Filtration Group MFS-05 User manual

Translation of the original instructions

Filter controller MFS-05 ∆p

Material No. of Instruction Manual

70303409

Page 2

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

1 Contents

1Contents...................................................................... 2

2General safety instructions....................................... 2

2.1 Safety instructions for installation and

operating personnel.......................................... 2

2.2 Warning structure.............................................. 2

2.3 Warning symbols used...................................... 2

2.4 Other symbols used:......................................... 3

3Glossary...................................................................... 3

4General information................................................... 3

4.1 Manufacturer..................................................... 3

4.2 Information about the Instruction Manual.......... 3

4.3 ATEX type key.................................................. 3

5Intended application .................................................. 4

6Main components....................................................... 4

6.1 Overview of types ............................................. 4

6.2 Controls, LEDs and displays............................. 4

7Technical data............................................................ 6

8Transport and storage............................................... 7

9Functions.................................................................... 7

9.1 Operating modes .............................................. 7

9.1.1 Interval time control ............................... 7

9.1.2 Switching threshold................................ 8

9.1.3Time control........................................... 8

9.2 Secondary functions ......................................... 9

9.2.1 Enable/stop (post-cleaning)................... 9

9.2.2 Rapid cleaning....................................... 9

9.2.3 Fault acknowledgement......................... 9

9.2.4 Pressure switch ..................................... 9

9.2.5 Cleaning signal...................................... 9

9.2.6 Alarm threshold ................................... 10

10 Installation................................................................ 10

10.1 Unpacking....................................................... 10

10.2 Installation procedure...................................... 10

10.3 Electrical connection....................................... 10

10.4 Start-up........................................................... 10

11 Shut-down................................................................. 10

12 Normal operation ..................................................... 11

13 Troubleshooting....................................................... 11

13.1 Test................................................................. 11

13.2 Troubleshooting table ..................................... 11

14 Maintenance, repair and retrofitting....................... 12

15 Appendix: Connection variants.............................. 13

15.1 Interval time and switching threshold control.. 13

15.2 Terminal assignment....................................... 14

16 Appendix: RS 485 serial port .................................. 15

17 Appendix: Set of instrument lines and protective

filter (ID No. 78341984).................................................. 16

18 Appendix: Dimension drawing MFS-05 Δp ............ 17

19 Appendix: Default settings...................................... 18

19.1 Main parameters of the MFS-05 Δp in

“interval time control” mode ............................ 18

19.2 Other operating modes................................... 18

19.2.1 “Switching threshold” mode................. 18

19.2.2 “Time control” mode............................. 18

20 Declaration of incorporation................................... 19

21 Declaration of conformity........................................ 20

22 Index.......................................................................... 24

2 General safety instructions

2.1 Safety instructions for installation and

operating personnel

This Instruction Manual contains important safety

instructions which must be heeded at all times during

installation, operation and maintenance. Non-observance

can result in risks to persons and the environment as well

as in damage to the machine or system, e.g.:

Failure of critical functions of the system or its

component parts.

Danger to persons from electrical or mechanical effects

as well as from chemical reactions.

Danger to the environment owing to the leakage of

hazardous substances.

Before installation/start-up:

•Read the Instruction Manual carefully.

•Make sure that installation and operating personnel are

adequately trained.

•Make sure that the contents of the Instruction Manual

are fully understood by the responsible persons.

•Define areas of responsibility and competence.

During operation of the system:

•Keep the Instruction Manual handy at the place where

the system is used.

•Heed the safety instructions.

•Always operate the system/machine in accordance with

its ratings.

If in doubt:

•Consult the manufacturer.

2.2 Warning structure

Where possible, warnings are structured according to the

following system:

Signal word

Possibly

with

symbol

Nature and source of the danger

Potential consequences of non-

observance.

•Action to avert the danger.

2.3 Warning symbols used

DANGER!

Immediate danger!

Non-observance will result in serious or fatal injury.

WARNING!

Potentially dangerous situation!

Non-observance can result in serious or fatal injury.

CAUTION!

Potentially dangerous situation!

Non-observance can result in minor or moderate

injuries.

CAUTION!

Potentially dangerous situation!

Non-observance can result in property damage.

Page 3

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

2.4 Other symbols used:

Danger from high voltage

Danger information about explosion

protection

Information about environmental protection

Wear protective clothing!

Wear goggles!

Hand symbol:

Indicates general information and

recommendations

•

Bullet:

Indicates the order in which actions are to be

carried out

Arrow:

Indicates responses to actions

3 Glossary

Pulsing:

Pressure cleaning of the filter elements with air or gas.

“Switching threshold” pulsing:

Pulsing is activated when a switching threshold is

exceeded.

“Time-controlled” pulsing:

Pulsing is activated at fixed time intervals.

Switching threshold:

Preset differential pressure that must not be exceeded or at

which a defined action, such as activation of a valve, must

take place.

