FINE INSTRUMENTS CORPORATION FINEST 135 User manual

._.;;

y...

.

.

.

.

.

.‘<’

.

..e

..‘.‘\

,

.

<...’

.,,.

.‘.‘...’

..:..,

‘l.1,

<.‘.

.“!

FINEST

135

TRUE

RMS

CLAMP-ON

METER

735 CLAMP METER

SOFT

AC

@

1994,

FINE

INSTRUMENTS

CORPORATION

All

rights

reserved.

Litho

in

Korea

This Meter measures the true-rms value of Alternating

Cur-

rent (AC) over from

0.3A

to 700A. AC measurements are

from

10Hz

to

1

KHz

and frequency measurements are from

0.5Hz

to

10KHz.

Clamp meters that measure

average

current flow are

in-

accuratefornon-linearcurrentsand theirmeasurements

may

have some

differentes

from those obtained using this Meter,

Ths

Meter

tan

also measure frequency while measuring

current

flow

simultaneously. AC and DC voltages and

resistances

tan

be measured and also continuity check

is

possible with this Meter.

This Meter also provides:

H

Auto Range

or

Manual Range

selection.

n

HOLD functionto freeze readings.

n

41segment

analog bar graph that displays current while

simultaneouslymeasuringfrequencyonthedigitaldisplay.

n Low-battery

indicator

and

battery

life

indicator

at

power-

up using bar

graph..

m

Automatic

power off after 10

minutes’

of inactivity and

power

leck

to disable the

automatic

power off

function.

w

When an

ineffective

pushbutton is pressed, this Meter

beeps twice continuously.

n A SOFT mode to display a

3-second

running

average.

n A CREST mode that measures half-cycle peak AC

amperes.

n A

MINIMAX

RECORD mode to

record

maximum,

minimum,

and

average

values of

rms

current,

softened

rms, frequency, voltage

or

Ohms.

Halfcycle

peak

maximum may also be

recorded

in the CREST mode.

:;:::.:;

::

.

n

Zero adjustment by the microprocessor when

measunng

DC amperes.

2. Clamp-on Meter Safety

In this manual, the word

“DANGER”

identifies a severe

or

immediatelyaccessiblepersonal hazardthat

tan

Cause

death

or

injury;

the word

“WARNING”

identifies a personal hazard

about

a

condition

or

procedure that could

Cause

death

or

injury;

the word

“CAUTION”

identifies an equipment hazard

about

a

condition

or

procedure that could

Cause

darnage

or

destruction

of this Meter.

Observe

the International Electrical Symbols listed below.

A

A

Warning!

Risk of electric

shock.

A

a

Caution!

Refer to this manual before using this Meter.

El

Double Insulation

(Protection

Class

II)

n

Never

clamp

around a conductor at 600V rms

or

greater

or with a frequency of

1OKHz

or

greater.

n

Never usea

meter

whose insulating

protection

has been

impaired.

n

Beextremelycautiouswhenclampingarounduninsulated

conductors

or

bus bars.

w

Use this Meter only as specified in this manual. Otherwise,

the

protection

provided by this Meter may be impaired.

W

Observe the safety messages

contained

in

thrs

manual

n

Avoidworkingalone.

n

Inspect the test leads for damaged insulation orexposed

metal.Check

test lead continuity. Damaged leads should

be

replaced.

n Disconnect the live test lead before disconnecting the

common test lead.

l

Be sure this Meter is in goodoperating condition. During

a continuity test, a

meter

reading that goes from

overflow

(OFL)to0 generally means this Meter is working properly.

3

W

Select the proper

function

and range for your

measure-

ment.

3. Explanation of Controls and

Indicators

@

CLAMP.

Opens2.04inches

(52mm)

to

enclose

con-

ductors.

(~$3

HOLD. Freezes reading in digital display.

@

DISPLAY. Liquid

crystal

display.

(+

RANGE. Selects 0

to

40A,

0

to

400A,

or

AUTO.

~7

ON OFF. Selects meters power ON

or

power OFF.

@

08)

. Selects continuity testing mode.

@

n.

Selects ohms measurement mode.

@

Vf2.

Volt, Ohms, Continuity Test Input Terminal.

(2

V. Selects

Volts

measurement mode.

@

COM. Common Terminal.

@

Hz. Selects frequency measurement mode.

@

A.

Selects amperes measurement mode.

@

MIN MAX. Selects RECORD mode and displays

recorded

MAX, MIN, and AVG.

@

SOFT CREST. Select SOFT for a running

3-second

average,

or

CREST for half cycle peak amperes.

.

@

AC DC. Selects AC

or

DC mode.

@

LEVER. Opens and

closes

clamp

jaws.

0

RECORD. Displayed (blinking) when MAX, MIN, and

AVG values are being

recorded.

Duration

of RECORD

is limited by

battery

life.

@

MAX MIN AVG. Displayed in RECORD mode by

pressing MIN MAX

pushbuttons.

@lxm.

Displyed when HOLD pushbutton has been

pressed.

5

@

ml

. Displayed when

G))

pushbutton has been

pressed.

12h

SOFT. Displayed when current flow readings or Hz or

V readings are softened out over

3-second

intervals.

@

KRVHz.

Displayed,when

measuring ohms or voltage or

frequency.

@t

PEAK.

Displayed when current flow readings are in

half-

cycle peak amperes (Crest

mode).

3

RMS. Displayed when current reading

is

in amperes

rms.

I,%

OFF-SCALE

ARROW.

Displayed when bar graph

pointer

is

Off

scale.

@

DUAL. Displayed when measuring frequency in digital

and amperes in bar graph simultaneously.

3

A. Displayed when

meter

is

measuring amperes.

DIGITAL DISPLAY. Displays 3999 counts, with two

decimal

Points

relative

to

the two

ranges.

But,

displays

9999 counts in frequency mode. Display

is

updated 4

times

each

second.

POINTERS.

