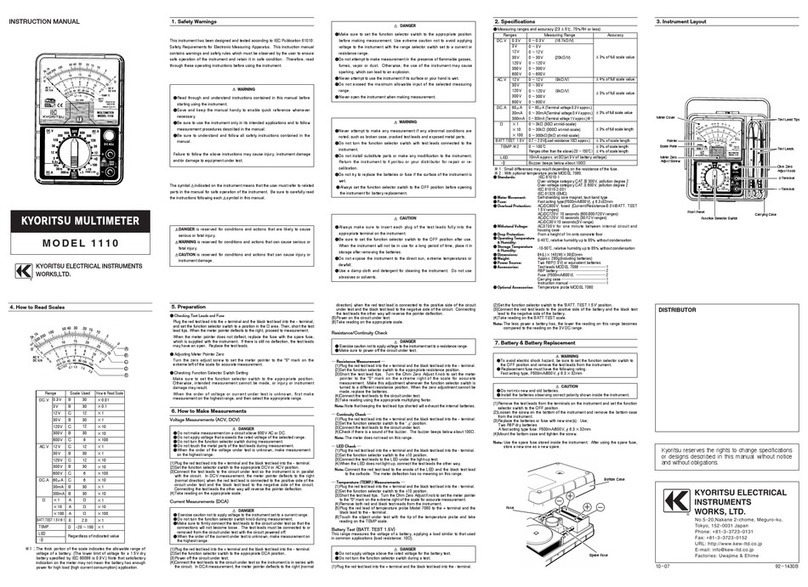

FINE INSTRUMENTS CORPORATION FINEST 716 User manual

Model 716

Automotive Multimeter

USER’S

MANUAL

FINE INSTRUMENTS CORPORATION

FINE INSTRUMENTS CORPORATION

341-5, SONGNAE-DONG, SOSA-GU, BUCHON-SHI, KYUNGGI-DO

KOREA

-TEL: (82-32) 668-6042 -FAX: (82-32) 656-5844

-E-mail: [email protected]

© Copyright 2003 Fine Instruments Corp. All right reserved.

Specifications subject to change without notice.

Litho in Korea.

a world leader in test & measurement

1

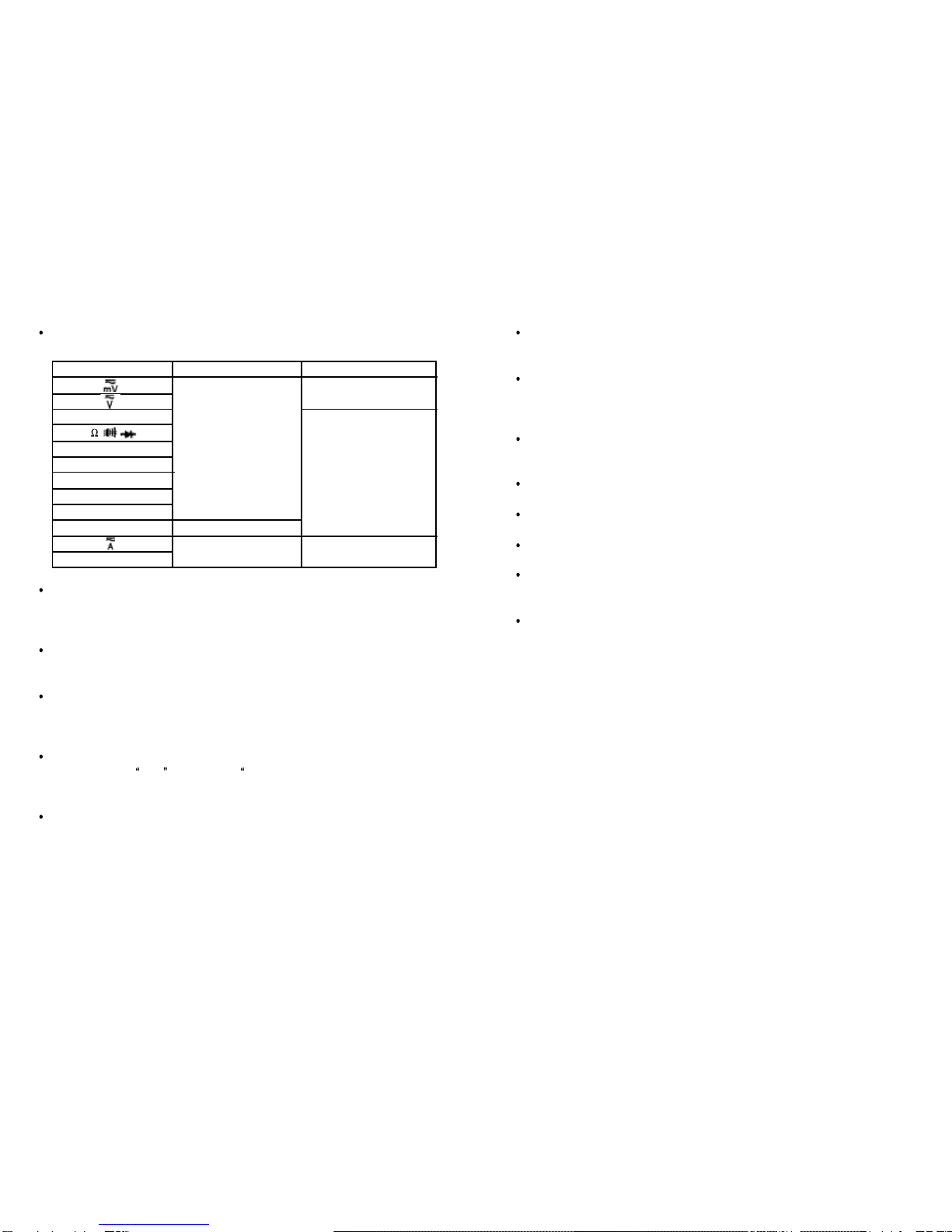

Basic Specifications

DC Voltage : 0 to 1000 V

AC Voltage : 0 to 1000 V (40 Hz to 2 kHz)

Basic Accuracy : DC voltage – 0.1 %

AC voltage – 0.5 %

RPM (4-stroke) : 120 to 20000 RPM

RPM (DIS & 2-stroke) : 60 to 10000 RPM

DC Current : 0 to 10 A (20 A for 30 seconds)

AC Current : 0 to 10 A (20 A for 30 seconds)

Resistance : 0 to 50 M

Frequency : 0.5 Hz to 1 MHz

Duty Cycle : 0 to 99.9 %

Dwell : 0 to 356.4

Pulse Width : 0.50 ms to 250.00 ms

Diode Test : 3.0 V

Temperature : – 50 C to 1,300 C (– 58 F to 2,372 F)

Audible Continuity Test : For quick open-short test

O

2

Sensor Test : For qu

i

ck a nd accu rat e d

i

a gno sin g a nd

simulating O

2

sensors

Ground Test : For

l

oca t

i

n g ba d gr oun ds, vol tag e dr op s,

intermittent connections or any source of high

resistance in automotive electrical circuits and

grounds

Charging System Test : For diagnosing battery and alternator

Battery Drain Test :

For measuring the car’s battery current when it is

turned off.

SOURCES LIKE SMALL HAND-HELD RADIO

TR ANSCEI VERS, FIXED STA TION RA DI O

AND TELEVISION TRANSMITTERS, VEHICLE

RA DIO TR ANSM IT TERS AND CEL LUL AR

PHONES GENERATE ELECTROMAGNETIC

RADIATION THAT MAY INDUCE VOLTAGES

IN THE TEST LEADS OF THE MULTIMETER.

IN SU CH CASES THE ACCURA CY OF T HE

MULT IMETER C ANNOT BE G UARAN TEED

DUE TO PHYSICAL REASONS.

WARNING!

Warning

Read

¡°

Safety Information” before using this Meter.

32

This manual contains information and warnings that must be followed for operating

the meter safely and maintaining the meter in a safe operating condition.

If

the meter is not used in a manner specified in this manual,

the pro

t

ection

provided by the meter may be impaired.

This meter complies

with the requirements for double insulation

t

o IEC 1010-1 (2001),

UL 3111-1 (6, 1994), EN 3121-1

(1998), CSA C

22.2

No.

1010-1-92 ; Overvoltage

1000 V

Category II and also the E.M.C.

standards to EN61326 : 1997+A

1

.

TERMS IN THIS MANUAL

A

Warning

identifies conditions and actions that could pose serious hazards to the

user. A Caution identifies conditions and

actions that could cause damage

the

meter or the vehicle under test. Notes are added to provide clarity and helpful tips.

INTERNATIONAL ELECTRICAL SYMBOLS

AC (Alternating Current)

DC (Direct Current)

Either DC or AC

Caution! Refer to the explanation in the manual.

