Fireworks SAM-A1 User manual

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 1

SAM-A1 Stereo Audio Valve Amplifier

Owner’s Manual

READ BEFORE OPERATING THIS EQUIPMENT

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 2

1. Introduction

Congratulations on the purchase of your SAM-A1 stereo valve amplifier, we hope you enjoy the

sound quality and its appearance.

READ THIIS MANUAL BEFORE USING YOUR AMPLIFIER!!

WARNING Lethal Voltages!

WARNING Valves get HOT!

Whichever variant you have chosen, your SAM-A1 will provide you reliable and impeccable music

reproduction for years to come and with the correct maintenance and service, can provide a

lifetime of listening pleasure.

This manual tells you about the precautions you must take in using this valve amplifier and how to

set up, connect and use your SAM-A1 amplifier safely.

The SAM-A1 must only be used for its intended use; this is defined as follows:

The SAM-A1 is intended for use as a stereo audio amplifier for indoor, domestic use only, being

operated within the specifications stated in this document and on the rear of the equipment. The

unit is intended for use when all earthed, protective covers are in place and with all the valves

correctly installed. Only fuses supplied with the equipment or replacements of identical

performance and rating are to be used.

FSL will not take any responsibility for any injury or damage to anything or anyone, the equipment

or any adjacent or connected property or equipment if the instructions and specifications in this

manual are not strictly adhered to.

1.1. Issue History and revisions

Version

Release Date

Reason For release

1

April 2020

First Issue

2

June 2020

Notes on use of Bluetooth receivers added

3

June 2020

Improved warnings for temperature and Voltage added symbols

4

June 2020

Clarified o/p impedance and Mains input range, selection and consequences

5

Aug. 2020

BS7671 lower mains requirement corrected, mains selection clarified 5.1 default 240Vac

This specification liable to change without notice, the latest version will be available for download from

www.fireworksolutions.com. This document master is held electronically.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 3

1.2. Contents

1. Introduction ................................................................................................................ 2

1.1. Issue History and revisions......................................................................................... 2

1.2. Contents .................................................................................................................. 3

1.3. Glossary/Abbreviations .............................................................................................. 4

1.4. Reference Documents................................................................................................ 4

1.4.1. Compatible/tested Valves. .................................................................................... 4

2. Safety and Warnings .................................................................................................... 5

2.1. Lethal Voltages ......................................................................................................... 5

2.2. High Surface Temperatures........................................................................................ 5

3.1. Equipment Operating Specifications ............................................................................ 6

3.1.1. Power Supply:..................................................................................................... 6

3.1.2. Signal Input........................................................................................................ 6

3.1.3. Signal Output...................................................................................................... 6

3.2. Hazardous Voltages & Fragile Components .................................................................. 8

3.3. Mechanical properties ................................................................................................ 9

3.3.1. Dimensions and Mass .......................................................................................... 9

4. Getting to know the SAM-A1 ....................................................................................... 10

4.1. Connections and controls ......................................................................................... 10

4.2. Connecting the SAM-A1 to your other audio equipment:.............................................. 11

5. Installing the valves ................................................................................................... 12

6. Using the SAM-A1 amplifier......................................................................................... 14

7. Installing or removing valves....................................................................................... 15

7.1.1. How to insert a valve into its base....................................................................... 15

7.1.2. How to remove a valve from its base................................................................... 16

7.1.3. New valves or replacement valves of the same type ............................................. 16

8. Routine Maintenance .................................................................................................. 17

8.1. Cleaning................................................................................................................. 17

8.1.1. Cleaning the case.............................................................................................. 17

8.1.2. Cleaning the valves ........................................................................................... 17

8.2. Servicing and configuration ...................................................................................... 18

8.3. Routine Output bias adjustment ............................................................................... 19

9. Troubleshooting......................................................................................................... 20

10. Manufacturer Information and Warranty....................................................................... 22

10.1. Warranty............................................................................................................. 22

10.2. FSL Contact details............................................................................................... 22

11. CE Marking: Declaration of Conformity ......................................................................... 23

12. RoHS and WEEE statement ......................................................................................... 24

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 4

1.3. Glossary/Abbreviations

ac

Alternating Current

dc

Direct Current

FSL

Fireworks Solutions Limited

HBC fuse

High Breaking Current (also known as high rupture current) fuses are designed

to break the circuit, without breaking themselves, at currents much higher

than the rated fuse blow current.

