FIOCCHETTI 130 User guide

Pag. 1di 56

Pag. 3di 56

READ THIS USER MANUAL CAREFULLY

Failure to read this manual and any misunderstandings regarding the instructions contained

within it can cause irreversible damage to the unit, as well as create a source of danger for

users and significantly decrease device performance.

The manufacturer declines all responsibility for any uses other than those listed below.

Any maintenance operations must be carried out by personnel authorized by the

manufacturer FIOCCHETTI.

The corresponding warranty will become immediately void in the event of use or

maintenance of equipment not in compliance with specifications by the manufacturer

FIOCCHETTI.

The material contained in this manual is for informational purposes only. Its contents and

the product itself may be subject to change without prior notification. In no event shall the

manufacturer FIOCCHETTI be held responsible for any damage due to use of this manual.

Provide all the information required regarding operation of the device being tested in

order to request technical support from FIOCCHETTI.

Natural gas but inflammable R290

The refrigerator contains fuel refrigerant, even if permanently sealed according

to the standard UNI EN 1127-1.

Do not damage refrigerant circuit tubes.

The environment of installation must have, in compliance with EN378, a volume of 1 m3

every 8 gr of R290 refrigerant contained in the circuit. The quantity of gas included in the

circuit is declared on the silver data plate attached inside the device.

Revision

Date

Description

B

09/2015

Update content.

C

06/2016

Updated content.

D

06/2017

Updated content.

E

10/2018

Updated introduction, alarms and failures tables.

F

06/2019

Warning on the refrigerant gas

MNL004_EN rev. F

Pag. 4di 56

TABLE OF CONTENTS

1GENERAL INFORMATION............................................................................................................................................ 6

1.1 CERTIFICATION.......................................................................................................................................................... 6

1.2 TESTING AND WARRANTY ........................................................................................................................................ 6

1.3 PURPOSE, CONTENT AND RECIPIENTS OF THE MANUAL ......................................................................................... 6

1.4 ARRANGEMENTS PREPARED BY THE CUSTOMER .................................................................................................... 6

1.5 REQUEST FOR TECHNICAL SUPPORT ........................................................................................................................ 7

2SAFETY ....................................................................................................................................................................... 7

2.1 GENERAL SAFETY RULES ........................................................................................................................................... 7

2.2 SAFETY AND ACCIDENT PREVENTION....................................................................................................................... 7

2.3 CONTRAINDICATIONS............................................................................................................................................... 8

2.4 WARNING ON THE REFRIGERANT GAS ..................................................................................................................... 8

3PRODUCT DESCRIPTION ............................................................................................................................................. 9

3.1 TECHNICAL DESCRIPTION ......................................................................................................................................... 9

3.2 INTENDED USE .......................................................................................................................................................... 9

3.2.1 laboratory devices................................................................................................................................................. 9

3.2.2 medical devices ................................................................................................................................................... 10

3.3 TRANSPORT AND HANDLING.................................................................................................................................. 11

3.4 POSITIONING .......................................................................................................................................................... 11

3.5 CLEANING................................................................................................................................................................ 12

3.6 WIRING AND ELECTRICAL CONNECTION ................................................................................................................ 12

3.6.1 ELECTRICAL PROTECTIONS .................................................................................................................................. 13

3.7 SET-UP OPERATIONS............................................................................................................................................... 13

3.8 USE OF THE INTERNAL COMPARTMENT AND MATERIAL STORAGE ...................................................................... 13

3.8.1 SHELVES INSTALLATION ...................................................................................................................................... 14

3.8.2 DRAWERS INSTALLATION.................................................................................................................................... 14

3.8.3 PLACING MATERIAL INSIDE THE COMPARTMENT .............................................................................................. 15

3.9 INDICATION FOR OPTIMAL USE.............................................................................................................................. 16

4ECT-F DISPLAY FUNCTIONING................................................................................................................................... 17

4.1 CONTROL PANEL ..................................................................................................................................................... 17

4.2 ECT-F CONTROL OPERATION .................................................................................................................................. 19

4.2.1 SWITCHING ON ................................................................................................................................................... 19

4.2.2 How to customise the display ............................................................................................................................. 20

4.2.3 ECT-F Menu Functions......................................................................................................................................... 21

4.2.3.1 Turning off the equipment .......................................................................................................................................... 21

4.2.3.2 Changing the setpoint.................................................................................................................................................. 21

4.2.3.3 Manual defrost function.............................................................................................................................................. 22

4.2.3.4 Recorded alarms log .................................................................................................................................................... 22

4.2.3.5 Language selection ...................................................................................................................................................... 23

4.2.3.6 Setting the user password ........................................................................................................................................... 24

4.2.3.7 Service menu ............................................................................................................................................................... 24

4.2.3.8 Setting the date and time ............................................................................................................................................ 24

4.2.3.9 Doctor View test function............................................................................................................................................ 25

4.2.4 Alarm and failure signals .................................................................................................................................... 25

4.2.4.1 Fault in progress warning ............................................................................................................................................ 25

4.2.4.2 Fault ended warning.................................................................................................................................................... 25

4.3 DMLP DIGITAL MONITOR OPERATION ................................................................................................................... 26

4.3.1 DMLP Digital Monitor Switching On ................................................................................................................... 27

4.3.2 Display configuration .......................................................................................................................................... 27

4.3.3 DMLP Digital Monitor Menu Functions............................................................................................................... 28

