FINO 91463 Operation manual

FINO Kältetrockner

91463

Original FINO

Germany

Kältetrockner

refrigeration dryer

sécheur frigorifique

secador frigorífico

essiccatore a refrigerazione

vriesdroger

kondenzační sušič tlakového vzduchu

Kyltork

Osuszacz chłodniczy

hűtveszárító

Gebrauchsinformation•User Information•Mode d’emploi

Información sobre el uso•Informazioni d’uso

Gebruiksaanwijzing•Instrukcja stosowania

FINO

•der feine Unterschied•the fine difference•la fine différence•la fina diferencia•la fine differenza

Version 1/2016. Read the User Manual prior to commencing work!

1. Fields of application 3

2. Safety precautions 3

3. Commissioning 3

• Prior to commissioning • Location• Installation

4. Commissioning 4

• Safety precautions • Operation

5. Maintenance 5

6. Cleaning 5

7. Storage 5

8. Technical data 5

9. Delivery forms 5

10. Guarantee 5

11. Problem identification and handling 6

12. Disposal 6

TABLE OF CONTENTS

2

1. Fields of application

The FINO refrigeration dryer removes humidity from

the compressed air by cooling it down to nearly free-

zing point. This condenses the humidity in the com-

pressed air. The formed condensate is expelled

automatically. The air is heated prior to leaving the

refrigeration dryer. This reliably protects against cor-

rosion damage and thus extends the service life of all

technical equipment and instruments.

2. Safety precautions

The air generated by the refrigeration dryer does not

have breathing air quality. To generate breathing air

quality, the compressed air needs to be cleaned in

accordance with applicable laws and standards.

Never play with compressed air. Do not direct the jet

of compressed air at the skin or third parties. Under

no circumstances use compressed air to remove dirt

from clothes. Do not walk or stand on the refrigera-

tion dryer or its components.

The refrigeration dryer contains refrigerants:

• Do not inhale refrigerant vapours under any

circumstances. Ensure that the work room is

adequately ventilated, otherwise use breathing

protection.

• Direct contact with refrigerants causes frostbite

of the skin. Always wear refrigerant-resistant

gloves to prevent localised hypothermia. If the

skin comes into contact with refrigerants, rinse

with water. If liquid refrigerant penetrates through

clothes to the skin, then under no circumstances

should the clothes be removed, instead apply

copious amounts of clear water to the clothes

until the entire refrigerant has been rinsed off,

then seek medical attention.

3. Commissioning

3.1 Prior to commissioning

Read the instructions for use carefully and keep

these readily available.

The device is to be checked on one's own responsi-

bility for operational safety prior to use. Defective

parts are to be replaced immediately. Prior to con-

necting the piping, remove all stoppers, caps or

bags of drying agents. Select air hoses and distribu-

tor pipes and connections of the correct size corres-

ponding to the operating pressure.

3.2 Location

Position the refrigeration dryer indoors on an even,

load bearing surface. Keep a minimum distance of

1.5 m between the top of the device and the room's

ceiling. Keep a minimum distance of 1.5 m between

the back of the compressor and the room's walls (1).

Choose the position of the refrigeration dryer such

that the ambient air is free of dust and the minimum

and maximum ambient temperature are maintained

(cf. Technical data » Limit values). The intake air

must not contain any inflammable particles, for

example, solvents, which could explode or ignite

inside the device. Do not block the air intake under

any circumstances. Ensure that loose-fitting clothing

cannot be sucked in.

Ensure that the pipelines can expand at heat and are

not positioned near combustible material.

No external forces may act on the air outlet valve.

The connected pipelines must be free of tension.

The electrical connections must comply with applica-

ble regulations. The refrigeration dryer must be

grounded and secured against short-circuiting with

fuses for all phases. A lockable circuit breaker (2)

must be installed in the immediate vicinity of the

device.