Displayed to indicate

Position

on bar graph

scale. Positions are updated 20 times

each

second.

ANALOG DISPLAY POLARITY.

Displays +or

-

when

the

Pointers

are displayed.

0

to 400A.

(or 0 to 800A.) Numericreference for the bar

graph.

m

. Displayed when internal battety needs replacing.

AC. Alternating Current or Voltage.

-

. Automatically indicate negative digital displays.

AUTO.

Displayed when autoranging controls bar graph

scale (0

to

40A scale, or 0

to

400A scale) and controls

Position

of

decimal

Point

on digital display.

POWER LOCK. Displayed when the Auto Power off

mode of the

meter

has been disabled.

BEEPER.

Beeps

for pushbutton Operation or current

overload.

OFL. Overflow

Indication

4. Alignment Marks

1

MARK

MARK

CONDUCTOR

-

MARK

HAND GUARD

Figure 1. Alignment Marks

Position the conductor within the jaws

at,the

intersection of

the indicated marks

as

much

as possible (Figure 1) in

Order

to

meet this

Meter’s

accuracy specifications.

If

the conductor

is

positioned elsewhere within the jaws, the

maximum additional error resulted

is

1.5

percent.

5.1

Battery

Replacement

This Meter

is

powered by a

Single

9V

battery

(NEDA

Type

1604A,

6LF22,

or

006~).

To guarantee the specified battery

life,

alkaline

or other long-life batteries are recommended.

If

the low-battery

indicator

on the digital display will be

dis-

played, replace the

battery

by using the following procedure

referring

to

Figure 2.

1.

Unclamp

this Meter from any conductor, and turn it off

by

pressing the ON OFF pushbutton.

2.

6

Place

thrs

Meter facedown on a nonabrasive surface and

completely loosen the three rear

Panel

screws with a

Phillips-head

screwdriver.

7

!

3.

4.

5.

6.

7.

Grasp the bottom of the rear

cover

and

lift

it free of the

case.

Lift the battery from the

case,

and carefully disconnect

the battery connector leads.

Snapthe batteryconnector leads

to

theterminalsofa new

battery and

insert

the battery into Position. Dress the

battery leads so thatthey will not be pinched between the

case

bottom and the

case

top.

Replace the rearcover,ensuring it

Slips

beneath the hold-

down lip (next to the jaws) and fits securely into Position.

Reinstall the three

securing

screws.

If

this Meter

is

not be used forperiodsof longer than 60 days.

remove the battery and store it separately.

Figure 2.

Battery

Replacement

a

A

5.2

Notes

For taking

full

advantage of this

Meters

capabilities, read

completely, in sequence,

each

of the following pages. lt

is

not

necessary

to make a measurement

to

learn how

to

use

this

meter.

Take the time

to

read this

section

completely

before attempting any meterapplications becausethis meter

has many features and operating sequences that are not

readily apparent.

0

WARNING!

MOST OF THE TYPICAL APPLICATIONS ARE EXPOSED

TO LETHAL VOLTAGES. BE CAUTIOUS WHEN TAKING

MEASUREMENTS. BEFORE THE METER

IS

CONNECT-

ED TO ANY CIRCUIT, REVIEW THE SAFETY INFORMA-

TION. ALWAYS KEEP YOUR HANDS BEHIND THE

METER%

HAND GUARD.

5.3 Power

Up/Self

Test

Press and hold the ON OFF pushbutton in

Order

to

power

up and initiate self

test.

This

meter

beeps and all LCD

seg-

ments will turn on (some

Segments

have nothing to do

with this Meter.)

as

patt

of a

self-test

routine.

Observe

a bar

graph

pointer

blinks

to

indicate the battety

condition

while

still pressing the ON OFF pushbutton. The

“Off-Scale”

arrow blinks for a battery life in excess of 40 hours and a

corresponding bar graph

pointer

blinks for a battery life of

less

than 40 hours. Read the

scale

as

0 to 40 hours for this

battery test. A

pointer

underthe 3 (6 is

not

displayed) on the

scale,

for example, represents approximately 30 hours of

rematning battery life.

Release the ON OFF pushbutton

to

initialize this Meter.

Replace the battery before using

this

Meter when the

bat-

terytestgives a reading of only a few hours or when the

low-

battery

indicator

is

displayed on the digital display.

If

the Meter does notturn ON, the battery

is

missing or worn

out. To replace the battery, see 5.1 Battery

Replacement.

8

9

Thrs

Meter shuts OFF after 10 minutes if no pushbutton is

pressed, even if it is making a measurement. To disable the

auto power off, press the ON OFF pushbutton

(

Ls

is displayed), when if

you

press the ON OFF pushbutton

again, the Meter

turns

OFF.

When you want touse this Meter in manual range, press the

RANGE pushbutton, then this Meter is in manual range.

Press RANGE pushbutton for 2 seconds

to

return

to

Au-

toranging mode.

This

Meter’s

auto power off feature is disabled when you

are using the RECORD mode.

5.4 Measuring AC Amperes

When this meter has been powered up, it defaults in the AC

amperes mode with

250-ms

measurement

intervals

(AC

dis-

played) and autoranging mode (AUTO displayed),

which

automatically selects the proper range for both the bar scale

and the digital display. Press the RANGE pushbutton

to

select a fixed scale instead of autoranging.Observethateach

press alternates between the 40A and 400A

scales

and

AUTO is no longer displayed. When the reading

is

beyond

the limits of the digital display, for example, 40A on a 40A

scale, OFL appears

on

the digital display.

:;::::‘:,

PresstheRANGEpushbuttonfor2secondsandthenrelease

in

Order

to

return

to

autoranging mode. This Meter

acknow-

ledges wrth a beep

Sound

and displays AUTO.

5.5 Measuring DC Amperes

Press the AC DC pushbutton

to

select the DC amperes

measurement

mode

(AC disappeard on the LCD), but the

meter

is still in the autoranging mode (AUTO displayed),

unless you press the RANGE pushbutton to enter into the

manual

ranging

mode.