4.3.3.1 Turning off the DMLP Digital Monitor ......................................................................................................................... 28

4.3.3.2 Recorded alarms log .................................................................................................................................................... 29

4.3.3.3 How to change temperature alarm limits.................................................................................................................... 30

4.3.3.4 Door openings visualization......................................................................................................................................... 30

4.3.3.5 Setting the user password ........................................................................................................................................... 31

4.3.3.6 Setting the date and time ............................................................................................................................................ 31

4.3.3.7 Printer menu................................................................................................................................................................ 32

4.3.3.8 Service Menu............................................................................................................................................................... 36

MNL004_EN rev. F

Pag. 5di 56

4.3.3.9 How to remove SD card............................................................................................................................................... 37

4.3.3.10 How to modify the language ....................................................................................................................................... 38

4.3.3.11 How to modify compartment functions (only for double temperature equipment)................................................... 38

4.3.3.12 Special function: TEST.................................................................................................................................................. 39

4.3.4 Alarm and failure signals .................................................................................................................................... 40

4.3.4.1 Fault in progress warning ............................................................................................................................................ 40

4.3.4.2 Fault ended warning.................................................................................................................................................... 40

5ROUTINE AND SPECIAL MAINTENANCE .................................................................................................................... 41

5.1 PROHIBITION OF SAFETY DEVICE REMOVAL............................................................................................................ 41

5.2 CLEANING THE UNIT INSIDE AND OUTSIDE.............................................................................................................. 41

5.3 CLEANING THE CONDENSER.................................................................................................................................... 41

5.4 CONDENSATE WATER DRAINING............................................................................................................................. 43

6DEMOLITION ............................................................................................................................................................ 44

7ANNEXES.................................................................................................................................................................. 44

8LABELLING................................................................................................................................................................ 45

8.1 MACHINE DATA PLATE............................................................................................................................................. 45

8.1.1 OTHER LABELLING ................................................................................................................................................... 46

9CONSUMABLE MATERIALS ....................................................................................................................................... 47

10 TROUBLESHOOTING ................................................................................................................................................. 48

11 DIAGNOSTIC............................................................................................................................................................. 49

ANNEXES .......................................................................................................................................................................... 53

ANNEX 1 ................................................................................................................................................................................. 53

ANNEX 2 ................................................................................................................................................................................. 54

MNL004_EN rev. F

Pag. 6di 56

1GENERAL INFORMATION

1.1 CERTIFICATION

All Refrigerated cabinets are built in accordance with the relevant European Directives applicable at the time of its

placing on the market. The Refrigerated cabinets are certified in accordance with Directives 2006/42/EC, 2014/30/EC,

2014/35/EC and subsequent integrations, built according to the safety requirements for electrical appliances for use in

the laboratory (CEI EN 61010-1). In the case of medical devices suitable for the storage of blood or blood products,

equipment is certified in accordance with Directive 93/42/EEC and its integration Directive 2007/47/EC.

1.2 TESTING AND WARRANTY

The machine is tested at our factory in accordance with current regulations and it is shipped ready to use. The warranty

is valid for 12 months from the date of delivery and establishes the right to repair/replace parts that are defective, not

including electrical and electronic parts. Apparent defects and any deviations from orders must be communicated to

the manufacturer within 5 days of receipt of the goods under penalty of invalidation of the warranty. Any other defects

(not apparent) must be communicated within 5 days of discovery, and in any case within the maximum 6 months

warranty period. The customer will only be entitled to the repair or replacement of goods, with the absolute exclusion

of any direct or indirect damages of any kind. In any case, the right to repair or replacement of materials must be

exercised within the maximum time limit provided by the warranty, with the time limits having been contractually

reduced with respect to those established by law. Repair or replacement of defective materials will occur at the

manufacturer's factory, where materials must be delivered with freight prepaid. The manufacturer will then return them

carriage forward.

1.3 PURPOSE, CONTENT AND RECIPIENTS OF THE MANUAL

This manual has been drafted for the purpose of providing all the instructions necessary for correct use of the machine

and for maintaining it in perfect condition, in particular with regard to the user's safety. The following professional

figures shall be defined in order to identify tasks and responsibilities:

Installer: qualified technician who performs machine placement and commissioning in accordance with the

instructions in this manual.

User: person who, after carefully reading this manual, uses the machine for his own permitted uses. It is mandatory for

the user to read the manual carefully and make reference to it.

Routine maintenance worker: qualified technician able to carry out routine maintenance on the machine, following

the instructions in this manual.

Special maintenance worker: qualified technician authorised by the manufacturer, able to carry out special

maintenance on the machine.

The manufacturer declines any responsibility for improper or unreasonable use of the machine and for all those

operations carried out on the same ignoring the instructions in this manual.

The manual must be kept in an accessible location known to all operators (installers, users, routine and special

maintenance workers).

No part of this manual may be reproduced and/or disclosed by any means and in any form whatsoever.

1.4 ARRANGEMENTS PREPARED BY THE CUSTOMER

The following arrangements are set by the customer:

-The machine electrical connection, with care of SUPERARTIC models

-Installation site arrangement

-Routine maintenance

-Refrigerator cleaning and the products used for it

MNL004_EN rev. F

Pag. 7di 56

1.5 REQUEST FOR TECHNICAL SUPPORT

Provide all the information required regarding operation of the device being tested in order to request technical support

from FIOCCHETTI.

