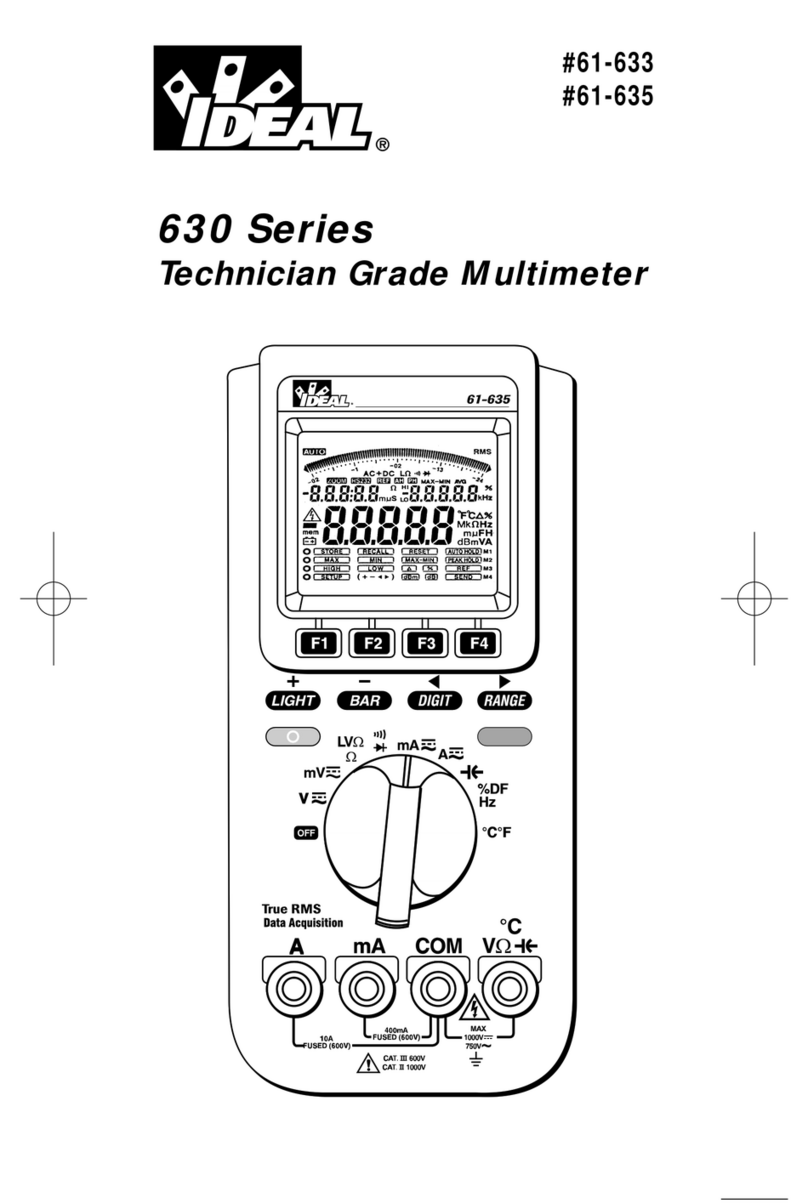

IDEAL 61-354 (TRMS) User manual

Other IDEAL Multimeter manuals

IDEAL

IDEAL 61-704 User manual

IDEAL

IDEAL 61-340 User manual

IDEAL

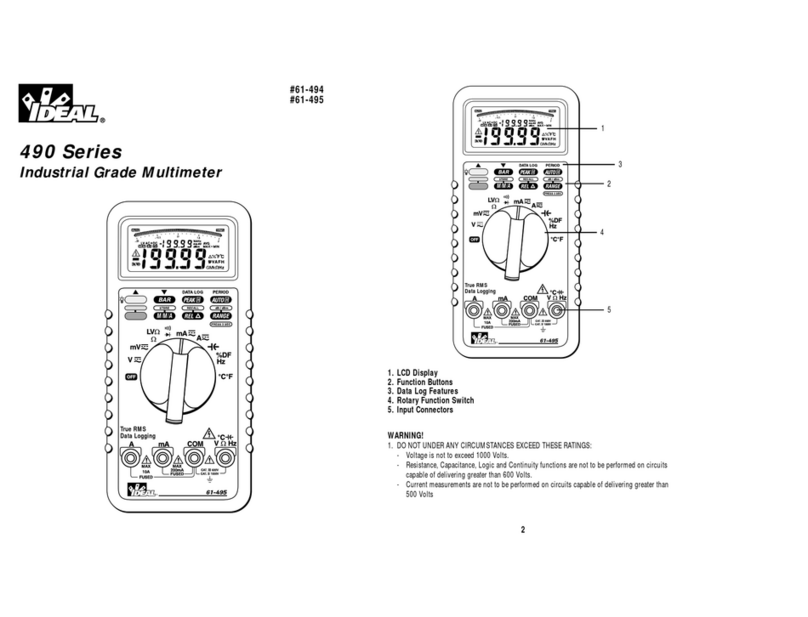

IDEAL 61-494 User manual

IDEAL

IDEAL 61-327 Use and care manual

IDEAL

IDEAL 61-340 User manual

IDEAL

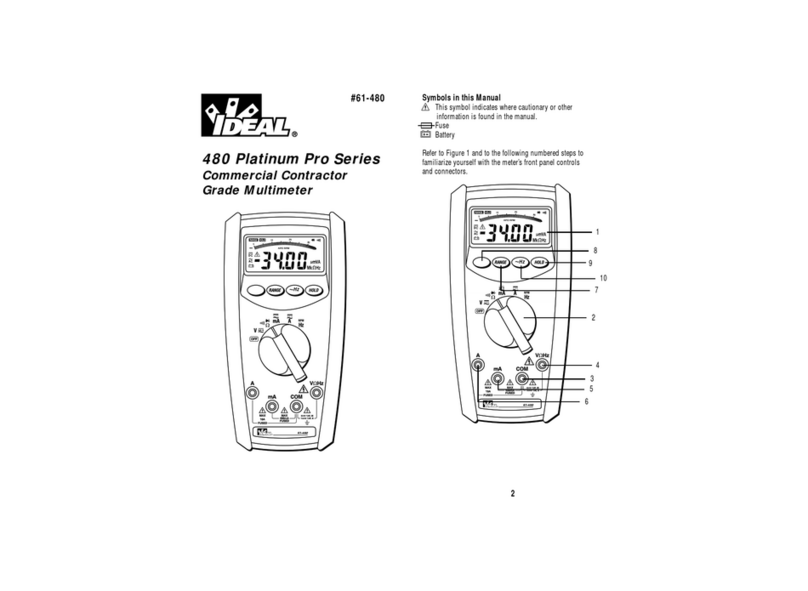

IDEAL 480 Series User manual

IDEAL

IDEAL ND 2352-1 User manual

IDEAL

IDEAL ND 2350-1 User manual

IDEAL

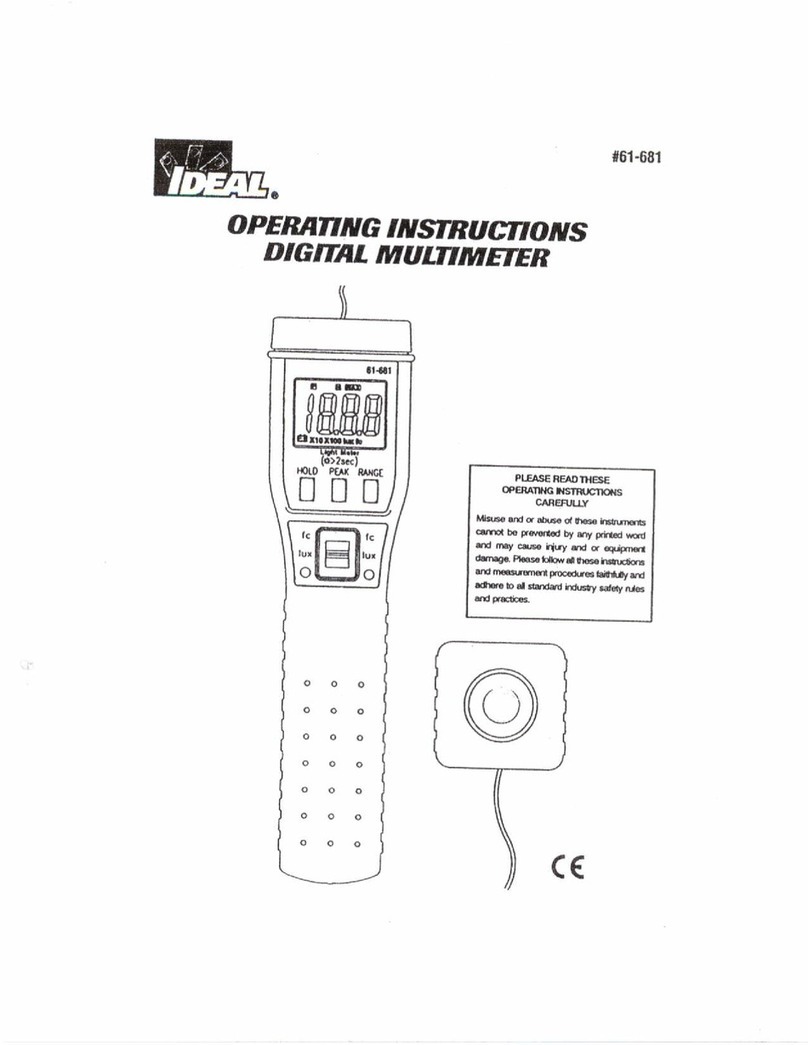

IDEAL 61-681 User manual

IDEAL

IDEAL 61-312 User manual

IDEAL

IDEAL ND 2366-1 User manual

IDEAL

IDEAL Resi-Pro 310 Series User manual

IDEAL

IDEAL 61-337 Use and care manual

IDEAL

IDEAL ND 4950-3 User manual

IDEAL

IDEAL 61-497 User manual

IDEAL

IDEAL 61-764 User manual

IDEAL

IDEAL ND 2351-1 User manual

IDEAL

IDEAL ND 1075-2 User manual

IDEAL

IDEAL 602 User manual

IDEAL

IDEAL 61-614 User manual

Popular Multimeter manuals by other brands

Gossen MetraWatt

Gossen MetraWatt METRAmax 6 operating instructions

PeakTech

PeakTech 4000 Procedure of calibration

YOKOGAWA

YOKOGAWA 90050B user manual

Gossen MetraWatt

Gossen MetraWatt METRALINE DMM16 operating instructions

Fluke

Fluke 8846A Programmer's manual

Tempo Communications

Tempo Communications MM200 instruction manual