RoHS

Restriction of Hazardous Substances regulations 2019

WEEE

Waste Electrical and Electronic Equipment 2002

Vac rms

Voltage Alternating Current Root Mean Square value = Vp ÷ 2

Vdc

Direct Current Voltage (equivalent toe the rms value of the Vac)

Vp

Maximum voltage amplitude in either polarity from the mean

1.4. Reference Documents

1.4.1. Compatible/tested Valves.

For the latest information on compatible valves and current stock and availability, please refer to

our website - https://www.fireworksolutions.com/valve_amp.html

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 5

2. Safety and Warnings

2.1. Lethal Voltages

WARNING Lethal Voltages! Valve amplifiers invariably use high voltages,

both Direct Current (DC) and Alternating Current (AC) that are available at

high currents: the combination can kill you. It is your responsibility to

operate in a safe manner at all times to avoid electrocution of you and others

and to make the products safe to use.

Modifying valve amplifiers is DANGEROUS there is no need for you to modify the SAM-A1

amplifier. Do not attempt to modify the equipment yourself! If you want to change the

configuration of your SAM-A1 amplifier please contact FSL.

Our amplifiers are assembled to the highest standards, the configuration of every unit is recorded

and each is fully tested before despatch/delivery. The SAM-A1 is CE marked and all aspects of the

design relating to user safety are covered in this manual, supplied with the equipment and full

details of the SAM-A1 conformance with the CE marking directives are recorded in FSL’s Technical

Construction File.

FSL accept no liability for any damage or injury sustained through, or as a result of the

modification of the amplifier, or its use for anything other than the stated intended use.

2.2. High Surface Temperatures

WARNING Valves get HOT! Up to 220oC1. Do not touch the valves when

they are on or until they have cooled down (at least ten minutes should be

allowed between removing power from the amplifier and touching or

cleaning/dusting the valves).

DO NOT COVER. It is recommended that at least 300mm be allowed above the top of the

amplifier to allow free flow of air to take heat away from the valves. DO NOT locate it under

flammable materials or materials likely to melt. The amplifier has vents on the underside and top

surface of the enclosure to allow air to flow through the enclosure by convection. Ensure these are

not blocked, i.e. ensure the amplifier is resting on a hard flat surface when in operation –and do

not cover.

Ensure the SAM-A1 is located where it cannot be reached by children or pets.

Never leave the amplifier unattended when it is switched on.

It is normal for the metal enclosure of the amplifier to get warm, especially the top plate, which

will be heated by radiation from the valves and components under the plate. The rear plinth is

used to dissipate heat generated in the linear power supply and may get warm depending on the

supply connected to the amplifier and its configuration.

1This is the specified maximum temperature that the glass bulb can achieve for the output valves

(V2,3,5 and 6) if the valves are operated at the maximum specified ambient temperature for the

valves and at maximum power.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 6

3.1. Equipment Operating Specifications

WARNING Operating the SAM-A1 outside of its stated operating limits can result in premature

failure of the equipment and in severe cases may result in the equipment overheating with a

subsequent risk of fire. These operating specifications must not be exceeded.

3.1.1. Power Supply:

Mains input: Fused IEC Plug

Voltage: 205 to 255Vac –internally selectable –this is NOT automatic. In the true spirit of

old valve equipment, the unit must be set up for your mains voltage, see below.

Frequency: 48-62Hz

Power: Nominal 70W depending on configuration, maximum 150W.

Insulation: Class 1 Protective earthed enclosure.

Fuse rating: 20 x 5mm HBC fuse rated at 2.5AT (delay)

IP Class: IP20

Temperature: Min 0oC Max 40oC Operating and storage.

Humidity: 30 to 70% Relative Humidity.