For this purpose, send the table in Annex 1 (pag. 53) “USER DATA FOR TECHNICAL SUPPORT REQUEST”

filled in.

Technical support department e-

mail

assistenza@fiocchetti.it

Sales department e-mail

commerciale@fiocchetti.it

Support request

http://www.fiocchetti.it/it/tecnico-frigo.asp

User manual request

http://www.fiocchetti.it/it/manuali-frigoriferi-congelatori-

emoteche.asp

Tel.

+39 0522 976232

Fax

+39 0522 976028

Our Technical Support Department can provide all the information you need for correct unit operation and can put

you in touch with your nearest authorised service centre. Our Sales Department staff provides information on prices

and availability of requested components.

2SAFETY

2.1 GENERAL SAFETY RULES

Read the manual carefully and follow instructions contained herein. Do not use the equipment for purposes other than

those for which it was designed.

The user assumes full responsibility in case of operations carried out without observing the instructions in the manual.

Below is a list of the main safety rules:

-Do not touch the equipment with moist or wet hands or feet.

-Do not insert screwdrivers or other objects into the guards or moving parts.

-Do not pull the power cord to disconnect the appliance from the electrical mains.

-Do not allow the machine to be used by unauthorised users.

-Before performing any cleaning or maintenance, disconnect the machine from the electrical mains by switching it

off and disconnecting the plug.

-In case of failure and/or malfunction, switch off the machine and do not attempt to repair or service it on your

own. It is absolutely necessary to contact qualified personnel.

2.2 SAFETY AND ACCIDENT PREVENTION

This machine has been designed with suitable measures to assure safety and the health of the user. The following is a

list of protections adopted against mechanical risks:

-Stability: the machine has been designed and built in order to guarantee its stability in all foreseen operating

conditions, even with shelves/drawers extracted, without any risk of tipping, falling, or sudden movement.

-Surfaces, edges, corners: within the limits permitted by their functions, accessible parts of the machine have no

sharp corners, sharp edges or rough surfaces that could cause injury.

-Moving parts: all components with the possibility of movement have been designed, built and configured to avoid

risk. Some parts are also protected by fixed guards to prevent contact or injury.

The following is a list of measures adopted to protect against other risks:

MNL004_EN rev. F

Pag. 8di 56

-Electrical power: the machine has been designed, built and fitted with the aim of preventing risks of electric shock,

in compliance with established safety regulations.

-Noise: the machine has been designed and built to minimise risks related to the emission of acoustic noise (always

lower than 70 dB).

The following is strictly forbidden:

-Tampering with or removing the evaporator cover enclosure that protects the user from a risk of cutting on the

evaporator fins

-Removal of the data plates fixed in the inside edge of the motor compartment that contain technical specifications

and earth connection warnings

-Removal of the data plate fixed on the evaporator unit guard and near the electrical wiring inside the motor

compartment, which warns the user to disconnect power before working on the unit.

The manufacturer declines any responsibility for safety of the machine if the above recommendations

are not observed.

2.3 CONTRAINDICATIONS

The refrigerated cabinet must not be used:

-exposed to weathering

-With adapters or extension cords

-In explosive atmospheres or where there is a risk of fire

-Near to heat sources (radiators, etc.)

-

2.4 WARNING ON THE REFRIGERANT GAS

If in the device a flammable gas is used like R290 refrigerant, the following label appears on the compressor.

In this case, some special precautions should be taken:

- position the appliance in an environment of suitable dimensions in compliance with EN 378: the environment must

have a volume of 1m3every 8gr of R290 refrigerant. The quantity of gas contained in the circuit is declared on the silver

data plate attached inside the cabinet.

- do not use the equipment if damaged.

- to avoid damages to the refrigerant circuit, do not use mechanical devices to accelerate defrost process.

- make sure that air grids are always free to guarantee a certain ventilation to the device.

- if there is refrigerant leakage, avoid using open flames, remove from the device flammable products and ventilate

immediately the environment.

- do not store potential explosive substances (for example spray cans containing flammable gases) inside the device.

Do not use electrical appliances inside the refrigerated cabinet.

If any malfunction, disconnect the equipment from the mains.

Extraordinary maintenance should be performed only by qualified personnel.

MNL004_EN rev. F

Pag. 9di 56

3PRODUCT DESCRIPTION

3.1 TECHNICAL DESCRIPTION

The refrigerated cabinet covered by this manual produces cold by means of low-pressure vaporisation of a liquid

refrigerant, such as HCFC, HFC, inside a heat exchanger (evaporator). The vapour thus obtained is brought back to

the liquid state by means of a higher pressure mechanical compression (via a compressor) followed by cooling in another

heat exchanger (condenser). The correct, uniform distribution of air inside the cabinet is guaranteed by one or more

fan motors, depending on the model.

The machine is composed of a modular monocoque coated with different materials and insulated with polyurethane

foam at a density of 43 kg/m³.

The instrumentation is grouped on the front panel. On some models, the motor compartment, where the condenser

unit and electrical wiring can be housed, closes automatically.

Inside, the machine is equipped with brackets suitable for supporting wire shelves, extractible drawers and steel baskets.

The doors on all machines are equipped with a closing device with automatic return and door lock and easily replaceable

magnetic seals for perfect tightness. Measures were taken during design and construction to obtain a machine that

meets specific safety requirements, such as internal rounded corners, condensate liquid drainage, no rough surfaces,

fixed guards on moving or potentially dangerous parts, and so on.