Dangerous voltage (Risk of electric shock)

Earth (Ground)

Double insulation or Reinforced insulation

Fuse

Battery

1. SAFETY INFORMATION

1. Safety Information 3

2. Introduction 6

3. Controls and Indicators 8

4. Basic Meter Functions 12

4-1. Voltage (V) 13

4-2. Dual Display RPM 14

4-3. Temperature 15

4-4. Resistance ( ) 16

4-5. Continuity ( ) 17

4-6. Diode test ( ) 18

4-7. Frequency 19

4-8. RPM 20

4-9. Fuel Injection On Time 21

4-10.Dwell 22

4-11.Duty Cycle 23

4-12.Charging System Test 24

4-13.Ground Test 26

4-14.O2 Sensor Test 28

4-15.AC or DC Current ( ) 30

4-16.Battery Drain Test 31

5. Advanced Features 32

5-1. MIN/MAX Mode 32

5-2. 1 ms Peak Mode 32

5-3. Manual and Auto Ranging 33

5-4. Trigger Level and +/- Trigger Slope Selection 33

5-5. RPM Selection 34

5-6. Relative Mode 34

5-7. Hold or Auto Hold 34

5-8. Memory (Data Store, Recall, & Clear) Mode 35

5-9. Backlight 36

5-10.Auto-Power-Off 36

5-11.RS-232C Interface 37

6. Maintenance and Replaceable Parts 38

7. Specifications 40

CONTENTS

4 5

WARNING

To avoid electrical shock hazard or damage to the meter, do not exceed the input

limits shown in the table below :

Observe the proper safety precautions when working with voltages above 60 V

DC or 25 V AC rms to avoid an elec

t

rical shock. These voltage levels pose

a

potential shock hazard to the user.

Wear an

ANSI

eye shield when testing or repairing vehicles. Objects can be

propelled by whirling engine components.

Inspect

test leads,

connectors, and probes for damaged insulation or exposed

metal before using the instrument. If any de

f

ects are found, replace

them

immediately.

Never attempt a voltage measurement with the test leads inserted into the “A”

terminal and the

COM terminal. The A” terminal is protected by a

f

use. You

might be injured or damage the meter.

Turn the engine off before connecting or disconnecting inductive pickup to avoid

a shock.

FUNCTION

Temperature

Hz

ms-Pulse

Dwell

Duty Cycle

Elec, O

2

RPM

Battery Drain

TERMINALS

& COM

RPM + & -

A & COM

MAXIMUM INPUT

1000 V DC or 1000 Vpeak

600 V DC or

600 V AC rms

10 A / 600 V

VWHzms

Elec Temp

CAUTION

Disconnect the test leads from the test points before changing functions to avoid

damaging the meter when testing above 350 V AC.

Choose the proper range and function for the measurement

.

Always set

t

he

meter to the highest range and work downward for an unknown value if you are

using manual ranging mode.

Do not try voltage or current measurements that may exceed the ratings marked

on the input limit for switch or terminal.

Use current probes to measure circuits exceeding 10 A.

Disconnect the “live” test lead before disconnecting the “common” test lead.

Do not test a recently recharged lead-acid battery.

Disconnect the power and discharge all high-voltage capacitors before testing in

the resistance, continuity, and diode functions.

If the engine has been running, do not place the meter and its accessories near

the engine

or

t

he exhaust manifold which might be hot and can

damage the

meter.

76

This meter is a handheld and battery operated professional automotive multimeter

des igned to provide

troubles hooting solutions

t

o the most dif

f

icul t problems

encountered with today’s sophisticated automotive electronic systems.

The User’s Manual tells you how to use this meter. You may also need a manual

that provides technical information for the vehicle you

plan to

test. The

most

important information resources are the vehicle’s repair service manuals generally

available for purchase through automotive dealers. They are also available through

a number of publishers that specialize in providing technical information manuals to

the independent repair garages.

This User’s Manual should be used as a guide to get you started in troubleshooting.

Your real learning can best be accomplished through experience. As you become

more proficient in using the automotive multimeters to

t

roubleshoo

t

, you will very

quickly learn how certain

electrical symptoms can relate

to various driveability

problems.

This meter is much more than a standard multimeter. This meter can replace the

following several automotive testers.

Full Function Multimeter

O

2

-Sensor Tester

(PFI type or TBI type) Fuel Injector Tester

Battery Drain Tester

Ground Tester

Charging System Tester

Especially, this me

t

er

gets a

quick

and accura

t

e diagnosis of the complete O

2

circuit. This me

t

er is capable of

sending

a Rich/Lean

signal to the ECM, and

displaying crossing-per-second (CC) and O

2

voltage simultaneously,

when the

secondary display shows test results.

This meter has a bright LED backlight as well as enhanced LCD with larger digits,

wide viewing angle and on screen menu selection

.

A ba

t

tery access door allows

us er s to replace the battery and fus e

wit hout v oiding c al ibrat ion seals .

Overmoulding technology in the case disperses various shock over more of the

case than a conventional rubber boot design. Convenient closed case calibration

allows adjustments to be made directly through the RS-232C port.

2. INTRODUCTION

FEATURES

4

4

/

5

digit, 50000 count (primary) and 9999 count (secondary) dual display with

bar-graph. (Frequency range : 99999 counts)

Closed case calibration through the phototronic RS-232C serial port.

Accurate RPM measurements for 2- and 4-stroke automotive engines with 1 to

12 Cylinders using the Inductive Pickup.

ms-Pulse Width function to test on-time of both

P

FI

t

ype and TBI type

fuel

injectors, idle air control motors, and electronic transmission controls.

Du

t

y

Cycle and direct

DWELL reading for electronic fuel injection,

feedback

carburetors, and ignition systems.

4 steps

adjustable

triggers on 1 to 12 Cylinders,

ei ther 2- or 4-Cycl e for

outboards, motorcycles and conventional engines.

Measure

temperature of

fan switch and

catalytic converters up to 2,372 F

(1,300 C).

O

2

Sensor test for a quick diagnosis and simulation of the complete O

2

Sensor.

Ground test to locate bad ground, voltage drops, intermittent connections, or any

source of high resistance in automotive electrical circuits and grounds.

Charging system test to diagnose the battery and the alternator.

Battery drain test to measure the car’s battery current when it is turned off.

Auto Hold, 50 ms highspeed MIN/MAX/AVG, and Relative mode.

1 ms Peak mode.

Memory store and recall (20 locations).

Backlit display.

Auto-power-off.

RS-232C phototronic serial port.

Overmoulded case.

IEC 1010-1, CAT II 1000 V rating.

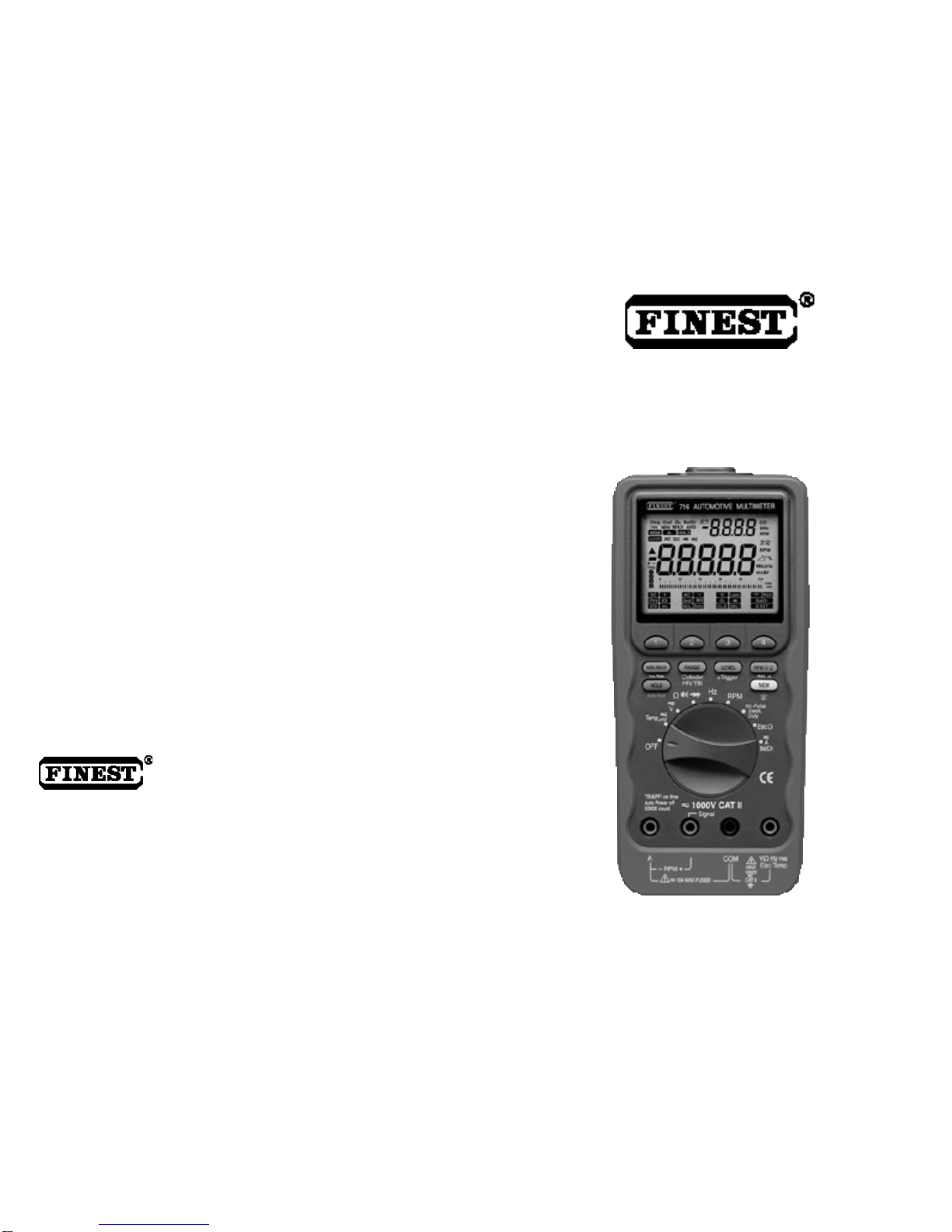

98

1. LCD display 4

4

/

5

digit, 50000 count (primary) and 9999 count (secondary)

dual display with bar-graph

2. On screen menu selection pushbuttons

3. Press this pushbutton momentarily to select

trigger lev els.