The input voltage is compatible with BS7671, requiring a range of 230Vac +10% -6%, 216V to

253V. The SAM-A1 will operate from 205 to 255Vac in, the input range is internally selectable for

the following supplies, with considerable overlap between the ranges: Blue is Neutral, primary Live

winding wires as follows:

210 ±5V: Violet

220 ±5V: Grey

230 ±5V: Red

240 ±5V: White –This is set as the default; good for around 225 –253Vac in*

250 ±5V: Black

*If the mains supply is too high for the selected input, the amplifier will get hotter (rear plinth),

wasting energy. The valve heaters will be run hotter and depending on the valves chosen, maybe

even too hot (this will reduce the life of your valves) –There is significant overlap between the

input ranges but for optimum performance and valve life, we strongly recommend the mains input

transformer winding is matched to your supply.

If the input is too low the regulators in the PSU may start to allow hum through to the speakers.

The input range is selected by connecting the appropriate input winding of the mains transformer

to the mains switch, with the alternative taps being terminated in female fast-on crimp connectors

and cable-tied back to retain them out of the way, the primary wire colours are identified above.

Input Voltage selection should only be performed by a competent technician capable of doing the

job safely and leaving the equipment in a safe state for use; alternatively, see FSL service section.

3.1.2. Signal Input

One pair of RCA Phono sockets; isolated from chassis.

Input impedance: 90 to 100kOhms.

Input sensitivity: 200 to 500mVrms for full power out (dependent on configuration).

3.1.3. Signal Output

Two pairs (right and Left) isolated from chassis 4mm sockets with binding posts for wires.

Output impedance: 8Ohms PASSIVE speakers only. It will work with impedances from 4 to

16Ohms but the SAM-A1 output is balanced with an 8Ohm load.

Output Voltage: Max 26.5V pk-pk at 11Wrms in to 8Ohms (dependent on configuration).

Output Power: 8Wrms per channel (default) 16W peak (22.6Vpk-pk).

Bandwidth: 5Hz-50kHz -1dB at 1Wrms

Frequency response and distortion dependent on configuration.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 7

Note that the 0V or negative of both the inputs and outputs is connected to 0V of the amplifier. By

default this is connected to chassis and Earth of the Mains power socket via a 10 Ohm 3W Metal

Film resistor. The SAM-A1 0V may be connected directly to Earth and Chassis if required, or via a

different resistance value as required; alternative options are 0(zero) or 10kOhms.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 8

3.2. Hazardous Voltages & Fragile Components

As specified in section 2.1, the equipment contains hazardous, potentially lethal voltages and must

be fully isolated from the mains supply before removing any covers or unplugging any of the

valves. (See also section2.2; surface temperature warnings).

POTENTIALLY LETHAL VOLTAGES INSIDE.

WARNING DC voltages as high as 400VDC may be present inside the unit

when in operation.

In addition to the hazard presented by the mains supply voltage, valves require hazardous DC

voltages for their operation. These DC supplies are smoothed using reservoir capacitors that are

capable of delivering significant short term current. The combination of high DC voltages and

available at high currents can be LETHAL.

In normal operation, when used as intended, these hazardous voltages are not accessible to the

user and the user is protected from them by a combination of insulation and earthed protection

offered by the metal case.

The IP20 rating specifies protection against solid objects >12mm i.e. fingers from gaining access

to hazardous voltages, the largest apertures are 5mm diameter vent holes around the valves and 4

x 20 mm ventilation slots in the lid and base. A standard test finger in accordance with IEC60529

cannot access any hazardous voltages through any of the apertures in the case. DO NOT insert

any conductive object/tool in to any of the vents/holes in the case.

The equipment is not protected against moisture ingress. In the event of a spillage on to the

equipment immediately isolate the equipment from the ac mains supply, then remove all

connections to the amplifier and seek advice from FSL.

Do not operate the amplifier in an environment where there is high humidity, water or splashing

with water is likely e.g. bathrooms or within 2m of a sink or tap.

All adjustments are to be made with the correct trimmer resistor adjustment tool. The correct tool

has a metal blade that fits in the trim put screw slot but a plastic handle the fully isolates the

operator from the circuit. The correct tool is one of the following:

Vishay ACCTRITOB308 (RS stock number: 543-434)

Bourns H-90 (RS Stock number: 743-2479)

Thermionic valves and safety

WARNING the outer case of the Valves is made from Glass and they are FRAGILE.