The maximum capacity of shelves and drawers load on all Fiocchetti models is 30 kg with weight uniformly distributed.

All models are for indoor use and cannot be installed outdoors. Warranty will immediately expire, if

equipment is installed improperly.

3.2 INTENDED USE

All the listed models are suitable for storage. For this reason, we suggest only storing products that have already been

refrigerated or frozen (depending on the model).

We declare that any use outside of those allowed by the machine is considered as “improper use” and therefore the

manufacturer declines all responsibility.

3.2.1 LABORATORY DEVICES

Laboratory devices are suitable for:

-Storage of correctly packaged drugs, vaccines, and reagents that are not liquids or body tissues intended for

administration or introduction into the body

-Storage of other substances or materials for general use in a non-flammable or non-explosive hospital, laboratory

or pharmaceutical environment

-They are not to be used for the storage of blood, fluids or body tissues.

This category includes series models:

MEDIKA +2°C +15°C

MEDIKA 2T +2°C +15°C

LABOR +2°C +15°C

LABOR 2T +2°C +15°C / -15°C -24°C

VISION -10°C -20°C

VISION 2T +2°C +15°C / -10°C -20°C

FREEZER -10°C -25°C

SUPERARTIC -20°C -40°C

SUPERARTIC 2T +2°C +10°C / -20°C -35°C

TER +15°C +30°C

SPARK PROOF +2°C +15°C

MNL004_EN rev. F

Pag. 10 di 56

3.2.2 MEDICAL DEVICES

According to Directive 2007/47/CEE and Directive 93/42/CEE, class IIa medical devices are intended to:

•Storage of blood, fluids or body tissues

•Storage of correctly packaged drugs, vaccines, and reagents of any kind

•Storage of other substances or materials for general use in a non-flammable or non-explosive hospital,

laboratory or pharmaceutical environment.

This category includes models:

EMOTECA +4°C

EMOTECA TWIN +4°C

PLASMA VISION -15°C -20°C

PLASMA VISION 2T +2°C +15°C / -15°C -20°C

PLASMA FREEZER -10°C -25°C

PLASMA-LABOR 2T +2°C +15°C / -15°C -20°C

PLASMA SUPERARTIC -20°C -40°C

PLASMA SUPERARTIC 2T +2°C +10°C / -20°C -35°C

MNL004_EN rev. F

Pag. 11 di 56

3.3 TRANSPORT AND HANDLING

The machine must be transported and handled solely in a vertical position and following the instructions printed on

the packaging. This precaution is necessary to avoid contamination of the compressor with oil which may cause the

rupture of valves, of the cooling coils and problems with electric motor starting.

The accessories supplied with the machine (slides, wire shelves, drawers, baskets, etc.) are shipped inside the unit. The

machine is fixed on a wooden pallet by means of screws, wrapped with polyethylene and packaged in cardboard, a

wooden crate or wooden case.

The machine must be handled using a forklift or pallet truck with suitable forks (fork length at least equal to 2/3 length

of the unit).

If the machine needs to be set down in order to bring it into the installation location, it is absolutely necessary

to wait at least 6 hours before switching it on.

The manufacturer declines any responsibility for problems due to transport carried out in any condition

different from those specified above.