Temperature hysteresis:

Response inertia to a change in temperature.

Temperature drift:

Temperature sensitivity of the transistor characteristics.

4 General information

4.1 Manufacturer

Filtration Group GmbH

Schleifbachweg 45

D-74613 Öhringen

Phone +49 7941 6466-0

Fax +49 7941 6466-429

fm.de.sales@filtrationgroup.com

www.filtrationgroup.com

4.2 Information about the Instruction Manual

FG Mat. No.:........................................................70303409

Date: .....................................................................16.01.18

Version: ..........................................................................03

4.3 ATEX type key

II

3

D

T60°C

IP65

1.

2.

3.

4.

5.

1.

II

Valid for use above ground

2.

Category

2

Use in

Zone 22

3.

Atmo-

sphere

G = Gas

D= Dust

D

4.

Maximum surface temperature 60°C

5.

Degree of protection IP65

Page 4

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

5 Intended application

DANGER!

The MFS-05 Δp filter controller must not be

operated in potentially explosive atmosphere

(Zones 0, 1 and 2).

DANGER!

This filter controller is only allowed to be used in

accordance with the operating conditions specified in the

contract documentation and in the Instruction Manual.

All forms of use which deviate from or exceed the limits of

use described above are considered to be contrary to the

intended purpose.

The manufacturer shall not be liable for any damage

resulting from such use.

The MFS-05 ∆p filter controller with integrated differential

pressure transmitter is used for demand based control of

cleaning systems of the kind encountered in industrial dust

removing applications. Up to 24 automatically actuated

diaphragm valves pulse the dust elements.

Numerous control and monitoring functions are

implemented in the controller.

The MFS-05 ∆p filter controller normally operates

according to the “interval time control” principle. The

variable interval time between valve actuations is

calculated from a characteristic curve according to the

differential pressure. Alternatively, the controller can be

operated in “switching threshold” or “time-controlled” mode.

Valve monitoring:

All valves are monitored for overcurrent (short-circuits) and

interruptions. The controller has three relays for

operating/fault signals, cleaning signals and “alarm

threshold exceeded”.

6 Main components

0,1

0,3

0,6

1,0

1,5

1,5

2,0

2,5

3,0

5

20

50

100

200

350

500

1

2

3

4

5

6

7

8

9

10

11

12

Puls Pause Ventile Nachrein

TEST

S1

4 5 6 7 10 13811 14912 15

25 26 27 28 31 3429 32 3530 33 36

42 43 44 45 48 5146 49 5247 50 53

54 55 56 57 60 6358 61 6459 62 65

18 19 20

39 40 41

16 17 20 21 22 23

37 38 66 67 68

1 2 3

F1

13 14 15 16 17 18 19 20 21 22 23 24

1 2 3 4 5 6 7 8 9 10 11 12

Ventilanzeige

Störung

(rot)

Betrieb

(grün)

Reinigung

(gelb)

XS1

69 70

T

0

9

8

7

6

5

4

3

2

1

0

12

11

1

10

2

3

4

5

6

9

8

7

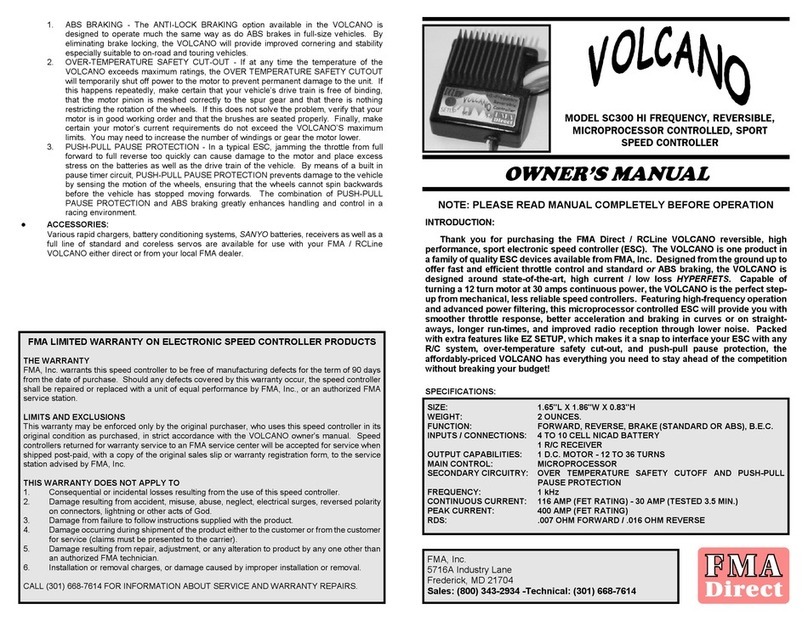

Fig. 1: Controls, LEDs and displays

6.1 Overview of types

The order numbers in parentheses apply to

units that are packed and ready for shipping.

