump2 alarm

xxx= LOW:

Low cooling current of pump2 alarm

xxx= HIGH:

High cooling current of pump2 alarm

Pump2 Tec: xxx

Xxx= HIHIGH:

Very high cooling current of pump2 alarm

xxx= LOLOW:

Very low +5V DC power supply alarm

xxx= LOW:

Low +5V DC power supply alarm

3.Alarm Status

+5V Status: xxx

xxx= HIGH:

High +5V DC power supply alarm

Technical passport / EDFA-1550

12-2016-v4

11

Xxx= HIHIGH:

Very high +5V DC power supply alarm

xxx= LOLOW:

Very low -5V DC power supply alarm

xxx= LOW:

Low -5V DC power supply alarm

xxx= HIGH:

High -5V DC power supply alarm

-5V Status: xxx

Xxx= HIHIGH:

Very high -5V DC power supply alarm

xxx= LOLOW:

Very low chassis temperature alarm

xxx= LOW:

Low chassis temperature alarm

xxx= HIGH:

High chassis temperature alarm

Device Temper: xxx

xxx= HIHIGH:

Very high chassis temperature alarm

Technical passport / EDFA-1550

12-2016-v4

6. Network management description

6.1 Interface description

RS232 communication interface

Adopt DB9 standard connector, the pin definitions as follow:

The serial communication uses the standard NRZ form, 1 starts bit, 8 data bits, 1 stop bit and the

baud rate is 38400.

1:No

Connect

4:No

2:TX

5:GND

8:No

3:RX

6:No

Connect

LAN communication interface

Adopt RJ45 standard connector, the pin definitions as follow:

1:TX+

4:No

Connect

2:TX-

5:No

Connect

3:RX+

6:RX-

12

Technical passport / EDFA-1550

12-2016-v4

6.2 Set up the super terminal

If you have not setup the Hyper Terminal in your Windows system, follow these steps:

Click “start menu programaccessorycommunicationHyper Terminal”:

This results in the following screen:

Then you input your connection name, such as “SNMP38400”,and choose the serial port to connect

with your equipment. As follows:

Press the “OK” button shows the configuration page of serial port. As follows:

Change the serial port configuration to 38400-baud rate, 8 data bits, no parity bit, 1 stop bit, no data flow

control, press the “OK” button, you have set up the Windows serial port Hyper Terminal.

13

Technical passport / EDFA-1550

12-2016-v4

You can click “filesave” menu to save this configuration of Hyper Terminal for later using.

6.3 Operating Parameter Configuration

Under the condition of power off, use the serial port lines to connect the RS232 port with the computer

port. Open the Windows Hyper Terminal which you have set up. Then turn on the power, you will see the

page as follows, at this time, you press the “OK” button into the boot program and do some advanced

configuration. Boot program is like the BIOS setting program of PC. Generally speaking, users do not

have to enter the boot program to configure the parameter, so we set the password to avoid damaging the

properly configuration.

14

Technical passport / EDFA-1550

12-2016-v4

Skip the boot program and the application program begins as follows:

You can input your command in this page, and then configure the operating parameter of the application

program.

System supports the following commands:

help

15

ethcfg

settrap

List internal commands of the system;

Configure the Ethernet operating parameters;

Configure the aim host IPaddress of the SNMPTrap;

Configure the SNMPgroup name;

community

Specific using as follows:

help

This command shows current application program version, program name and the internal commands list

of the system as follows:

Technical passport / EDFA-1550

12-2016-v4

You can also use the “help” command to show help information of other commands, such as “help

ethcfg”,ethcfg’s help information appears as follows:

ethcfg

This command configures the Ethernet parameters, including IP address, subnet mask and gateway. You

can refer to the help information for its using.

settrap

This command shows or modifies the aim host IP address list of the SNMP Trap,

settrap –l display command, settrap –m modify command; as follows:

IP address of 0.0.0.0 and 255.255.255.255 don’t exist. SNMP Trap does not send to these two addresses.

community

This command configures the read-only group name and read-write group name. “Group name” is the

concept of SNMP agreement like the password. Use the command “community ro” to configure the read-

only, and “community rw” for the read-write. For example, input “community rw public”, “public” is the

read-write group name. The group name for read-only and read-write are both “public” as the equipment

default setting from factory.

6.4 WEB Network Management

Opening the IE browser and entering the equipment IP address leads to the following interface:

16

Technical passport / EDFA-1550

12-2016-v4

Enter the user name admin and password 123456 (factory default), to show the following interface:

There are 3 sub-interfaces:

1. Display Parameter interface: Describes the equipment display menu.

2. Set Parameter interface: Change the equipment parameters in this interface.

3. Modify password interface: Change the login password in this interface.

Click Set Parameter to open the following interface:

17

Technical passport / EDFA-1550

12-2016-v4

The Item shows the changeable parameters, Current—the current parameters; New—select or enter

the new parameters; Update—update the parameters.