When the

DC

amperes measurement

mode

is

entered, the

display reads a non-Zero DC amperes (positive or negative)

value due

to

the presence of the Earth’s Magnetism. This

value is variable according

to

the

location

measuring DC

amperes.

Zero Adjustment

by

the Microprocessor

To initiate the Zero

Adjustment

procedure, press the HOLD

pushbutton for 2

second.

Then, the

meter

beeps and the

display reads Zero just

after

the microprocessor memorized

the right preceding display value

that

is

used for calculating

the

exact

DC

amperes measurement value when measuring

the DC amperes of a

current-carrying

conductor.

When measuring the DC amperes of a

current-carrying

conductor, the DC amperes value

has

a positive or negative

polarity according

to

the

direction

of

current-cartying.

This

value is

posrtive

when thecurrentflows through theconductor

in the

forward-moving

direction

of a right-hand threaded

screw.

And it is negative when the

current

flows through the

conductor in the

backward-moving

direction

of a right-hand

threaded

screw.

10

11

5.6 Measuring Frequency

To enable

the

frequency measurement mode, press the Hz

pushbutton. This Meter displays Hz, DUAL, and AUTO. The

frequency of the current flow is displayed. AUTO (auto-

ranging)

is

applied

to

the bar graph,

which

represents rms

value of the current flow. When in AUTO, frequency

mea-

surement uses an auto trigger threshold based on one-half

ofthe peakcurrentmeasurement.This providesthebest

sen-

sitivity and noise immunity.

To select a fixed 40A or 400A bar graph display (AUTO

is

no longer displayed), press the RANGE pushbutton. With a

fixed 40A or 400A scale, fixed trigger thresholds areimpdsed

for frequency readings. The thresholds are

6A

(40A scale)

or 40A (400A scale). The frequency display

is

O.OHz

when

a trigger threshold is not reached.

PresstheRANGEpushbuttonfor2secondsandthenrelease

in

Order

to

return

to

autoranging mode. This Meter

acknow-

ledges with a beep

Sound

and displays AUTO on the digital

display.Press theotherfunction(Aor Vor

0

or

l

II)

)

push-

button

to

exit the frequency mode.

5.7 Using Data Hold

When HOLD

is

used while measuring frequency, RANGE

tan

be

changed

only for imposing trigger thresholds of 6A

on the 40A

scale,

and 40A on the 400A scale. The frequen-

cy reading will be

O.OHz

when HOLD

is

released, if the

trig-

ger threshold is not reached.

When in the HOLD mode,

this

Meter

function

tan

be

changed

from the held

function

to

one of the other

functions,

when HOLD is automatically released.

Press the HOLD pushbutton again

(

CT~I@I

is no longer

displayed) in

Order

to

exit HOLD.

PresstheRANGEpushbuttonfor2secondsandthenrelease

in

Order

to

autoranging mode. This Meter acknowledges with

a beep

Sound

and displays AUTO on the digital display.

5.8 Measuring

AC/DC

Voltage

Press the V pushbutton

to

enable the voltage measurement

mode and then select AC or DC by toggling the AC DC

push-

button. This Meter defaults in the autoranging mode and

displays

V,

AC and AUTO. AUTO (autoranging) is applied

to

the bar graph.

To measure voltage, connect this Meter in parallel with the

load or circuit

under

test.

Esch

of the three

ACIDC

voltage

rangespresents an input impedance of approximately 10

M12

in parallel with less than 100 pF.

Measurement errors due to circuit loading

tan

result

when

makingeitherACorDCvoltagemeasurementoncircuitswith

high

Source

impedance. In most

cases,

the error is

negligi-

ble (0.1% or

less)

if the measurement circuit

Source

im-

pedance

is

10 Kilohms or

less.

To freeze the digital display reading (HOLD

is

not applied

tothe bar graph.), press the HOLD pushbutton.

m

is

displayedwhen HOLDis enabled.

12 13

5.9 Measuring Resistance 5.10 Continuity Testing

Press the

R

pushbutton

to

enable the resistance

measure-

mentmode.ThisMeterdefaultsintheautorangingmodeand

displays KR and AUTO. And also the

off-scale

arrow of the

bar graph blinks and the digital display reads OFL.

AUTO (autoranging)

is

applied to the bar graph.

This Meter measures resistance by comparing the internal

reference resistance given by a resistor array with the

unknown resistance

to

be measured. Remember, the

re-

sistance displayed by this Meter

is

the total resistance

throughall possiblepaths betweenthe probes.This explains

why in-circuit measurement of resistors does not

often

yield

the ohms value indicated by the resistor’s

color

Code.

Ei

CAUTION!

TURN OFF POWER ON THE TEST

CIRCUIT

AND

DIS-

CHARGE ALL CAPACITORS BEFORE ATTEMPTING

IN-

CIRCUIT RESISTANCE MEASUREMENTS.

IF

AN

EX-

TERNAL VOLTAGE

IS

PRESENT ACROSS A

COM-

PONENT, IT WILL BE IMPOSSIBLE TO TAKE AN

AC-

CURATE MEASUREMENT OF THE RESISTANCE OF

THAT COMPONENT.

The resistance in the

test

leads

tan

diminish accuracy on

y.::

:.,>.:::y:

i

the lowest

(400-ohm)

range. The error

is

usually

0.1 to 0.2

ohms for a Standard pair of test

leads.

Press the

l

$j

pushbutton

to

enable the continuity testing

mode. This Meter

defaults

in the

400-ohm

range and then

highest bar graph scale

Shows

400. The digital display reads

OFL.

Continuity testing verifies

that

circuit connections are

intact.

Test resistances below

35R

Cause

the Meter

to

emit a

con-

tinuous tone.