If the valves are broken; the hazardous voltages will be accessible to the user/operator.

The unit must not be operated with missing or broken valves.

Inspect the equipment before connecting to a mains supply; if any of the valves appear damaged

or is missing, disconnect the supply immediately.

NEVER remove valves while the equipment is connected to the mains ac supply.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 9

3.3. Mechanical properties

3.3.1. Dimensions and Mass

Dimensions: 382mm Wide x 341mm Deep x 77mm high

This excludes the connectors to the rear and 60mm should be allowed for connections to the

amplifier at the rear.

The height excludes the feet (depending on which feet are fitted) the standard rubber feet add

another 3mm to the height of the enclosure. There will always be an air gap under the amplifier to

allow air to circulate through the unit.

The Height also excludes the valves which depends on the configuration used; regardless of which

valves are fitted, it is recommended that at least 300mm be allowed above the top surface of the

amplifier for heat dissipation; see section 2.2.

The mass of the assembled unit is: 7.75kg ±0.25kg.

According to HSE guidelines for Manual Handling, this is less than the maximum recommended

mass for a one-person lift. The unit has no moving parts that can cause injury or trap fingers as

such the SAM-A1 amplifier does not fall under the remit of the Mechanical Directive for CE

marking.

The mass of the unit is sufficient that the unit may cause injury and may suffer damage if it is

dropped e.g. on to a hand or foot. Care is to be taken when lifting or moving the unit to avoid

dropping it.

Structural integrity

The unit should never be moved while the unit is connected to anything. Due to the mass of the

components inside the unit, the unit will survive a 25mm drop test and remain safe but may

become aesthetically damaged.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 10

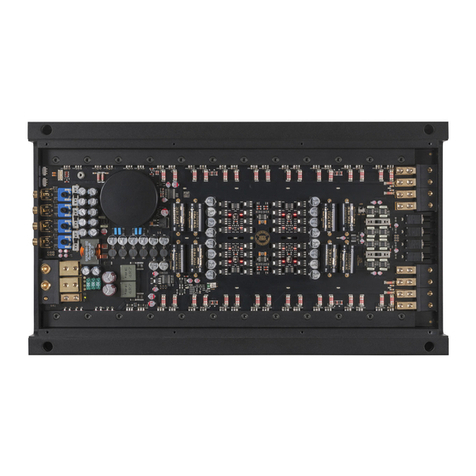

4. Getting to know the SAM-A1

4.1. Connections and controls

On the rear of the amplifier you will find the following connections:

1) Mains supply input socket (a 90 degree plug reduces the space needed behind the amplifier).

2) Power Switch (shown here in the OFF position, switch down is ON).

3) A pair of input sockets (RCA) for connection to your pre-amplifier or direct to your source.

4) Two pairs of 4mm sockets/wire termination posts for connection to your loudspeakers.

On the front of the unit there is the volume control. Fully anti-clockwise = zero volume, turn it

clockwise to increase the volume –always start at minimum volume position when switching on

for the first time!

1

2

3

4

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 11

4.2. Connecting the SAM-A1 to your other audio equipment:

Note the audio source connected to the inputs must be a big enough amplitude/voltage to drive

the amplifier, i.e. a turntable/record player with an output of only a few tens of millivolts will

require a preamplifier to get the signal up to the 250 –500mV input required by the SAM-A1

amplifier.

If your audio source already has a compatible signal it may be connected directly to the SAM-A1

inputs as shown with the dotted lines.

Bluetooth connectivity to your existing devices (e.g. phones, tablets) can be achieved by using an

external Bluetooth Audio receiver. We have only tried one –an MPOW BH070. This device worked

as advertised and did not add any significant hum or hiss even when plugged in to a USB plugtop

charger.

Preamp

Left

Speaker

Right

Speaker

Mains

Supply

Analogue

Audio Sources

Bluetooth

Receiver

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 12

5. Installing the valves

If your SAM-A1 amplifier did not come with the valves installed; see section 7 for instructions on

how to fit a valve to its base.