MFS-05 ∆p AC 230 V

76341440 (76341838)

MFS-05 ∆p DC 24 V

76341457 (76341846)

Accessories:

Valve extension

13 to 24 valves

79742982 (76109664)

Replacement fuses

(pack of 5)

76186597 (76186605)

Set of instrument lines

with protective filter

78341984 (79759846)

6.2 Controls, LEDs and displays

LC display:

Fig. 2: LC display

3-digit, 7-segment display showing the current differential

pressure or the switching threshold.

Display selection:

Fig. 3: Display selection

Position

Display

0

Current differential pressure [mbar]

1

Cleaning cycles

2

High threshold

3

Alarm threshold

4

Not assigned

5

Current valve or faulty valve

(in this case, the first digit is a blinking line):

Down = interruption

Up = overcurrent

6

Post-cleaning cycles

7

No. of valves

8

Interval time

9

Pulse time

Potentiometers:

The time settings have a logarithmic scale with a control

range of 240°.

Page 5

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

On the motherboard:

Pulse time

0.1 s ... 3.0 s

Interval time

5 s ... 500 s

No. of valves

1 ... 12 valves

13 ... 24 valves if a valve extension

board is installed

If the number of valves is set to an

intermediate value, two adjacent valve

LEDs blink

Post-cleaning

cycles

0 ... 12

If the number of cycles is set to an

intermediate value, the complete LED

row blinks

0

12

11

1

10

2

3

4

5

6

9

8

7

Fig. 4: Controls on the motherboard:

On the ∆P module:

Cleaning cycles

1 … 10

High threshold

0 ... 40 mbar

Alarm threshold

0 ... 40 mbar

Fig. 5: Controls on the Δp module

Zero:

The ∆p zero adjusting screw is located to the right of the

LC display.

Fig. 6: Zero adjustment

Jumper XS1:

Fig. 7: Factory setting for interval time control

Pressure

switch*

Analogue

input

Cleaning

mode

Cleaning

cycle

Desig-

nation

Nein/ja

DS

(press-

ure

switch

yes/

no)

0/4 -

20 mA

Schw./

Reg

(threshol

d/control)

T/G Cycle

(partial/

full cycle)

Yes

4 – 20 mA

Interval

time

control

Full cycle

No

0 – 20 mA

High

threshold

Partial

cycle

* Function not supported

TEST button S1:

Press this button to start cleaning the next valve for the

duration of the set pulse time.

Fig. 8: TEST button S1

Page 6

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

LEDs:

Fault (red)

Operation (green)

Cleaning (2 x yellow)

Pulsing (red, 1x per valve)

Alarm threshold on ∆P module (red)

Fig. 9: LEDs

Valve alarm LED:

Valve LED blinks.

Cause: Overcurrent or interruption

7 Technical data

The inputs are not isolated!

•Provide external isolation if necessary.

Fig. 10: Nameplate

Analogue inputs

(not isolated)

•Start or Δp input not assigned

(time control: 16-17 jumpered)

Digital inputs

•Enable (contact closed, terminal

18-19) / stop (contact open)

•Post-cleaning

•Rapid cleaning

•Fault acknowledgement

(momentary contact signal)

Pressure

measuring lines

•P1 = pressure on

dirty side = [+]

(upstream of filter element)

•P1 = pressure on

clean side = [-]

(downstream of filter element)

•Measuring hose diameter: 4 mm

Valve outputs

12, extendable to 24

Valve voltage

24 V DC ± 10%

Valve current

1 A for pulse time ≤ 1 s,

otherwise 0.5 A

Relay outputs

•Contact load 250 V AC / 5 A

•1 changeover contact for

operating/fault signals

(FAIL-SAFE circuit)

•1 NO contact for cleaning signal

•1 changeover contact for ∆p alarm

Analogue output

•0 (4) ... 20 mA

∆p sensor

•Measuring range: 0 ... 40 mbar

•Max. static pressure: 1 bar

•Linearity: ±1%

•Temperature hysteresis: ±0.5%

•Temperature drift / zero:

±0.025% / K

•Temperature drift / upper range

value:

±0.01% / K

Time settings

•Pulse time: 0.1 ... 3.0 s

•Interval time: 5 ... 500 s

•Post-cleaning: 0 ... 12 cycles

LEDs

•Operation: Green

•Cleaning: Yellow

•Fault: Red

Page 7

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

•Valve alarm: Red

•Alarm threshold: Red

Electrical

connection

•Screw-type terminal strips

2.5 mm²

•Valve connections 1.0 mm²

Ambient

temperature

0 ... 50°C

Climatic

category

KWF acc. to DIN 40040

(≤ 75% relative humidity, no

condensation allowed)

Design

•Dust-tight Makrolon casing

(Ex II 3D T60°C IP65)

•175 x 175 x 100 mm (W x H x D)

Mains power supply

230 V AC,

50-60 Hz

24 V DC

Tolerance

±10%

±10%

Mains fuse

0.315 A time-

lag

3.15 A time-

lag

Power consumption

30 W

42 W

8 Transport and storage

Transport

•Always transport in the original packaging

•Avoid vibrations

Storage

•Always store in the original packaging

•The unit must be stored in a dry room at 0 … 70°C

•Avoid vibrations

•Avoid direct UV radiation (sunlight)

9 Functions

9.1 Operating modes

The controller can operate in three different modes. The

mode is selected by altering the assignment of terminal

16-18 and the setting of the “XS1” jumper.

