FISCH LS 8000 User manual

12 x 20 Log Splitter

LS 8000 Type H

Instruction Manual

TABLE OF CONTENTS

SAFETY INSTRUCTIONS .........................................3,4

ELECTRICAL CONNECTIONS

Power Source ............................................................ 5

Extension Cords ........................................................ 5

Grounding Instructions .............................................. 5

UNPACKING MACHINE ...............................................6

ASSEMBLY INSTRUCTIONS

Installing Leg Assembly ............................................. 7

Attaching Operating Lever ......................................... 7

Attaching Wheel Bracket ........................................... 7,8

OPERATING CONTROLS, MAINTENANCE,

AND ADJUSTMENTS

Starting and Stopping Machine Cycle ....................... 8

Maintaining Proper Oil Level ..................................... 8

Adjusting Air Bleed Screw ......................................... 9

OPERATION, SHIPPING, AND STORAGE

Splitting a Log ............................................................ 9

Transporting and Storing Log Splitter ........................ 9

SAFETY RULES

As with all machinery there are

certain hazards involved with operation

and use of this machine. Using the

machine with respect and caution will

considerably lessen the possibility of

personal injury. However, if normal

safety precautions are overlooked or

ignored, personal injury to the

operator may result. This machine

was designed for certain applications

only. Fisch strongly recommends that

this machine NOT be modified and/or

used for any application other than

for which it was designed. If you

have any questions relative to a

particular application, DO NOT use

the machine until you have first

contacted Fisch to determine if it can

or should be performed on the product.

Fisch Precision Tools Inc.

Route 40 West

RO. Box 644

Claysville, PA 15323

_ WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

1. For your own safety, read instruction manual before

operating the tool. Learn the tool's application and limitations

as welt as the specific hazards peculiar to it.

2. Keep guards in place and in working order.

3. Always wear eye protection. Wear safety glasses. Everyday

eyeglasses only have impact resistant lenses; they are not safety

glasses. Also use face or dust mask if cutting operation is dusty.

These safety glasses must conform to ANSI Z87.1 requirements.

Note: Approved glasses have Z87 printed or stamped on them.

4. Remove adjusting keys and wrenches. Form a habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it "ON".

5. Keep work area clean. Cluttered areas and benches invite

accidents.

6. Don't use in dangerous environment. Don't use power tools

in damp or wet locations, or expose them to rain. Keep work

area welt-lighted.

7. Keep children and visitors away. All children and visitors

should be kept a safe distance from work area.

8. Make workshop childproof- with padlocks, master

switches, or by removing starter keys.

9. Don't force tool. It wilt do the job better and safer at the rate

for which it was designed.

10. Use the right tool. Don't force tool or attachment to do a job

fro which it was not designed.

11. Wear proper apparel. No loose clothing, gloves, neckties,

rings, bracelets, or other jewelry to get caught in moving parts.

Nonslip hard-toed footwear is recommended. Wear protective

hair covering to contain long hair.

12. Don't overreach. Keep proper footing and balance at all times.

13. Maintain tools in top condition. Keep tools sharp and

clean for best and safest performance. Follow instructions for

lubricating and changing accessories.

14. Disconnect tools before servicing.

15. Never stand on tool. Serious injury could occur if the tool is

tipped or if the cutting tool is accidentally contacted.

16. Check damaged parts. Before futher use of the tool, a

guard or other part that is damaged should be carefully checked

to ensure that it wilt operate properly and perform its intended

function - check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

17. Stay alert, watch what you are doing, and use common

sense when operating a power tool. Do not use tool while

tired or under the influence of drugs, alcohol, or medication.

A moment of inattentioin while operating power tools may result

in serious personal injury.

18. Make sure tool is disconnected from power supply while

motor is being mounted, connected or reconnected.

19. _\ WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead-base paints

• Crystalline silica form bricks and cement and other masonry products.

•Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

SAVE THESE INSTRUCTIONS

Refer to them often and use them to instruct others.

ADDITIONAL SAFETY RULES FOR LOG SPLITTERS

_ARNING: DO NOT OPERATE YOUR LOG SPLITTER UNTIL IT IS COMPLETELY

ASSEMBLED AND INSTALLED ACCORDING TO THE INSTRUCTIONS.

1. If you are not thoroughly familiar with the operation of

a log splitter, obtain advice from your supervisor, instructor

or other qualified person.

2. Make sure wiring codes and recommended electrical

connection instructions are followed, and that the machine

is properly grounded.

3. Make all adjustments with the power off.

4. Machine must be positioned on a solid work surface

before using.

