Fibre Glast 126-A Parts list manual

Information present herein has been compiled from sources considered to be dependable and is accurate and reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing

herein is to be construed as recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the user’s responsibility to determine for himself the suitability

of any material for a specific purpose and to adopt such safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material and, since conditions of use

are not under our control, we must necessarily disclaim all liability with respect to the use of any material supplied by us.

© Copyright 2020 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone: 800.214.8572

Fax: 937.833.6555

www.fibreglast.com

Usage Instructions & Parts List

Operating Instructions & Suggestions

This is a heavy duty gun offering a range of adjustments that will allow

the spray pattern to be customized to the specific project. This gun excels

at large surface spraying, such as new mold construction, composite

refinishing andlarge boat repair.

This gun comes fitted with a 2.5mm nozzle, which is ideal for any of our

gel coats. Ships complete with 1.25 pint cup, cleaning brush, and 1 mini

filter.

Read this Instruction Manual carefully. Basic precautions should be

strictly followed to prevent the damage to the tool and injury to the

operator. Retain this manual for further reference.

.6 Liter (20 oz.) Touch Up Spray Gun

126

Information present herein has been compiled from sources considered to be dependable and is accurate and reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing

herein is to be construed as recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the user’s responsibility to determine for himself the suitability

of any material for a specific purpose and to adopt such safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material and, since conditions of use

are not under our control, we must necessarily disclaim all liability with respect to the use of any material supplied by us.

© Copyright 2020 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone: 800.214.8572

Fax: 937.833.6555

www.fibreglast.com

Feed Type

Standard Diameter of Nozzle

Recommended air pressure

Material Capacity

Air Consumption

Compressor Required

Air Connection

126-A

Gravity

2.5 mm

2.5 - 3.5 bar (40 - 80 psi)

.6 Liter (20 ounces)

4.7 - 7.1 cfm

1.5 H.P

1/4 n.p.t.

Important Safety Instructions

1. Certain materials can create toxic vapors, intoxication and serious damage to health. Always wear safety glasses,

gloves and respirator to prevent the toxic vapor hazard, or solvent and gel coat coming into contact with your eyes or

skin.

2. Never use oxygen, combustible or any other bottle gas as a power source to avoid explosion and serious personal

injury.

3. Fluid and solvent can be highly flammable or combustible. Use in wellventilated spray booth and avoid any ignition

sources, such as smoking, open flames and sparks.

4. Disconnect tool from air supply when not in use or maintaining also a shut off valve. As an emergency stop is

recommend.

5. Use clean, dry and regulated compressed air rated at 2.0-3.5 bar, (40-80PSI). Never exceed maximum permissive

operating pressure.

6. Never use homogenate hydrocarbon solvent, which can chemically react with aluminum and zinc parts and

chemically compatible with aluminum and zinc parts.

7. Never point gun at you or others at any time.

8. Before operating the tool, make sure all the screws & caps are securely tightened in case of leaking.

9. Before spraying, be sure the trigger and related parts operate smoothly.

10. Never modify this tool for any applications. Only use recommended parts, nozzles and accessories.

Features

126

Information present herein has been compiled from sources considered to be dependable and is accurate and reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing

herein is to be construed as recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the user’s responsibility to determine for himself the suitability

of any material for a specific purpose and to adopt such safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material and, since conditions of use

are not under our control, we must necessarily disclaim all liability with respect to the use of any material supplied by us.

© Copyright 2020 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone: 800.214.8572