Table 1. Beeper

Response

in Continuity Test

Input Range

400R

Beeper On

If

Approx.

~35

Il

The continuity mode is extremely fast and

tan

be

used

to

detect either

Shorts

or opens that last for as

little

as 100

mil-

liseconds. When a

Change

is

detected, the beeper tone is

“stretched”

to

last at least

1/4

second,

so you

tan

hear it

and detect both

Shorts

and opens.

This

tan

be a valuable troubleshooting aid when looking for

intermittents associated with cables connections, switches,

relays, etc.

If

the

test

value is very

close

to the threshold,

er-

ratic

beeps

tan

also occur due

to

environmental electrical

noise(EMI).

When measuring resistance, be sure

that

the contact

be-

tween the probes and the circuit

under

test

is

good.

Dirt,

Oil,

Solder

flux,

or otherforeign matter seriouslyaffectresistance.

14

15

5.11 Using Soft

SOFT

AUTO

n

n

n

AC

Lt.

1,1

dlA

ws

Observe that SOFT is displayed

after

pressing the SOFT

CREST pushbutton once. This SOFT mode digitally displays

a

running

average

of readings over

3-second

interval to

reduce the

fluctuation

of the readings. The bar graph is

un-

affected by this SOFT function and updates 20 times

each

second.

SOFT function

tan

be used for ampere readings or voltage

readings.

Press the SOFT CREST pushbutton twice when in the AC

or DC amperes mode, or once when in the voltage mode,

in

Order

to exit SOFT.

5.12 Using Crest

AUTO

AC

Observe that PEAK is displayed

after

pressing the SOFT

CREST pushbutton twice. PEAK is available for AC ampere

readings only and

tan

not be selected when in the other

modes.

60th

the digital display and bar graph measure the halfcycle

peak AC amperes when PEAK is displayed.

The

crest

factor

of a waveform is the ratio of its half-cycle

peak amperes

to

its rms amperes.

Crest

Factor

=

Half-Cycle Peak Amperes

RMS Amperes

The Crest

Factor

is a nominal 1.414 for linear

current

flow

without

current

wave

drstortion.

Crest

Factors

other than

1.414 indicate the presence of

harmonic

current

flow.

(See

6.1 Non-Linear Loads.)

Press the SOFT CREST pushbutton once

to

exit CREST.

Then. PEAK is no longer displayed.

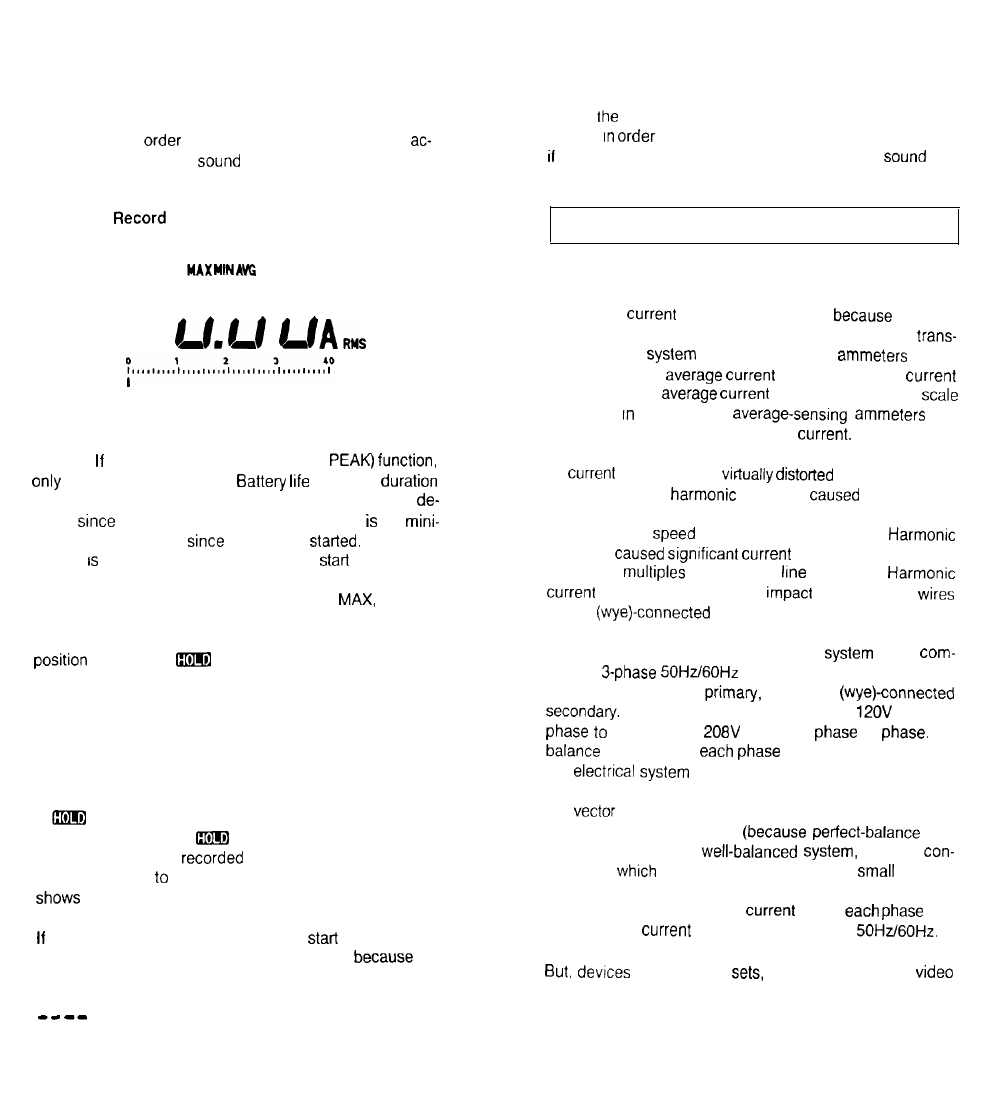

5.13 Enabling

Record

AC

RECORD

nnn

UL/

L/A,s

0

1

23

40

A

I,,,,I,,,,I~~,,I~,,,I,,,,l,,,,I,,,,I,,~,I

t

To enable RECORD, press the MIN MAX pushbutton. The

blinkingRECORD

is

displayed. The recording of a new

max-

imum or

minimum

IS

Indicated

by beep

Sounds.