5. Do not split wood larger than the recommended

capacity. If jam should occur, release motor switch

button and use pry bar to remove jammed log.

NEVER use your hands.

6. Do not try to remove split logs until the unit has totally

completed work cycle.

7. Stack logs as you work. This will provide a safer,

uncluttered work area.

8. Disconnect machine from the power source when

making repairs.

9. Replace all guards after servicing.

10. Before leaving the machine, make sure the work area

is clean.

ELECTRICAL CONNECTIONS

Power Source

A seperate electrical circuit should be used for your tool. This circuit should not be less than #12

wire and should be protected with a 20 amp time lag fuse. Before connecting the motor to the power

line, make sure the switch is in the "OFF" position and be sure the electric current is of the same

characteristics as indicated on the tool. All line connections should make good contact. Running on

low voltage will damage the motor.

Extension Cords

Make sure your extension cord is in good condition and is a 12 guage, 3-wire extension cord which

has a 3-prong grounding type plug and matching receptacle which will accept the tool's plug. When

using an extension cord, be sure to use one heavy enough to carry the current of the tool. An under-

sized cord will cause a drop in line voltage, resulting in loss of power and overheating. Extension

cords should be no longer than 100 ft.

(_ WARNING: DO NOT EXPOSE THE TOOL TO RAIN OR OPERATE IN DAMP LOCATIONS.

Grounding Instructions

_) ARNING: THIS TOOL MUST BE GROUNDED WHILE IN USE TO PROTECT THE

OPERATOR FROM ELECTRIC SHOCK.

All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric

shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances. Do not modify the plug provided - if it

will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The

conductor with insulation having an outer surface that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do

not connect the equipment grounding conductor to a live terminal. Check with a qualified electrician

or service personnel if the grounding instructions are not completely understood, or if in doubt as to

whether the tool is properly grounded.

Figure. 1

Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

less than 150 volts will have a grounding plug

similar to illustration.

Fig. 1

(_ WARNING: INALL CASES, MAKE SURE THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

UNPACKING THE MACHINE

Carefully unpack the Log Splitter from the shipping container. Check to see that you have all of the

following items. Do not turn the machine ON if any of these items are missing. You may cause injury

to yourself and /or damage the machine.