Pres s this pushbutton for more

t

han 1 second to toggle

between positive and negative trigger slopes.

4. Press this pushbutton momentarily to toggle between RPM

and RPM in RPM function. Press this pushbutton for more

than 1 second to select Relative Zero.

5. Press

this

pushbutton momentarily

t

o select Memory mode.

Press this pushbutton for more than 1 second to turn the LCD

backlight on.

6. Selector Turn the power On or Off and select a functions.

7. COM Common (Ground re

f

erence) input

t

erminal for all

functions

except RPM function

8. Input terminal for all

f

unctions except Current and

RPM

functions

9. Input

t

erminal (+)

for

RPM function. Output terminal for

s ending

out a Rich c ommand or a Lean c ommand for 5

seconds in O

2

Sensor test mode.

10. A/RPM- Input terminal (+)

f

or current

f

unction. Ground reference

(-)

input terminal for RPM function.

11. Press this pushbutton momentarily

to ac tivate

HOLD for

simply freezing a reading.

Press this pushbutton for more than 1 second to activate Auto

Hold for automatically capturing a stable reading, beeping to

acknowledge, and holding it on the LCD.

12. Press this pushbutton momentarily to activate Record function.

Press this pushbutton for more than 1 second to activate 1 ms

Peak function.

3. CONTROLS AND INDICATORS

14

1

2

3

4

5

6

7

8

13

12

11

10

9

V Hz ms

Elec Temp

RPM + /

Signal

13.

P

ress this pushbut

t

on momentarily to

selec

t

ranges in the

manual ranging mode of most functions or number of cylinders

on Dwell function. Press this pushbutton momentarily to toggle

between the PFI mode and the TBI mode when measuring on-

time of fuel injectors.

Press this pushbutton

f

or more than 1 second to toggle

Auto/Manual ranging in most functions.

14. RS-232 Optical interface

15. Menu on screen

16. These annunciators indicate trigger level status.

17. These annunciators indica

t

e that positive (+) or

negative (-)

Trigger Slope is selected.

18. This symbol indicates Negative Polarity.

19.

This symbol indicates the Relative function is activated.

20. DATA Primary digital readings of data being measured.

21. This annunciator indicates Autoranging.

22. AC DC AC annunciator indicates alternating current is selected.

DC annunciator indicates direct current is selected.

23. This annunciator indicates the Memory function is activated.

24. annunciator indicates the HOLD functions is selected

and annuncia

t

ors indicate the Auto

Hold

f

unction

is selected.

25. 1 ms MAX MIN These annunciators indicate 1 ms MAX (+) Peak, or 1 ms MIN

(-) Peak reading is being displayed.

26. MAX MIN AVG These annunciators indicate MAX (Maximum), MIN(Minimum),

or AVG(Average) reading is being displayed.

27. Chrg This annunciator indicates the Charging system test function is

selected.

28. Gnd This annunciator indicates the Ground test

function is

selected.

29. O

2

This annunciator indicates

t

he O

2

Sensor test function is

selected.

30. BatDr This annuncia

t

or

indicates the

Battery Drain

t

est function is

selected.

31. This symbol indicates the Diode test function is selected.

32. This symbol indicates the Continuity test function is selected.

33. Low Battery alert. Replace the battery as soon as possible to

ensure accuracy.

34. DATA Secondary display for Dual Display data.

35. CC... These annunciators indicate the function being selected and/or

the appropriate measurement units.

36. Analog bar-graph with scale.

10 11

+ –

TRIG

1312

Making Measurements and Tests

All measurements and tests are made by first setting the rotary selector switch to a

function setting (so that the meter is put in the default measurement function) and

then selecting a measurement from the menukeys. Note that not all function knob

settings have corresponding menukey settings.

For example, the steps below show how to make an ac voltage measurement.

1. Set the rotary selector switch to position for voltage measurements.

Then, the meter is set to the default dc voltage measurement mode.

2. Select the menukey 2 for ac voltage measurement.

3.

Connect the test leads to the measurement points.

4. BASIC METER FUNCTIONS

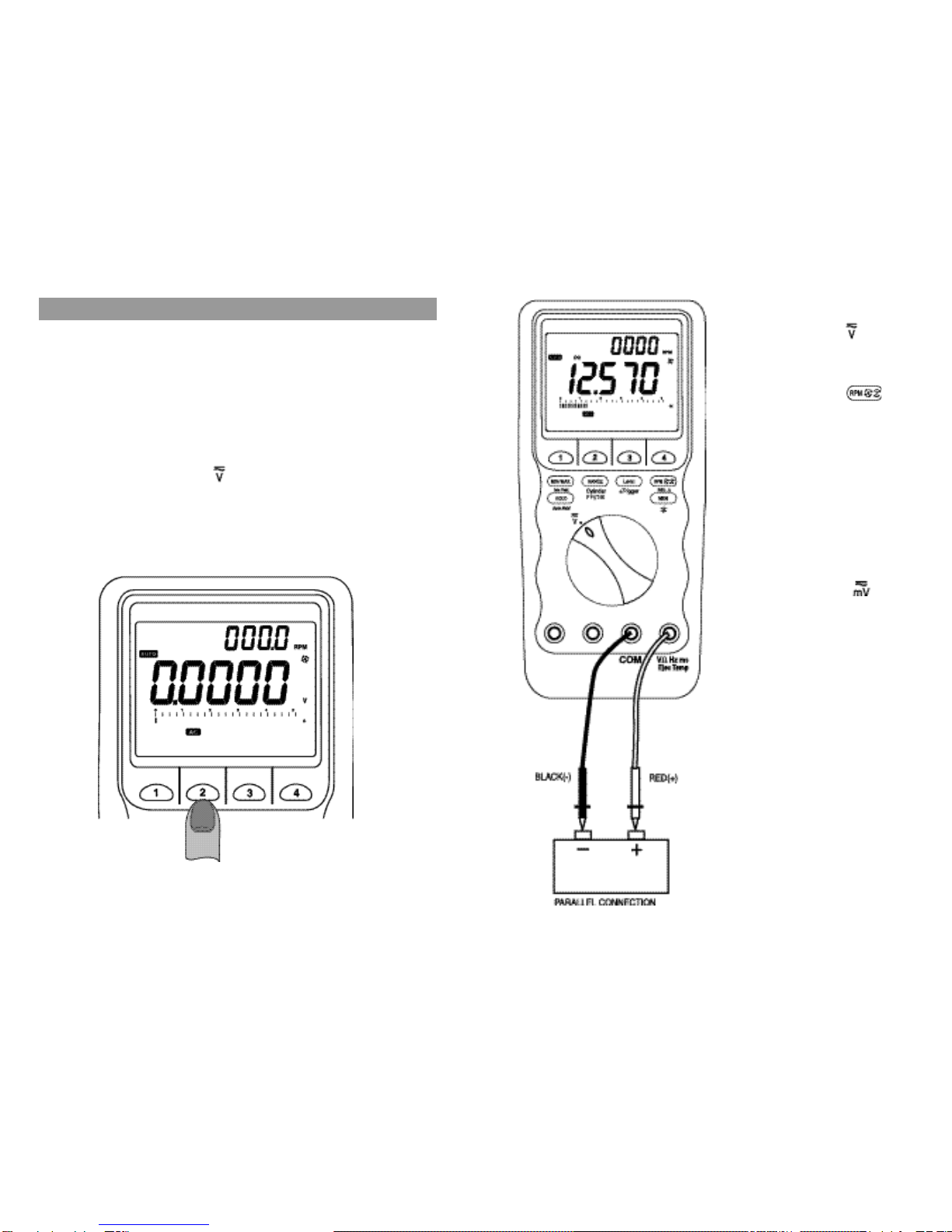

4-1. Voltage (V)

1. Set rotary selector to position.

The meter defaults at DC.

2. Press menukey

2 momen

t

arily to

select AC, and press twice

to sel ect H z in the secondary

display, if required.