The valves will all be in boxes labelled with their position in the amplifier, valve V1, V2, V3, V4, V5

and V6.

(Each valve will also have a unique number that will be written on the box and written on the glass

between the pins at the base of the valve –just in case the valve and its box get separated/mixed

up).

Remove the valves one at a time from their box and insert them in their defined locations as per

the picture below.

If the valves are correctly installed, the base of the valve will sit flush with the top of its ceramic

socket there will be no pins (or virtually no pins) visible and the valve will be vertical –see next

picture.

V1

V2

V1

V3

V2

V1

V4

V5

V4

V6

V5

V4

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 13

Correctly installed valves:

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 14

6. Using the SAM-A1 amplifier

Once the amplifier has been connected as per section 4.2 and the valves are fitted as per section

5, your amplifier is ready to use!

Ensure the volume control is at minimum, see picture above and turn on the amplifier. Within 10

seconds you should see all the valves glowing orange (and if you look carefully –probably some

blue too –remember they get hot!).

Within about 20-30 seconds from switch on the amplifier will be starting to work (it can take up to

5 minutes to reach full specification).

Select your audio source (pre-amplifier) or press play etc. to start the music/audio source.

Turn the volume control up (clockwise) until the desired listening volume is achieved.

Volume

Minimum

Maximum

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 15

1

7. Installing or removing valves

Before carrying out any work on the amplifier the unit must be switched off, isolated from the

supply and allowed to cool.

HANDLE VALVES WITH CARE!!!

Valves are glass and fragile; even if they are not visibly damaged, incorrect handling can result in

the breaking of their hermetic seal allowing air into the valves resulting in their untimely demise.

Dropping valves is also a bad idea as a fall on to a hard surface can dislodge the internal

mechanical arrangement of the valve resulting in premature failure and internal short circuits

which can damage the amplifier.

If you have dropped your valves during the installation –do not switch on your amplifier; contact

us and we will arrange for your valves to be sent back to us to be tested before you fit them.

Follow the following steps to remove and insert valves from their bases in the amplifier.

7.1.1. How to insert a valve into its base.

Use suitable gloves or wrap a microfiber cloth around the valve (to avoid marking the valve and to

protect against the unlikely event that the glass envelope breaks).

Valve base –top view (note pin 1 identified)

Note that there is only one way that a valve can be inserted in to its socket/base (see image of

valve base). Holding the valve close to the base, align the pins with the sockets in the valve base

and push the valve firmly in to its base with a small circular motion as illustrated.

Ensure that the valve pins are fully inserted in their sockets (no pins visible) and that the valve is

vertical/perpendicular to the valve base.

Inserting a valve in to its base.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 16

7.1.2. How to remove a valve from its base

Use suitable gloves or wrap a micro-fibre cloth around the valve (to avoid marking the valve and

to protect against the unlikely event that the glass envelope breaks).

Holding the valve close to the base, pull the valve firmly, steadily, upwards out of the socket while

gently, slowly rotating the valve in conical motion

If the valve glass envelope is damaged, care is to be taken to avoid cutting yourself on the glass.

Remove the glass using a suitable cloth and/or gloves. Dispose of the broken valve by wrapping it

in several layers of paper, sealing it with sticky tape and then dispose of the broken valve in

domestic waste. Do not recycle.

Removing a valve from its base.

7.1.3. New valves or replacement valves of the same type

If for any reason you wish or need to change the valves in your SAM-A1; it is imperative that you

note the following:

Valves should always be replaced as sets i.e. a pair of input valves and a quad of output valves.

Not doing so may make it very difficult or impossible to balance the amplifier and as the new

valves age their characteristics will change more rapidly than the older valves requiring much more

frequent re-tuning of the amplifier.

If replacing the input stage valves only, the output valve bias setting should not need adjustment.