4

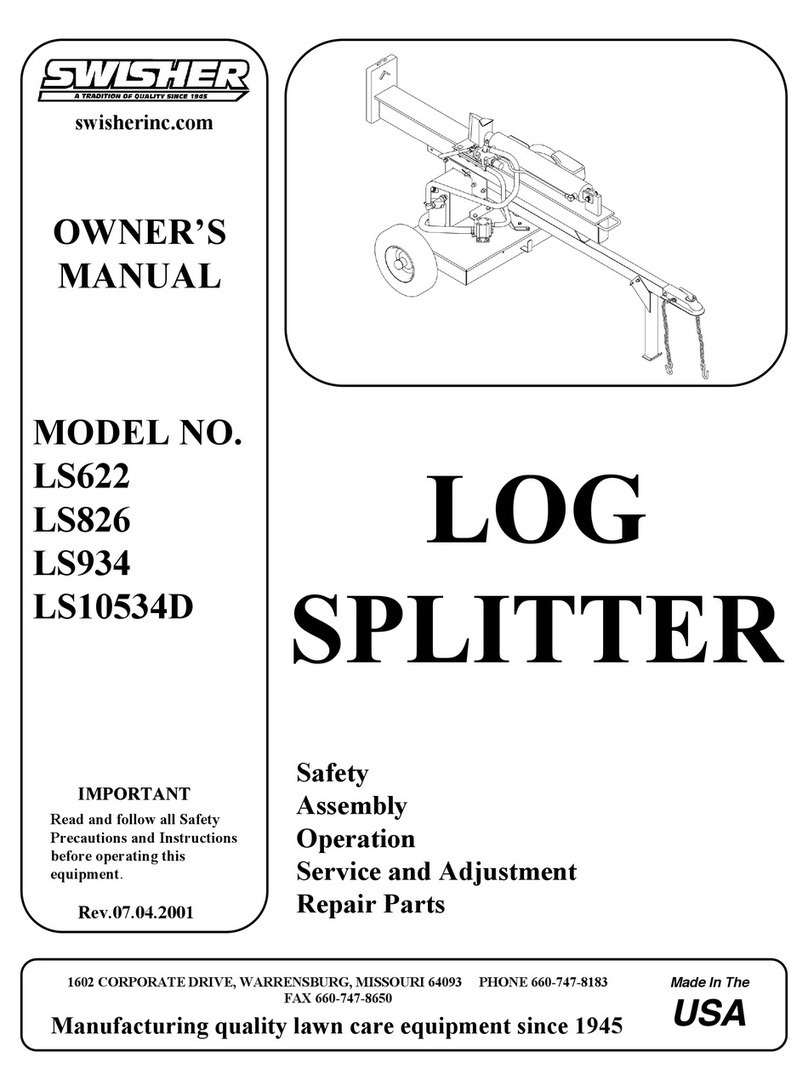

Figure. 2

1. Basic Unit and Motor

2. Operating Lever

3. Hex Head Screws (2)

and Lock Nuts (2)

4. Support Leg Assembly

Fig. 2

5. Assembly/Adjustment Wrenches (2)

6. Wheel Bracket, Axle, and Wheels (2)

ASSEMBLY INSTRUCTIONS

_WARNING:FORYOUR SAFETY,DO NOTCONNECTTHE LOGSPLI'I-I'ERTOA POWERSOURCEUNTILTHE

TOOLISCOMPLETELYASSEMBLEDANDYOU READANDUNDERSTANDTHE ENTIREINSTRUCTIONMANUAL.

Installing Leg Assembly

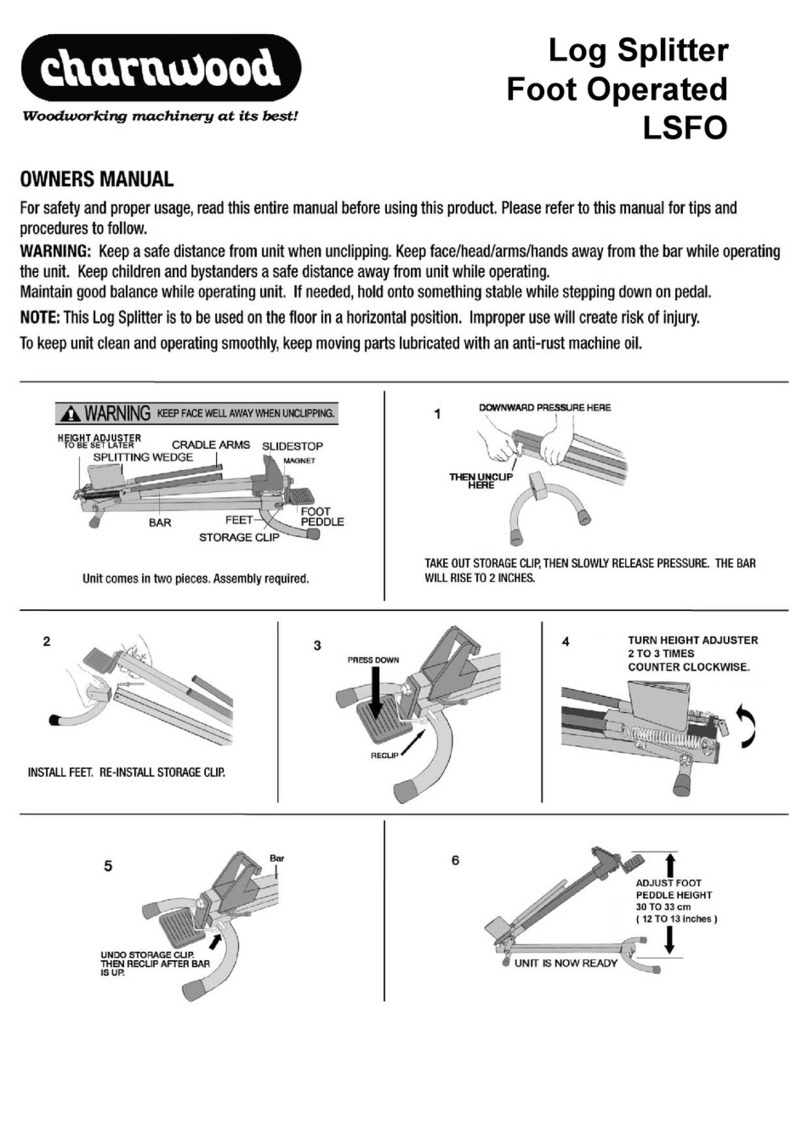

Figure. 3

Place packing block (A) under machine body for

support. Insert two hex head screws thru leg

mounting bracket (B). Attach leg assembly (C).

using two locking nuts.

Figure. 4

This view shows finished installation of leg

assembly.