9.1.1 Interval time control

If “interval time control” mode is selected, the controller is

permanently active. The interval time varies as a function

of ∆p.

Factory settings:

•Terminal 16-17 not assigned

•Terminal 18-19 jumpered

•XS1 jumper Schw./Reg. switch up

•XS1 jumper T/G Cycle switch up

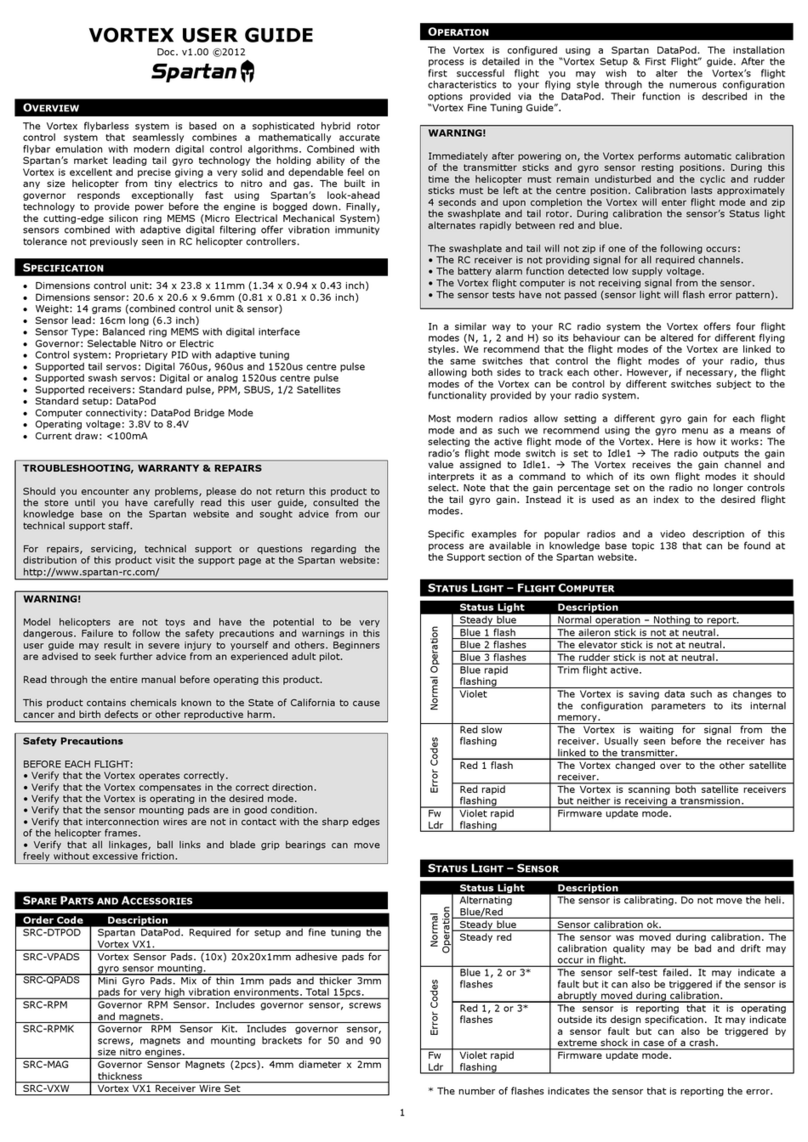

Fig. 11: Jumper settings for interval time control

Valve activation is controlled by a ∆p-dependent interval

time.

The interval duration is determined by Δp and the

selected controller characteristic.

Possible controller characteristics:

04812 16 20 24 28 32 36 40 mbar2

aus ein

Fig. 12: Controller characteristics

Example:

The filter must be cleaned at a differential pressure

equivalent to 30% of the differential pressure measuring

range (= 12 mbar) with an interval time of approximately

70 s.

To select the characteristic:

•Find and plot the 30% line.

•Find and plot the 70 s line.

The point of intersection is located on characteristic 60.

•Set the “interval” potentiometer to 60 s.

Page 8

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

0

12

11

1

10

2

3

4

5

6

9

8

7

Fig. 13: “Interval” potentiometer

The controller determines the required interval time from

the current differential pressure and the selected

characteristic.

The interval time is shorter if the differential pressure

increases and longer if it is reduced.

The change in the interval time is non-linear.

The cleaning process ends if the differential

pressure falls below approximately 5% of the

measuring range.