3. Insert red lead into V terminal and

black lead into COM terminal.

4. Touch black probe to

ground

or

neg ativ e s ide

of the circ ui t and

touch red probe to positive side of

the circuit coming from the power

source.

5. Set rotary selector to

position

for voltage application below 0.4 V

with similar operation procedures.

6. Refer to 4-2 for c onvenient dual

display RPM function.

NOTE: Voltage must be measured

in p arallel (r ed prob e

measuring

circuit from

power source).

The analog bar graph is easier to read

when the da

t

a caus es the digi tal

display to

rapidly change.

It is al so

useful for trend setting

or direc tional

data.

1514

4-2. Dual Display RPM

T his function

i s avai lable

for the

primary functions ; DC mV, AC mV, DC

V, AC V, Dwell, ms-Pulse, and Duty

Cycle. The trigger level selection is not

available for this function, but available

for the primary display RPM function.

See 4-8 for more details.

1. Set the meter to the corresponding

primary function.

2. Press bu

t

ton to toggl e

between RPM (for 4-s

t

rok e

engine) and RPM

(for 2-stroke or

DIS engine).

3. Insert the Dual Banana Connector

into the RPM – and the R

P

M +

input terminals as shown. Ensure

the plug with the Ground Tab goes

into the RPM – terminal.

4. Clamp the induc

t

ive pi ckup to a

spark plug wire with the arrow sign

facing the spark plug as shown.

Ens ure

t

he pic kup

jaws ar e

completely closed.

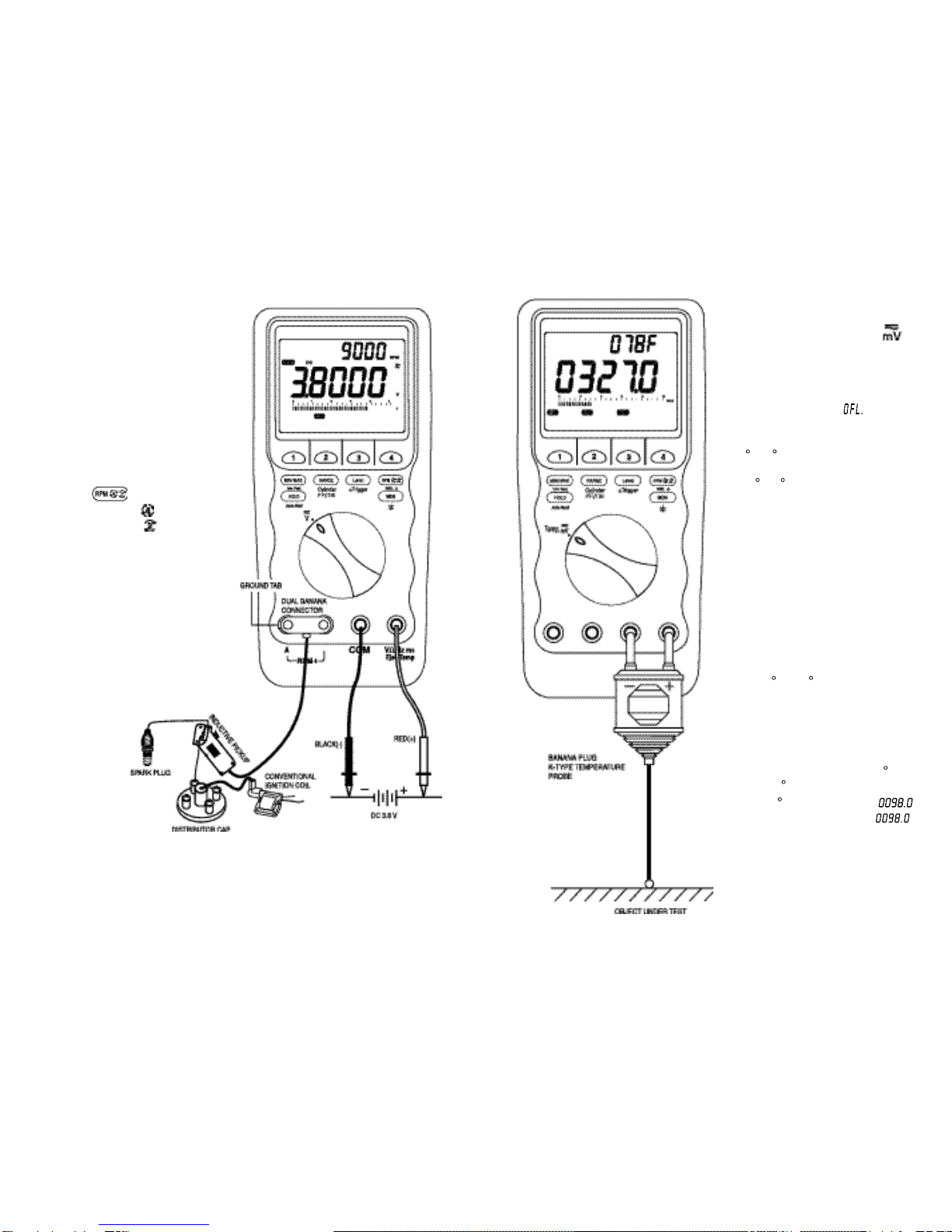

4-3. Temperature

1. Se

t

rotary selector to Temp.

position.

2. Pres s menukey

3(or 4) to select

temperature function. The

primary

displ ay wi ll show and t he

secondary display will always show

the meter’s internal temperature in

C or F alternatively matching with

the selected primary display mode

of C or F.

3.

I

ns e r

t

banana plug K- ty pe

temperature

bead probe w ith

correct + / - polarities. You can also

use a thermocouple probe adapter

(optional accessory) to adapt other

st andard K-t y pe t empera ture

probes.

4. Touch the end of the thermocouple

probe to the measurement surface

and read the primary digital display

wit h C (or F). We c an ea s ily

recognize the temperature uni

t

of

the pri ma ry dis play

f

rom the

secondary display.

NOTE: The measured temperature

is

displayed with 0.1 C (or

0.1 F) reso

l

ution.

For example,

98 C is displayed as

and 98 F is d

i

sp

l

ayed .

5. Read RPM in the secondary display.

NOTE:

Position the pickup as far away from the distributor and the exhaust

manifold as possible.

Pos

i

tion the pickup with

i

n 6 inches of the spark plug or move it to

another plug wire if no reading or an erratic reading is received.

1716

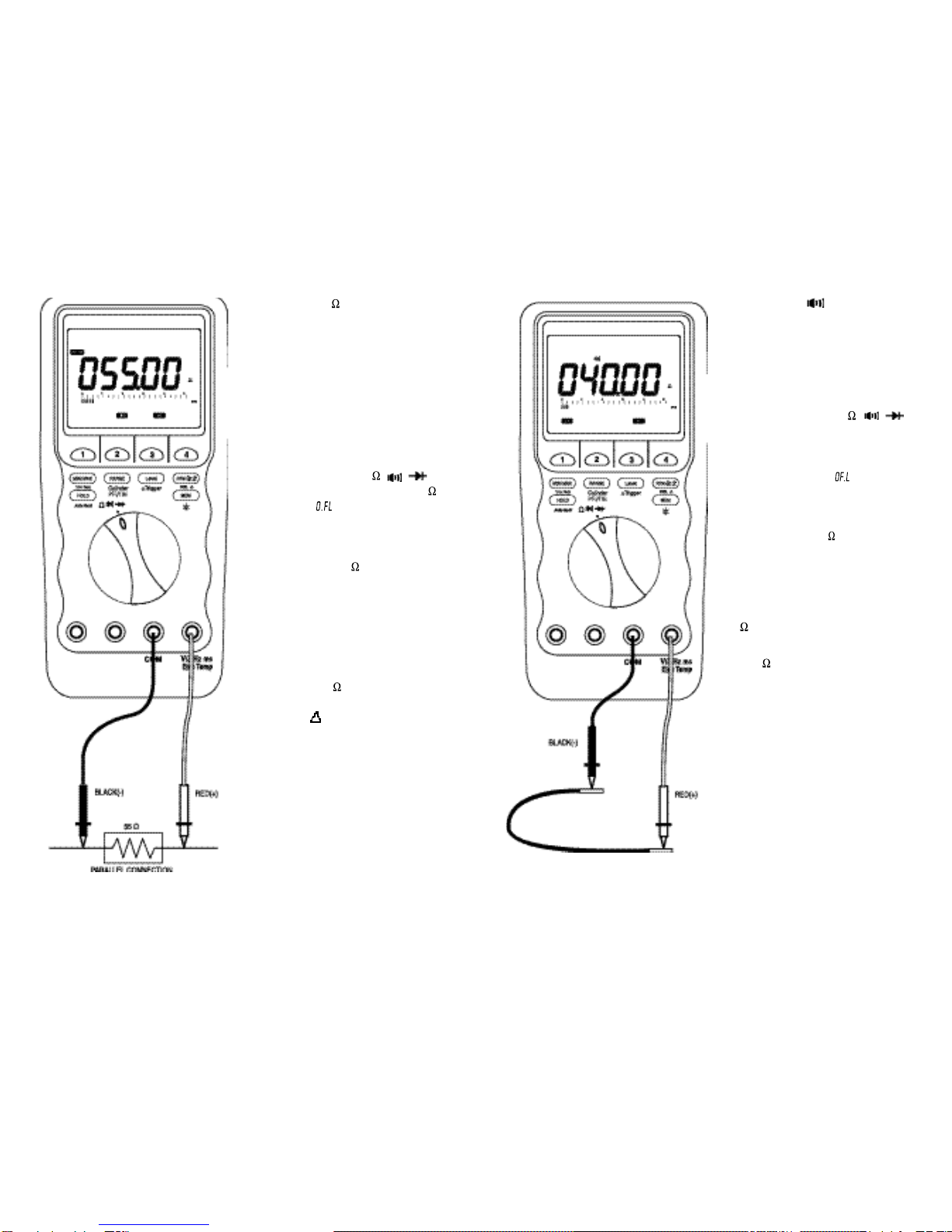

4-4. Resistance ( )

CAUTION

Tu rn off p ower and dischar ge all

capacitors on circuit to be tested

b efor e attem pting incircu it

resistance

measurements. Accurate

m easurem ent

i

s no t possible if

external o r r esidu a

l

voltage

is

present.

