Field Controls CAS-34U User manual

www.eldcontrols.com

Please retain these instructions after installation.

This device MUST be installed by a qualied agency in accordance with the manufacturer's installation instructions. The denition of

a qualied agency is: any individual, rm, corporation or company which either in person or through a representative is engaged

in, and is responsible for, the installation and operation of HVAC appliances, who is experienced in such work, familiar with all the

precautions required, and has complied with all the requirements of the authority having jurisdiction.

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE PROCEEDING WITH THE INSTALLATION.

Installation Date:

Installed By: Phone:

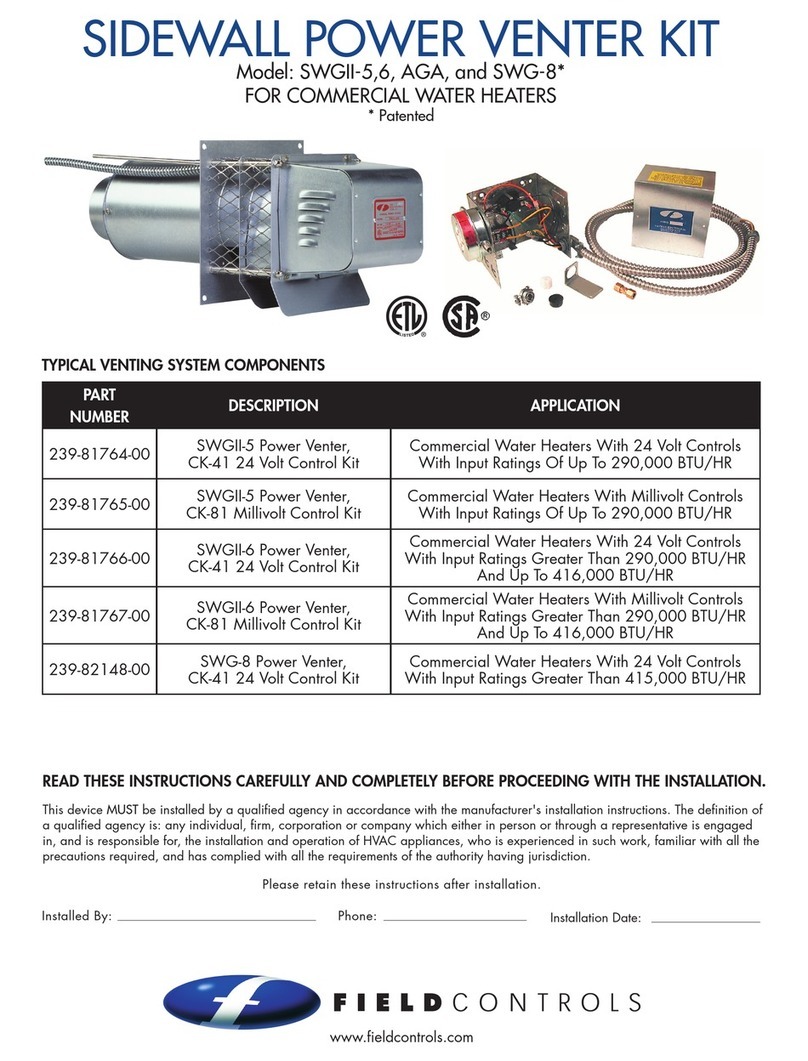

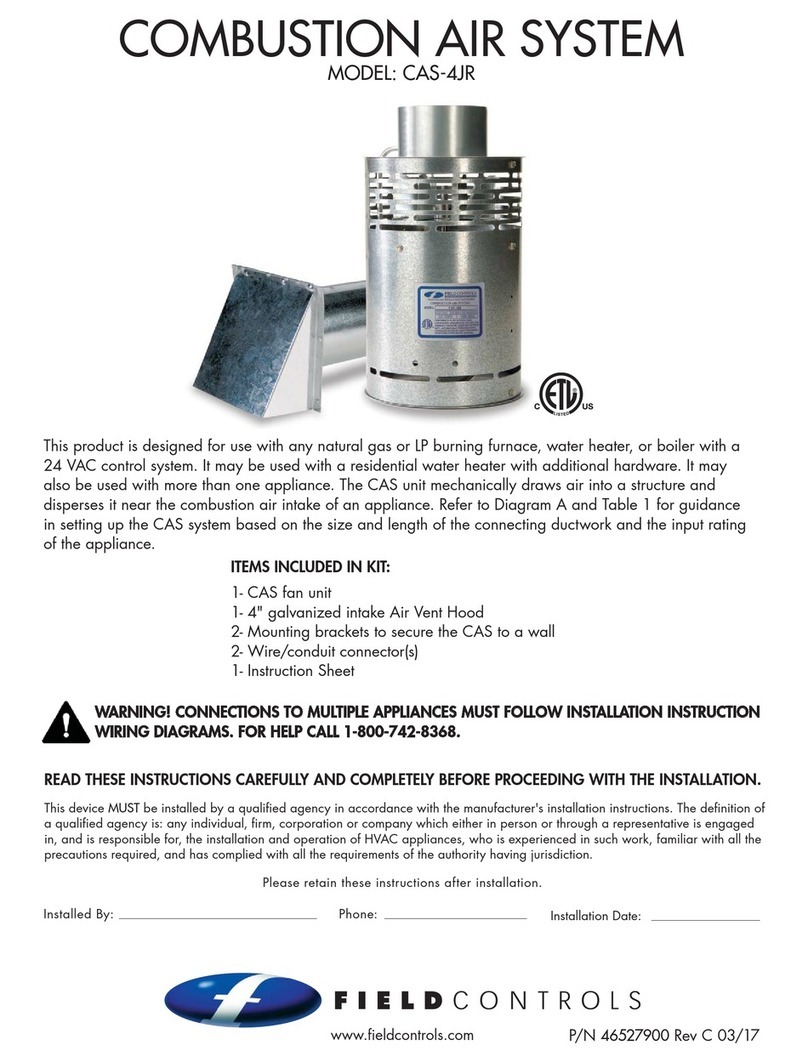

COMBUSTION AIR SYSTEM

Model: CAS-34U

ITEMS INCLUDED IN KIT:

1 - Motorized Blower

2 - Mounting Brackets

1 - 4" x 6" Pipe Increaser Fitting

1 - Instruction Sheet

1 - 4” Intake Air Hood

1 - 6” Orice Ring

WARNING

CONNECTIONS TO MULTIPLE APPLIANCES MUST FOLLOW INSTALLATION INSTRUCTION WIRING DIAGRAMS.

CONNECTIONS TO MULTIPLE APPLIANCES MUST FOLLOW INSTALLATION INSTRUCTION WIRING DIAGRAMS.

P/N 780107600 Rev B 05/23

page 2 of 16

The model CAS-34U is a combustion air system based on the CAS-3 and CAS-4 units. This product is designed

for use with any oil, natural gas, or LP burning furnace, water heater, or boiler. The CAS-34U is a universal com-