Fax: 937.833.6555

www.fibreglast.com

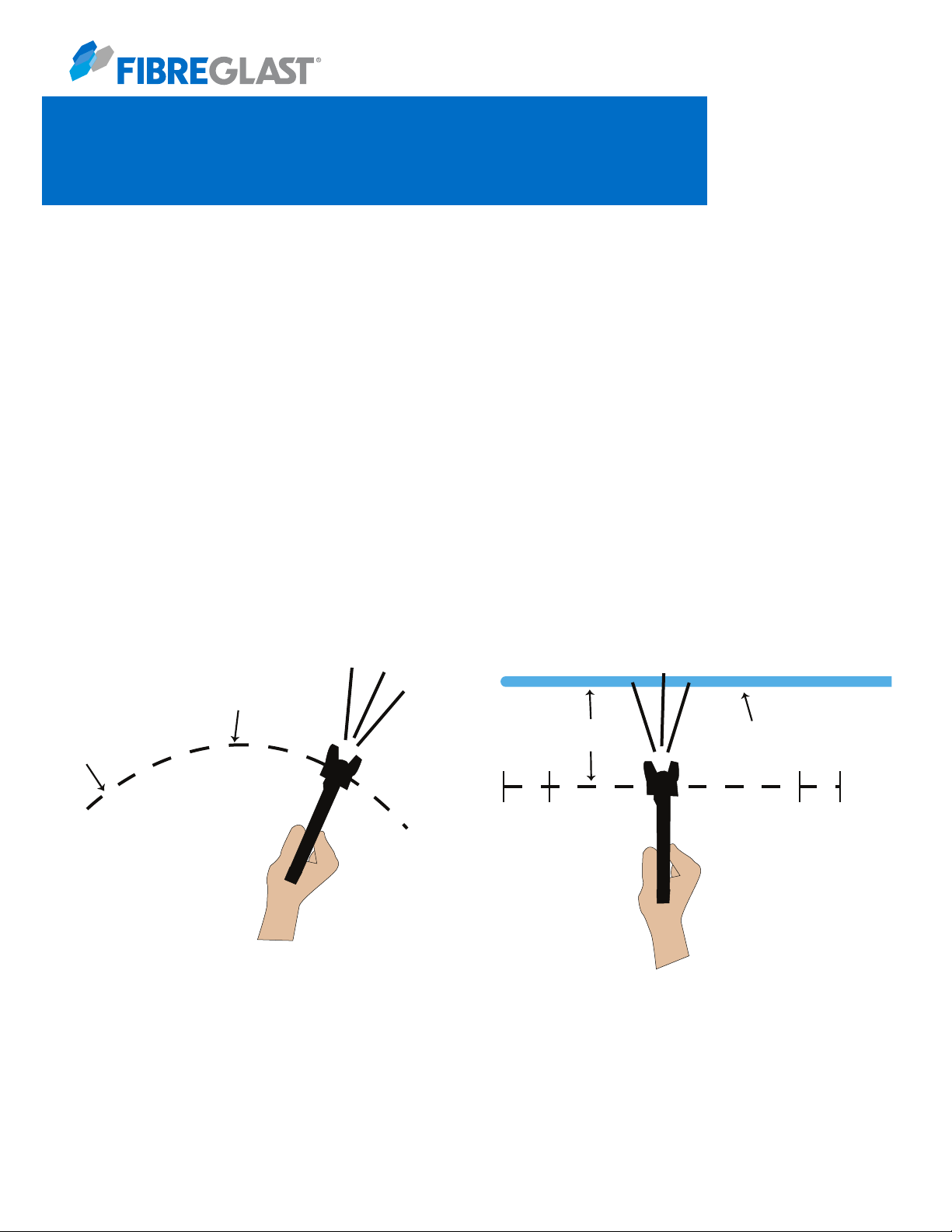

Wrong Right

Coating will

be light

at this point.

Coating will

be heavy

at this point.

6 to 12 inches

Start

stroke Pull

trigger

Coating should be even

and wet when spraying

Release

trigger

End of

stroke

Operating Instructions:

This tool operates on clean, dry, compressed air at regulated pressure at 40 - 80 PSI. Too low or too high pressure

will adversely affect the gun and the quality of spray.

Check and replace any damaged or worn parts on the tool. Make sure the trigger and nozzle can operate will.

Connect the gun to air supply. Be sure fluid cap, container and air hose should be connected tightly with spray gun.

When spraying, hold the gun perpendicular to spraying area, and then move it parallel several times. The trigger

should be locked before the stroke ended. Keep the appropriate distance of 6-12 inches between gun and surface

area, according to the atomization pressure and spraying conditions.