We

tan

use

RECORD in all modes of this Meter, but we

tan

not

Change

Meter modes while in RECORD, for example, from voltage

to

amperes.

In the AC amperes mode, the bar graph displays the rms

value of currentflow and also blinking

Pointers

at the record-

ed MAX and MIN.

But,

in the frequency mode, the bar graph

displays the rms value of

current

flow only. No

blinking

Pointers.

In SOFT, the softened values of rms currentflow, frequency

or voltage

is

recorded

for MAX, MIN, and AVG. The bar

graph displays instantaneous values of rmscurrent

wtth

blink-

ing

Pointers

for MAX and MIN.

In CREST(thatis,

PEAK)

mode, the half-cycle peak amperes

are recordedfor MAX.ln CREST mode,MIN and AVG are not

available. The bar graph displays a

Single

blinking

pointer

for MAX. The CREST (that is,

PEAK)

function is not

availa-

ble

in

the

other (V or Hz or

Q)

modes.

To stop recording, use the HOLD pushbutton. Then,

RECORD no longer blinks, and the

values

of MAX, MIN, and

AVG are frozen. Press the HOLD pushbutton again

to

restart

recording, when the values of MAX, MIN, and AVG are not

reset. The recording simply

Starts

again from where it

left

off.

16 17

Press and hold the MIN MAX pushbutton for 2 seconds and

Press

the

MIN MAX pushbutton for 2 seconds and then

then release in

Order

to exit RECORD. This Meter

ac-

release

tn

Order

to exit RECORD (or HOLD and RECORD

knowledges with a beep

Sound

and RECORD is no longer

if

selected). This Meter acknowledges with a beep

Sound

and

displayed.

RECORD is no longer displayed.

5.14 Using

Record

RECORD

MAX

HIN

AVG

nnn

AC

L/.dl

dlA,,s

After enabling RECORD. press the MIN MAX pushbutton to

cycle through the MAX, MIN, and AVG readings held in

memory.

If

this Meter is in CREST (that is,

PEAK)

function,

only

MAX is held in memory.

Battery

life

limits the

duration

of RECORD. The MAX reading is the maximum value

de-

tected

since

RECORD started. The MIN reading

is

the

mini-

mum value detected

since

RECORD

started.

The AVG

reading

IS

calculated continuously from the

Start

of RECORD.

To stop recording and to freeze the values of

MAX,

MIN, and

AVG in memory, press the HOLD pushbutton. Press the MIN

MAX pushbutton to cycle through the readings, including a

Position

where the

m

blinks. In this mode, readings

may be taken without disturbing the values held in memory.

To restart recording, press the HOLD pushbutton. Then,

RECORDblrnks.

.

.j

:.:.::::‘...

When using HOLD and RECORD, note that when RECORD

is blinking, this Meter is recording values; when RECORD

is not blinking, this Meter is not recording values. When

m

is blinking, the digital display is showing a real

measurement; when

m

is not blinking, the digital dis-

play is showing a

recorded

measurement. HOLD and

RECORD apply

to

the digital display only. The bar graph

Shows

a real measurement only at all times.

If

you press the MIN MAX pushbutton to

Start

recording while

in the HOLD mode, RECORD is not blinking

because

this

Meter is not recording values. And if you cycle through the

MAX. MIN, and AVG readings, this Meter displays just

-M-B

.

18

6. Applications of Measurement

6.1 Non-Linear Loads

True-RMS

current

flow is very impot-tant

because

it directly

relates to the amount of heat dissipated in wiring,

trans-

formers, and

System

connections. Most

ammeters

in the

market measure

average

current

flow, not true rms

current

flow, even if this

average

currentflow is displayed on a scale

calibrated

In

rms. These

average-sensing

ammeters

are

accurate only for a pure sign-wave

current.

All currentwaveforms are virtuallydistortedin some way. The

most common is

harmonic

distortion

caused

by non-linear

loads such as household electrical appliances, personal

Computers or

Speed

controls for motor drives.

Harmonie

distortion

caused

signrficant

current

flow at frequencies that

are at odd

multiples

of the power

Irne

frequency.

Harmonie

current

flow gives a substantial

impact

on the neutral

wires

of star

(wye)-connected

power distribution Systems.

In most countries a power distribution

System

uses

com-

mercial

3-Phase

50Hz/60Hz

power applied to a transformer

with a delta-connected

primary,

and a star

(wye)-connected

secondar-y.

The secondary generally provides

12OV

AC from

Phase

to

neutral, and

208V

AC from

Phase

to

Phase.

To

balance

the loads for

each

Phase

was a big headache for

the

electrical

System

designer, historically.

Thevectoradditionofthecurrentsinthetransformer’sneutral

wire was zero or quite low

(because

perfett-balance

was

rarely achieved) in a

weil-balanced

System,

devices

con-

nected to

which

were incandescent lighting,

small

motors,

and other devices that presented linear loading. The result

was an essentially sine-wave current flow in eachPhaseand

a low neutral

current

flow at a frequency of

50Hz/60Hz.

But,

devlces

such as TV

Sets,

fluorescent lighting,

Video

machines, and microwave ovens are commonly drawing

19

power line current for only a

fraction

of

each

cycle so that

they

Cause

non-linear loading and subsequent non-linear

current

flow.

This generates odd harmonics of the

5OHz/6OHz

line frequency. Therefore, the current in the transformer of

today contains not only a

50Hz

(or

60Hz)

component, but a

150Hz

(or

180Hz)

component, a

250Hz

(or

300Hz)

com-

ponent, and the other

significant

harmonic components up

to a

750Hz

(or

900Hz)

component and beyond.