If replacing just the output valves it may be possible to leave the input valve adjustments alone,

but this is a lot less likely to be successful. It is always better to completely reset the amplifier

settings and retune the amplifier. (See Section 8.2). Replacing valves in an amplifier without re-

tuning it will very seldom achieve good results and in the worst case my result in damage to the

valves and/or premature failure of other components in the amplifier. Please contact FSL for

advice before attempting this operation.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 17

8. Routine Maintenance

The valves are made from glass and they are fragile; if they are smashed or damaged then

dangerous voltages may be accessible if the unit is turned on. This is not classified as normal

operation as intended.

Refer to the safety and warning section of this document. Potentially lethal voltages are accessible

if the unit is operated with the covers or removed (or if the glass valve envelopes are damaged).

Before carrying out any work on the amplifier the unit must be switched off, isolated from the

mains supply and allowed to cool

8.1. Cleaning

Before carrying out any work on the amplifier the unit must be switched off, isolated from the

supply and allowed to cool.

8.1.1. Cleaning the case

Marks on the case e.g. fingerprints should be removed with a dry micro-fibre cloth. Particularly

stubborn marks may be removed using a damp cloth e.g. baby wipe followed by a dry microfiber

cloth to dry the surface. If using a damp cloth, do not clean inside the diameter of the cooling vent

holes around each valve base; keep moisture away from the holes and valve bases. If there is any

doubt that moisture has come in to contact with the valve bases, remove the valves and allow the

unit to dry in a warm dry environment for 24hrs before re-fitting the valves or applying power.

White spirit on a cotton cloth can be used (sparingly and occasionally) to remove stubborn marks

and greasy finger prints –always rub in the direction of the grain.

8.1.2. Cleaning the valves

The valves are glass and they are fragile, In addition, note that the gold/ink labelling on the valve

is very delicate.

DO NOT USE ANY CLEANING AGENTS OR SOLVENTS.

The valves should not be touched in routine use and if they are then gloves (or a microfiber cloth)

should be used to avoid leaving fingerprints. Fingerprints and dust may be removed with a dry

micro-fibre cloth –apply the minimum pressure possible, especially over printed labelling on the

glass.

Take particular care when using the cloth to clean the glass in the area of the labels and printed

quality stamps (unless they are not important to you!). The durability of the identification markings

and quality stamps is very variable depending on the manufacturer and date of manufacture of the

valve. Removing the labels, any OEM quality stamps, or FSL markings from the underside of the

valve will invalidate any warranty on the valves.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 18

8.2. Servicing and configuration

FSL offer a comprehensive service for the SAM-A1 amplifier and we are happy to provide you a

quote for work on your amplifier. Services offered include:

Mains Input set up –matching the SAM-A1 to your domestic mains supply is important. Too

low a supply setting and the amplifier may produce hum at the output; too high and the unit

will waste energy, get warmer than it should and run the valves heaters hotter, reducing the

life of your valves. If you do not know what your mains supply voltage is –a qualified

electrician will be able to test it for you if your provider is unable to tell you what it is. Active

sockets are also available to tell you how much power/energy an appliance is consuming and

they often have a voltage readout (we can recommend a device for you but are unable to loan

them out for liability insurance reasons). If you measure your mains supply with one of these

active sockets, write down the voltage reading at different times of day for a few days and

then send us the active socket and your readings, we will then check the reading on your

smart socket and select the most appropriate mains input setting for your amplifier before

delivery.

Failing that FSL can survey your mains supply for you during a visit to your installation and we

will configure your SAM-A1 to your mains supply. This is only offered to UK mainland and may

be subject to travel charges incurred.

6 month or annual re-biasing

Annual service including valve check, complete set-up and re-calibration of the amplifier.

Amplifier valve exchange –change the valves for a new set of the same type or a different

grade –including a complete set-up and re-calibration of the amplifier.

Amplifier valve roll - change either the input and driver or the output stage or all valves for a

new set of a different type of valve - including a complete set-up and re-calibration of the

amplifier.

Amplifier re-configuration, e.g.

Change output stage: e.g. from small triode to large triode, from large triode to

pentode or pentode as triode

Change input stage, e.g. from paraphrase inverter to cathodyne

This includes a complete set-up and re-calibration of your amplifier.

Amplifier repair –in the very unlikely case that the amplifier develops a fault out of warranty or

is damaged; we will assess your amplifier and quote to repair it, either to a functioning but as

received condition or back to the as-bought condition.