Fig. 3

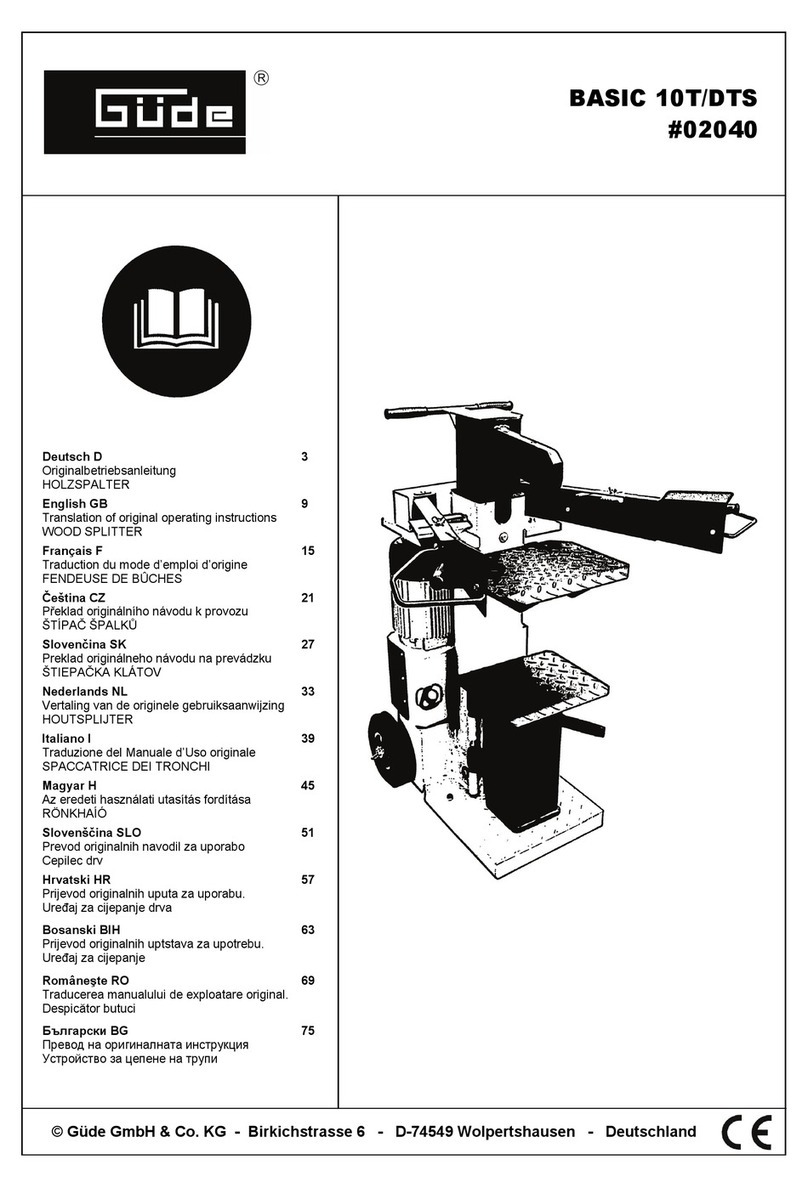

Attaching Operating Lever

Figure. 5

Thread operating lever (A) into operating lever

base (B). See (C)in Fig. 6 for finished

installation.

Fig. 4

Attaching Wheel Bracket

Figure. 6

With supplied wrenches, remove cap nuts (A)

prior to wheel bracket assembly.

Fig. 5

7Fig. 6

Figure. 7

Mount wheel bracket assembly on the log splitter

and attach using the two cap nuts (A). Tighten

with supplied wrenches.

OPERATING CONTROLS,

MAINTENANCE AND

ADJUSTMENTS

Starting and Stopping Machine Cycle

Figure. 8

To start the cycle, depress the motor start switch

(A). When the motor is up to speed, depress the

operating lever (B). The log ram (C) will push the

log into splitting wedge. To complete the cycle,

release lever (B) until ram retracts. Then release

motor switch (A).

Fig. 7

Maintaining Proper Oil Level

NOTE: As with all hydraulic equiptment, a

certain amount of oil seepage is common. Do

not be alarmed if this is noticed. This oil assures

that the ram and other components are properly

lubricated during operation and storage. Always

check oil level before using splitter.

Figure. 9

With log splitter raised 90 degrees to the work

surface, unscrew the dip stick (A) and remove.

Figure. 10

Clean the dip stick and insert in oil cylinder (A).