The update steps: Find the item which needs to be changed, select a new value, and click the Update

button.

Click Modify Password to open the following interface:

7. Installation debugging

7.1 Unpack and Check

Insure the package is not defaced. If it has any damage or water mark, please contact local agency or carrier.

After unpacking, check equipments and accessories according to package list. Any question, please contact local

agency or our company.

If you think the equipment has been damaged, please don't electrify to avoid worse damage. Please contact local

agency or our company in time.

18

Technical passport / EDFA-1550

12-2016-v4

19

7.2 Instruments and Tools

1. An optical power meter;

2. A digital multimeter;

3. A standard optical fiber test jumper (FC/APC or SC/APC);

4. Some absolute alcohol and medical cotton wool.

7.3 Installation Steps

1. Before installing the equipment, please read the <User's manual> carefully and install the equipment

according to the <User's manual>. Note: For the man-made damage and other all consequence

caused by error installation that not according to the <User's manual>, we will not be responsible and

will not supply free warranty.

2. Take out the device from the box; fix it to the rack and reliably grounding. (The grounding resistance

must be < 4Ω).

3. Use the digital multimeter to check the supply voltage, make sure the supply voltage comply with the

requirements and the switch key is on the “OFF” position. Then connect the power supply.

4. Input the optical signal according to the display message. Turn the switch key to the “ON” position

and observe the front panel LED status. After the pump working status indicator turn into green, the

device is working normal. Then press the menu button on the front panel to check the working

parameters.

5. Connect the optical power meter to the optical signal output end by the standard optical fiber test

jumper, then measure the optical output power. Affirm the measured optical output power and the

displayed power are the same and have reached the nominal value. (Affirm the optical power meter is

on 1550nm wavelength test position; the optical fiber test jumper is the matched one and on the

connector surface has no pollution.) Remove the standard optical fiber test jumper and optical power

meter; connect the device to the network. So far, the device has been completely installed and

debugged.

8. Clean and maintenance method of the optical fiber active connector

In many times, we consider the decline of the optical power as the equipment faults, but actually it

may be caused by that the optical fiber connector was polluted by dust or dirt. Inspect the fiber connector,

component, or bulkhead with a fiberscope. If the connector is dirty, clean it with a cleaning technique

following these steps:

1. Turn off the device power supply and carefully pull off the optical fiber connector from the adapter.

2. Wash carefully with good quality lens wiping paper and medical absorbent alcohol cotton. If use the

medical absorbent alcohol cotton, still need to wait 1~2 minutes after wash, let the connector surface

dry in the air.

3. Cleaned optical connector should be connected to optical power meter to measure optical output

power to affirm whether it has been cleaned up.

4. When connect the cleaned optical connector back to adapter, should notice to make force appropriate

to avoid china tube in the adapter crack.

5. If the optical output power is not normal after cleaning, should pull off the adapter and clean the

other connector. If the optical power still low after cleaning, the adapter may be polluted, clean it.

(Note: Be carefully when pull off the adapter to avoid hurting inside fiber.)

6. Use compressed air or degrease alcohol cotton to wash the adapter carefully. When use compressed

air, the muzzle aims at china tube of the adapter, clean the china tube with compressed air. When use

degrease alcohol cotton, insert directions need be consistent, otherwise can’t reach a good clean

effect.

Technical passport / EDFA-1550

12-2016-v4

20

Special notice:

a. In the process of clean the active optical fiber connector, you should avoid direct shining at eye,

which will cause permanence burn!!!!

b. Use proper energy to install the active optical connector, or the ceramic tape in the adaptor will

lead to break. Once the ceramic tape is broken, the optical output power will decrease rapidly.

And turn the active optical fiber connector slightly, the optical output power changes obviously.

c. Please operate the optical fiber under the condition of shut off the pump laser. Or the high

output power will lead to burn the joint of the optical output fiber, which will cause the output

power decrease.

Equipment changes result in some parts does not match with this manual, without prior notice.

Disclaimer

We reserve the right to change any products described herein at any time, and without prior notice. We

assume no responsibility or liability arising from the use of the products described herein, except as

expressly agreed to in writing by us. The use and purchase of this product does not convey a license under

any patent rights, copyrights, trademark rights, or any intellectual property rights of us. Nothing

hereunder constitutes a representation or warranty that using any products in the manner described herein

will not infringe any patents of third parties.

This manual suits for next models

1

Table of contents