9.1.2 Switching threshold

If “switching threshold” mode is selected, the controller is

activated when the set threshold is exceeded.

Factory settings:

•Terminal 16-17 not assigned

•Terminal 18-19 jumpered

•Jumper 3 down

Full cycle (optional)

•XS1 jumper T/G Cycle switch up

A full cycle is executed if the switching threshold is

exceeded.

Fig. 14: Jumper settings for full cycle

Partial cycle (optional):

•XS1 jumper T/G Cycle switch down

A cleaning process is executed if the switching threshold

is exceeded.

The cleaning process ends if the differential pressure

falls below the switching threshold.

The next valve is activated when the controller is

activated again.

Fig. 15: Jumper settings for partial cycle

9.1.3 Time control

Factory settings:

•Terminals 16-17 and 18-19 jumpered

•Both pressure measuring lines disconnected

•XS1 jumper Schw./Reg. switch down

Fig. 16: Jumper settings for time control

A time-controlled cleaning process starts if contacts 16-17

and 18-19 are closed.

Page 9

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

9.2 Secondary functions

9.2.1 Enable/stop (post-cleaning)

The input (terminal 19) enables valve activation (terminals

18 + 19 are jumpered).

•Set the number of post-cleaning cycles with the

post-cleaning potentiometer.

The closed contact opens.

An automatic post-cleaning process starts with an

interval time of 30 s.

0

12

11

1

10

2

3

4

5

6

9

8

7

Fig. 17: Post-cleaning potentiometer

9.2.2 Rapid cleaning

•Close the switching contact (terminals 18 and 20).

A cleaning process starts with an interval time of 8 s.

9.2.3 Fault acknowledgement

If a fault occurs, the red fault LED lights up.

•Find the fault.

•Rectify the fault.

•Acknowledge the fault by applying a momentary contact

signal at terminals 18 and 21.

The fault signal is reset.

Fig. 18: Fault

9.2.4 Pressure switch

The pressure switch settings are not

supported. The pressure switch jumper on the

XS1 switch should always be down.

Fig. 19: Jumper settings for pressure switch

9.2.5 Cleaning signal

The yellow cleaning LED lights up during a cleaning

process.

The yellow cleaning LED lights up if the test button S1

is pressed.

The yellow cleaning LED goes out again at the end of

the cleaning process.

Fig. 20: Cleaning

Page 10

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

9.2.6 Alarm threshold

•Set the alarm threshold with the alarm potentiometer.

The red alarm LED lights up if the alarm threshold is

exceeded.

The alarm relay is switched.

Fig. 21: Alarm threshold and alarm LED

10 Installation

DANGER!

The system is only allowed to be installed,

accepted and tested by a suitably qualified

person (99/98/EC).

WARNING!

All installation work must be carried out by suitably

qualified personnel!

10.1 Unpacking

WARNING!

Risk of damage to the unit!

Safe operation can be impaired.

•Inspect the MFS-05 ∆P for damage. Return to FG for

maintenance if necessary.

•Remove the MFS-05 ∆p filter controller from the

packaging.

•Check the separately enclosed accessories (Instruction

Manual, fastening elements) for completeness.

10.2 Installation procedure

The controller must be installed in a dry, low-dust room.

The ambient temperature at the place of installation must

not exceed the maximum value specified in the data sheet

for the nominal range of use.

•Ensure adequate heat dissipation (especially if several

units are installed together with a high packing density).

•Provide the necessary sealing components (e.g. seals)

for the specified degree of protection.

10.3 Electrical connection

We recommend using twisted and screened

instrument lines to prevent interference from

interference fields.

•The electrical connection should correspond to the

connection/terminal diagrams for the unit concerned.

•All electrical wiring should be laid in accordance with the

relevant EMC specifications as well as any nationally

valid regulations (VDE 0100 in Germany).

•Instrument lines should be laid separately from signal

and power leads.

•The protective conductor terminal (inside the instrument

rack) must be connected to a protective earth conductor.

•Install a suitable main switch.

10.4 Start-up

Check the following points before switching on the unit:

•The supply voltage must be identical the voltage

indicated on the nameplate.

•The contact protection covers must be fitted.

•The unit is only allowed to be operated when installed.

Class I units:

•The protective conductor terminal inside the instrument

rack must be conductively connected to the protective

earth conductor.

If the unit is interconnected with other units and/or

equipment, the possible consequences should be

considered before it is switched on and appropriate

precautions taken.

11 Shut-down

•Switch off the auxiliary power.

•Protect the unit against inadvertent operation.

If the unit is interconnected with other units and/or

equipment, the possible consequences should be

considered before it is switched on and appropriate

precautions taken.

•Either switch off the system with the motor

circuit-breaker or shut it down on the machine controller.

•All parts must be disposed of in a

manner which does not pollute the

environment.

Emergency shut-down

•Switch OFF the main switch.