1. Set rotary selector

t

o

position. The me

t

er defaults at

function. is

dis played in the

primary display.

2. Insert black lead into COM terminal

and red lead into terminal.

3. Touch the test lead probes across

t

he resis

t

anc e or ci rcu it to be

tested.

NOTE: The res

i

stance in the test

leads can affect accuracy in

the 500 range.

S

hort

the

leads together and press the

REL

button to automatically

subt

r

act th e t est lead

resistance from

the measured

resistance.

4-5. Continuity ( )

CAUTION

Turn

th e pow er OF F on the t est

circuit. A beeper ton e do es not

necessarily mean zero resistance.

1. Set rotary selector to

position.

2. Pr ess menukey 2

to selec t

Continuity function. is displayed

in the primary display.

3. Insert black lead into COM terminal

and red lead into

terminal.

4. Touch the test lead probes across

the device being tested.

If the resistance of the device is below

70 , there is a continuous beep tone.

If the resistance of

the device

is more

than 70 , there is no beep tone.

This is us eful for c hec ki ng wiri ng

connections and operation of switches.

1918

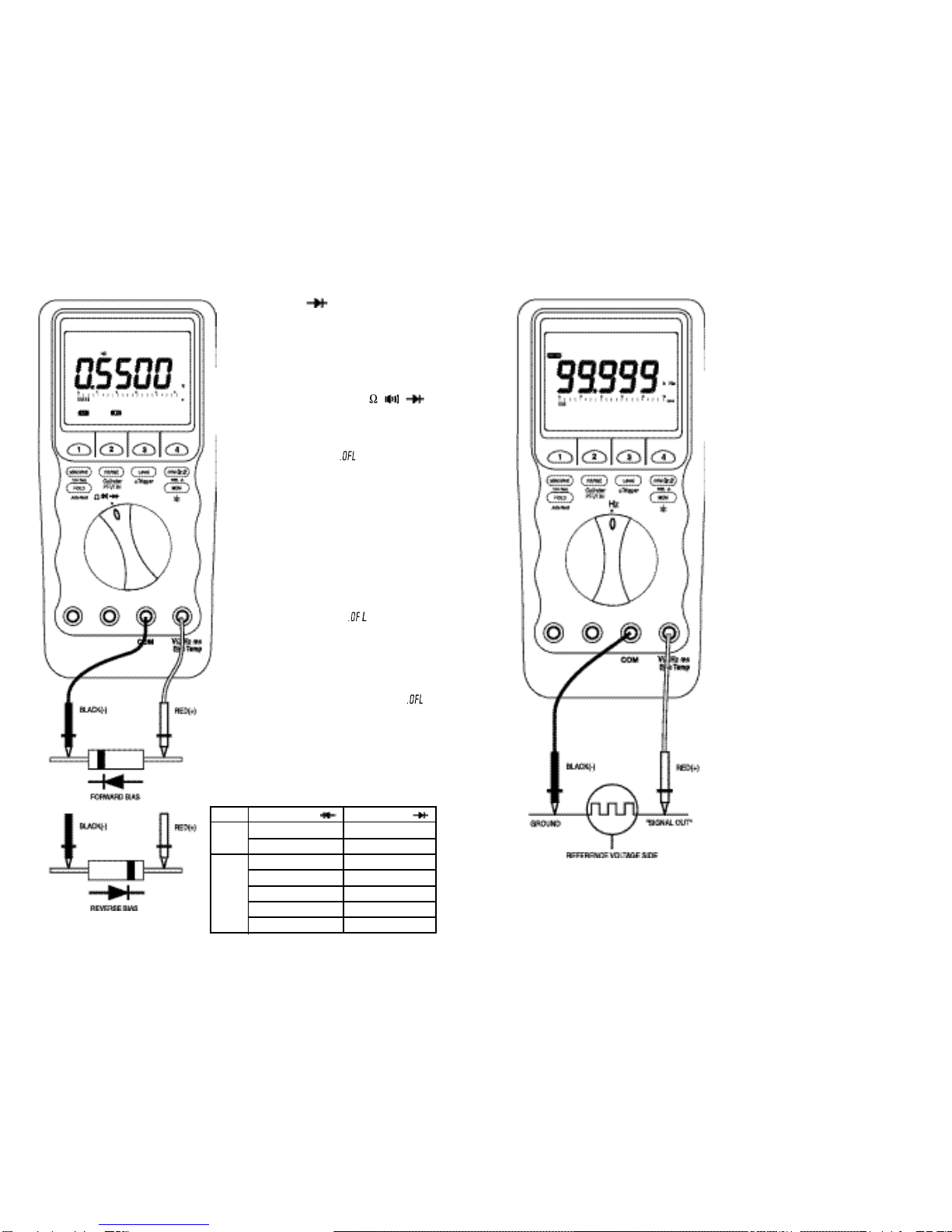

4-6. Diode ( ) Test

CAUTION

T urn th e pow er OFF on the test

circuit.

1. Set rotary selector to

position.

2. Press menukey 3

to select Diode

Test function. is

displayed in

the primary display.

3. Connect

t

he test

leads as shown

and observe the digital display.

Normal forward v oltage dr op

(forward biased) for a good silicon

diode is between 0.4 V to 0.9 V. A

reading higher than that indicates a

leak y d iode (def ec

t

i ve). A z ero

reading indicates a shorted diode

(defective). An

indicates an

open diode (defective).

4. Reverse the test leads connections

(reverse biased) across the diode.

5. The primary

display

shows if

the di ode

is good.

A

ny other

readi ngs i ndicate t he di ode is

resistive or shorted (defective).

Use the table below to determine if the

diode is Good or Bad.

4-7. Frequency

1. Set rotary selector to Hz position.

2. Insert black lead into COM terminal

and read lead into Hz terminal.

3. Touch black probe

t

o ground and

touch red probe to the “Signal out”

wire on the sensor.

FORWARD BIAS( )

0.4 to 0.9 V

OFL

OFL

1.0 to 3.0 V

0.4 to 0.9 V

OFL

0.0000 V

REVERSE BIAS( )

OFL

0.4 to 0.9 V

1.0 to 3.0 V

OFL

0.4 to 0.9 V

OFL

0.0000 V

DIODE

Good

Bad

2120

4-8. RPM (primary display)

WARNING

Be su

r

e the inductive pickup is in

t he te

r

m in als m a

r

ke d “ - RP M +”

w

hen m easu

r

in g RPM’s. If th e

p ickup is in th e

w

r

ong te

r

minal,

p e

r

son al inju

r

y o

r

m ete

r

dam ag e

may occur.

The ignition system can gene

r

ate a

potential shock haza

r

d. Ensu

r

e that

the engine is off befo

r

e connecting

or removing the inductive pickup.

1. Set rotary selector to RPM position.

The meter defaults at TRIG

(trigger) level.

2. Pr ess button to toggl e

between RPM for 4-stroke engine

and RPM for 2-stroke and DIS

engine.

3. Insert the Dual Banana Connector

into the RPM - and the RPM+ input

terminals as shown. Ensure the

plug with the Ground Tab goes into

the RPM- terminal.

4. Clamp the inductive pickup to a

spark plug wire with the arrow sign

facing the spark plug as shown.

Ens ure the pic kup jaws ar e

completely closed.

5.

Read RPM in the primary display.

NOTE:

4 t

r

igge

r

le

v

el

s

(TRI

G

TRIG

TRIG

TRI

G

) a

r

e

s

ele

c

table

b

y

p

r

e

s s

ing button

momentarily in this function.

Refer to 5-5 for more details.

4-9. Fuel Injection On Time

This function applies to both Port Fuel

Injectors (PFI) which operate with a

single On Time pulse and Throttle Body

Injectors (TBI) which operate with twin

pulses.

1. Set rotary selector to ms-Pulse,

Dwell, Duty position.