126

Information present herein has been compiled from sources considered to be dependable and is accurate and reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing

herein is to be construed as recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the user’s responsibility to determine for himself the suitability

of any material for a specific purpose and to adopt such safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material and, since conditions of use

are not under our control, we must necessarily disclaim all liability with respect to the use of any material supplied by us.

© Copyright 2020 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone: 800.214.8572

Fax: 937.833.6555

www.fibreglast.com

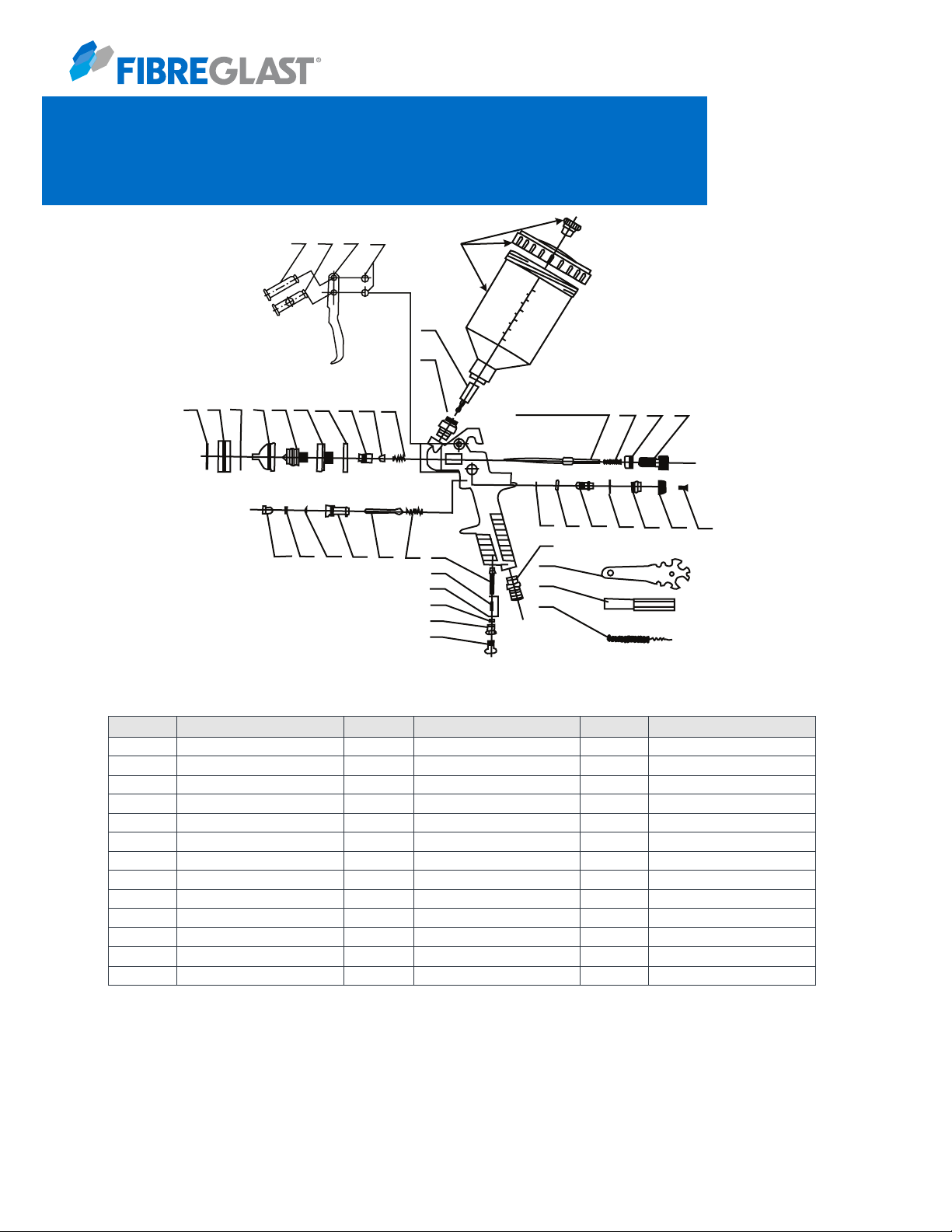

23 24 25 27 28P

28A

30

31

NK NK NK NK NK 18

12 11 10 09 18 07 06

45

44

NK 35 36 37

43 42 41 40 39 38

46

47

48

05

04

03

02

01

19 20 21 22

126-A Parts List - Available through Special Order Only

126

No

01

02

03

04

05

06

07

08

09

10

11

12

18

Description

Air Adj Knob

Air Adj Screw

Air Adj O-Ring

Air Adj Washer

Air Adj Spring

Air Inlet Valve

Switch Spring

Air Inlet Valve Body

Switch Knob

Swith Knob O-Ring

Switch Knob Washer

Lock Knob

Fluid Nozzle Joint

No

19

20

21

22

23

24

25

26

28 A

28 P

30

31

35

Description

Polypro Joint Washer

Direction Screw

Mat. Neddle Washer

Locking Spring

Trigger Lever 1

Trigger Lever 2

Trigger

Upper/Lower Snap Retainer

Alum Cup Assy (1.0 L)

Plastic Cup Assy (.06 L)

Material Filter

Mat Inlet Joint

Fluid Needle Spring

Description

Mat Lock Nut

Mat Adj Knob

Pattern Phillips Screw

Pattern Adj Knob

Pattern Adj Screw

Pattern Adj Washer

Pattern Adj Screw

Pattern Adj 0-Ring

Snap Retainer

Air Inlet Joint

Tool Wrench

Hex Wrench

Cleaning Brush

No

36

37

38

39

40

41

42

43

44

45

46

47

49

Information present herein has been compiled from sources considered to be dependable and is accurate and reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing

herein is to be construed as recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the user’s responsibility to determine for himself the suitability

of any material for a specific purpose and to adopt such safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material and, since conditions of use