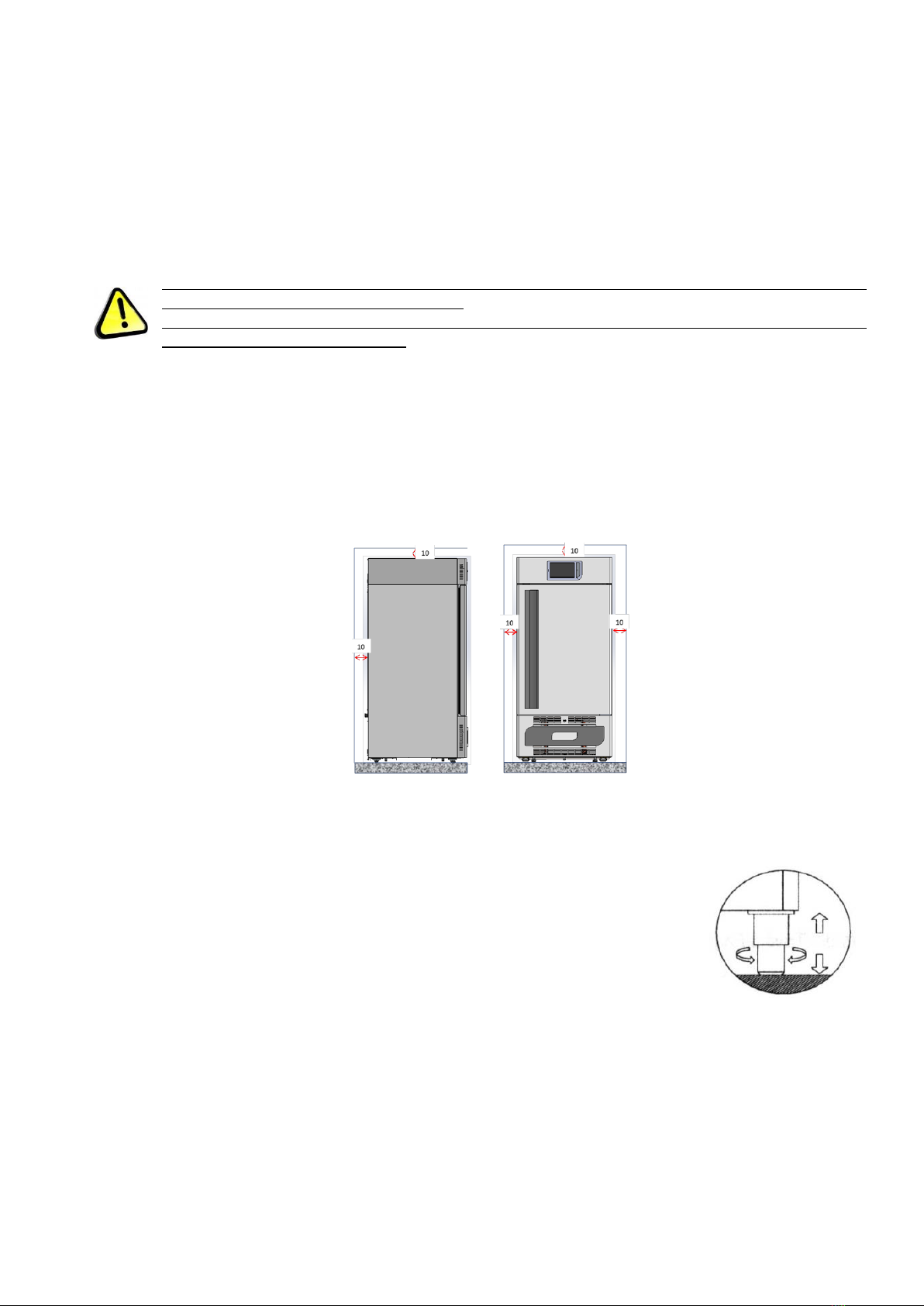

3.4 POSITIONING

Incorrect positioning can cause damage to the machine and create dangerous conditions for users; therefore, the

installer must comply with the following general rules:

-Position the machine keeping a minimum distance of 10 cm from all walls. If the machine is embedded in any type

of furniture, a correct air flow of the condensing unit (compressor/fan motors) must be always ensured. The

warranty will immediately expire, if this is not guaranteed. (Figure 1 –equipment position)

Figure 1 –equipment position

-Set the machine in a sufficiently ventilated environment.

-Place the machine far from heat sources and far from sources of electromagnetic interferences (such as motors,

generators, infrared beams, telephones) which can have negative effects on equipment functioning.

-Avoid exposure to direct sunlight and air conditioning flows.

-Remove the supplied accessories and the wooden pallet base.

-Position the machine with the aid of a spirit level. If necessary, adjust the levelling feet

on the metal base (on models fitted with adjustable feet) (Figure 2 –adjusting feet).

Figure 2 –adjusting feet

MNL004_EN rev. F

Pag. 12 di 56

3.5 CLEANING

Equipment is shipped already cleaned. However, it is advised to carry out a further washing following the instructions

below:

-Remove the protective PVC film from the external surfaces of the machine.

-Clean the inside of the chamber with a cloth dampened with alcohol in order to eliminate the

protective oil.

The glass door must be cleaned using a cloth dampened with water.

Do not therefore use chemicals.

3.6 WIRING AND ELECTRICAL CONNECTION

The electrical system and connection must be set up by qualified personnel.

Please follow the instructions below for safety reasons:

-Make sure that the system is suitably sized for the absorbed power of the machine.

-It is essential to properly connect the machine to an effective grounding system set in accordance with current

legislation.

-In the event of incompatibility between the outlet and machine plug, replace the outlet with a suitable type, provided

that the part is approved according to the laws in force.

-If electrical cable is damaged, it must be replaced by qualified personnel to prevent any risk.

-If the freezer is supplied without a plug, connect it directly under the switch board.

-Do not interpose adapters and/or reducers.

Special attention should be paid to SUPERARTIC model electrical connection as absorption is high. Prepare

cables with a cross section of at least 2.5 mm2 and with a limited length.

Figure 3 - glass

cleaning label

MNL004_EN rev. F

Pag. 13 di 56

3.6.1 ELECTRICAL PROTECTIONS

Fiocchetti devices are equipped with 2 safety fuses (phase and neutral) with integral protection against electric shocks,

short circuits and over-currents, and according to the standards for laboratory devices.

The fuses can be accessed from the front: open the refrigerator door and the fuses will be found behind the front

control unit panel. The replacement must be done by qualified personnel.

Figure 4 –Fuse housing

3.7 SET-UP OPERATIONS

Before turning on the appliance, it is necessary to check that it has not been damaged during transport, handling and

installation.

-Check the condition of the packaging (it must not show dents and/or breakages)

-Check the condition of the external frame (it must not show dents and/or breakages)

-Check the condition of the power cord (it should not have scratches or cuts).

-Check that the feet and/or wheels are stable.

-Check that door opens correctly and closes hermetically

-Check door gaskets (they should not have scratches or cuts)

-Check that display do not show cracks.