The meter default s at ms-Pul se

with –TRIG level in the PFI

mode. (“ ” appear s in the

secondary display for 1 second.)

Pr ess button to toggl e

between the PFI mode and the TBI

mode. (“ ”

appear s in the

secondary display for 1 second.)

4 trigger levels (–TRI

G

–TRIG –TRIG –TRIG

) ar e sel ectable by

pressing button momentarily

in this function.

2. Insert black lead into COM terminal

and red l ead into ms (-P uls e)

terminal.

3. Connect the test leads as shown

and read

O

n Time in the primary

display.

4. The fuel injection frequency can

be displayed in the second display

by pr ess ing t he butt on

momentarily twice.

( l

2322

4-10. Dwell

1. Set ro ta ry selec tor

to ms-Pulse,

Dwell, Duty position.

2. Press

menukey 3 to select Dwell

function.

The meter

defaul

t

s

at 4

cylinders ( ).

Pres s

Cy inder) button

momentar ily and repeatedly

to

selec t the required number o

f

cylinder and display the cylinder

setting in the second display.

3. Insert black lead into COM terminal

and red l ead into ms (-Pulse)

terminal.

4. Connec

t

the

test leads as shown

and read Dwel l angle in the

pr imary di splay . Adjus

t

tri gger

levels by pressing

button

momentarily, if necessary.

5. Press menukey 2 momentarily to

display

Dwell reading in terms of

percentage if required.

6. The frequency of

t

he same signal

sourc e can

be displayed in the

second display by pressing

t

he

button momentarily twice.

7. Adjust the dwell angle according to

the

procedures outlined in your

vehicle service manual.

NOTE: Recheck the

timing whenever

the

d well ang

l

e has been

adjusted.

4-11. Duty Cycle

1. Set rotary selector

to ms-Pulse,

Dwell, Duty position.

2. Press

menukey 2 to select Duty

function.

3. Insert black lead into COM terminal

and red l ead into ms (-P uls e)

terminal.

4. Connect the

test leads as shown

and read the duty cycle percentage

in the primary display.

Adjust trigger levels

by pressing

but

t

on momentari ly, if

necessary

5. Press menukey 1 or 3 momentarily

to dis play Duty Cycle reading in

ter ms o

f

ms (P uls e Wi dth) or

(Dwell) angle if required.

6. The

frequency of the

same signal

source

can be dis pl ayed in the

second display

by pressing the

button momentarily twice.

I

n mos

t

app lic ati ons ,

t

he negativ e

trigger slope is assigned to display the

percentage of time that the plunger is in

the c los ed posit ion (low du

t

y

cy cle)

during one duty cycle. The positive slop

is assigned to display the percentage of

time that the plunger

is in the open

posit ion. Ref er to the c ar’s servic e

manual to v erify slope ass igned t o

position for each component.

Press the (±Trigger) button for

more than 1 second to toggle between

t

he negative (-) slope and the positive

(+) slope, if required.

2524

4-12. Charging System Test

Charging system problems often

are

identified with a No-Start complaint.

The battery will

have discharged and

the starter won’t crank the engine. To

properly check the charging system,

the battery must be fully charged.

WARNING

Be sur e

the battery to a

l

ternator

connection and lead

connectio ns

are all secure, or damage may result.

1. Set rotary selector to Elec position.

The meter de

f

aults at Char ge

System Test function.

2. Insert black lead into COM terminal

and red lead into Elec terminal.

Battery Condition Test

1. Co nnec t

r ed lead probe to

the

alternator output.

2. Connec t bl ack l ead probe

t

o

ground.

3. With engine Off, turn the headlights

On low.

4. Read the secondar y

displ ay

to

check the condition

of the bat

t

ery.

Use the table below.

Alternator Charging Test

1.

Connect red lead probe to the alternator output.

2. Connect black lead probe to ground.

3. Start engine and run at 1000 - 2000 rpm.

4. Turn the headlights On low.

5. Allow the secondary display to stabilize.

6. Read the secondar y

displ ay

t

o chec k t he

alternator charging conditions.

A display “ ” or “ ” in the secondary display together with beep sound

indicates that the alternator charging system is in bad condition.

• No display in the secondary display : System normal.

• “ ” displayed : Suspect open field (current) or regulator.

•“ ” or “ ” displayed alternatively : Suspect bridge rectifier or grounded

stator winding.

• “ ” displayed : Suspect bridge rectifier or open stator winding.

NOTE: When the alternator and the associated rectifier diodes are in good

condition, the ripple voltage of the alternator output signal should be

less than 0.49 V AC (typical).

SECONDARY DISPLAY

(Battery Condition)

(Low Battery)

(No Charge)

(Good)

PRIMARY DISPLAY

< 11.399 V

11.400 ~ 13.299 V

13.300 ~ 15.599 V

• “ ” not displayed : Check wiring and battery leads.

• “ ” displayed : Good battery, proceed.

• “ ” and “ ” displayed : Low Battery, correct before proceeding.

2726

4-13. Ground Test

This function is designed to locate bad

grounds , volt age drops, intermi ttent

c onn ec tions, o r any sourc e

of high

res istanc e

in automoti ve electrical

circuits and grounds.

It provides

a very efficient check o

f

a

vehicle’s electrical system condition.

T his

t

es t work s by measuri ng the

voltage drop across any cable to which

it is connected. The amount of voltage

drop is displayed as “ ”, “ ”,

“ ”, and “ ” annunciators in the

secondary display.

1. Set rotary selector to Elec position.

2. Press menukey 2 to select Ground

Test function. “ ” is displayed in

the primary display and “ ” is

displayed in the secondary display.

3. Insert black lead into COM terminal

and red lead into Elec terminal.

4. Connect the two probes to the

cable being tested. A good

connection is indic ated by the

display of “ ” in the secondary

display.

5. Apply power to

t

he vehicle. The

condition of the cable between the

two probes is indicated by either

“ ”, “ ”, or “ ” in the

secondary display.

If either “

” or “

” is displayed

,

check the cable closely

for poor connections

between the two test leads.

Make certain all connectors are clean and secure.

NOTE: When checking ground connections

,

always clean

or scrape off the

area of the chassis where the ground lead is being connected. Dirt,

grease, and paint are insulators and will prevent the unit from making

a good

connection

.

If a ground connection is suspect, connect the

unit to the chassis as close as possible.

When

testing charging or

starting circuits from the battery, always make the first connection to

the battery

post, and not the battery connector. Corrosion on the

battery post and connector surfaces can be the source of the problem

very frequently.

SECONDARY DISPLAY

(Good)

(Suspect)

(Bad)

(Open)

PRIMARY DISPLAY (Amount of Voltage Drop)

< 0.1999 V

0.2000 ~ 0.3999 V

0.4000 ~ 1.9999 V

2.0000 V

4-14. O

2

Sensor

This is a very efficient method to check

and simulate O

2

Sensors.

This

test hooks

in parallel

with the O

2

Sensor circuit. The primary display will

s how O

2

Sensor voltage, while the

s ec ondary dis pl ay will sho w Cross

Counts (CC).

Cross Counts are the number of times

the readi ng crosses 0.45 V DC per

second.

Nominal CC is 1

t

o 3 for a good O

2

Sensor.

During this test, the secondary display

will indicate Full Lean, Lean, Rich, and

Full Rich respectively, according to the

measuri ng value of the O

2

Sensor

output, together with the corresponding

Cross Counts(.x).

2928

1. Set rotary selector to Elec position.

2. Press menukey 3 to select O

2

Sensor function.

“Lean” and “Rich” annunciators will be displayed on menu screen.

3. Insert black lead into COM terminal, red lead into Elec terminal, and green lead

into Signal terminal.

4. Unplug the O

2

Sensor connector.

5. Connect a jumper wire between the connector halves.

6. Connect red lead probe to the O

2

Sensor side of the jumper wire.

7. Connect black lead probe to ground.

8. Connect green lead probe to the ECM side of the jumper wire.

9. Press menukey 3 (Lean) or 4 (Rich) to send out a Lean or Rich signal for 5

seconds.

PRIMARY DISPLAY

< 0.29999 V

0.3000 ~ 0.4499 V

0.4500 ~ 0.5999 V

0.6000 V

SECONDARY DISPLAY

X(Full Lean)

X(Lean)

X(Rich)

X(Full Rich)

Also during this test the menukey 3 (Lean) or menukey 4 (Rich) might be pressed

to send out a rich command or a lean command for 5 seconds, which will make the

“Lean” or “Rich” annuncia

t

or on menu screen

f

lash depending upon which

was

commended. During this time the primary display will show the signal level that is at

the O

2

Sensor to see that the condition is being compensated for. The green lead is

required to be connected between the “Signal” terminal and the O

2

connector on the

ECM side.

NOTE: Signal out and CC may not funct

i

on properly on some Toyota O

2

Sensors.

3130

4-15. AC or DC Current ( )

WARNING

D o not measur e an y circuit

that

draws more than the

current rating

of the installed fuse. Replace the

defective fuse with a pr oper fuse

only. Failure to do this may result in

injury or damage to the meter. Do

not attempt current

measurements

where the o pen circuit voltage is

above 600 V.