bustion air system that will operate with 120VAC or 24VAC control systems. The CAS-34U may also be used in

combination with a 30mV standing pilot gas water heater with the use of an additional CK-20 series control kit.

Additional 120V or 24V controlled appliances may also be served by the CAS-34U with the addition of one CAC-

120 or CAC-24 control kit (per each additional appliance, see note*.) The CAS-34U mechanically draws air into

the structure and disperses it near the combustion air intake of an appliance. Refer to Table 1 for guidance in set up

of the CAS-34U based on the size and length of the connecting ductwork and the input rating of the appliance(s).

*NOTE: This product will meet the NFPA-31 standard. Please note that there are dierences

in construction, operation and installation of this CAS as compared to legacy product.

SPECIFICATIONS

Internal motor 120VAC, 0.8A, 60Hz. Maximum loaded speed 2600 RPM

L1 terminal Idle current at 120VAC: 18.25mA (no call for heat, no signal on M

terminal)

M terminal

input signal 120VAC, 5mA. Trigger voltage above 89.6VAC

Appliance: Oil, 120VAC nominal (voltage selection switch in the120VAC position)

T1 Minimum operating voltage 89.6VAC, drop out voltage 58.4VAC

T2 Must be connected to neutral in reference to T1 supply voltage

T1 & T3 Maximum Full Load Conditions: 120VAC, 60Hz, FLA 9.8A, LRA 58.8A

(1/2HP)

