Fireye BurnerLogiX YB110 User manual

1

®

DESCRIPTION

The Fireye®BurnerLogix™ System is a microprocessor based burner management control system

designed to provide the proper burner sequencing, ignition and flame monitoring protection on auto-

matically ignited oil, gas, and combination fuel burners. In conjunction with limit and operating con-

trols, it programs the burner/blower motor, ignition and fuel valves to provide for proper and safe

burner operation. Through SMART LED’S, the control provides current operating status and lockout

information in the event of a safety shutdown. Optional VFD and LCD displays are available that

may be either plugged in or mounted remotely to give full language descriptors of current status and

diagnostic lockout information. Refer to BurnerLogix PROGRAMMER SELECTION later in this

document for the various combinations of programmer and display modules.

A complete BurnerLogix system includes the YB110 (YB230) chassis equipped with the type of

flame amplifier required for the application, appropriate flame detector, plug-in programmer mod-

ule, wiring base and optional alpha-numeric display. Interchangeable programmer modules allow for

complete versatility in selection of function, timing and flame failure response times.

The optional alpha-numeric display has 2 lines by 16 characters per line. It is available in either vac-

uum fluorescent or liquid crystal formats. The advantage of VFD is high brightness and extended

temperature range down to –40°F. Both displays contain a fully functional keypad. You can easily

scroll through the various menus to view the current operating status, review programmer configura-

tion, and lockout history. When mounted remotely, the displays provide NEMA 4x(IP66) protection.

An advantage of the BurnerLogix control family is the ability to set many of the operating parame-

ters associated with proper and reliable burner operation allowing inventory of various programmer

types to be kept to a minimum.

The YB110 (YB230) is a chassis/flame amplifier module complete with mounting screws and blank

display module. The display module (BLV512 (vfd) or BLL510 (lcd)), if required, must be ordered

separately. Interchangeable YP programmer modules allow for complete versatility in selection of

control function, timing, and flame scanning means. Functions such as pre-purge time, recycling or

non-recycling interlocks, high fire proving interlock, and trial for ignition timing of the pilot and

main flame are determined by the programmer module. The BurnerLogix system can be used with

ultra-violet, auto-check infrared, flame rod, self-check ultra-violet flame scanners or direct coupled

integrated scanners by choosing the proper chassis/flame amplifier module.

YB110/YB230 FIREYE®

BurnerLogiX™

MICROPROCESSOR-BASED

INTEGRATED BURNER

MANAGEMENT CONTROL

BL-1001

August 7, 2018

APPROVED

2

Wiring bases for the BurnerLogix control are available pre-wired with 4 foot (1.2m) lead wires color

coded and marked for easy installation or with an integral terminal block capable of a accepting up to

2 X 14 AWG wires. The wiring base terminal block is available with knockouts for conduit or open

ended for cabinet mounting. The pigtail wiring base is 4" X 5" (101.6mm x 127mm) and the terminal

block wiring base is 4" X 7" (101.6mm x 177.8mm).

Additional functions of the BurnerLogix system include:

•A non-volatile memory allows the control to remember its history and present position even

when power is interrupted.

•A consistent flame signal read-out via display module or 4-20 mA output.

•Read-out of main fuel operational hours and complete cycles via display module.

•Modbus communications via RS485 multi-drop link.

•Proof of fuel valve closure during the off cycle.

•Burn-in time of program parameters occurs after 8 hours of main valve on time.

•A run/check switch allows the operator to stop the program sequence in any of four

different positions (Purge, PTFI, MTFI or Auto).

•Remote Display mounting with NEMA 4 protection.

•Remote Reset.

•Programmable communication baud rate allows for DCS compatibility.

•Keypad selectable language readout.

•Revert to pilot can increase burner turn down.

•Additional terminals provided for applications requiring additional inputs and outputs.

CAUTION: While programmers are mechanically interchangeable in that they mate with a

common chassis/amplifier module, you must select the correct model for your application.

Inappropriate application of a control can result in an unsafe condition hazardous to life

and property. Selection of a control for a particular application must be made by a compe-

tent professional, such as a boiler/burner service technician licensed by a state or other gov-

ernment agency.

NOTICE: This equipment generates and can radiate radio frequency energy, and if not

installed and used in accordance with the instruction manual may cause interference to

radio communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area may cause interference in

which case the user, at his own expense, will be required to take whatever measures which

may be required to correct the interference.

3

®

TABLE OF CONTENTS

BURNERLOGIX SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PART NUMBERS ANDAPPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

WIRING BASE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PTFI*MTFI TIMINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LED INDICATOR LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

REPLACEABLE FUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DESCRIPTION OF FUNCTIONS OF OPERATING CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SETTING PROGRAMMER PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

KEYPAD DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PROGRAM SET UP SUB-MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

TO VIEWAND MODIFY A PROGRAMMABLE PARAMETER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FLAME SCANNERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

INSTALLATION - UV SCANNERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

OPERATION — 45UV5 & 55UV5 SELF-CHECKING UV SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

WIRING - UV SCANNERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

INSTALLATION—INFRARED SCANNER TYPE 48PT2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

OPERATION - IR LEARN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

INSTALLATION - 69ND1 FLAME ROD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

INSTALLATION - 85 SERIES PHOENIX SCANNER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

INSTALLATION - 95 SERIES INSIGHT SCANNERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SYSTEM INFO SUB-MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SYSTEM OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

YP100 OPERATING SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

START-UP (NORMAL CYCLE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

YP200 OPERATING SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

YP300 OPERATING SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

YP138 PROGRAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

LOCKOUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

SAFETY SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DIAGNOSTIC MESSAGES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

RESETTING THE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

LOCKOUT CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

LOCKOUT HISTORY SUB-MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

COMMUNICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

MESSAGE FORMAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

MODBUS MESSAGE TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

INPUTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

OUTPUTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

EXPLANATION OF LOGSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

BURNERLOGIX MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

INTERLOCK ANNUNCIATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

OPERATIONAL FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4-20 mA TEST JACKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

CHECK-RUN SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

OPERATIONAL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

TEST CHECKOUT PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SUGGESTED GROUNDING RULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4

Table of Figures

FIGURE 1. BURNERLOGIX ORDERING INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FIGURE 2. WIRING BASE DETAILS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FIGURE 3. YP110 PROGRAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

FIGURE 4. KEYPAD DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FIGURE 5. BURNERLOGIX MENU STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FIGURE 6. MAIN MENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FIGURE 7. FLAME SCANNERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FIGURE 8. AIMING YOUR SCANNER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 24

FIGURE 9. TYPICAL SCANNER INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FIGURE 10. UV SELF CHECK SCANNER OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

FIGURE 11. SCANNER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

FIGURE 12. PHOENIX WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

FIGURE 13. BURNERLOGIX TYB110DC/YB230DC WITH 85UVF4-1QDWR SCANNER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

FIGURE 14. INSIGHT WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FIGURE 15. CONNECT BURNERLOGIX & INSIGHT I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

FIGURE 16. SYSTEM INFO SUB-MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

FIGURE 17. YP100 OPERATING SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

FIGURE 18. YP200 OPERATING SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FIGURE 19. YP300 OPERATING SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

FIGURE 20. BURNERLOGIX WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

FIGURE 21. YP300 WIRING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

FIGURE 22. YP138 WIRING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

FIGURE 23. LOCKOUT HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

FIGURE 24. BOTTOM VIEW COMMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

FIGURE 25. DEFAULT WIRING FOR YZ300 INTERLOCK ANNUNCIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

FIGURE 26. BOTTOM VIEW 4-20 mA JACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

FIGURE 27. TEST JACKS (4-20 mA) VS. FLAME STRENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