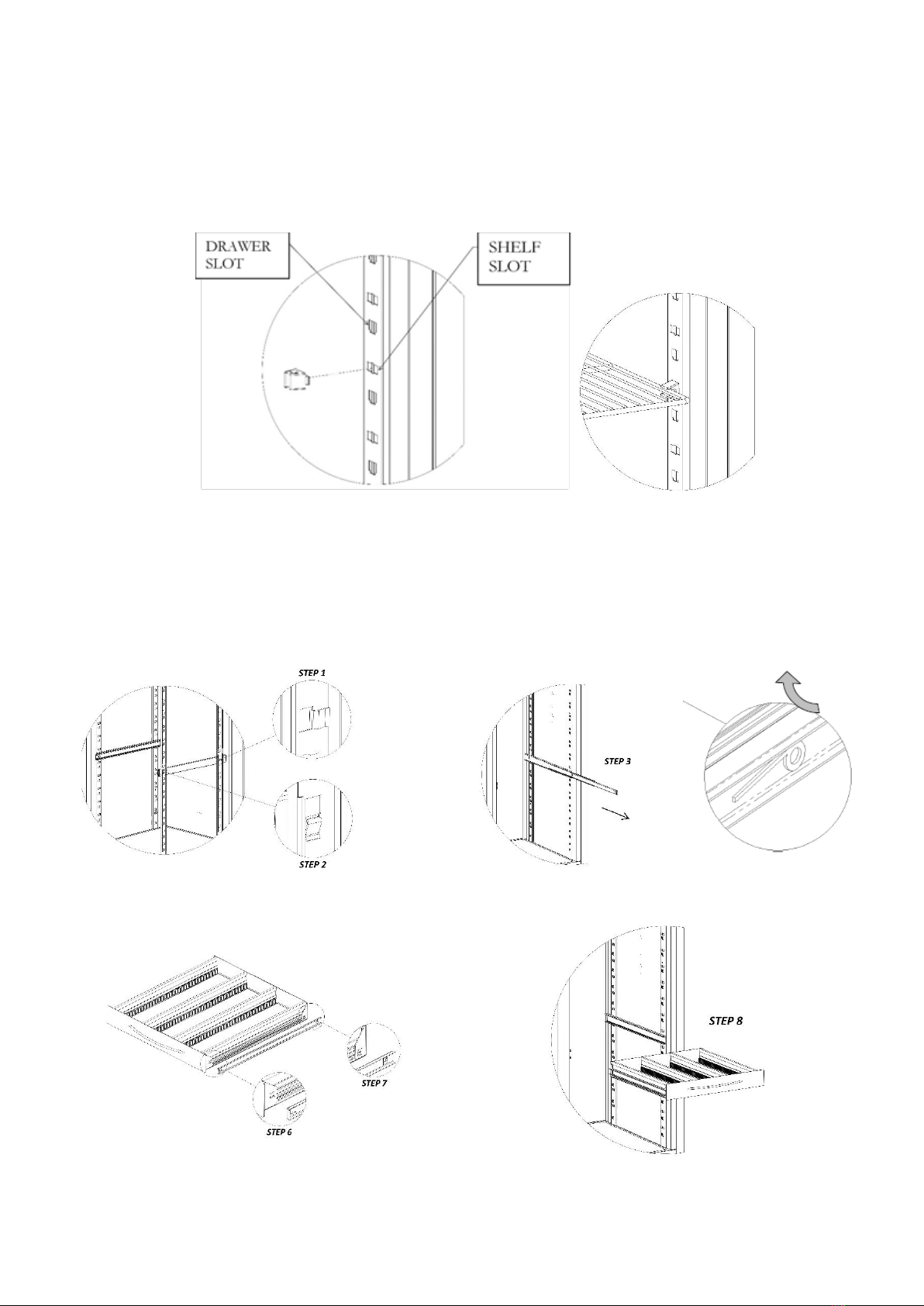

3.8 USE OF THE INTERNAL COMPARTMENT AND MATERIAL STORAGE

The stainless-steel rack system allows for the installation of fully extractable drawers on telescopic guides with "bayonet

connection" and with the possibility of having a mixed arrangement of completely interchangeable drawers/shelves

SUPERARTIC and PLASMA SUPERARTIC models use drawers mounted on extractable slides, not telescopic.

Figure 5 –Slots for internal fittings

MNL004_EN rev. F

Pag. 14 di 56

3.8.1 SHELVES INSTALLATION

Position the shelf supports on the rack at the desired position, inserting them into the special slots and turning them of

90° to block them. At this point, insert shelves (Figure 6 –shelves installation)

Figure 6 –shelves installation

3.8.2 DRAWERS INSTALLATION

Insert the guides into the special slots of racks (Figure 7) and pull out the telescopic guides by gently pressing on the

white lever (Figure 8), install them on the drawer (Figure 9) and fill the drawer on the guides installed on racks (Figure

10).

Figure 9 –installation of drawer on rack

Figure 8 –guides installation on drawer

Figure 7 –pulling guides out

Figure 10 –guides installation

MNL004_EN rev. F

Pag. 15 di 56

3.8.3 PLACING MATERIAL INSIDE THE COMPARTMENT

Care must be taken when loading material, to avoid malfunctions and allow air flow to ensure temperature uniformity

inside the refrigerated compartment.

Observe the following instructions:

✓Do not place material over the label indicating the maximum permitted loading level, if present.

✓Store material leaving a distance of at least 6 cm from sides and at least 18 cm from the top of the compartment

(Figure 11-12)

Figure 12 –Correct material storage

Figure 13 –INCORRECT material storage

NO

PO

SI

Figure 11 - Max. level label

MNL004_EN rev. F

Pag. 16 di 56

✓Do not position material in contact with or near the temperature probes (Figure 14).

Figure 14 –probes position

✓Do not block air vents (Figure 15) and pressure equalising valve in SUPERARTIC models (Figure 16).