The power supply is interrupted.

Page 11

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

12 Normal operation

The green ‘operation’ LED lights up when the unit is

switched on.

The unit is now ready.

Fig. 22: Operation LED

•The yellow LED lights up if the differential pressure

is > 5% (> approx. 2 mbar) and the valves are

activated.

The controller is active.

13 Troubleshooting

13.1 Test

•Press the S1 test button in the top right-hand corner of

the controller to switch the valves.

•A settable differential pressure must be supplied for the

duration of the test.

Alternatively:

•Test the controller in “time control” mode

(terminals 16-17 and 18-19 jumpered).

13.2 Troubleshooting table

Fault

Possible cause

Remedy

Green

‘operation’

LED not lit

Power supply

faulty

Test the voltage

Fuse F1 defective

Replace the fuse

Yellow

LED not lit

No start signal

Check the differential

pressure

No signal enable

18-19 jumpered

Jumper XS1 set

incorrectly

Check the jumper

settings

Both red

valve

LEDs blink

Valve

potentiometer

inadvertently

altered

Set the potentiometer

correctly

One red

LED blinks

Valve not switched

Test the valve cable

Potentiometer set

incorrectly

Potentiometer setting =

no. of valves

Red LED

lit

Valve not activated

Test the valve

connection

Acknowledge the fault

Terminal 18 + 21

Red LED

row blinks

Post-cleaning

potentiometer

inadvertently

altered

Set the post-cleaning

potentiometer correctly

Page 12

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

14 Maintenance, repair and retrofitting

CAUTION!

Danger if work is carried out on the system by

unauthorised persons!

Risk of injury.

•All maintenance work must be carried out by

SUITABLY QUALIFIED PERSONNEL.

The filter controller does not require any special

maintenance.

CAUTION!

Electrostatic discharge

Components which are sensitive to

electrostatic discharge (ESD) may be

exposed when the units are opened.

•In this case, all subsequent work is only

allowed to be carried out at workplaces

that are protected against electrostatic

discharge.

During retrofitting:

If the unit is tampered with during the

warranty period, all warranty claims

are rendered invalid.

•Switch off the filter controller.

•Take steps to prevent the system from being switched

on again by unauthorised persons.

•Take any necessary safety precautions

•Carry out the maintenance work.

•Start up the filter controller again.

•Observe the filter controller.

Does it operate normally?

•Check whether any of the values indicated on the

nameplate need to be altered/corrected.

•Correct this data if necessary.

If a fuse blows:

•Determine and rectify the cause.

•Install a replacement fuse with the same ratings as the

original fuse.

•The use of rewired fuses is prohibited, as is short-

circuiting the fuse holder.