FIGURE 28. CHECK RUN SWITHCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

FIGURE 29. PILOT FLAME TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table of Tables

Table 1: OPERATING TEMPERATURE LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2: LOAD RATINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3: AGENCYAPPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4: APPLICABLE BULLETINS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 5: ORDERING INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 6: PROGRAMMER MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 7: BURNERLOGIX DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 8: BURNERLOGIX WIRING BASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 9: BURNERLOGIX ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 10: SCANNER SELECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 11: PRE-WIRED WIRING BASE, P/N 60-2810-1 (shown for 120 VAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 12: BURNERLOGIX PROGRAMMER SELECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 13: PTFI & MTFI TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 14: LED INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 15: MODIFIABLE PARAMETERS LOCATED IN PROGRAM SETUP MENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 16: PHOENIX SCANNER CABLE COLOR CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 17: DIAGNOSTIC MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 18: LED CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 19: MESSAGE FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 20: MODBUS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 21: MODBUS MESSAGE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 22: INPUTS AND OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 23: YZ300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 24: LOGSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 25: BURNERLOGIX MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 26: DIAGNOSTIC MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 27: ANNUNCIATOR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5

®

..BURNERLOGIX SPECIFICATIONS

Supply Voltage:

YB110 120 VAC (+10%, -15%) 50/60 Hz

YB230 230 VAC (+10%, -15%) 50/60 Hz

Power Consumption:

25 VA

Temperature Rating:

-40°C (-40°F) to +60°C (140°F)

Protection Category:

YB110 (YB230) control NEMA 1 (IP01)

Display, remote mounted NEMA 4X (IP66)

Unit Dimensions:

Wiring base 60-2810-1 - 4.0" (101 mm) W x 5.0" (127mm) H

Wiring base 60-2812-1, 60-2814-1 - 4.0" (101 mm) W x 7.0" (178 mm) H

Shipping Weight:

YB110 (YB230) Approx. 3.2 lbs. (1.45kg)

Table 1: OPERATING TEMPERATURE LIMITS

CONTROL MAXIMUM MINIMUM

YB110, YB230 140°F 60°C -40°F -40°C

YP Programmers 140°F 60°C -40°F -40°C

BLV512, VFD Display 140°F 60°C -40°F -40°C

BLL510, LCD Display 140°F 60°C -4°F -20°C

Scanner UV1A, UV2, UV8A, UV90, 45UV3 200°F 93°C -40°F -40°C

45UV5-1005, 45UV5-1105

45UV5-1007, 45UV5-1009

55UV5-1007, 55UV5-1009

200°F 93°C -40°F -40°C

48PT2 140°F 60°C -40°F -40°C

Flame Rod (Tip 2460°F) 1500°F 816°C -40°F -40°C

Humidity: 90% R.H. (Non-condensing)

Phoenix 85 Series 150°F 65°C -40°F -40°C

InSight 95 Series 150°F 65°C -40°F -40°C

6

Table 2: LOAD RATINGS

Combination of fuel and igniter terminals

Composition of each combination

Maximum connected load must not exceed 2000 VA

ELECTRICAL RATINGS

VA ratings (not specified as pilot duty) permit the connection of transformers and similar devices

whose inrush current is approximately the same as their running current.

VA Pilot Duty ratings permit the connection of relays, solenoid valves, lamps, etc. whose total oper-

ating load does not exceed the published rating and whose total inrush current does not exceed 10

times the rating.

Running and locked rotor ratings are intended for motors. VA and VA Pilot Duty loads may be added

to a motor load provided the total load does not exceed the published rating.

Terminal Typical Load A. Maximum Rating

@120V-50/60 Hz

B. Maximum Rating

@230V-50/60 Hz

C. Alternate Rating

M Burner/Blower Motor 9.8 F.L.A. *

58 L.R.A.

4.0 F.L.A. *

20 L.R.A.

240 VA Pilot Duty

(Motor Starter Coil)

10-11-12-X Modulator 125 VA Pilot Duty

A Alarm 50 VA Pilot Duty

Terminal ratings may be selected from either column A or C for 120 VAC or from either column B or C for 30 VAC:

(select the rating from the column which best applies to the connected load on that terminal).

* F.L.A. = full load amps; L.R.A = locked rotor amps

Combination No. Pilot Fuel

Trm 6

Main

Trm 7

Ignition

Trm 5

Delayed Valve

Trm W

1C E No Load No Load

2B E No Load No Load

3No Load E No Load B

4E E A No Load

5No Load E A E

6D E A No Load

7DDAD

8No Load D A No Load

AB C D E

4.5A Ignition

@120 VAC

50 VA Pilot Duty

plus 4.5A ignition@

120 VAC

180 VA Ignition plus

motor valves with: 660

VA inrush, 360 VA

open, 250 VA hold.

2A Pilot Duty

@120 VAC

65 VA Pilot Duty plus

Motor valves with: 700

VA open 250 VA hold.

2.2A Ignition

@230 VAC

50 VA Pilot Duty

plus 2.2A ignition

@230 VAC

1A Pilot Duty

@230 VAC

CAUTION: Published load ratings assume that no contact will be required to handle inrush

current more often than once in 15 seconds. Using control switches, solenoid, relays, etc.

which chatter lead to premature failure. Run through a test operation (with fuel shut off)

following the tripping of a circuit breaker, a blown fuse, or any known instance of chattering

of any external current consuming devices.

7

®

APPROVALS

Underwriters Laboratories Inc.:

MCCZ File MP1537

Controls, Primary Safety - Listed

MCCZ2 File MP1537

Controls, Primary Safety - Component

MCCZ7 File MP1537

Controls, Primary Safety Certified for Canada

MCCZ8 File MP1537

Controls, Primary Safety Certified for Canada - Component

Factory Mutual: Approved

Acceptable by: Industrial Risk Insurers (I.R.I.)

CE: Gas Appliances

Gas Appliance Directive: 90/396/EEC

Low Voltage Directive: 73/23/EEC

EMC Directive: 89/336/EEC

GASTEC: 0063BT1754

(EN298, 2003; EN230, 2005)

NOTICE: This equipment generates and can radiate radio frequency energy, and if not

installed and used in accordance with the instruction manual may cause interference to

radio communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area may cause interference in

which case the user, at his own expense, is required to take whatever measures which may be

required to correct the interference.

8

PART NUMBERS AND APPROVALS

Table 3: AGENCYAPPROVALS

BurnerLogix

Chassis/Flame Amp. Module

YB110UV XXX

YB110UVSC XXX

YB110IR XXXX

YB110IR2 XXXX

YB110FR XXX

YB110DC XXX

YB230UV X

YB230UVSC X

YB230IR XX

YB230IR2 XX

YB230FR X

YB230DC X

BurnerLogix Programmer Module

YP100 XXX

YP102 XXX

YP138 XXX

YP118 XXX

YP183 XXX

YP200 XXX

YP202 XXX

YP300 XXX

YP302 XXX

YP113 XXXX

YP115 XXXX

BurnerLogix Displays

BLV512 XXXX

BLL510 XXXX

BurnerLogix Wiring Bases

60-2810-1 XX X

60-2812-1 XXX

60-2814-1 XXX

X = CERTIFICATION IN HAND

APPROVED

9

®

Table 4: APPLICABLE BULLETINS

Table 5: ORDERING INFORMATION

Table 6: PROGRAMMER MODULES

Note: All programmers: when used with the YB110DC or YB230DC, the FFRT is 0.2 seconds

Programmers, Non-recycle Operation

YP-1001Programmers, Recycle Operation

Programmers, Non-modulating

Displays BD-5001

Wiring base installation, 60-2810-1 133-676

Wiring base installation, 60-2812-1 133-677

Wiring base installation, 60-2814-1 133-677

BurnerLogix Chassis/Flame Amplifier Module

YB110UV 120 VAC input with UV non self-check amplifier

YB110UVSC 120 VAC input with UV self-check amplifier

YB110IR 120 VAC input with IR auto-check amplifier

YB110IR2 120 VAC input with IR auto-check amplifier (special application only -consult factory)