For measuring circuits of more than

10 A

,

use voltage output cu rrent

c

l

amp adapters

compatible with

the

meter voltage functions.

1. Set rotary s elec tor t o BatDr

position. The meter defaults at DC

current.

2. Press menukey 2 to select AC.

3. Insert black lead into COM terminal

and red lead into A terminal

4. Connect red lead probe to the side

of the

circui

t

closes

t

to the power

source.

5. Connec t black lead

probe to the

side of the circuit closest to ground.

6. turn the power ON and test. DO

NOT crank the engine.

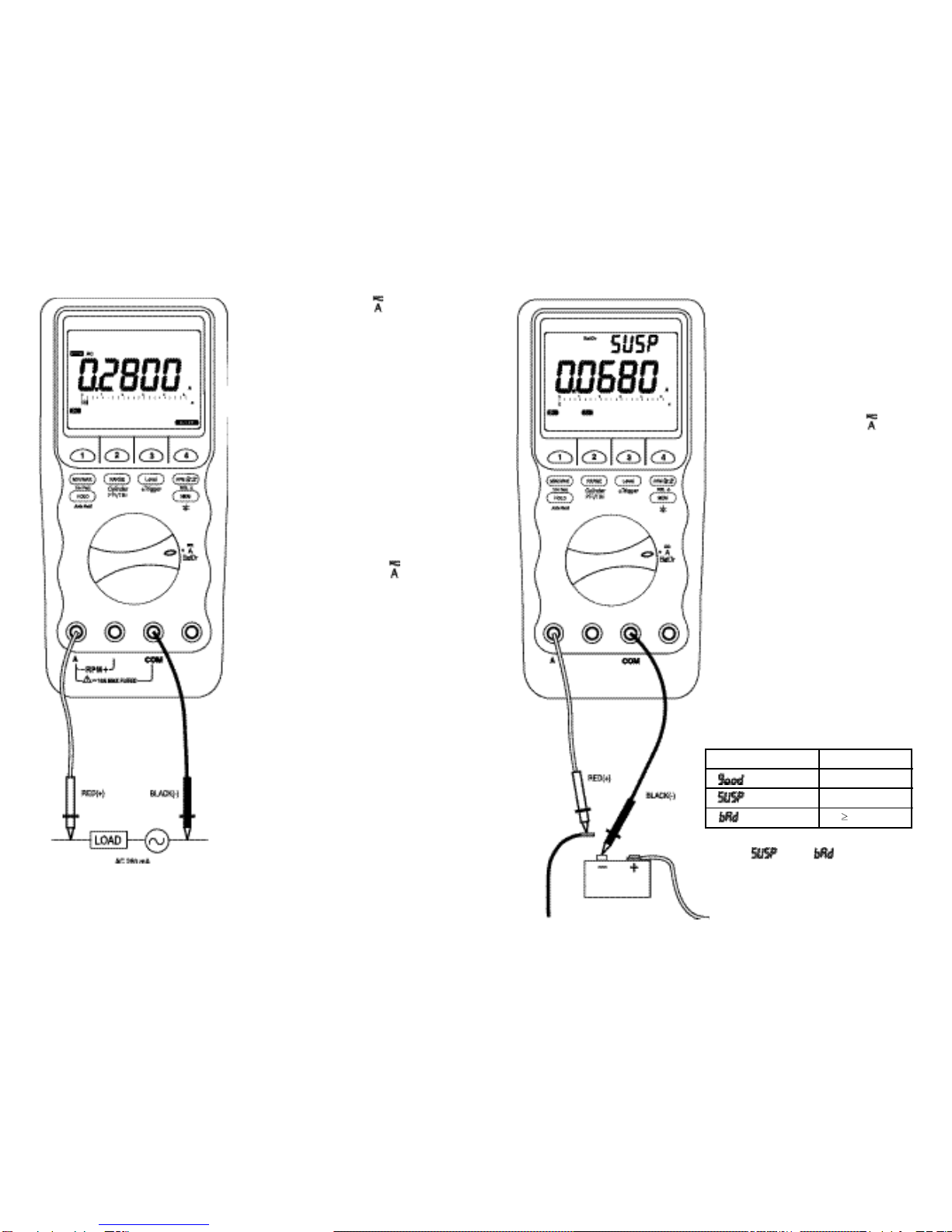

4- 16. Battery Drain Test

This f uncti on measur es

the c ar’s

battery current when it is turned off.

This test

will run continuously so

t

he

Au

t

o-Power-O ff feature wi ll be

automatically disabled in this mode.

1.

S

et rotary selec tor to

BatDr

position.

2. Press menukey 4 to select BatDr

test function.

3. Insert black lead into COM terminal

and read lead into A terminal.

4. Turn the ignition and accessories

Off.

5. Disconnect the negativ e battery

cable.

6. Touch red lead probe to the cable.

7. Touch blac k l ead pr obe to

t

he

negative battery post.

8. Observe the

s econdary display

(allowing up to 30 minutes).

If a “ ” or “ ” is displayed,

check fused and non-fused c

i

rcuit

for malfunction.

SECONDARY DISPLAY

(Low Drain)

(Marginal Drain)

(High Drain)

PRIMARY DISPLAY

< 0.0199 A

0.0200 ~ 0.0799 A

0.0800 A

3332

5-1. MIN/MAX Mode

Press the button momentarily to activate MIN/MAX(Record) mode with LCD

annunciators

MAX MIN

A

VG turned

on. Press this button

momentarily to read

throughout the maximum(MAX), Minimum(MIN), and Average(AVG) readings in the

primary display. Press this button for more than 1 second to exit MIN/MAX (Record)

mode.

With

t

he Autoranging MIN/MAX

(Record) mode, you can easily

t

rack intermittent

signals, capture turn on/ turn off surges, and monitor line voltage changes over a

much wider dynamic rage wi

t

h the best resolution. It surpasses manual ranging

recording which is apt to be overflowed or to have insufficient resolution. The meter

fea

t

ures

a fast sampling speed o

f

50 ms for MAX,

MIN and

AVG readings.

The

faster the sampling speed, the more accurate the measurements will be. The true

average (AVG) feature calcula

t

es all

readings con

t

inually

t

aken over time. The

Auto-Power-Off feature will be automatically disabled in this mode.

5-2. 1 ms Peak Mode

Press the (1 ms Peak) button

for more than 1 second

t

o activate 1

ms Peak mode with LCD annunciators

1 ms MAX MIN

turned on. The meter

defaults at 1 ms MAX (posi

t

ive

peak

value reading) mode.

Press the

menukey 2 momentarily to

select 1 ms MIN (negative peak value

reading) mode.

Press the menukey 4 ( on

menu screen) to exit 1 ms Peak mode.

With 1 ms Peak mode, transient signal

peak voltage as short as 1 ms can be

captured.

5. ADVANCED FEATURES

5-3. Manual and Auto Ranging

Press the button momentarily to select manual ranging, and the meter will

remain in the range it was with LCD annunciator

turned off.

Press this button

momentarily again to step

t

hrough

the ranges. Press this button for more than 1

second to resume autoranging.

In Dwell( ) function, press this (Cylinder) button momentarily to display

the cylinder setting on the secondary display. Default is

CL

4 (4 Cylinder). Press this

button momentarily again to select the number of cylinders from 1 through 12 (1, 2,

3, 4, 5, 6, 8, 10, and 12 cylinders) to match the engine under test.

NOTE: The secondary display defaults at rpm

i

n the

, , and Hz

function.

The selected cylinder setting or RPM setting is maintained until

the meter is turned off.

5-4. Trigger Level and +/- Trigger Slope Selection

This feature is available for RPM, Dwell, ms-Pulse, or Duty measurement function.

The meter is set at selected trigger level as power up default in individual function

as follows :

However, car signal levels under

t

est may

vary due to

aging of components,

abnormal conditions,

and each car manufacturer’s different design. Therefore

,

positive and

/

or

negative

4 selectable

trigger levels, which are carefully designed

and tested to cover all the extreme conditions, are available in these functions to

provide more flexibility to cope with your applications.

If your reading is unstable, select lower sensitivities (higher trigger level number) by

pressing the button momentarily. If your reading shows zero, select higher

sensitivities (lower trigger level number).

FUNCTION

RPM

Dwell, ms-Plulse, Duty

DEFAULT TRIGGER LEVEL

+ TRIG

– TRIG

3534

In some

cases, positive trigger levels may be required for measuring Dwell, ms-

Pulse, or Duty. Press the (±Trigger) button for more than 1 second to toggle

between positive (+) and negative (-) trigger level for the selected trigger level.

NOTE: Positive (+) trigger or negative (-) trigger is to identify whether the On

or

Off portion of

the s

i

gnal under test

is of measuring interest. For

example, if you get a reading of 10 % Duty Cycle in the Positive (+)

Trigger (On portion), you then will get a reading of 90 % Duty Cycle in

the Negative (-) Trigger (Off portion).