Figure 15 –air vents at the top of the compartment Figure 16 –position of the SUPERARTIC model pressure equalising valve

3.9 INDICATION FOR OPTIMAL USE

The following instructions are provided to the user to follow in order to get the best equipment performances:

-The power supply must comply with the information provided on the technical data plate (+/- 10%).

-The units have been designed and built to work in environment with temperatures falling within the climatic class

temperatures indicated on the technical data plate (see Par. 9.1) and at a relative humidity of 60%.

-Do not block the motor compartment air vents.

-Load stored material gradually at ambient temperature to grant proper refrigeration.

-Store material on shelves (or drawers). Do not place products directly on the bottom, or against the wall, doors or

fixed guards of the unit (see Par. 4.6.3)

-Make sure doors are closed properly.

-Limit door opening frequency and duration. Each time the door is opened, the internal temperature will alter and

there will be possible ice formation on the evaporator

-Keep the defrost water drain outlet clear.

-Follow a regular maintenance schedule (see Par. 6)

MNL004_EN rev. F

Pag. 17 di 56

4ECT-F DISPLAY FUNCTIONING

The device is equipped with a latest generation Electronic Controller, with a back-lit LCD alphanumeric display, to

display temperature and working operations with an accuracy of 0·1°C. The controller gives maximum safety in case

of alarms and fault conditions, signalling critical conditions and registering every event in order to help the service

engineer to speed up the analysis and thus the fixing of any problems.

4.1 CONTROL PANEL

Figure 17 –User panel interface

Figure 18 –DMLP Printer

9

10

5

4

3

6

7

2

1

DMLP

DIGITAL

MONITOR

(Optional)

ECT-F

CONTROL

8

STATUS OK

COOL + 4.3°C

DMLP

PRINTER

(Optional with

DMLP)

11

12

13

14

MNL004_EN rev. F

Pag. 18 di 56

Table 1 –Keypad functions

ECT-F

CONTROL

1

/

Alphanumeric LCD Display, back-lit.

2

To confirm.

3

To Enter and Esc from the menu.

4

To increase values, scroll menu and for INFO DOCTOR VIEW special

function.

5

To decrease values, scroll menu. Switching on/switching off glass door LIGHT

(timed for Medical Devices)

DMLP

DIGITAL

MONITOR

6

/

Alphanumeric LCD Display, back-lit.

7

To confirm.

8

To Enter and Esc from the menu.

9

To increase values, scroll menu.

10

To decrease values, scroll menu and test.

DMLP

PRINTER

11

Feed paper.

12

/

Paper space.

13

Power

Led (green light) when printer is fed (during print out).

14

Error

Led (red colour) will blink feebly when data is transmitted or with a brighter

colour when no paper is available or paper is stuck.

MNL004_EN rev. F

Pag. 19 di 56

4.2 ECT-F CONTROL OPERATION

4.2.1 SWITCHING ON

To switch on the equipment for the first time follow these below instructions:

1.

Connect the plug to the electric socket.

2.

The display will show “STAND-BY”, which indicates

the presence of mains power.

3.

To switch on the equipment, press any button for two

seconds.

4.

When ECT-F is switched on, the display can be

customised in four different modes using OK button

(see par. 5.2.2)

mode 1

mode 2

mode 3

mode 4

5.

Once connected the equipment to the mains, if DMLP

Digital Monitor is installed, the STAND-BY string will

appear.

Switch on the DMLP Digital Monitor pressing any

button for two seconds.

STAND-BY

56% Rh

+4,5°C

12:44 01/11/2017

S + 4.0°C +4,5°C

PAUSE +4,5°C

STAND-BY

MNL004_EN rev. F

Pag. 20 di 56

4.2.2 HOW TO CUSTOMISE THE DISPLAY

Pressing the button , the LCD display can be customized in four different modes.

Figure 19 –display customization

Mode 1

Mode 2

Mode 3

Humidity mode

Working status and

temperature

Setpoint and temperature

Date and hour

(nnot present with DMLP

Digital Montor)

Relative humidity %

(only if humidity probe is

installed)

When Mode 1 is selected, the following strings can be visualized:

Table 2

STRING

OPERATION IN PROGRESS

PAUSE

The compressor is OFF, waiting for next cooling cycle

COOL

The compressor is ON to reach setpoint

WAITING DEFROST

After request of manual defrosting, the controller waits for the necessary conditions to

proceed automatically with defrosting

ACCESS DENIED

Attempt to access a disabled menu or after a manual defrost request if the conditions are not

suitable for such action

DEFROST

The refrigerator defrosts, warming up the evaporator

DRIPPING

Last phase of defrosting to allow evaporator dripping

RECOVERY

The compressor is ON after defrosting to re-acquire the temperature

DOOR

Door open (close immediately)