If what you are looking for is not listed here, please contact us for assistance and advice (see the

end of this manual for contact details).

Please note that Transportation to and from FSL must be in the original packaging or hand carried

door to door. FSL will accept no liability for products that are lost or damaged in transit; customers

are advised to choose a delivery method that offers adequate insurance against loss or damage.

FSL will reimburse reasonable postage/delivery costs if the unit is returned for repair and FSL

agree that the repair is covered by our warranty, see section 10.1.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 19

8.3. Routine Output bias adjustment

This is the simplest of the routine maintenance activities. If you are in any doubt of your

competence to perform this operation or you are not in the possession of/competent with the

appropriate test equipment then DO NOT UNDERTAKE THE TASK; please contact FSL for our

maintenance service.

WARNINGS:

As adjustments can only be made when the amplifier is on and the valves’ temperatures have

stabilised, this operation must only be performed by a competent person with the appropriate test

equipment.

Trim pot adjustment tool

The correct, insulated tool must be used for all trim pot adjustments.

The correct tool is one of the following:

Vishay ACCTRITOB308 RS stock number: 543-434 OR Bourns H-90 RS Stock number: 743-2479

The output valves’ bias should be checked at 6 month or 12 month intervals depending on the

level of use. The objective is to ensure that the output valves are still biased correctly for the

desired mode of operation of the output stage, to correct for any drift over time as the valves age

through use and ensure that they are driving their output transformers and so the loudspeakers

equally and linearly.

The bias current is measured by measuring the bias Volts on the 10R current sense resistors in

series with the cathodes for each output valve, R19, R20, R47 and R48. 50mA reads 500mV. There

are test points labelled Vb at the 3 o’clock position of each output valve (accessible with the top

plate on). These are J51, J52, J53 and J54.

The bias current is increased by reducing the negative bias at the grids of the output valves. This

is achieved by winding the trim pots at the 6 o’clock position of each output valve in an

anticlockwise direction (accessible with the top plate on). These are RV7, RV6, RV13 and RV12.

If the output valves have been replaced, the bias setting will have to be done from scratch; all four

bias adjusters. RV6, RV7, RV12 and RV13 should be set at their maximum bias voltage (minimum

current) turn them all fully clockwise (clicking heard or 25 full turns) before the mains supply is

applied.

If the bias is just being checked do not touch the adjusters and proceed with the check.

1. Connect the DMM negative to 0V, e.g. speaker output negative socket; set to read up to 2Vdc.

2. Connect and switch on the mains supply.

3. Wait 5 minutes before adjusting the valve bias currents.

4. Adjusting the bias:

5. The bias currents for V2 and V3 should be adjusted together; use the DMM to measure the dc

bias Voltage for each valve as it is adjusted. In increments of no more than 100mV (10mA) at

a time, increase V2 then V3 bias current until they are both at the desired value e.g. 250mV.

6. The bias currents for V5 and V6 should be adjusted together; use the DMM to measure the dc

bias Voltage for each valve as it is adjusted. In increments of no more than 100mV (10mA) at

a time, increase V5 then V6 bias current until they are both at the desired value e.g. 250mV.

7. Wait 5 minutes before checking the valve bias currents again,

8. Repeat steps 5 and 6 until all the output valve bias currents are within 5mV of each other and

stable.

SAM-A1 Owner’s Manual FSL0132

Fireworks Solutions Limited (FSL) has proprietary rights in the information disclosed herein. The recipient, by accepting this document agrees that neither this document nor the

information disclosed herein nor any part(s) thereof shall be produced in any manner whatsoever or transferred to other documents or media or used or disclosed to any third party

for any purpose except as specifically authorised in writing by FSL. All rights reserved under the copyright laws.