YB110FR 120 VAC input with flame rectification amplifier

YB110DC 120 VAC input with direct coupled amplifier

YB230UV 230 VAC input with UV non self-check amplifier

YB230UVSC 230 VAC input with UV self-check amplifier

YB230IR 230 VAC input with IR auto-check amplifier

YB230IR2 230 VAC input with IR auto check (special application only-consult factory)

YB230FR 230VAC input with flame rectification amplifier

YB230DC 230VAC input with direct coupled amplifier

BurnerLogix Programmer Modules

YP100 Keypad selectable parameters, non-recycle operation, modulation, open damper proving, 4 second FFRT

YP102 Keypad selectable parameters, non-recycle operation, modulation, open damper proving, 2 second FFRT

YP113 Keypad selectable parameters, non-recycle operation, modulation, open damper proving, 1 second FFRT

YP115 Keypad selectable parameters, non-recycle operation, modulation, open damper proving, 1 second FFRT

YP118 Keypad selectable parameters, non-recycle operation, modulation, open damper proving, indefinite pilot hold,

revert to pilot from auto, 1 second FFRT

YP138 Keypad selectable parameters, non-recycle operation, modulation, open damper proving, voltage on terminal 16

is indefinite pilot hold during lightoff, applied voltage on term 16 is revert to pilot from auto, 4 second FFRT

YP183 Same as YP138, except, removal of voltage on terminal 16 will suspend pilot hold during lightoff sequence. Ter-

minal W used for purge complete.

YP200 Keypad selectable parameters, recycle operation, modulation, 4 second FFRT

YP202 Keypad selectable parameters, recycle operation, modulation, 2 second FFRT

YP300 Keypad selectable parameters, recycle operation, low fire start, early spark termination, 4 second FFRT

YP302 Keypad selectable parameters, recycle operation, low fire start, early spark termination, 2 second FFRT

10

Table 7: BURNERLOGIX DISPLAYS

Table 8: BURNERLOGIX WIRING BASES

Table 9: BURNERLOGIX ACCESSORIES

BurnerLogix Displays

BLV512 Display, 2 line X 16 characters, VFD, with cable, NEMA 4

BLL510 Display, 2 line X 16 characters, LCD, with cable, NEMA 4

BurnerLogix wiring bases

60-2810-1 Pigtail wires, 4 foot long, 4"W x 5"H

60-2812-1 Closed base with terminal block and knockouts, 4"W x 7"H

60-2814-1 Open base with terminal block. 4"W x 7"H

BurnerLogix Accessories

129-178-4 Kit, remote mounting, BurnerLogix display, 4 ft. cable, provides NEMA 4 protection

129-178-8 Kit, remote mounting, BurnerLogix display, 8 ft. cable, provides NEMA 4 protection

BLD500 Blank display module, included with YB module

IT1000 Alarm annunciation system using wireless technology

PPC6000 Parallel Positioning System

61-5745-3 Shutter drive assembly for redundant self-check scanners

Table 10: SCANNER SELECTION

FIREYE P/N DESCRIPTION USE WITH CHASSIS BULLETIN

48PT2-1003

48PT2-9003

48PT2-1007

48PT2-9007

4-263-1

Infrared 1/2" straight mount 96"(2438mm) TC-ER cable

Infrared 1/2" 90° angle mount 96" (2438mm) TC-ER cable

Infrared 1/2" straight mount 48" (1219mm) TC-ER cable

Infrared 1/2" 90° angle mount 48" (1219mm) TC-ER cable

Replacement photo detector

YB110IR

YB230IR

YB110IR2

YB230IR2

SC-103

UV1A3

UV1A6

UV8A

UV2

UV2A6

45UV3-1050

UV90-3

UV90-6

UV90-9

UV 1/2" straight 36" (915mm) TC-ER cable

UV 1/2" straight 72" (1830mm) TC-ER cable

UV 1/2" 90° head 72" (1830mm) no armor flex

UV 3/8" straight 36"(915mm) TC-ER cable

UV 3/8" straight 72" (1830mm) TC-ER cable

UV 3/4" cast aluminum housing 96" (2438mm) unshielded leads

UV 90° lateral view with 36" (915mm) flex conduit

UV 90° lateral view with 72" (1830mm) flex conduit

UV 90° lateral view with 108" (2745mm) flex conduit

YB110UV

YB230UV

SC-102

45UV5-1007

45UV5-1009

4-314-1

Self-check UV 1" BSP threads, 102-264VAC

Self-check UV 1" NPT threads, 102-264VAC

Replacement UV tube

YB110UVSC

YB230UVSC SC-101

69ND1-1000K4

69ND1-1000K6

69ND1-1000K8

Flame rod, 12”, 1/2” mount

Flame rod, 18”, 1/2” mount

Flame rod, 24”, 1/2” mount

YB110FR

YB230FR

SC-103

45UV5-1005

45UV5-1105

Self-check UV 1" NPT threads, 61-5745-3 required

Self-check UV 1" BSP threads, 61-5745-3 required

YB110UVSC

YB230UVSC

133-645

55UV5-1007

55UV5-1009

Self-check UV 1" BSP, 102-264VAC, Suitable for hazardous locations.

Self-check UV 1" NPT, 102-264VAC, Suitable for hazardous locations.

YB110UVSC

YB230UVSC

SC-106

PHOENIX

11

®

85UVF4-1QDWR

85UVF4-2QDWR

85IRF4-1QDWR

85IRF4-2QDWR

Phoenix Integrated Scanner, 4 sec FFRT – Ultra-violet with 8-pin electri-

cal quick disconnect. FM, UL_CUS approved.

Fiber optic version of standard Phoenix Integrated Scanner, 4 sec FFRT

– Ultra-violet with 8-pin electrical quick disconnect. FM, UL_CUS

approved.

Phoenix Integrated Scanner, 4 sec FFRT – Infrared with 8-pin electrical

quick disconnect.. FM, UL_CUS approved.

Fiber optic version of standard Phoenix Integrated Scanner, 4 sec FFRT

– Infrared with 8-pin electrical quick disconnect. FM, UL_CUS

approved.

YB110DC

YB230DC

CU-114

35-318-1

35-318-2

Mounting flange for Phoenix, 1“ NPT

Mounting flange for Phoenix, 1“ BSP

59-546-3

59-546-6

59-546-9

59-546-12

59-546-15

59-546-30

59-546-45

59-546-60

59-546-90

8-Conductor 3-meter (9 ft. 10 in.) cable assembly with 8-pin female

connector.

8-Conductor 6-meter (19 ft. 8 in.) cable assembly with 8-pin female

connector.

8-Conductor 9-meter (29 ft. 3 in.) cable assembly with 8-pin female

connector.

8-Conductor 12-meter (39 ft. 4 in.) cable assembly with 8-pin female

connector.

8-Conductor 15-meter (49 ft. 2 in.) cable assembly with 8-pin female

connector.

8-Conductor 30-meter (98 ft. 5 in.) cable assembly with 8-pin female

connector.

8-Conductor 45-meter (147 ft. 7 in.) cable assembly with 8-pin female

connector.

8-Conductor 60-meter (196 ft. 10 in.) cable assembly with 8-pin female

connector.

8-Conductor 90-meter (295 ft. 3 in.) cable assembly with 8-pin female

connector.

INSIGHT

95IRS2-1, 2

95UVS2-1, 2, 3

95DSS2-1

Enhanced Model InSight Scanner – Infrared with quick disconnect, FM,

UL_CUS approved.