The vectoraddition in a properly-balancedpower distribution

System

feeding

non-linear loads may still be quite low. But,

the addition does not cancel all the harmonic currents. The

odd multiples of the 3rd harmonic (called the

“TRIPLENS”)

are,

particularly,

added together in the neutral. These

harmonics

tan

form a total rms current in the transformer’s

neutral wire that is normally 130% of the total rms current

measured in any individual

Phase,

whose theoretical

maxi-

mum

is 173%. For example,

Phase

currents of 80 amperes

may

Cause

harmonic current flow in the neutral of 104

amperes. The dominant current flow in the neutral is most

commonly the 3rd harmonic.

The electrical

System

designer

must consider the following

3 issues when he designs a power distribution

System

containing harmonic current flow.

1.

2.

The AC neutral wiresmust be of suff icient gauge

to

allow

for harmonic current flow.

The distribution transformer must have additional cooling

to continue Operation at its rated

capacity,

if it is not

harmonie-rated.This

is

becausethe harmonic current flow

in the secondary neutral wire

is

circulating in the

delta-

connected

primary

winding, after it

is

reflected

to the

primary winding. The circulating harmonic current heats

up

the transformer.

Phase current harmonics are reflected to the

primary

winding and they continue back towards the power

Source.

This

tan

Cause

distortion of the voltage wave so

that any powerfactorcorrection capacitors on the line

tan

be easily overloaded.

We

tan

use this Meter to analyze components such as power

distribution transformers and power

factor

correction

capacitors.

20

6.2 General Applications

AEI

You

tan

measure

any

conductor carrying AC unless this

conductor is at a potential above 600V AC or at a frequency

above

10KHz.

True rms measurement yields the

effective

current value.

Press the ON OFF pushbutton to turn on this Meter.

Clamparound theconductor tobe measured.Be surethe

clampjaws are securely closed, or measurements will not

be accurate.

Observe the display for true rms current flow.

Press the Hz pushbutton to measure frequency.

Press the HOLD pushbutton to freeze the digital display,

if

necessary.

6. To soften readings, press the SOFT CREST pushbutton

once (SOFT displayed) or

to

measure half-cycle peak

amperes, press this pushbutton twice (PEAK displayed).

A

crest

factor

(see

5.11

Using Crest) other than 1.414

is

an

indication

of non-linear current flow.

7. To

record

readings and

to

view readings, press the MIN

MAX pushbutton.

8.

To

clear

RECORD, press the MIN MAX pushbutton for

2 seconds.

6.3 Motors

A

NEI

You

tan

measure starting (inrush) current, running current,

and current imbalance.Inrush current

is

typically 6 times the

value of running current, depending on the motor type.

l.Press

the ON OFF pushbutton

to

turn on this Meter.

9.Repeat

step 6, if necessary.

2.Clamp

around a motor

Phase

conductor. Be sure the

clampjaws are securely closed, or measurements will not

be accurate.

3.While

watthing

the bar graph, turn on the motor and

observe the

level

of inrush current. In this

case,

the bar

graph is

better

than the digital display

because

the bar

graph

response

is

faster

than the digital display.

~

.,

:,:

.:,.:

1::

!,L<’

..:.:

‘.

4

4.When

the motor

reaches

the desired

Speed,

observe the

running

curren!.

5.Repeat

your

measurement for

each

motor

Phase.

Un-

balanced

current may be

caused

by a voltage

imbalance,

or a shorted motor winding.

6.Repeat

Steps

1 thru 3, then press the MIN MAX

pushbutton

to

enable RECORD.

7.Turn

on the motor. When the motor gets

to

the desired

Speed,

note the blinking upper bar on the bar graph

(inrush rms current), and the displayedlevel(running rms

current).

8.To

view the maximum inrush current, press the MIN MAX

pushbutton once.

lO.To

clear

RECORD, press the MIN MAX pushbutton for

2 seconds.

6.4 Distribution Transformers

Am

You

tan

measure

excessive

current, load

balance

between

phases, true rms and frequency of neutral current. True rms

measurement yields the

effective

value.

1.

2.

3.

4.

5.

Press the ON OFF pushbutton to turn on this Meter.

Clamp around a Phasewire of the transformer. Be sure

the

clamp

jaws are securely closed, or measurements

will

not

be accurate.

Observe the display for true rms current flow.

Repeat your measurement for

each

Phase

to observe

balance.

Unbalanced

phases

Cause

large neutral

currents

flow.

Clamo

around the neutral wire.

22 23

6.

7.

8

9

10

11

Observe the display for true rms current flow. Any

significant

flow,

with

balanced

phases, indicates the

presence of harmonic

currents

Press

the

Hz pushbutton

to

measure the frequency of

neutral wire. Reading indicates the frequency of the

dominant current flow (in caseof harmonic current flow,

180Hz

reading in a

60Hz

System).

To freeze the digital display, press the HOLD

pushbutton.

To measure half-cycle peak amperes, press the SOFT

CREST pushbutton twice (PEAK displayed). A

crest

factor

other than 1.414

is

an

indication

of harmonic

current

flow.

. .

To

record

readings and

to

view maximum,

minimum,

and

average

values, press the MIN MAX pushbutton.

To

clear

RECORD, press the MIN MAX pushbutton for

2

seconds.

6.5 Adjustable Speed Motor Controllers

Ajoj

You

tan

measure inputcurrent, outputcurrentand frequency

of the adjustable

Speed

motor controllers.The output current

frequencyis used

to

calculate the rotating

Speed

ofthemotor,

while input current frequency

is

used

to

measure the

frequency of the power line. The frequency of the output

current is important

because

the voltage frequency

is

often

meaningless for the calculations of motor

controller

Speed.

24

1.

2.

3.

.:i

5.