Appliance: Gas, 24VAC (voltage selection switch in the 24VAC position)

T1 Minimum operating voltage 18.75VAC, drop out voltage 13.8VAC

T2 Must be connected to 24VAC common in reference to T1 supply voltage

T1 & T3 Full load conditions 3.3A up to 5A. Typical gas appliance 3.3A or

less, Class II

Voltage

Selection Switch Sets the desired voltage on the T1 terminal

P/N 780107600 Rev B 05/23

page 3 of 16

SIZING AND SETUP

Table 1 shows the maximum equivalent length and size of duct pipe that should be used when installing the

CAS-34U system. Using this table will help ensure that the proper amount of air is drawn into the structure as

needed by the appliance. Follow the guidelines below to properly size and set up the CAS-34U.

1. Determine the maximum input ring rate of the appliance, or the maximum total ring rate of multiple

appliances that will be used.

2. Position the motorized CAS-34U unit according to the guidelines in the "Installation" section.

3. Determine where the intake air hood will be located based on the recommendations in the "Installation"

section.

4. The CAS-34U is equipped with a High/Low motor speed control switch. When calculating the maximum

equivalent feet, determine which speed is appropriate for the application. (Refer to Tables 1 and 2)

5. Calculate the total equivalent length of duct pipe including elbows and ttings needed to connect the

CAS-34U unit to the intake air hood. (Refer to Table 1)

6. On Table 1, locate the point that corresponds to the correct combination of ring rate and duct size.

GENERAL SYSTEM OPERATION

1. The thermostat (wall thermostat or aquastat) calls for heat which activates the CAS-34U unit. After the

CAS-34U fan has come up to speed and air ow into the CAS-34U inlet is established, an internal air

pressure switch closes and completes the circuit to allow the burner to re. If the appliance is power

vented, the venter and CAS-34U activate simultaneously. After the CAS-34U and power venter have come

up to speed, a pressure switch in the power venter control also closes and allows the appliance to re.

2. After the heating requirement has been satised, the thermostat circuit will open and deactivate the

burner and CAS-34U unit.

3. For power vented systems with a post purge device, the power venter and CAS-34U operate for a period

of time after the burner has shut o to purge remaining ue gases from the vent system.

CAUTION

This device must be installed by a qualified installer in accordance with the manufacturer’s installation instructions.

P/N 780107600 Rev B 05/23

page 4 of 16

P/N 780107600 Rev B 05/23

Equivalent Feet for Intake Pipe Fitting

Intake Pipe Fittings Intake Diameter

4” 6”

90° Elbow 7 feet 11 feet

45° Elbow 4 feet 5 feet

Table 2

TOTAL INPUT OF

APPLIANCE MAXIMUM EQUIVALENT FEET OF INSTALLATION

Oil (gph) Gas (BTU)

6” Duct And 6”

Intake Air Hood

4” Duct And 4”

Intake Air Hood

4" Duct And Hood w/

Orifice Ring

HI LOW HI LOW HI LOW

0.50 - 0.75 50,000-100,000 300 300 300 300 300 300

0.90 125,000 300 300 300 220 300 220

1.00 150,000 300 300 232 118 174 108

1.25 175,000 300 300 152 63 99 48

1.35 200,000 300 300 102 32 52 14

1.55 225,000 300 239 68 13 20

1.75 250,000 300 150 45

2.00 300,000 300 53 16

2.50 350,000 193 8

2.75 400,000 109

3.25 450,000 56

Table 1

page 5 of 16

INSTALLATION

PLACEMENT OF THE CAS-34U UNIT

The motorized CAS-34U unit should be located in a dry location on a at

horizontal surface within the space of the appliance or appliances, and try

to be within 3' of the combustion air intake of the appliance. Two mounting

brackets are provided for securing the unit against a solid structure, such

as a wall, column, or the side of the appliance itself. Use the included

screws to attach the brackets to the CAS-34U housing as shown in Figure

1. Secure the brackets to a solid structure with appropriate fasteners. It is

not required to use the brackets as long as the unit is located so that it may

not be bumped, moved, or tipped over.