Enhanced Model InSight Scanner – Ultra-violet with quick disconnect,

FM, UL_CUS approved.

Enhanced Model InSight Scanner – Dual detector with quick discon-

nect, FM, UL_CUS approved.

YB110DC

YB230DC

CU-95

60-2692

60-2693

1” NPT mounting flange for InSight Scanner, includes heat insulator 35-

127-1.

1” BSP mounting flange for InSight Scanner, includes heat insulator 35-

127-3.

59-497-020-WR

59-497-020C-WR

59-497-020R-WR

59-497-020RC-WR

12-Conductor cable with straight connector (129-164), 20 feet(6 meter)

12-Conductor cable with straight connector (129-164C) and flex con-

duit adapter, 20 feet(6 meter)

12-Conductor cable with right angle connector (129-164R), 20 feet(6

meter)

12-Conductor cable with right angle connector (129-164RC) and flex

conduit adapter, 20 feet(6 meter)

POWER SUPPLIES

60-2685-25

60-2685-50

Power Supply, 24 VDC, 2.0A, 120/240 VAC, 50/60Hz

Power Supply, 24 VDC, 4.0A, 120/240 VAC, 50/60Hz

CU-118

Table 10: SCANNER SELECTION (Continued)

FIREYE P/N DESCRIPTION USE WITH CHASSIS BULLETIN

12

FIGURE 1. BURNERLOGIX ORDERING INFORMATION

WIRING BASE

60-2810-1

PRE-WIRED

4 FOOT

COLOR CODED

FRONT VIEW

(WITH OPTIONAL DISPLAY INSTALLED)

WIRING BASE

60-2814-1

OPEN BOTTOM

CABINET MOUNT

60-2812-1

CLOSED BOTTOM

CONDUIT KNOCKOUT

60-2814-1 SHOWN

SIDE VIEW

CHASSIS/AMPLIFIER

120 VAC, 50/60 Hz

YB110UV

YB110UVSC

YB110IR

YB110FR

YB110DC

230 VAC, 50/60 Hz

YB230UV

YB230 UVSC

YB230IR

PROGRAMMER MODULE

YP100

YP102

YP200

YP202

YP300

YP302

YP113

YP138

YP118

DISPLAY MODULE

BLV512 - VACUUM FLUORESCENT

BLL510 - LIQUID CRYSTAL

(WITH OPTIONAL PROGRAMMER AND DISPLAY INSTALLED)

NOTE: The Phoenix QDWR models with electrical quick-disconnect have replaced the original WR

models equipped with ten feet of captive cable. The QDWR models (with 59-546-X cables) are also

suitable for use in Class I Division 2 hazardous areas, thereby eliminating the need for the “EXWR” models.

13

®

INSTALLATION PROCEDURE

WIRING BASE

Select either the pre-wired wiring base (60-2810-1) or terminal block style (60-2812-1, 60-2814-1).

Either wiring base type can be mounted on a din rail or directly mounted to the cabinet back plate.

Refer to Figure 2 for mounting dimensions.

FIGURE 2. WIRING BASE DETAILS

The location should be free from excessive vibration and within the ambient temperature rating.

Table 11: PRE-WIRED WIRING BASE, P/N 60-2810-1 (shown for 120 VAC)

UL does not apply to 230 VAC operations

Terminal No. Wire Color Type Description Rating

L1 (Hot) Black Line voltage supply 120/230 VAC (+10%,-15%), 50/60 Hz

L2 (Neutral) White Line voltage common

EARTH Green Ground

S1 Red/Wht Scanner Input 300 VAC, 3 mA (UV models only)

S2 Blu/Wht Scanner Input 300 VAC, 3 mA (UV models only)

A Red Output Alarm 120/230 VAC, 1 A pilot duty

M Brown Output Combustion Blower 120/230 VAC, 9.8 FLA, 58.8 LRA

3 Yellow Input Operating Control 120/230 VAC, 1 mA

13 Orange Input Fuel Valve End Switch,

Pre-Ignition Interlock

120/230 VAC, 1 mA

P Gray Input Running Interlock 120/230 VAC, 1 mA

D Wht/Brn Input Low Fire Start Switch 120/230 VAC, 1 mA

8 Wht/Gry Input Open Damper Proving Switch 120/230 VAC, 1 mA

W Wht/Orn Output Delayed Main Valve See Load Ratings (Page 7)

5 LT Blue Output Ignition / Pilot Valve See Load Ratings (Page 7)

6 Tan Output Pilot Valve See Load Ratings (Page 7)

7 Violet Output Main Fuel Valve See Load Ratings (Page 7)

16 DK Blue Input Pilot Valve Hold 120/230 VAC, 1 mA

21 Pink Input Start Input 120/230 VAC, 1 mA

10 Wht/Red Output Modulator Common 120/230 VAC 75 VA

12 Wht/Yel Output Modulator Low Fire 120/230 VAC 75 VA

X Wht/Blue Output Modulator High Fire 120/230 VAC 75 VA

11 Wht/Grn Output Modulator Auto 120/230 VAC 75 VA

22 Wht/Vio Input Remote Reset 120/230 VAC, 1 mA

23 Brn/Wht Input Spare 2 120/230 VAC, 1 mA

HEIGHT WITH CONTROL INSTALLED IS 5.8" (147MM)

14

INSTALLATION PROCEDURE

WIRING BASE

Install the wiring base where the relative humidity never reaches the saturation point. The Burner-

Logix system is designed to operate in a maximum 90% relative humidity continuous, non-condens-

ing environment. Do not install the BurnerLogix system where it can be subjected to vibration in

excess of 0.5G continuous maximum vibration. The BurnerLogix system does not use a weather

tight enclosure. The standard vertical position is recommended. Allow at least one inch clearance

around the control for service and installation.

1. Wiring must comply with all applicable codes, ordinances and regulations.

2. Wiring must comply with NEC Class 1 (Line Voltage) wiring. )(EU or Local Codes)

3. Torque rating on terminal block screws is 4.4 in/lbs to 5.3 in/lbs.

4. Limits and interlocks must be rated to simultaneously carry and break current to the ignition

transformer, pilot valve and main fuel valve(s).

5. Recommended wire routing of lead wires:

a. Do not run high voltage ignition transformer wires in the same conduit with any other

wires.

b. Do not route flame detector lead wires in conduit with line or high voltage circuits. Use

separate conduit where necessary.

6. Maximum wire lengths:

a. The maximum lead wire length is 200 ft. (61 meters) to terminal inputs (Operating limits,

interlocks, valves, etc.).

b. Flame Detector lead wires: see section on flame scanners

c. Remote reset: The maximum length of wire is 500 feet (152 meters) to a normally open

remote reset push-button, which must remain within sight and sound of the burner.

d. Modbus communications: The maximum cable length of wire is 3300 feet (1000 meters)

for RS-485.

A good ground system must be provided to minimize the effects of AC quality problems. A properly

designed ground system meeting all the safety requirements ensures that any AC voltage quality

problems, such as spikes, surges and impulses have a low impedance path to ground. A low imped-

ance path to ground ensures that large currents with any surge voltages follow the desired path to

earth ground.

BEFORE INSTALLING THE BURNERLOGIX CONTROL

WARNING: Controls require safety limits using isolated mechanical contacts. Electronic

limit switches can cause erratic operation and must be avoided.

CAUTION: Ensure that electric power is turned off. Refer to SN-100 for recommended

grounding techniques.

Power to some interlocks (operating controls, air flow switches, modulating circuits, etc.)

can be derived from sources other than what is controlling the BurnerLogix.