FSL0132 Version 5.1 © 2020 Fireworks Solutions Limited Page 20

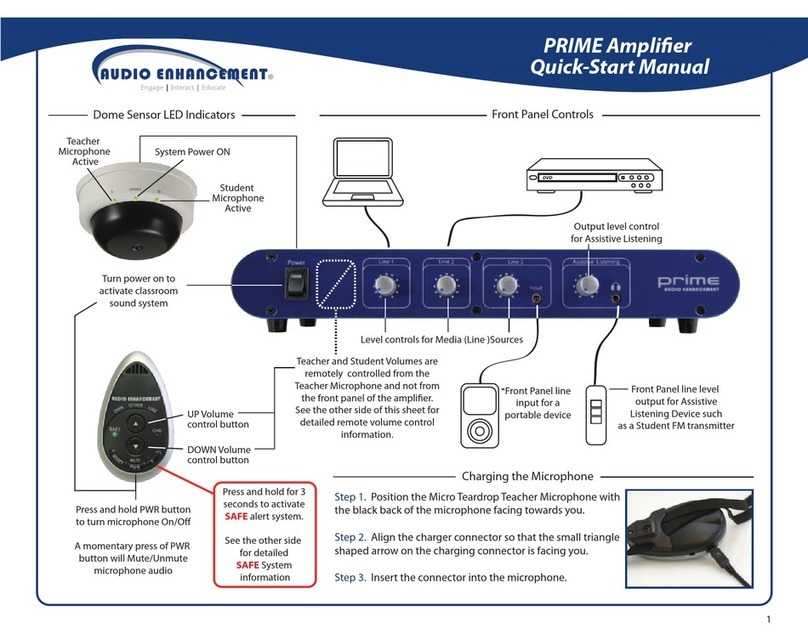

9. Troubleshooting

In the unlikely event that the SAM-A1 doesn’t do what it is supposed to do, please check the

following steps before contacting us.

Symptom

Probable Cause

Solution

The amplifier does not turn

on (valves are not glowing)

Mains lead is not plugged

in properly.

Check both ends of the mains lead

are plugged in.

Is it switched on? At the

wall outlet and at the back

of the amplifier.

Check the wall outlet switch and

the power switch on the rear of the

amplifier (see 4.1) are both on

Fuse in the mains lead or

in the amplifier mains inlet

plug is blown or not fitted

The fuse are 5x20mm HBC 2.5AT

Internal Fuse is blown

If you have checked/replaced both

the

Valves are all glowing no

sound is produced

Speakers not connected

Check the speakers are connected

properly, both at the speaker

terminals/connectors and at the

amplifier, ensure the wire and not

the insulation is in the terminal post

if unterminated wires are used.

Input not connected or

turned on (e.g. Bluetooth

receiver)

Check the input is connected

properly at both ends and that the

output of your source is connected

to the input sockets on the SAM-A1

–i.e. the amplifier is not connected

to another input or disused line

output on your pre-amp. Follow

Bluetooth receiver manufacturer’s

instructions.

Input signal too small

Check your audio source does not

have a level or output volume

control and ensure it is not set low.

Is your audio source compatible –is

it capable of delivering adequate

signal amplitude in to the SAM-A1

inputs? Check the specification of

your audio source against section

3.1.2

Sound is coming out of the

speakers but it is very quiet

Input signal not connected

properly.

Check the input is connected

properly at both ends and that the

output of your source is connected

to the input sockets on the SAM-A1

–i.e. the amplifier is not connected

to another input or disused line

output on your pre-amp.

Troubleshooting continued….

Table of contents

Popular Amplifier manuals by other brands

Audiotec Fischer

Audiotec Fischer Helix Precision P400 instruction manual

DPA

DPA Type HMA4000 user manual

Velocity

Velocity V450 Fitting instructions / operating instructions

Audio Enancement

Audio Enancement PRIME Quick start manual

Channel D

Channel D Lino C 2.0 Installation and use manual

Bosch

Bosch Plena PLE-1MA030-US Installation and user instructions

Hertz

Hertz marine HCP 1MDK user manual

SineWave Amplifiers

SineWave Amplifiers CYN-DRIVE owner's manual

PCB Piezotronics

PCB Piezotronics HT426E01 Installation and operating manual

Consonance

Consonance A120 linear user guide

Oklahoma Sound

Oklahoma Sound PAW-90x instruction manual

Bose

Bose SoundTouch SA-5 owner's guide