Remove again and make sure oil level is at

high mark or above (B) on the dip stick. If unit

needs oil, use only clean, high quality hydraulic

oil specifically made for this type of use (such as

NAPA).

Fig. 8

Fig. 9

Fig. 10

8

Adjusting Air Bleed Screw

Figure. 11

Before operating the log splitter, loosen the

bleed screw (A) three to four turns. Retighten

bleed screw before moving or storing log splitter

to avoid oil leakage.

OPERATION, SHIPPING,

AND STORAGE

Splitting a Log

Figure. 12

The log splitting operation requires use of both

hands on the controls, keeping them away from

the splitting action. Load a log, no larger than

12"x 20", onto the log guides (A) and up against

the splitting wedge (B).

Fig. 11

Figure. 13

When it is safe to do so, depress the motor start

switch (A) with one hand. Wait until the motor is

up to speed, then depress the operating lever

(B). The log ram (C) will make contact with the

log and compress it against the wedge.

NOTE: Both hands are on the controls.

Fig. 12

Figure. 14

This view shows the wedge (A) splitting log in

half. Once the log is split, release the operating

handle and the motor start switch. The log ram

will retract.

Fig. 13

Transporting and Storing Log Splitter

Retighten bleed screw as per Fig. 11. It is also

recommended that you remove the operating

lever to avoid breakage. Fig. 14

PARTS LIST

REF. NO.

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

DESCRIPTION QTY.

MAIN BODY 1

FLAT WASHER (8MM) 4

LOG GUIDING PLATE 2

SOC HD CAP SCR M8 X 10MM 4

PLASTIC SLEEVE PLATE 2

WARNING LABEL 1

NAMEPLATE 1

LOG PUSHER ASSEMBLY 1

NUT (M6) 2

CR-HEAD SCREW (M6 X 20) 2

CARRY HANDLE 1

SUPPORT LOG 1

BOLT (U6 X 14) 2

NUT (M6) 4

RUBBER FOOT 1

RUBBER FOOT 1

BOLT (M8 X 25) 4

O-RING OIL SEAL 2

PUMP BRACKET 1

FLAT WASHER (8MM) 3

SPRING WASHER (8MM) 3

MOTOR/PUMP ASSEMBLY 1

SWITCH ASSEMBLY 1

ELECTRICAL BOX 1

POWER CORD 1

SCREW 4

MOTOR FOOT 1

WHEEL FRAME 1

RUBBER WHEEL 2

FLAT WASHER (M10) 2

END CAP 2

REF. NO.

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

DESCRIPTION QTY.

SPRING WASHER (8MM) 2

HAND BAR 1

HAND BAR 1

HANDLE KNOB 1

COPPER WASHER 4

SUPPORT PLATE 1

NUT (M 10) 4

NUT (M 10) 4

FLAT WASHER (M10) 6

HANDLE BASE 1

INNER HEX NUT(M8 X 10) 1

SPRING 1

O-RING OIL SEAL 1

VALVE BODY KIT 1

CONTROL VALVE ASSEMBLY 1

DIP STICK 1

OIL SEAL 1

OIL CYLINDER COVER-END 1

BLEED SCREW (M4) 1

SEAL O-RING 1

SEAL O-RING 1

HEX NUT 2

HEX NUT 4

PISTON RAM 1

CYLINDER BODY 1

HEAD BOLT (SHORT) 2

HEAD BOLT (LONG) 2

SPRING 1

O-RING OIL SEAL 1

PISTON 1

U-PACKING 1

10

PARTS ASSEMBLY

11

WARRANTY

One Year Warranty

Fisch will repair or replace, at its discretion, any items that are defective in

normal use for a period of 1 year. Fisch will not be responsible for any damage

incurred while using this machine other than under normal use and in accordance

with the instructions provided in this Owners Manual. This warranty is Fisch's

only warranty. Any other warranties expressed or implied are null and void.

Please direct any questions or comments to:

Fisch Precision Tools Inc.

Route 40 West

P.O. Box 644

Claysville, PA 15323

Phone: (724) 663-9072

Fax: (724) 663-9065

This manual suits for next models

1

Table of contents

Popular Log Splitter manuals by other brands

Primus

Primus HCWP1- 26 Owner's/operator's manual

Woodstar

Woodstar lv 60H Translation from the original instruction manual

Wen

Wen 4225 user manual

Maaselan Kone Oy

Maaselan Kone Oy Hakki Pilke 37 Series Instructions for assembly, operation and maintenance

COX

COX l2T owner's manual

Dovre

Dovre 18163 instruction manual