*NOTE: The CAS-34U unit can be suspended o the oor by utilizing the

brackets to avoid wet or damp oors. Figure 1

Figure 2

INTAKE AIR HOOD LOCATION

The Intake Air Hood should be located on an outside

wall maintaining minimum clearances to other intake and

exhaust vents in accordance with the National Fuel Gas

Code, ANSI Z223.1, manufacturer's recommendations

and/or local codes which are applicable. The intake air

hood should be located at least 10' from a power vented

exhaust outlet.

An exterior air intake should be installed above snow line

or a minimum of 18” above ground level, whichever is

greater. ASHRAE recommends that the air intake be located

at least 10 feet from any source of pollutants such as auto

exhaust, dryer exhaust, exhaust from any fuel-burning ap-

pliance, etc. Avoid installation near odor sources such

as garbage bins or barbecue grills. Do not use a crawl

space, basement or attic as a source of intake air. Always

be sure to comply with local building code requirements

regarding combustion air inlets.

Figure 3: CAS-34U Internal Schematic Figure 4: General Terminal Descriptions

P/N 780107600 Rev B 05/23

POWERCONNECTION(115VAC)

NEUTRAL CONNECTION

EXTERNALMOTORCONTROLINPUT

MOTORCONNECTIONTERMINALS

EARTHGROUNDCONNECTIONS

APPLIANCECONTROLINPUT

APPLIANCECONTROL

COMMON/NEUTRAL

APPLIANCECONTROLOUTPUT

VOLTAGESELECTIONSWITCH

page 6 of 16

INSTALLATION OF INTAKE AIR HOOD

After determining the location of the intake air hood, cut a 4 1⁄2" round or square hole in the wall. Insert the

intake air hood and secure with appropriate fasteners. Take precautions to avoid interference with wiring or

other plumbing when cutting the wall opening.

INSTALLATION OF DUCT

Connect the duct pipe from the top of the CAS-34U unit to the Intake Air Hood in the wall. If using 4" diameter

pipe attach the provided 4" x 6" Pipe lncreaser Fitting to the top of the CAS-34U unit. The duct should be

supported with appropriate mounting straps from oor joists, walls, or other solid structures. The straps should

be placed so as to keep the ductwork out of passageways. (See Figure 2) A minimum of 12' of pipe should be

run to help temper outside air being drawn in.

WIRING INSTRUCTIONS

Wire the CAS-34U unit in accordance with the National Electrical Code and applicable local codes. THE UNIT

MUST BE GROUNDED. Check the ground circuit to make certain that the unit has been properly grounded. The

wiring should be protected by an over-current circuit device rated at 15 amperes.

Remove the wiring access cover to access the wiring terminals. Use the enclosed conduit connector(s) to route

the appropriate wires through the CAS-34U housing. The incoming ground wire must be attached to the green

colored ground screw near the wire terminals. The following sections describe the most common applications.

The references to various series of control kits implies that any kit in that series may be used.If further information

or additional wiring diagrams are needed please consult Field Controls’ technical support.

For Oil Applications, please refer to the Oil, 120VAC Section. For Gas Applications, please refer to the

Gas, 24V Section.

WARNING

CONNECTIONS TO MULTIPLE APPLIANCES MUST FOLLOW INSTALLATION INSTRUCTION WIRING DIAGRAMS.

CONNECTIONS TO MULTIPLE APPLIANCES MUST FOLLOW INSTALLATION INSTRUCTION WIRING DIAGRAMS.

CAUTION

CAUTION must be taken to ensure that the wiring does not come in contact with any heat source. All line

voltage and control circuits between the CAS-34U unit and the appliance MUST be wired in accordance

with the National Electrical Code for Class I wiring or equivalent.

P/N 780107600 Rev B 05/23

IMPORTANT

MAKE SURE TO SET THE VOLTAGE SELECTION SWITCH TO THE CORRECT POSITION FOR THE APPLICATION!

MAKE SURE TO SET THE VOLTAGE SELECTION SWITCH TO THE CORRECT POSITION FOR THE APPLICATION!

page 7 of 16

Diagram A - Chimney Vent Single Oil Fired System

EXTERNAL WIRING CONNECTIONS

Refer to Figures 3 thru 6 for appropriate wiring method.