6.

Press

the

ON

OFF

pushbutton

to

turn on this Meter.

Clamp around an input or output

Phase

(as required),

and run motor at desired

Speed.

Be sure the clamp jaws

are securely closed, or measurements will not be

accurate.

Observe the display for

true

rms current

flow.

Measure an output

Phase

of the motorcontrollerand use

Hz mode

to

measure frequency. Nominal motor

Speed

is calculated from RPM

=

120

FIP,

where F is the

fre-

quency measured, and P is the number of motor

poles.

To

record

readings and

to

view readings, press the MIN

MAX pushbutton.

To

clear

RECORD, press the MIN MAX pushbutton for

2

seconds.

7. Maintenance and Calibration

I

7.1 Maintenance

Repairs or

servicing

should only be performed by qualified

personnel.

25

Table 2. Replaceable Parts

l!a

WARNING!

TO AVOID ELECTRIC SHOCK, DO NOT PERFORM ANY

SERVICING PROCEDURE UNLESS YOU AREQUALIFIED

TO DO SO. READ

“CIAMP-ON

METER SAFETY” AT THE

BEGINNING OF THIS MANUAL BEFORE PROCEEDING.

To

assure

continued safety of

this

Meter, inspect this Meter

before use for

Cracks

or missing portions of the insulating

cover,

or for loose or weakened components. Pay

particular

attention

to

the insulation surrounding the clamp jaws and

clamp lever. Any Meter that fails this

inspection

should be

made inoperative by taping the clamp

shut.

Periodically wipe the

case

with a damp cloth and detergent;

do not use abrasives or solvents. Open the clamp jaws and

wipe the

magnetic

pole

pieces

with a lightly oiled cloth. DO

not

allow

rust or

corrosion

to

form on the pole

pieces.

The serial number is stamped on the back of the unit. The

serial

number should be used when ordering

Parts

or

requesting

servicekalibration

information.

7.2 Replaceable Parts

A

m

WHEN SERVICING THIS METER, USE ONLY THE

RE-

PLACEMENT PARTS SPECIFIED.

Replaceable

pans

are shown

In

Figure3andlisted inTable2.

7.3 Calibration

This Meter should be calibrated annually. Regarding the

servicelcalibration

information on this Meter, contact the

nearest distributor of this Meter.

I

DESCRIPTION

Lens, LCD

Cover, Rear

Screw,

Case

(metric)

Battery,

9V

User’s Manual

Clip-On

Holster

Test Lead Set

T

PART

NUMBER

CL2 LENS

CL2 CASE

CL2 SCRW

CL1 BT09

CL3 MAN

Cl30

TL34

26

Figure 3. Replaceable Parts

27

8 Technical Data and Specifications

AC Current

RMS AMPERES

”

8.1 Technical Data

Display: Digital

-

4000 counts

(3%

digits)

[Hz: 9999 counts], updates 4

times/sec.

Analog

-

Updates 20

timeslsec,

41

Segment

bar

graph.

Maximum Conductor Size:

$

51mm (2.00”)

Maximum Jaw Opening: 52mm (2.04”)

Max. Conductor Voltage: 600V rms

Frequency Range: Current Measurement

-

10Hz

to

2KHz

Frequency Measurement

-

0.5Hz

to

1OKHz

Crest

Factor,

Continuous Waveform: (45Hz

to

65Hz,

less

than

1000A

peak)

1.4 to 2.0 add 20. digits

to

accuracy below

100A

2.0

to

3.0 add 1%

to

accuracy

(+

20 digits below

100A)

3.0 to

5.0

add 2%

to

accuracy

(+

20 digits below

100A)

Adjacent Conductor

Effect:

1% of

current

in adjacent

conductor

max.

Operating Temperature:

-

10°C

to

55OC

Operating Humidity: 0%

to

80%

@

40°C,

70%

@

50°C

Storage Temperature:

-

20°C

to

60°C

Standard Equipment: Clamp-on Meter, Clip-on

Holster,

Test-leads, User’s manual,

and

9V

battery (installed)

’

1

Sm

Waw

measured

wh

conductot

centefed

at

allgnmenl

marks and

banery

I~fe

mdlcamn

greater

than

40

hours

on

meter

power

up

‘2 RMS

Utn/Max

ADD

10

comts

‘3

1A

and

above.

30Hr

-45Hr

‘C

AVG

only.

2 SA and

above

RMS

MtnlMax

Add 2%

of

readlng

INSTANTANEOUS AMPERES

(CREST

MODE1”’

RANGE

Battery Type:

NEDA

1604A

9V

or

6LF22

9V

Battery Life: 80 hours typical (alkaline)

Safety Standards: UL 1244, IEC

348/1010,

IEC 664

(Appropriate Parts) Installation Category

Ill,

CSA C22.2

No. 231,

ANSIIISA

S82, VDE 0411

Weight: Approx. 1.21 Ib

(5459)

Size:

4.39cm

H x

9.75cm

W x

24.5cm

L

(1.73”H

x

3.84”W

x

9.65”L)

04103999A

(40A

Scale)

0410 3999A

(4OOA

Scale)

400 to 599A

(400A

Scale)

8.2 Specifications

Accuracy

is

given as

f

([Yo

of reading]

+

[number of least

significant

digits]) at

18OC

to

28OC

with relative humidity up

to

80%,

for a period of one year after calibration.

6OOto

999A

(400A

Scale)

“1

Sames

as ‘1

“2

Samee

as

‘3“3

25Aand

above

P

ot

Speafied

~OHZ-~OHZ'~

1

.