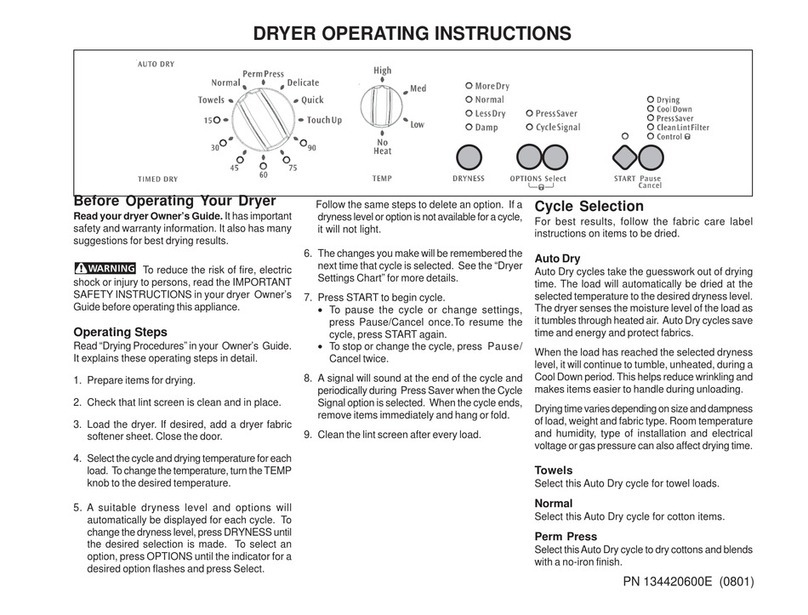

3.3 Installation

Provide the dryer with the voltage given on the type

plate via a power cable (1). Lay the condensate drain

hose (2) to the condensate collector via a funnel for

visual inspection of the effluent.

Attach an air inlet line and an air outlet line (5) inclu-

ding seal (6) to the marked inlet (3) and outlet pipes

(4) of the refrigeration dryer. Seal the ends of the

valves well with Teflon tape and screw a coupling (7)

to each. Connect the compressed air lines.

3

ENU

4. Commissioning

4.1 Safety precautions

Do not operate the machine outside the limit values.

Keep all sound-proofing covers closed during opera-

tion. Wear hearing protection if a sound-proofing

cover has to be opened for a short time, e.g. to per-

form routine inspection.

Check regularly that:

• all panels are fitted and secured safely,

• all hoses and pipes in the machine are tight,

• all securing elements are tightened firmly,

• the safety valves and other overpressure devices

are not blocked through dirt or paint,

• the air outlet valve and air network is free of wear

or damage.

12 7

3 4

56

4.2 Operation

pressure dew point indicator (1)

ON/OFF switch of the dryer (2)

To ensure best efficiency, do not operate the

ON/OFF switch of the dryer repeatedly over a short

period of time. Do not restart the dryer before

at least 5 minutes after switching off to allow

pressure compensation.

Start the dryer before the compressor and

switch off after the compressor to avoid forming

condensate in the compressed air network.

Starting:

1. Operate the ON/OFF switch of the dryer.

2. Open the air inlet valve.

3. Open the air outlet valve

approx. 5 minutes later.

4. The nominal dew point is reached

approx. 10 minutes later.

Stopping:

1. Close the inlet and outlet valves of the dryer.

2. Operate the ON/OFF switch of the dryer.

The dryer stops.

The following should be checked regularly:

• the pressure dew point indicator on the operating

panel. Under conditions deviating from the

nominal conditions (air inlet conditions or volume

flow), the pressure dew point will also deviate

from the nominal value.

• whether condensate flows out via the condensate

drain. The volume depends on the operating

conditions.

4

5. Maintenance

All maintenance work should be carried out after

cooling of the machine.

Close the inlet and outlet valves and release the

pressure in the dryer by operating the test key on the

condensate drain. Then switch off the power voltage.

Open the circuit breaker to prevent unintentional

starting.

Only perform maintenance work and repairs with

suitable tools and safety wear. Only use original

spare parts. Do not perform repairs in the refrigera-

tion dryer yourself, contact the dealer.

Observe cleanliness during all maintenance work.

Cover components and exposed openings with clean

cloths, paper or tape to keep dirt away. Under no cir-

cumstances should corrosive or inflammable sol-

vents or carbon tetrachloride be used for the

cleaning of components. Protect the motor and

electrical components against moisture, for exam-

ple, during steam cleaning.

Under no circumstances should welding or other

modifications be carried out on the pressure vessel.