OIL 120 VAC APPLIANCE SECTION

Diagram B - Riello Oil Fired Boiler

P/N 780107600 Rev B 05/23

The “M” terminal on this appliance is no longer directly connected to the unit’s motor. The “M” terminal’s

function has been changed to a 120VAC input control circuit.

page 8 of 16

Diagram C - Single Vent Oil Fired System

P/N 780107600 Rev B 05/23

page 9 of 16

Diagram D - Chimney Vent Two Oil Fired System with CAC-120

P/N 780107600 Rev B 05/23

page 10 of 16

GAS 24 VAC APPLIANCE SECTION

Diagram F - Power Vent Single 24V Furnace

EXTERNAL WIRING CONNECTIONS

Refer to Figures 7 thru 13 for appropriate wiring method.

Diagram E - Chimney Vent Single 24V Furnace

P/N 780107600 Rev B 05/23

page 11 of 16

Diagram G - Chimney Vent 24V Furnace and 30 mV Water Heater with CK-20FV and CK-20FG

P/N 780107600 Rev B 05/23

Diagram H - Wiring with a Smart Valve Water Heater

Set Voltage Selection Switch to 24V

page 12 of 16

Diagram I - Chimney Vent 24V Boiler

P/N 780107600 Rev B 05/23

page 13 of 16

Diagram J - Power Vent Single 24 Bolier

P/N 780107600 Rev B 05/23

page 14 of 16

Diagram K -Chimney Vent Two 24V Gas Appliances with CAC-24

P/N 780107600 Rev B 05/23

page 15 of 16

Diagram L - One Power Venter Two 24V Gas Appliances

P/N 780107600 Rev B 05/23

Phone: 252.522.3031 • Fax: 252.522.0214

www.fieldcontrols.com

© Field Controls, LLC P/N 780107600 Rev B 05/23

This manual may be downloaded and printed from the Field Controls website (www.eldcontrols.com)

This manual may be downloaded and printed from the Field Controls website (www.eldcontrols.com)

WARRANTY

WARRANTY

For warranty information about this or any Field Controls product, visit:

For warranty information about this or any Field Controls product, visit:

www.eldcontrols.com

www.eldcontrols.com

Field Controls Technical Support

Field Controls Technical Support

1.800.742.8368

1.800.742.8368

eldtec@eldcontrols.com

eldtec@eldcontrols.com

MAINTENANCE

1. Inspect the system annually to ensure proper operation by observing that the fan activates when a call for

heat occurs and deactivates when the call for heat is satised.

2. Disconnect power to the CAS-34U unit and repeat Step 1. Note: The unit should not run and the appliance

should not re in this condition.

3. Inspect the duct pipe for cracks and that it is secure to the CAS-34U unit and intake airhood. The CAS-

34U unit will not allow the appliance(s) to re if there is inadequate air ow into the inlet of the CAS-34U.

4. Clear any obstructions, if present, from the inlet of the intake air hood and the outlet of the CAS-34U unit.

5. Periodically, the fan blade chamber may need cleaning. First, disconnect the power supply to the CAS-34U.

Next, disconnect the duct pipe from the unit. Then remove the top pan and clean the fan housing area as

needed. Reattach the top pan, reconnect the duct pipe and the power supply.

TROUBLESHOOTING

1. Burner does not re when thermostat calls for heat.

a. Make sure draft tube is securely fastened to the air pressure switch and is not blocked.

b. Check for continuity across pressure switch terminals when system is operating.

c. Check wiring connections between air pressure switch and appliance.

2. System does not activate when thermostat calls for heat.

a. Check to see if relay closes when thermostat calls for heat.

b. Check wiring connections.

c. Check motor for unrestricted shaft rotation.

3. Exhaust gas odor.

a. Check system draft level during operation.

b. Check vent system on appliance.

c. Check for negative pressure in building.

REPLACEMENT PARTS

MODEL DESCRIPTION PART NO.

CAS-34U

PCB Control Assy, CAS-34U 602400200

Motor Assy, CAS-34U 602400300

IAH-4 Intake Air Hood 46292000

IAH-6 Intake Air Hood 46293000

Pressure Switch, CAS-34U 602400400

Table of contents

Other Field Controls Boiler Supplies manuals