are not under our control, we must necessarily disclaim all liability with respect to the use of any material supplied by us.

© Copyright 2020 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone: 800.214.8572

Fax: 937.833.6555

www.fibreglast.com

Troubleshooting

126

Symptom

Fluttering or Spitting

Pattern is arc

Pattern is not evenly spread

The center of the pattern is

too narrow

Pattern width of fan-shape

is not enough

Problems

1. Material level tool low

3. Loose fluid inlet connection

4. Loose or damaged fluid tip/ seat

1. Worn or loose Fluid nozzle

2. Material build up on air cap

1. Material build up on air cap

2. Fluid nozzle dirty or worn

1. Material too thin or not enough

2. Atomization air pressure too high

1. Material too thick

2. Atomization air

Solution

1. Add material into container

3. Tighten

4. Adjust or replace

5. Lubricate and or tighten

1. Tighten or replace fluid nozzle

2. Remove obstructions from holes, but don’t use

metal objects to clean it

1. Clean or replace air cap

2. Clean or replace fluid nozzle

1. Regulate material viscosity

2. Reduce air pressure

1. Regulate material viscosity

Information present herein has been compiled from sources considered to be dependable and is accurate and reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing

herein is to be construed as recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the user’s responsibility to determine for himself the suitability

of any material for a specific purpose and to adopt such safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material and, since conditions of use

are not under our control, we must necessarily disclaim all liability with respect to the use of any material supplied by us.

© Copyright 2020 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone: 800.214.8572

Fax: 937.833.6555

www.fibreglast.com

126

Gel Coat Troubleshooting Guide

Proper gel coat application is difficult for professionals and is probably the most common problem area for those new

to fiberglass work. Most common gel coat problems are related to temperature variation, catalyzation and a variety of

handling techniques. The following list of gel coat problems and causes should help to resolve some of the difficulties

associated with gel coat.