•

•

Page 13

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

15 Appendix: Connection variants

15.1 Interval time and switching threshold control

Page 14

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

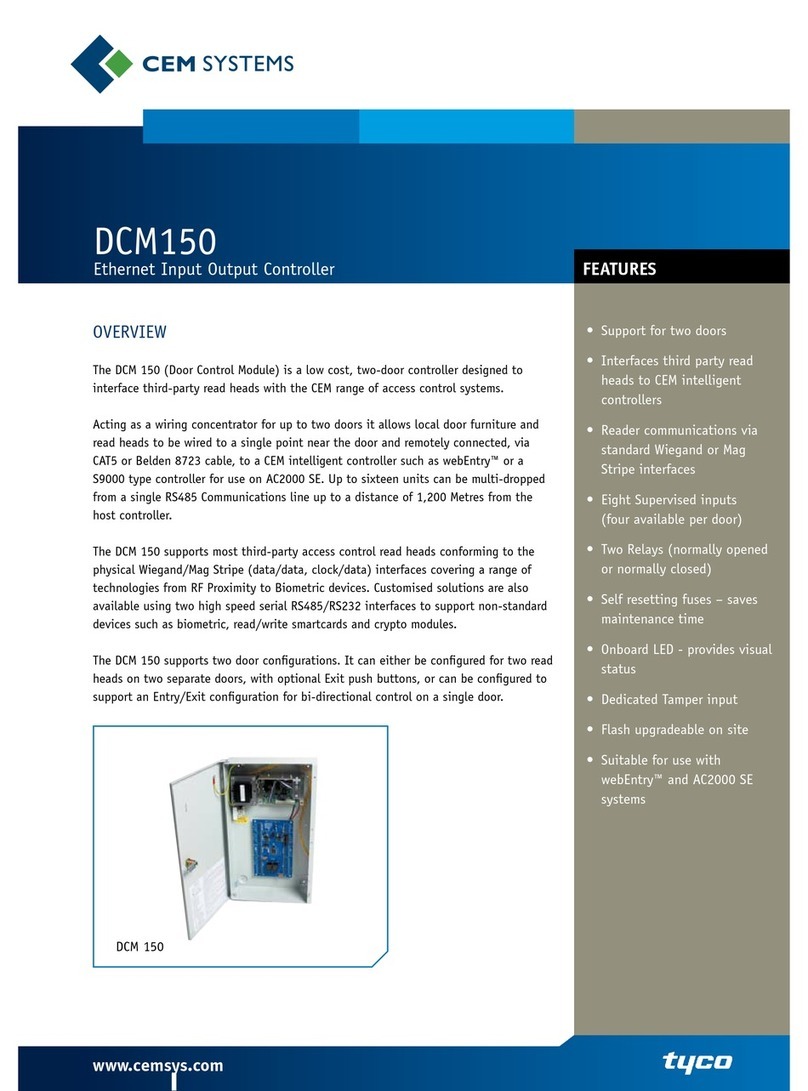

15.2 Terminal assignment

123

12316 17 18 19 20 21 22 23 24

45678910 11 12 13 14 15

25 26 27 28 29 30 31 32 33 34 35 36

42 43 44 45 46 47 48 49 50 51 52 53

54 55 56 57 58 59 60 61 62 63 64 65

37 38 39 40 41 66 67 68 69 70

B

RS 485

+-+-+-+ - + - + -

+-+-+-+ - +-+ -

+ - +-+-+-+ - +-

+ - + - +-+ - + - +-

+-+-

PE

24 V DC

230 V DC

Valve extension

A

Lag/Discharge Δp Alert

25 mA

Start

GND (-DP-In)

Release/Stop/

Post-cleaning

0(4)...20 mA

Output

Rapid-cleaning

Malfunction

acknowledgement

+: common potential

-: switched output

Valve 1 Valve 2Valve 3Valve 4Valve 5Valve 6

Valve 7

Valve 13

Valve 19

Valve 8

Valve 14

Valve 20

Valve 9

Valve 15

Valve 21

Valve 10

Valve 16

Valve 22

Valve 11

Valve 17

Valve 23

Valve 12

Valve 18

Valve 24

Malfunction/

operation

Page 15

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

16 Appendix: RS 485 serial port

The controller has an RS 485 serial port that can be used to query the current unit settings on a PC, for example.

Data format:

1 start bit, 8 data bits, no parity, 1 stop bit

Baud rate:

19200 baud

Protocol:

The data is queried by sending one byte (‘A’, ‘B’, etc.) to the controller. The controller responds with one

word (16 bits). This response must be converted to the appropriate measurement unit by the PC.

Connection:

Terminal 69: RS 485 B

Terminal 70: RS 485 A

Query Response Calculation Unit Comments

20 mA input

“A” 65 hex

0-1020

x / 45

mA

Start input

Configuration

“B” 66 hex

0-1020

Not possible, see program version

Configuration 2

“C” 67 hex

0-1020

Not possible, see program version

Pulse

“D” 68 hex

0-1020

(((x div 4)² div 44) * 2 +100) / 1000

s

Interval

(potentiometer)

“E” 69 hex

0-1020

(((x div 4)² div 64) +10) / 2

s

Valves

“F” 70 hex

0-1020

(x+46) / 92 + 0.5

Post-cleaning

“G” 71 hex

0-1020

((x div 4)² div 53) / 10

min.