15

®

INSTALLING THE YP PROGRAMMER MODULE

FIGURE 3. YP110 PROGRAMMER

The YP programmer module plugs into the side of

the YB110 (YB230) chassis module. They can

only be installed in one direction. DO NOT

ATTEMPT TO FORCE THE YP PROGRAM-

MER INTO THE CHASSIS. Referring to the illus-

tration on the right, align the holes in the YP

programmer housing with the posts located within

the YB chassis. Push the YP module into the chas-

sis until the YP module is flush with the YB hous-

ing.

If it is necessary to remove the YP programmer

module from the YB chassis, 2 slots are provided

on the top and bottom of the YP housing. A small screwdriver can be used to ‘pop’ the programmer

from the chassis.

ELECTRICAL CHECKOUT

If either a ground or a short circuit is detected, it must be eliminated before the control is plugged

into the wiring base and power turned on.

Test the electrical field wiring for short circuits and grounds. The recommended method requires the

use of an ohmmeter set on its lowest resistance scale.

7. Touch the meter probes together and calibrate accurately to ensure a reliable test.

8. Disconnect the neutral wire (L2) from the control system at the power source. Clip one meter

test lead to the grounded green wire or to terminal E and with the other probe touch each other

terminal. At no time should the meters show continuity or read 0 ohms.

9. Reconnect the neutral wire (L2) at the power source. Remove the test probe from the grounded

terminaland reconnect it to Terminal L2 in the wiring base. With the other probe, touch each

other terminal. It is normal to obtain a resistance reading on the meter at some terminals during

this test as there are resistive loads (coils, transformers, lamps, etc.) connected whose normal

DC resistance may be less than 5 ohms. The test meter should not read zero ohms.

10. With your BurnerLogix installed, measure the voltage from L2 to all other terminals. The read-

ing must be zero on all terminals except Ll.

INSTALL BURNERLOGIX INTO WIRING BASE

The BurnerLogix YB chassis/amplifier module contains 2 screws permanently retained into the top

and bottom of the housing. The wiring base contains two brass inserts with recessed threads to ease

the installation. Line up the printed circuit board spacer located in the YB chassis/amplifier module

with the alignment tabs located in the wiring base. Firmly push the YB model into the wiring base to

assure the connectors mate properly. Tighten the screws into the brass inserts until snug.

YB110

YP100

NOTICE: For installations requiring CE certification:

After installation, the equipment should be protected from general access by means of a cabinet

which is only accessible with a key or special tool and therefore a clear responsibility who

replaced the fuse. If the fuse is blown during installation or operation, the control must be sent to

the manufacturer to check.

NOTICE: Restore power for the following test.

16

BURNERLOGIX PROGRAMMER SELECTION

All programmers for the BurnerLogiX Series are designated with the prefix “YP”. The functional

operation, flame failure response time, purge timings, firing rate motor circuit, trial for ignition tim-

ings, recycling function and display messages are determined by the programmer.

Table 12 contains the most common programmers.

Check the programming sequence table for each programming module for the proper explanation of

prepurge timings.

Table 12: BURNERLOGIX PROGRAMMER SELECTION

FIREYE

PART

NUMBER

Pre-purge

Programming

(Seconds)

Proven

High Fire

Interlock

(M-8)

Proven

Low Fire

Interlock

(M-D)

Terminal 6,

Interrupted

or

Intermittent

Early Spark

Termination

SETTINGS SHOWN ARE FACTORY DEFAULT

YP100 30 YES YES INTRP NO

YP102 30 YES YES INTRP NO

YP138 30 YES YES INTRP NO

YP118 30 YES YES INTRP NO

YP183 30 YES YES INTRP NO

YP112 30 YES YES INTRP NO

YP113 30 YES YES INTRP NO

YP115 30 YES YES INTRP NO

YP200 30 NO YES INTRP NO

YP202 30 NO YES INTRP NO

YP300 30 NO YES INTMT YES

YP302 30 NO YES INTMT YES

WARNING: THE INAPPROPRIATE SELECTION OR APPLICATION OF A PROGRAM-

MER MODULE CAN RESULT IN AN UNSAFE CONDITION HAZARDOUS TO LIFE

AND PROPERTY. The various programmer modules are interchangeable because they plug

into a common YB chassis. Many parameters are configurable through the keypad display.

Care must be taken to insure the proper parameters are set. Refer to the appropriate pro-

grammer bulletin for appropriate settings. Selection of the programmer module and setting

the various parameters for a particular application must be made by a competent profes-

sional, such as a Boiler/Burner technician licensed by a state or government agency, engineer-

ing personnel of the burner, boiler or furnace manufacturer (OEM) or in the performance of

duties based on the information from the OEM.

CAUTION: FOR IR MODELS, PRIOR TO VERSION 12, IT IS HIGHLY RECOM-

MENDED THAT AN "IR LEARN" OPERATION BE PERFORMED TO GUARANTEE

RELIABLE OPERATION. REFER TO IR LEARN SECTION FOR MORE INFORMA-

TION.

17

®

Table 12 Continued

1FFRT with YB110DC or YB230DC is 0.2 seconds.

2Terminal W is igniter, terminal 6 is pilot valve. (Terminal 5 is not intended for use)

Note additional 10 second proving time during PTFI.

3 Revert to pilot models.

PTFI*MTFI TIMINGS

The BurnerLogix system provides keypad selectable timings for both PTFI and MTFI. The selections offered can pro-

vide 5 or 10 second timing for terminal 5 and 6 or a shortened time for terminal 5, allowing for early spark termina-

tion. BurnerLogix also provides selectable interrupted or intermittent operation for terminal 6.

FIREYE

PART

NUMBER

PTFI

(5/6)

PTFI

(W/6)

PILOT

PROVING

6 Only

MTFI

(5/6)

MTFI

(W/6)

Running

Interlock

(3-P)

1Flame

Fail Time

(Seconds)

Firing

Rate

Motor

SETTINGS SHOWN ARE FACTORY DEFAULT

YP100 10/10 - 10/15 Non-recycle 4 YES

YP102 10/10 - 10/15 Non-recycle 2 YES

YP138310/10 - 10/15 Non-recycle 4 YES

YP118310/10 - 10/15 Non-recycle 1 YES

YP183310/10 - 10/15 Non-recycle 4 YES

YP1122-5/5 10 - 0/5 Non-recycle 2 YES

YP1132- 5/5 10 - 0/5 Non-recycle 1 YES

YP1152- 5/5 10 - 0/5 Non-recycle 1 YES

YP200 10/10 - 10/15 Recycle 4 YES

YP202 10/10 - 10/15 Recycle 2 YES

YP300 10/10 - 10/intmt Recycle 4 NO

YP302 10/10 - 10/intmt Recycle 2 NO

18

The selections provided for PTFI*MTFI timings are:

Table 13: PILOTAND MAIN TRIALFOR IGNITION TIMING

LED INDICATOR LIGHTS

The BurnerLogix YB control module has seven (7) LED indicator lights. These annunciate the oper-

ating status of the control, and provide the reason for the last lockout condition. The “Open Damper”

and “Close Damper” LED's provide easy set-up of the modulating motor end switches. Each LED

has a graphic symbol to describe its function (see Table 14).

SELECTION PTFI MTFI COMMENT

Term 5 Term 6 Term 5 Term 6

10/10*10/15 10 10 10 15

5/5*0/10 5 5 0 10 NO SPARK DURING MTFI

5/5*0/5 5 5 0 5 NO SPARK DURING MTFI

5/5*10/15 5 5 10 15 SHORTENED PTFI

5/5*10/10 5 5 10 10 SHORTENED PTFI

5/10*0/15 5 10 0 15 EARLY SPARK TERMINATION

5/10*0/10 5 10 0 10 EARLY SPARK TERMINATION

10/10*0/10 10 10 0 10 NO SPARK DURING MTFI

10/10*0/5 10 10 0 5 NO SPARK DURING MTFI

10/10*10/10 10 10 10 10

Table 14: LED INDICATORS

FAN Lights when the blower motor is energized (terminal M) and flashes when the RUN/CHECK

switch is in the “CHECK” position during Purge, PTFI, MTFI and AUTO.