1. Wrinkles And Pinholes: A coating less than five mils thick may wrinkle, especially when brush marks are present.

Check the thickness using a gel coat thickness gauge. The preferred thickness is .010” to .020”. A wrinkle can also

occur if the gel coat is not cured enough prior to lay-up. Before lay-up check the surface for tack. The surface should

be sticky but not transfer to your finger. Several things can affect a slow cure; solvent or water entrapment, under

catalyzation, cold temperatures and other factors. If the gel coat film contains pinholes, check the spray equipment

for moisture in the air lines or dirt in the traps. It is also important to review your spray techniques.

2. Slow Gel Coat Cure: Any temperature below 70 degrees F will retard the gel time. An under-catalyzed gel coat will

also result in a slow cure but this is not a recommended technique for deliberately lengthening gel time. High

moisture and humidity will lengthen the gel time.

3. Sagging Of The Gel Coat: The most common reasons for gel coat sags would be when the gel coat is applied in an

excessively heavy application in one or more passes. To avoid sagging, spray in multiple light coats at a 15” distance

from the mold. The maximum thickness to be sprayed at one application is .016”.

4. Porosity: Gel coat porosity (air bubbles) is normally caused by trapped air or moisture. This can be prevented by

limiting the spray thickness per pass to .005”. It is also important to verify that the proper air pressure is being used

because an over pressurized spray can cause fine porosity. Air pressure should be set at 40-80 PSI, depending on

viscosity.

5. Separation Of Color: Most color separations are related to improper spray techniques. Reduce or lower thinning

agents and lower the per pass thickness of the gel coat. It is also important to avoid any spray overlap areas.

6. Discoloration On Finished Parts: This problem is caused from porosity related to air entrapment while spraying.

This can be overcome by spraying the mold surface with several light passes. It is also important to bleed any

moisture from the air lines and to be sure that the mold surface is dry.

Information present herein has been compiled from sources considered to be dependable and is accurate and reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing

herein is to be construed as recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the user’s responsibility to determine for himself the suitability

of any material for a specific purpose and to adopt such safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material and, since conditions of use

are not under our control, we must necessarily disclaim all liability with respect to the use of any material supplied by us.

© Copyright 2020 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone: 800.214.8572

Fax: 937.833.6555

www.fibreglast.com

126

Gel Coat Troubleshooting Guide, Continued

7. Craters And Pock Marks: These surface blemishes can be caused by improper resin to catalyst ratios and improper

air pressure both high and low. Another cause for craters would be oil or moisture on the surface of the mold.

8. Fisheyes: Fisheyes are usually caused by contaminates on the mold like dirt, moisture or oils. Bleeding the air lines

and using air filters will lower any air related contaminates. Try to isolate the spray area from any oils, especially

silicones.

9. Blisters When Immersed In Water: Blisters can be caused for the following reasons:

1. Incomplete cure

2. Improper wetting of the back up fibers

3. Bad bond between the gel coat and the back up laminate. This is often caused by contamination.

4. Thin gel coat

10. Lifting Of Gel Coat Before Laminating: This condition is usually related to shrinkage of the gel coat. Shrinkage can

be caused by:

1. Too fast of a curing time normally caused by over- catalyzation.

2. Delays between the gel coat and laminating can cause shrinking

3. Variations in gel coat thickness can vary the gel time which can cause shrinkage.

4. The mold surface is too hot.

11. Back Up Pattern Showing Through Gel Coat: This visual pattern is caused by too low a gel coat thickness or the

gel coat was not properly cured.

12. Gel Coat Sticking To The Part: This condition is caused by improper releasing of the mold surface. It is important

to use release agents formulated for the reinforced plastics industry. Proper training and common sense will

eliminate most of the problems associated with gel coats. Proper handling of gel coats will result in a part with a

blemish free surface.

Table of contents

Other Fibre Glast Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Graco

Graco Optimiser 2K 02748 instructions

Graco

Graco VIBRA-FLO 17P002 Operation, parts

Worx

Worx HYDROSHOT WG620E Safety and operating manual

The Fountainhead Group

The Fountainhead Group SMITH PERFORMANCE NL403 use and care manual

Graco

Graco Ultra Max II 695 Operation manual

Graco

Graco ti2652a instructions