HEATING

Heating action active

PAUSE +4,5°C

S + 4.0°C +4,5°C

12:44 01/11/2017

56% Rh

+4,5°C

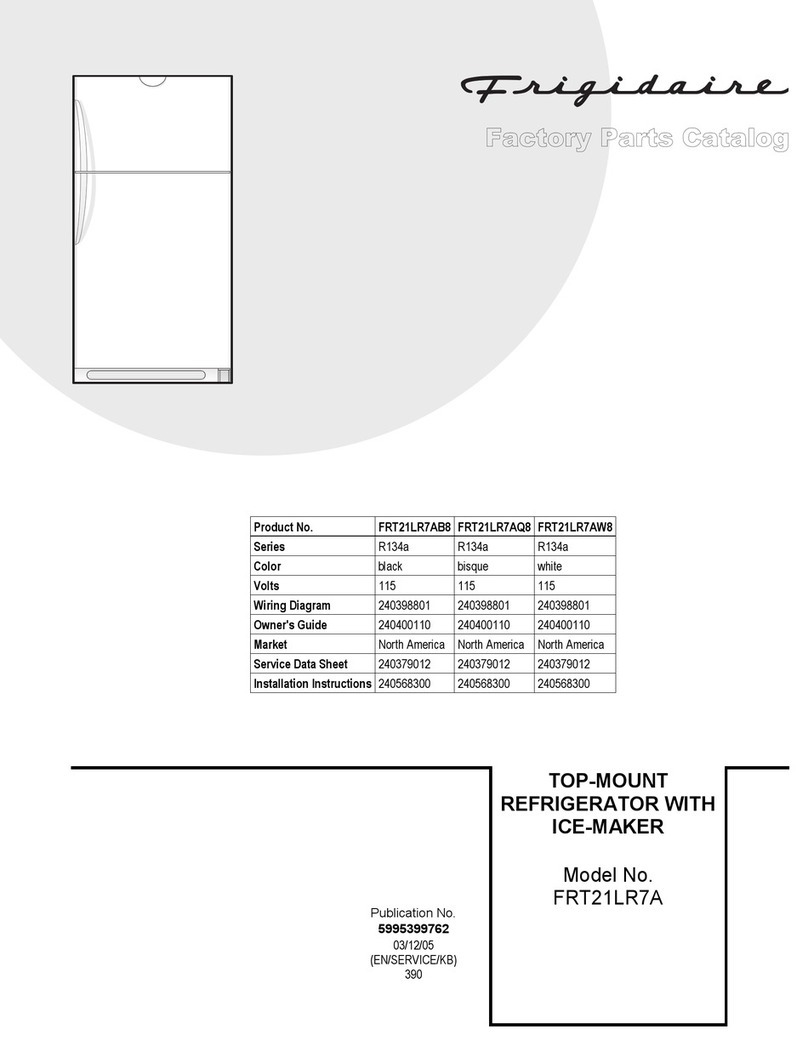

This manual suits for next models

7

Table of contents

Popular Refrigerator manuals by other brands

Frigidaire

Frigidaire FRT21LR7A Factory parts catalog

Zanussi

Zanussi DI 3165 - DI 3243 Instructions for the use and care

Schmick

Schmick HUS-SC50 Operation manual

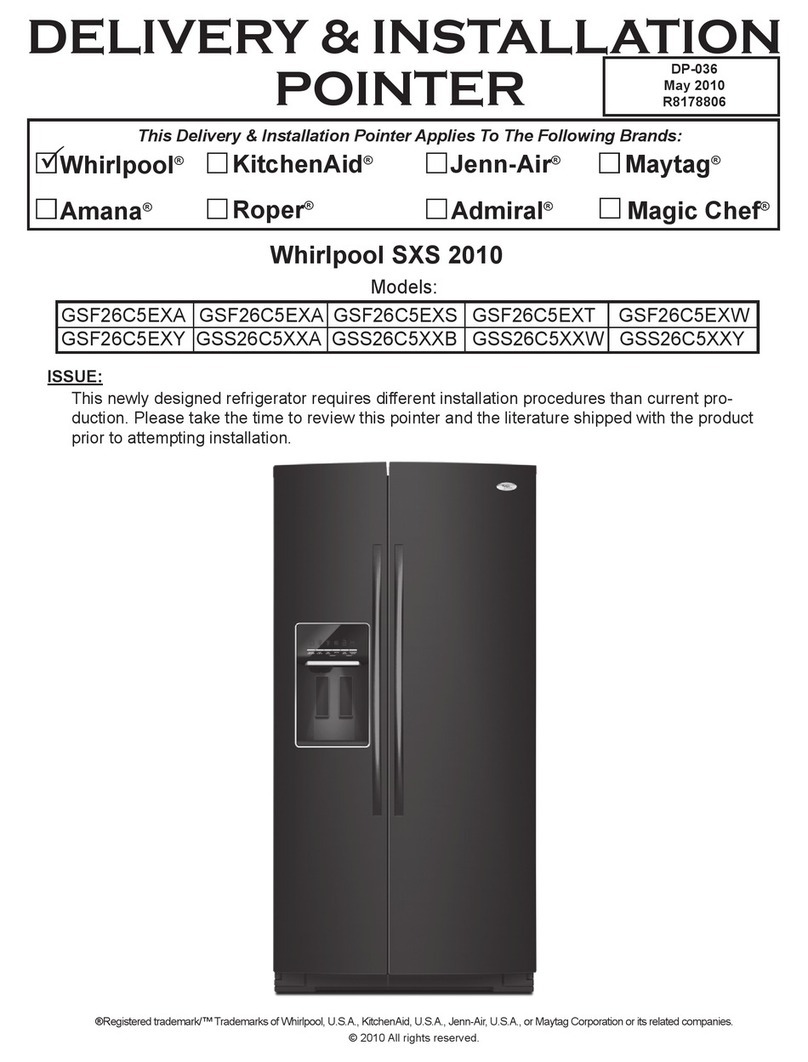

Whirlpool

Whirlpool GSF26C5EXT Delivery & installation pointer

Hisense

Hisense RQ-52WC4S User's operation manual

VESTEL

VESTEL RD 26T Service manual