OPEN

DAMPER

Blinks when the modulator motor is being driven to the high fire position. (circuit 10-X

made). Once the high purge switch closes (M-8), this LED stays lit. This LED provides the

status of the high fire purge interlock circuit (M-8). This LED lights anytime the M-8 circuit

closes during Prepurge, PTFI, MTFI, Post Purge.

CLOSE

DAMPER

Blinks when the modulator motor is being driven to the low fire position (circuit 10-12

made). Once the low fire switch closes (M-D), this LED stays lit. This LED provides the sta-

tus of the low fire start interlock circuit (M-D). This LED lights anytime the M-D circuit closes

during Pre-purge, PTFI, MTFI, post purge.

AUTO Lights when the control releases to automatic modulating control (circuit 10-11 made).

IGNITION Blinks during Pilot Trial For Ignition (PTFI). Stays lit during Main Trial For Ignition (MTFI).

FLAME Lights whenever flame is detected by the flame scanner.

ALARM Alarm LED blinks during lockout. The remaining LED's indicate the lockout condition. See

“Safety Lockout Codes.”

19

®

REPLACEABLE FUSE

The following applies only to the YB110 controls operating at 120 VAC, 50/60 Hz:

The chassis/amplifier modules are designed with a field replaceable fuse to protect Terminals 5, 6, 7

and W against short circuit loads or mis-wiring. In the event the fuse becomes OPEN, the display

will indicate CHECK FUSE or the CLOSE DAMPER, AUTO and IGN LED’s lights. An OPEN or

blown fuse is a result of an over current condition on Terminals 5, 6, 7, or W. The over current con-

dition causing the fuse to OPEN must be resolved before another attempt to apply power.

The fuse is located on the printed circuit board containing the relays. To replace the fuse, remove

power from the system and remove the control from its wiring base. Using an appropriate tool,

remove the defective fuse and discard. Install a Fireye replacement fuse (P/N 23-197). Re-install the

BurnerLogix control in accordance with the installation procedure detailed in a previous section.

The YB230 control contains a non-replaceable fuse and must be returned to the manufacturer for

repair or replacement.

20

OPERATING CONTROL FUNCTIONS

1. Operating Controls: Pressure or temperature activated, the operating control closes, causing

the burner start-up sequence to begin. When the operating control opens, the burner shuts off.

The operating control is connected in the L1-3 circuit on the wiring base.

2. Limit Switches: These are pressure, water level or temperature activated

a. Recycle — To stop the burner when the limit switch opens and restart it when the limit switch

recloses, recycle limit switches connected between Terminals L1 and 3.

b. Non-Recycle —when it is necessary to stop the burner when the limit switch opens and pre-

vent it from starting until both the limit switch recloses and the manual reset is activated, they

are connected between terminals 3 and P.

3. Fuel Valve End Switch Interlock: This is an integral switch mounted on the main fuel valve

and activated by the valve stem. It is connected between Terminal L1 & 13. The fuel valve end

switch interlock prevents a burner start-up if the valve stem is not in the “valve closed” position.

This interlock must remain closed while in STANDBY and until the start of PTFI.

4. Purge Interlock: A firing rate motor linkage position switch or a differential air-pressure

switch, that proves a maximum purge air flow rate. It is connected between Terminals M and 8.

The purge interlock proves that the air damper is fully open and purge air flow rate is at maxi-

mum during the purge.

5. Running Interlocks: These are air flow switches, high and low fuel pressure switches, oil tem-

perature switches, atomizing media pressure switches, and excess smoke density controls. These

interlocks prove proper conditions for normal operation of the burner. They are wired in series

and connected between Terminals 3 and P.

6. Low Fire Start Interlock: A firing rate motor linkage position switch or a damper position

switch, proves both the linkage and dampers are in their proper positions to begin burner light

off. This switch is connected between Terminals M and D.

SETTING PROGRAMMER PARAMETERS

To change the factory default parameters stored in the programmer module an optional keypad/dis-

play (BLV512 or BLL510) is required. All configurable parameters are stored within the PRO-

GRAM SETUP sub-menu. The keypad/display module provides tactile feedback keys that are used

to access the sub-menus inherent in the BurnerLogix system.

The BurnerLogix display has 2 lines with 16 characters per line. The default display top line shows

the current operating status. This includes the current point in the burner sequence followed by the

parameter pertaining to that point in the sequence, such as time or the flame signal level. The bottom

line displays the current operating status. The BurnerLogix display also provides the historical infor-

mation stored in the control’s memory such as burner hours, cycles, lockouts and system hours. The

remainder of the display items are menus with sub-menus indicated by a right facing arrow >. The

sub-menus indicate the current value of the selected item and in some cases can be modified to suit

the application.

NOTICE: All programmed settings become permanent after 8 hours of main burner (Terminal 7) on time.