<1 minute = off

Lag time

“H” 72 hex

0-1020

∆p

“I” 73 hex

0-1020

X/204

V

0 ... 5 V = measuring

range

Inputs

“J” 74 hex

0-31

2^0 = Enable

2^1 = Rapid cleaning

2^2 = Fault acknowledgement

2^3 = Pressure switch

2^4 = Test button

Program

version

“K” 75 hex

16000

(x div 32) / 100 + 45

2^0 = 4 mA

2^1 = Pressure switch

2^2 = Pressure switch version

2^3 = Full cycle

2^4 = Controller

Current interval

time

“L” 76 hex

20-2052

x / 4

s

Valve alarm

“M” 77 hex

0-248

2^0-2^4 = Valve

2^5 = Interruption

2^6 = Overcurrent

2^7 = Pressure monitoring

Alarm threshold

“N” 78 hex

High threshold

“O” 79 hex

Low threshold

“P” 80 hex

Display

selection

“Q” 81 hex

Δ p measuring

range

“R” 82 hex

Δ p reference

“S” 83 hex

Δ p da

“T” 84 hex

Other

characters

32000

Unknown query

div = Integer division with no remainder

Page 16

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

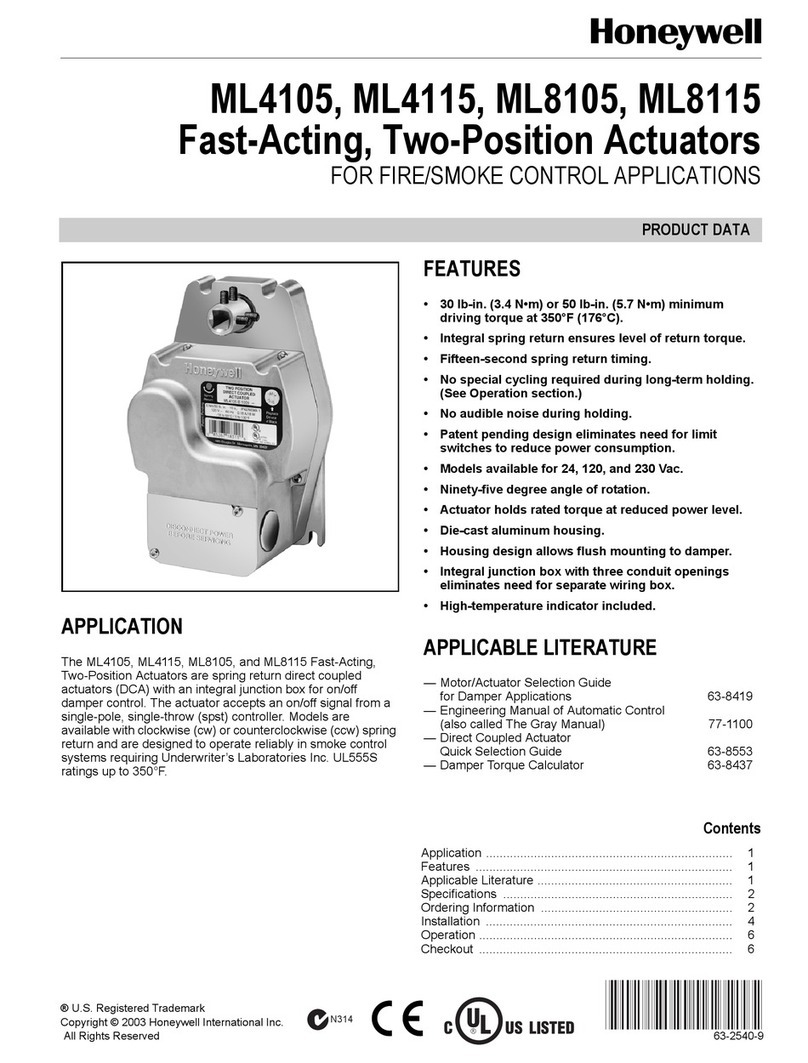

17 Appendix: Set of instrument lines and protective filter (ID No. 78341984)

To measure the differential pressure:

•Connect the sensor to the measuring points upstream and downstream of the filter plate using the instrument lines.

•The instrument lines should be protected and laid without any kinks.

•No condensate must be allowed to accumulate on the instrument lines. Provide a condensate trap if necessary.

•No dust protection is necessary for the cleaned gas line.

Leaking or dirty lines can lead to measurement errors and malfunctions.

Fig. 23: Installation drawing and spare parts

Elbow bulkhead screw

fitting for hose

OD 6 mm

77974413

Instrument line

Hose PU/4 black

78238248

Screw-on connection

G 1/4“

77940166

Sealing ring PVDF

76141188

Filter plate

Hole ∅13.5 mm

Casing

Hole 2 x Ø14 mm

Nipple G 1/4"

78342024

Membrane filter Ti 56

Bottom side coated

78342032

Snap ring

15x1 DIN 472 1.4310

77749500

+

-

Page 17

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

18 Appendix: Dimension drawing MFS-05 Δp

Fig. 24: Connection diagram for optional pressure switch

Page 18

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

19 Appendix: Default settings

19.1 Main parameters of the MFS-05 Δp in “interval time control” mode

Parameter

Comments

Factory setting

Operation

No. of valves Refer to section 6 for information about settings N

Interval potentiometer Controller characteristic, section 10.9 60

Pulse time Pressure cleaning

Rotating wing 0.1 s

1.5 s

Post-cleaning cycles 0

Alarm threshold 18 mbar

Terminal assignment See circuit diagram Jumper 18-19

Jumper settings Schw./Reg. jumper Up

T/G Cycle jumper Up

19.2 Other operating modes

19.2.1 “Switching threshold” mode

Parameter

Comments

Factory setting

Operation

Jumper settings Schw./Reg. jumper Down

T/G Cycle jumper Up

High threshold 14 mbar

Cleaning cycles 1

Terminal assignment See circuit diagram Jumper 18-19

Jumper settings Schw./Reg. jumper Down

T/G Cycle jumper Up

19.2.2 “Time control” mode

Parameter

Comments

Factory setting

Operation

Terminal assignment Terminals 16-17 and 18-19 jumpered

Interval time 600 divided by the number of valves n xx

Jumper settings Schw./Reg. jumper Down

T/G Cycle jumper Up

Page 19

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

20 Declaration of incorporation

As defined by the EC Machinery Directive.

Page 20

Translation of the original instructions MFS-05 Δp, Filtration Group GmbH, 16.01.18, Mat. No. 70303409, Version 03

21 Declaration of conformity

Table of contents