5-5. RPM Selection

In

the RPM

f

unction,

the meter de

f

aults to RPM

f

or

conventional 4-stroke engine

.

Press the button momentarily to toggle to RPM for 2-stroke or DIS

engine. And also in the , , or Hz function, press the button momentarily

to toggle between RPM and RPM setting for the dual display RPM function.

5-6. Relative Mode

Press the (REL ) button for more than 1 second to select the Relative

Zero ( ) mode with LCD annunciator turned on. This feature allows the user

to offset the measured value with a relative reference value.

Press the (REL ) button for more than 1 second to exit relative mode and

resume normal measurements.

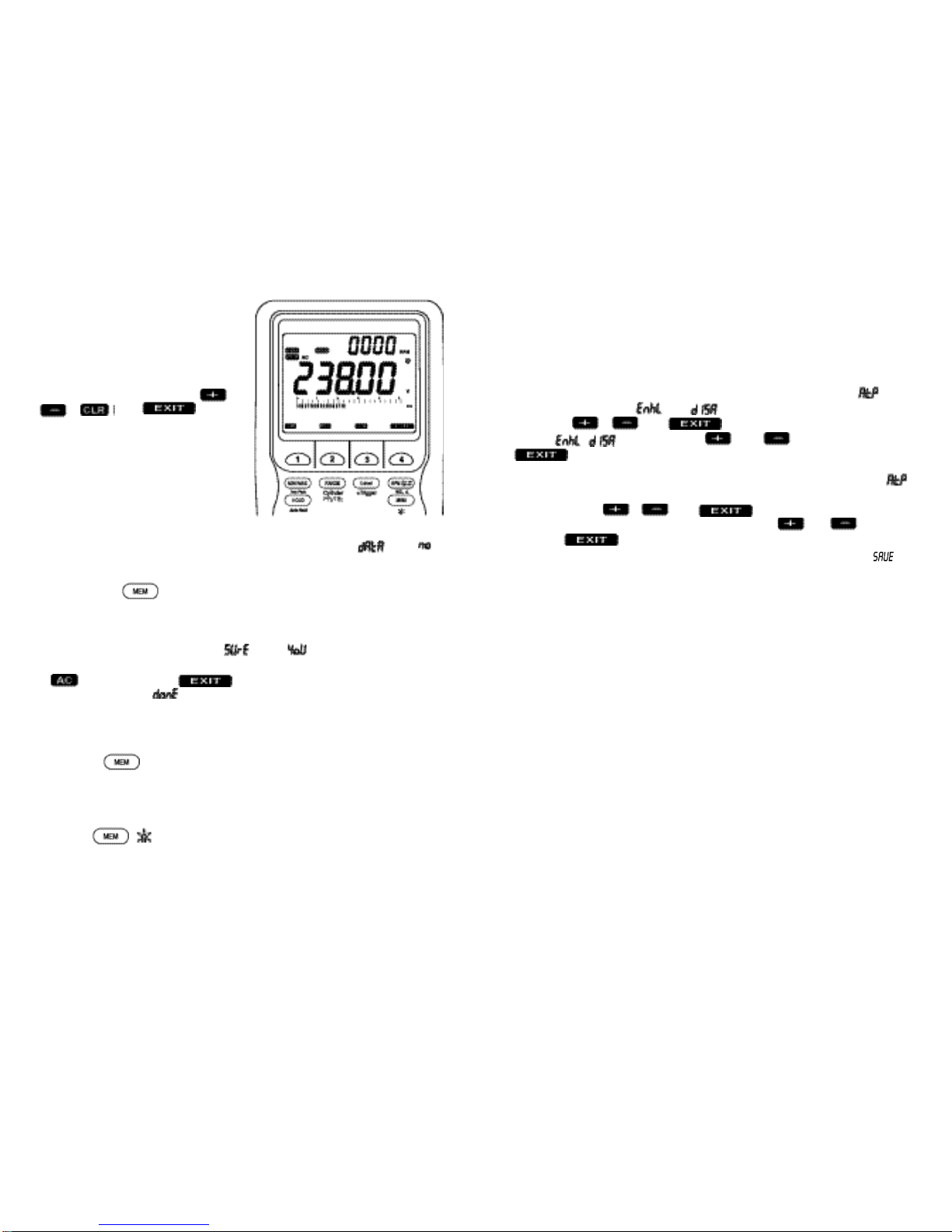

5-8. Memory (Data Store, Recall, & Clear) Mode

Press the

but

t

on momentarily to

activate the Memory

mode with LCD

annunciators

and

turned on. The menu screen shows four menu

selections : (Store), (Recall), (Clear), and (Exit).

Store : Press the menukey 1 to store

the

di splay in g data. The av ai lable

memory location number momentarily

shows in

t

he secondary

display

and

“

SA U E

” momentari ly s how s in the

primary display. If no memory location is

available, “

FULL

” and “

” momentarily

show in

the primary display and in the

secondary di splay respectively

and

nothing

is stored

,

when you

must clear

all the memory loca

t

ions by pressing

the Clear menukey to secure memory

locations. You can store up to 20 data.

You can exit the store mode by pressing

either the EXIT menukey or the

button momentarily.

5-7. Hold or Auto Hold

P

ress the

button

momentarily to activate the Hold func

t

ion with LCD

annunciator

turned on. Press

this

button momentarily again to exit Hold

function. This feature freezes the display for later view.

Press the

(Auto Hold) button for more than 1 second

to activate

the Auto Hold

func

t

ion with

LCD annunciators

turned on

.

This feature automatically

freezes the dis play and the

meter beeps when the measurement reading is

stabilized. The displayed value will be updated when a new measurement value is

stabilized. This mode is very use ful when it is impossible

f

or you to press the

button

or

see the me

t

er display while probing and

taking measurements. Press the

(Auto Hold) button for more than 1 second to exit Auto Hold function.

The 4 selectable trigger levels are cycled through as follows :

• RPM :

+

TRIG

+

TRIG

+

TRIG

+

TRIG

• Dwell, ms-Pulse, Duty

:

–

TR

I

G

–

TRIG

–

TRIG

–

TRIG

3736

Clear

:Select Clear to clear all stored data in

t

he Store mode or only the data

stored at

the selected memory location in

t

he Recall

mode. In

t

he Store mode,

when you press the Clear menukey, “ ” and “ ” continuously show in the

primary display and in the secondary display respectively with two menu selections

; (ALL CLEAR) and turned on in the menu screen. When you

press the menukey 2, “ ” momentarily shows in the primary display and all the

stored data are erased. Press the EXIT menukey to exit the memory mode without

erasing any stored data.

EXIT :Select E

X

IT

t

o exit memory mode. You can also

exi

t

memory mode by

pressing the button momentarily or turning the rotary selector.

5-9. Backlight

Press the ( ) button for more than 1 second to toggle the backlight On

and Off.

The backlight wi ll also automatically be

Off 30

seconds a

f

ter eac h

activation to extend the battery life.

5-10. Auto-Power-Off

The meter automatically turns off after approximately 30 minutes of no activities to

extend battery life.

You can enable or disable the

A

uto-Power-Off mode. Turn the meter on while

pressing the menukey 4 to activate this feature, when the meter shows “ ” in the

Secondary display, and “ ” (or “ ”) in the primary display with three menu

selections ; , , and turned on in the menu screen. You can

toggle / by pressing the and menukeys. Press the

menukey to get into the next Setup.

The meter will display “ MIN

” annunciator at the upper lef

t

corner

of the LCD, “

”

in the secondary display, and a two digit number in the primary display with three

menu selections ; , , and turned on in the menu selection.

You can set up a new auto-power-off time by using the and menukeys.

Press the menukey to save the newly customized default values during

the entire Setup cycle. The meter will resume normal operation just after “ ” is

displayed in the primary display.

NOTE:

The newly customized default values in any Setup can be saved only

w

hen the entire Setup cycle

i

s ended. The

meter

displays “

SAUE

” at

the end of the entire Setup cycle only.

5-11. RS-232C Interface

The meter

provides an optically isolated

inter

f

ace port at the top

f

or

the data

communication. The RS70 optical adapter cable and the WS716 software disc are

required to connect the meter to the PC computer. These accessories are provided

to the end users as optional items.

Recall : Selec t Recall

t

o review the

stored data by pressing the menukey 2.

When you press the menukey 2, the last

memory location number used in the

prev ious memory op erat ion wil l

moment ari ly s how in

t

he s ec ondary

display with four menu selections ;

,

, , and turned

on in the menu screen. The

required

memory location can be s elected by

using the menukey 1 and the menukey

2, when the data stored at the selected

memory loc ati on wil l s how in t he

primary

display

.

In the Recal l mode

,

when you press the Clear menukey, the

data stored a

t

the recalled memory locat ion only is

erased. If

no stored

data is

available

in

the Recall mode, when

you press the Recall menukey, “

” and “ ”

momentarily show in the primary display and in the secondary display respectively

and nothing is retrieved. You can exit the Recall mode by pressing either the EXIT

menukey or the button momentarily

Table of contents