STANDBY

PROGRAM SETUP >

Other manuals for BurnerLogiX YB110

1

This manual suits for next models

1

Table of contents

Other Fireye Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Toa

Toa DP-K1 Brochure & specs

NXP Semiconductors

NXP Semiconductors MSC8113 Reference manual

NXP Semiconductors

NXP Semiconductors Symphony SoundBite Reference manual

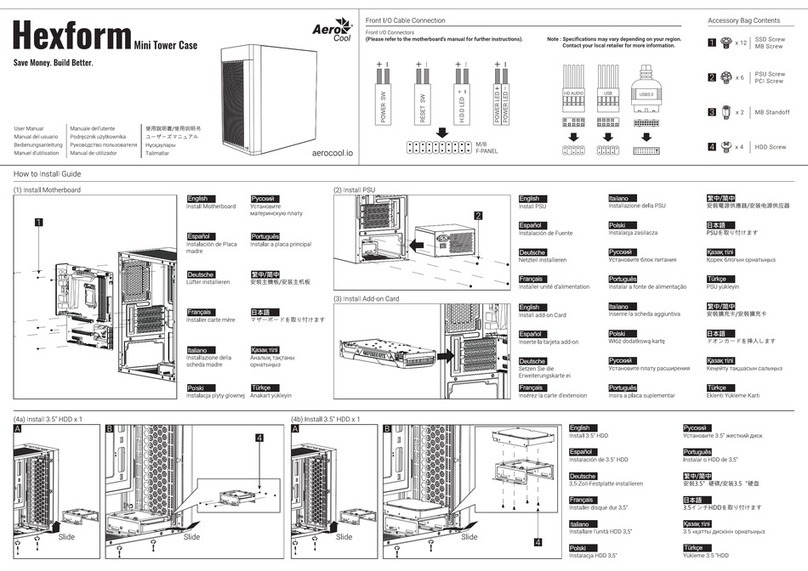

Aerocool

Aerocool Hexform user manual

One Stop Systems

One Stop Systems OSS-PCIe-HIB2-EC-x1 user manual

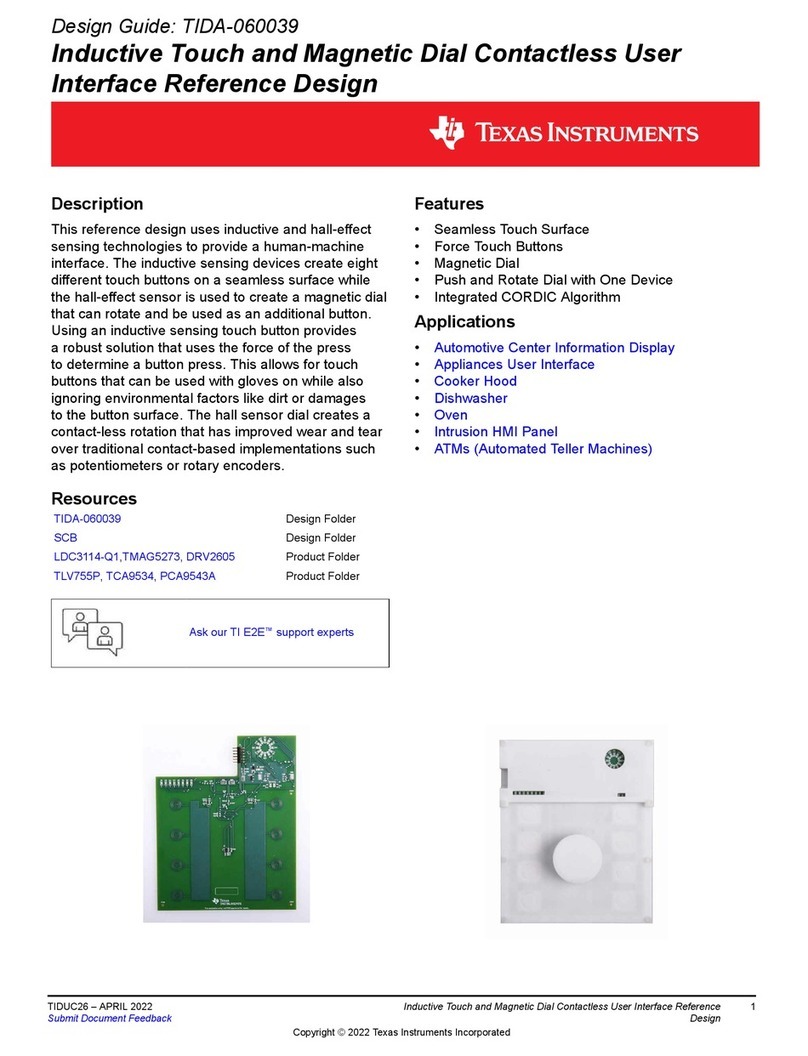

