English

1 INTRODUCTION

This introduction booklet explains the different functions of the 60 software compared to the 54 software.

The main changes in the software affect operation when the BRAVO 3XX computer is set as a multi-row

sprayer or orchard sprayer.

1.1 New functions

The main changes are:

• Setting the minimum and maximum nozzle pressure alarms (section 2.1):

the minimum and maximum pressures can be set for correct operation of each nozzle: the computer will

trigger an alarm signal outside these limits.

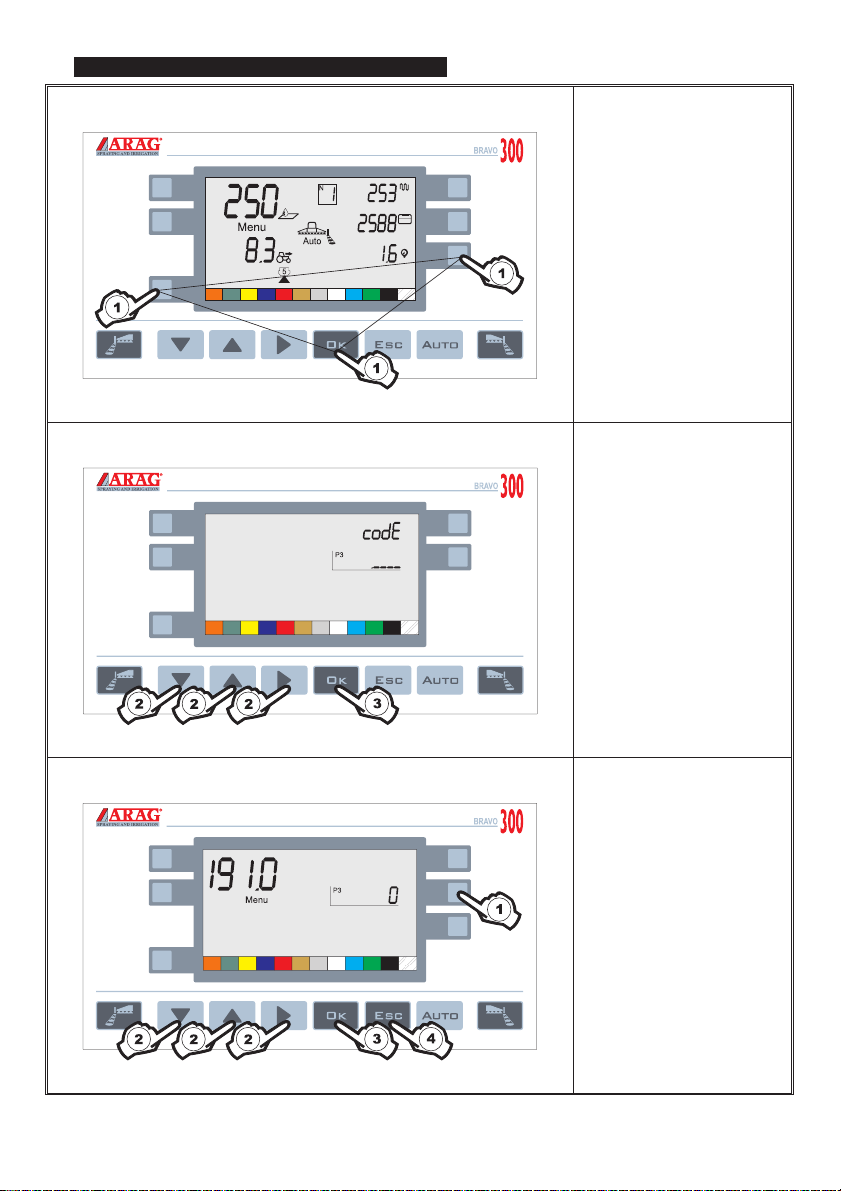

• Setting the minimum speed for adjustment (Menu 191.0 section 2.3):

It is possible to set a minimum speed so that automatic adjustment will not triggered below it.

This makes it possible to remain within a range of pressure so that the nozzles always provide effective

coverage.

IATTENTION: below this speed, dosing no longer corresponds to the preset amount

•Setting the minimum speed for the automatic closure of the main valve

(Menu 191.0 - 192.1 section 2.4):

it is possible to set a speed so that the main valve will be closed automatically below this (only for

systems with separated unit, item code 46732XX)

IATTENTION: this function AUTOMATICALLY excludes the setting of the minimum adju

-

stment speed (Menu 191.0 section 2.3)

•Incorrect operating pressure signal (section 2.2):

the computer triggers an alarm signal when the nozzle operating pressure does not correspond to the

preset level.

• Calibration of 0 for the pressure transducer (section 2.5):

the reading of 0 of the pressure transducer can be calibrated, if necessary.

• Resetting the liquid present in the tank (section 2.6):

the quantity of liquid in the tank can be reset rapidly.

• Display of the "FIELD 0" counters (section 2.7):

it is possible to display the data with more than 4 or 5 digits relating to field 0 (field can not be reset).

•Pump failure signal (section 2.8):

when the sensor signals pump failure, the computer triggers a visual and acoustic alarm signal.

4