I

RESOLUTION

ACCURACY

f(3%

+

30

dgts)

45Hz

-

65Hz

0.2A

+(4% +30 dgts) 30Hz-45Hz"z

f(4%t30

dgts)

65Hz-1KHz

'(4%t40

dgts) 20Hz-

30Hz"3

2A

4A

4A

+(3Vo

+3 dgls) 45Hz-65Hz

*(4%t3

dgts)

30Hz-45Hz‘.z

+(4%+3

dgls)

30Hz-45KHz

+(4%

+

4 dgts)

20Hz-

3OHz"z

*

3%

45Hz-65Hz

f

4% 30Hz-45Hz"z

*

4910

65Hz-1KHz

f

4%

20Hz

-

3OHz

“3

&7%

45Hz-65Hz

&7%

30Hz-45Hz“p

f

7%

65Hz-1KHz

*7%

20Hz-30Hz"3

28

29

Measurement Limits:

AC Amperes

:

True-rms 0.3

to

700A

DC Amperes

:

0.3 to 700A

AC Voltage

:

True-rms

0

to

750V

DC Voltage

:

0

to

750v

Frequency

:

0.5

to

9999Hz

Resistance

:

0

to

4KR

Continuity Check

:

Beep at Approx.

<35R

in the

40012

range

IB

WARNING!

READ “CLAMP-ON METER SAFETY” BEFORE USING

THIS METER.

Contents

1.

Introduction

2. Clamp-on Meter Safety

3. Explanation of Controls and

Indicators

4. Alignment Marks

5. How

to

Use this Meter

6. Applications of Measurement

7. Maintenance and Calibration

8. Technical Data and Specifications

..,

~;~.~,y:~,~,~:.:::

:.:.:::,“.‘;:

,..

.’

1.

Introduction

I

This Meter is a

handheld

and

battery

operated True-RMS

i:;,

,!j:;;::;

::.::::;iil~f’::,:::;~~:~:~,~~

Clamp-on Meter that is designed and tested according

to

IEC

Publication

348, Safety

Requirements

for Electronic

Measuring Apparatus

(Protection

Class

II)

and other safety

Standards (see “Technical Data”).

This Meter combines the

Speed

and

versatllity

of a high

resolution analogdisplaywith the precision of a digitalmeter.

Table of contents

Popular Power Tools manuals by other brands

Hilti

Hilti NPR 019 IE-A22 Original operating instructions

Bosch

Bosch Professional GBH 18V-34 CF Original instructions

Drill Master

Drill Master Drill Doctor 500X user guide

Hilti

Hilti NURON SIW 8-22 Original operating instructions

Taurus

Taurus BT-CK 18 2B-1.5 Kit instruction manual

Baileigh Industrial

Baileigh Industrial SBR-5216 Operator's manual

Xytronic

Xytronic lf-852d operating manual

Omega Lift

Omega Lift 13120 Operating instructions & parts manual

Chicago Pneumatic

Chicago Pneumatic MS 690 Safety and operating instructions

Briggs & Stratton

Briggs & Stratton Simplicity 1752205 Customer Contact Guide

Craftex

Craftex CT106 owner's manual

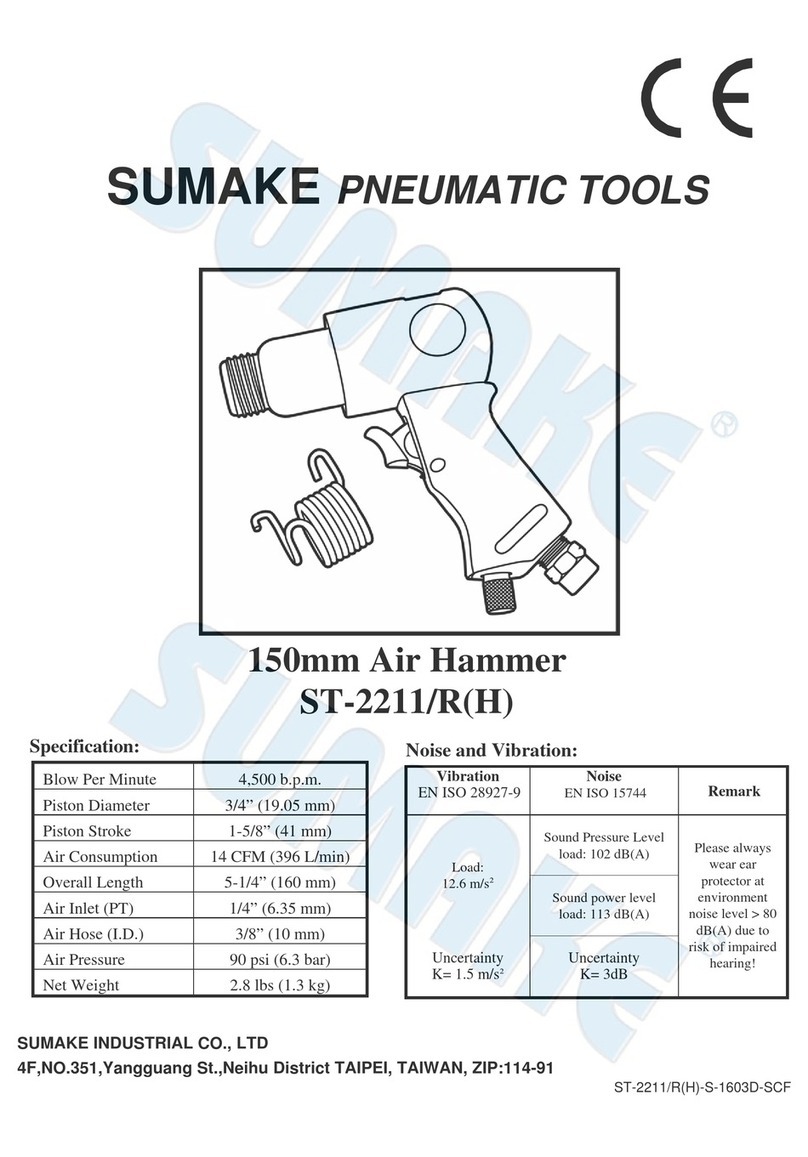

Sumake

Sumake ST-2211 quick start guide