If overheating of an internal component is

suspected, stop the machine. Do not open any

panels until the machine has cooled down sufficient-

ly to avoid the risk of spontaneous inflammation of

the oil vapours at the air inlet.

Under no circumstances use a light source with open

flame to inspect the interior of the device.

Ensure that no tools or other loose parts are left in or

on the machine.

Prior to releasing the refrigeration dryer for renewed

operation, ensure that the settings for operating

pressure, temperature and time are correct. Check

whether the control and cut-off devices are installed

and in perfect working condition.

6. Cleaning

Always keep the refrigeration dryer clean.

Take the same safety precaution before cleaning as

those before maintenance.

Clean the filter once a week. To this purpose, remo-

ve the filter from the automatic condensate drain.

Clean from the inside to the outside with an air jet.

Then re-install the filter.

Brush or air-blast the ribbed surface of the conden-

ser once per month. Do not clean with water or

solvents.

7. Storage

Store the device in its original packaging vibration-

free in a dust-free and dry place at a temperature

between 0 °C and 40 °C.

8. Technical data

External dimensions: 35.0 x 50.5 x 48.5 cm

Power rating: 230 V/50 Hz

Output: 130 W

Operating pressure: 7-13 bar

Weight: 19.0 kg

Reference conditions:

Compressed air inlet pressure: 7 bar

Compressed air inlet temperature: 35 °C

Ambient temperature: 25 °C

Pressure dew point: 3 °C

Limit values:

Maximum compressed air inlet pressure: 13 bar

Min./max. ambient temp.: 5-43 °C

Max. compressed air inlet temperature: 55 °C

9. Delivery forms

FINO refrigeration dryer complete with air/air and

air/refrigerant plate heat exchanger, refrigerant

compressor, condenser, condensate drain and

0.15 kg of refrigerant.

10. Guarantee

Our technical recommendations for use are based

on our own experience and tests and only represent

reference values. It is left to the specialist knowled-

ge of the user to check whether the products sup-

plied by us are suitable for the intended processes

and purposes. Our products are subject to continu-

ous further development. We therefore retain the

right to changes in design and composition. Of cour-

se, we guarantee the perfect quality of our products.

5

ENU

11. Problem identification and handling

1. The pressure dew point is too high.

• The air intake temperature is too high.

Install pre-cooler.

• The ambient temperature is too high.

Position the dryer at a cooler place.

• The air intake pressure is too low.

Adjust pressure switch.

• Dryer capacity exceeded. Reduce air flow.

• Insufficient refrigerant. To be checked and

corrected by manufacturer.

2. The condenser pressure is too high or too low.

• The fan is not working. Change fan motor.

• The condenser is blocked on the outside.

Clean condenser.

3. The compressor misfires or does not start.

• The power supply to the compressor is

interrupted. Check and rectify if required.

• Thermal protection of the refrigerant compressor

motor has been triggered. Reset thermostat

protection.

• Dryer has been restarted too quickly,

not enough time for pressure compensation.

Wait several minutes and restart.

4. The condensate drain does not work.

• Drain system blocked. Have system checked by

manufacturer.

5. The evaporating pressure is too high or too low

during discharge.

• The condenser pressure is too high or too low.

See 2.

• Insufficient refrigerant.

To be checked and corrected by manufacturer.

12. Disposal

This device may not be disposed of as

domestic waste! Refrigerant may not be pas-

sed into the atmosphere. Dispose exclusively

via certified specialist companies.

Important!

FINO GmbH has prepared these instructions to help

users operate the unit and to make it easier to take

the unit into operation for the first time and then use

it. FINO GmbH cannot be held liable for damages

due to improper use or due to modifications made to

the device itself. The warranty will be voided if the

unit is used for any purpose other than its proper

intended purpose.

FINO GmbH has a policy of continuously developing

and improving its products. FINO retains the right to

change or improve the products described in this

documentation or the document itself without prior

announcement. FINO offers no guarantees for the

completeness or correctness of this document.

6

7

ENU

FINO GmbH

Mangelsfeld 18

D-97708 Bad Bocklet

Tel +49-97 08-90 94 20

Fax +49-97 08-90 94 21

Table of contents