Texas Instruments

Texas Instruments LDC3114-Q1 manual

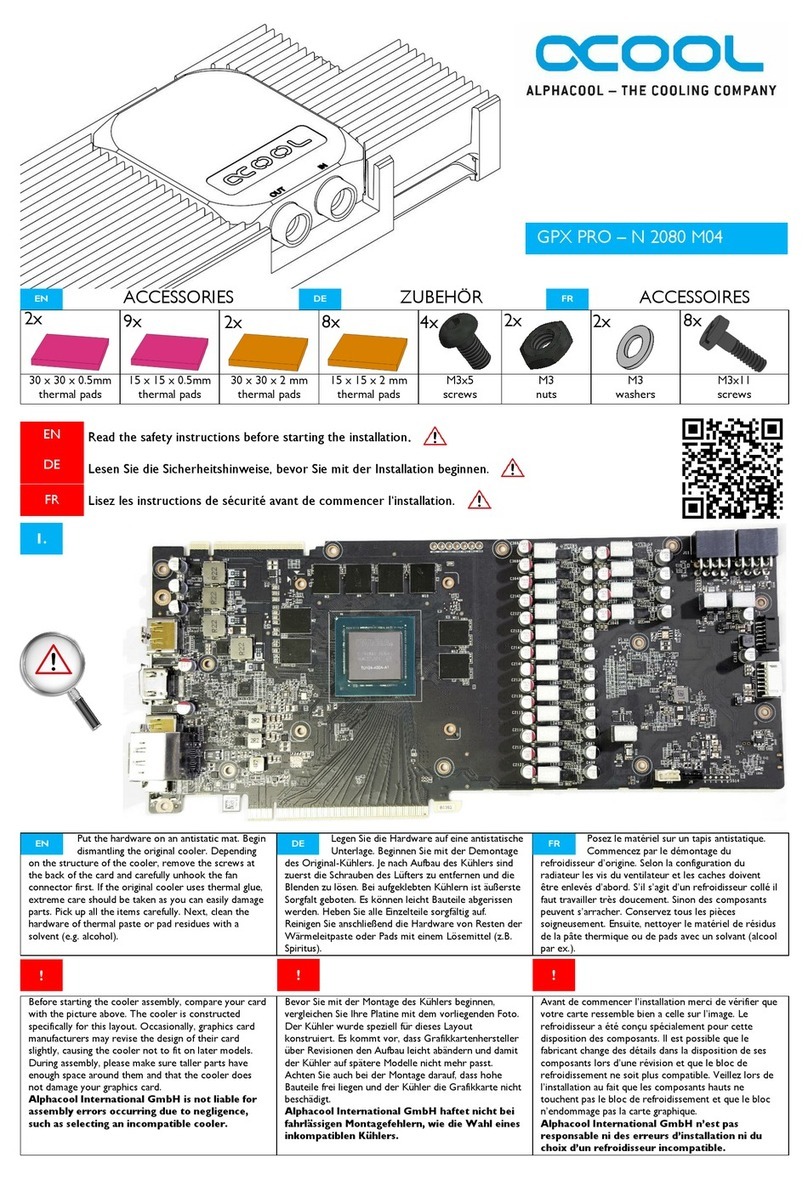

Alphacool

Alphacool GPX PRO - N 2080 M04 manual

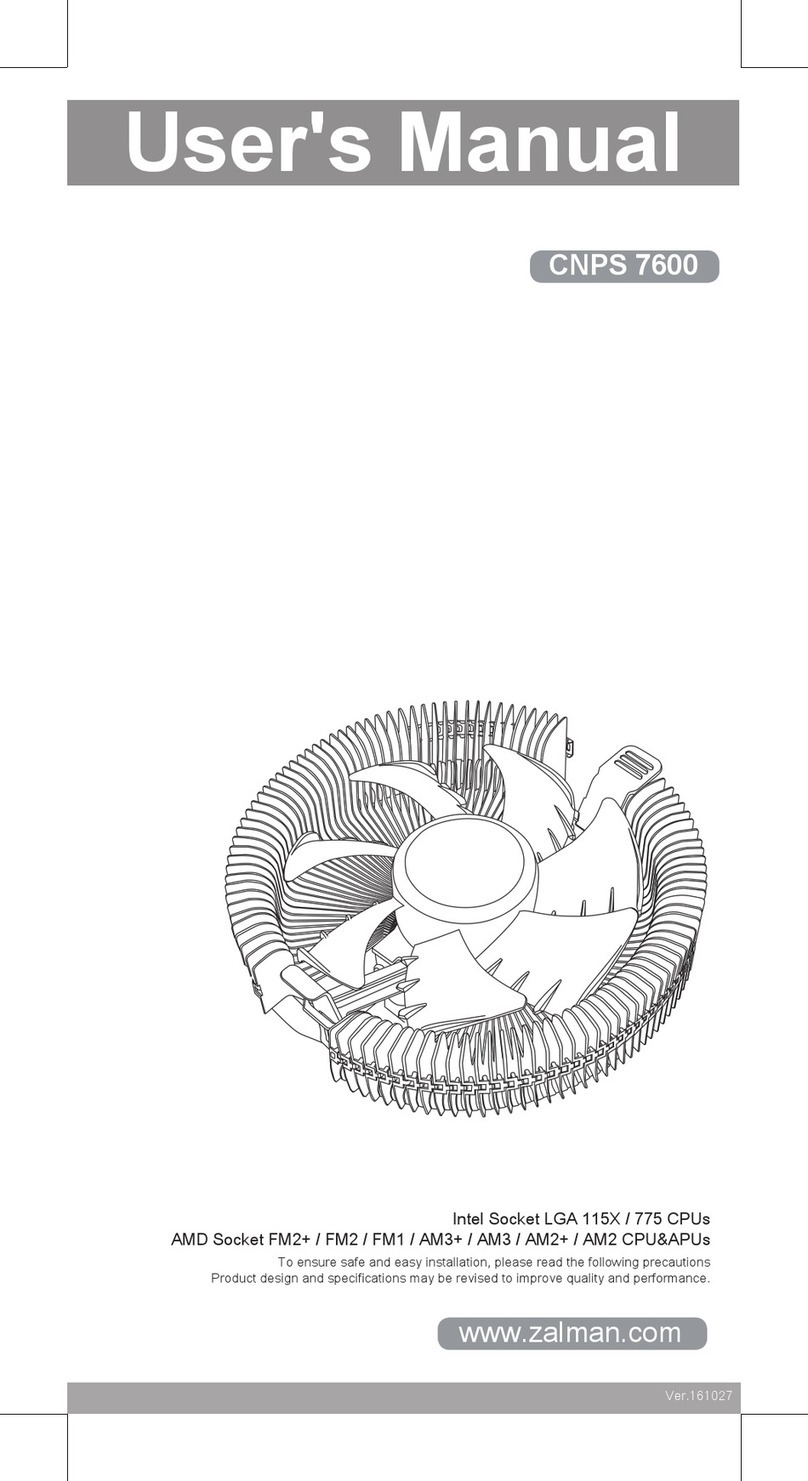

ZALMAN

ZALMAN CNPS 7600 user manual

Noctua

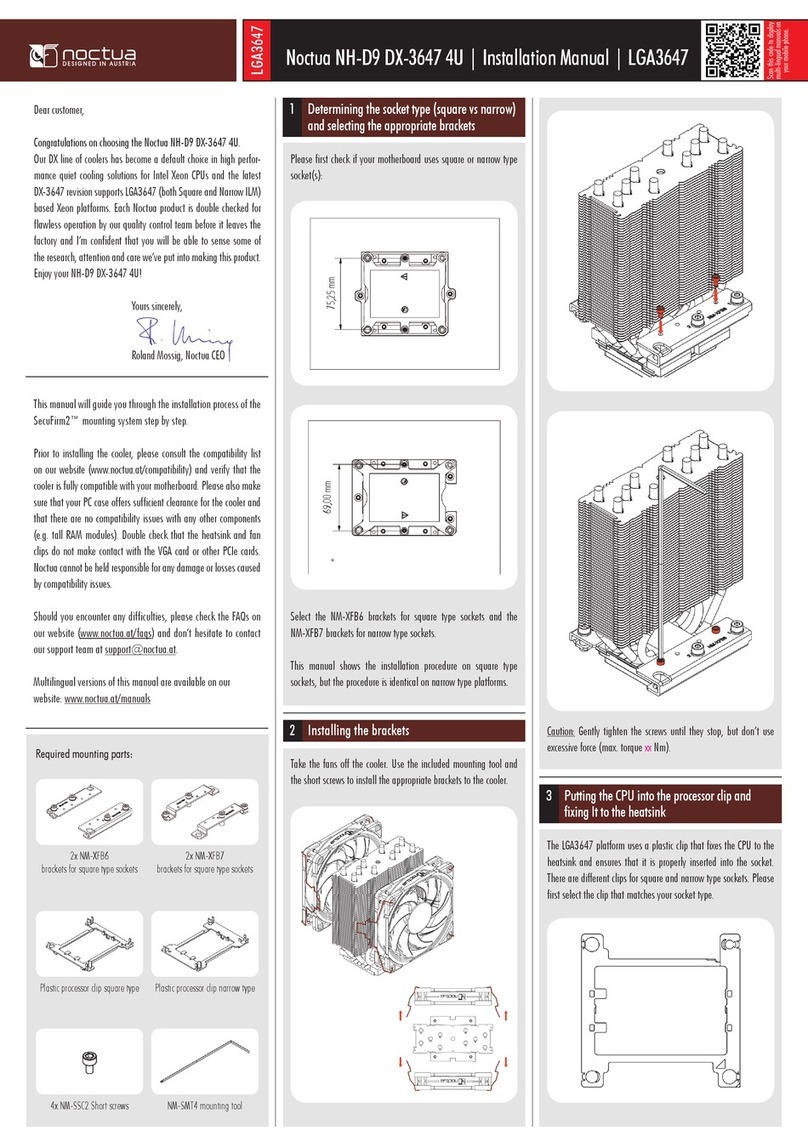

Noctua NH-D9 DX-3647 4U installation manual

Conrad

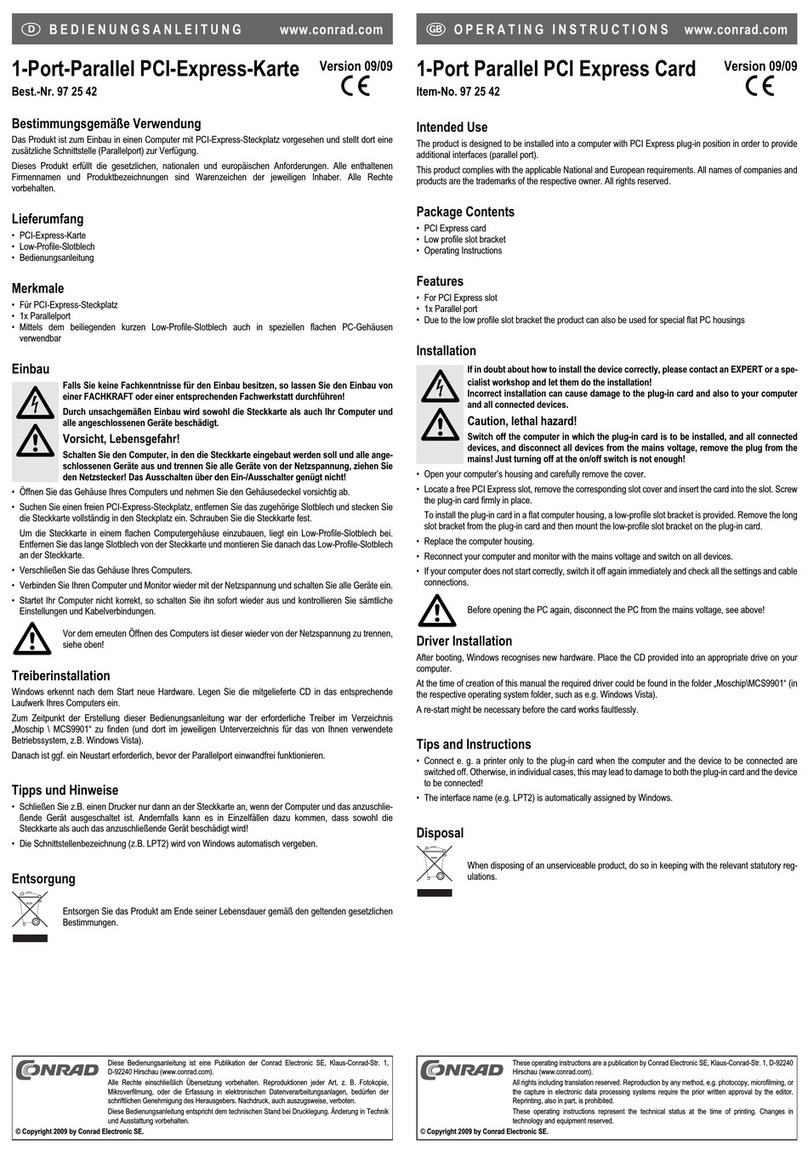

Conrad 97 25 42 operating instructions

Thermaltake

Thermaltake Water 3.0 240 ARGB Sync Premium Edition... user manual

Behringer

Behringer Sonic Exciter SX3040 user manual