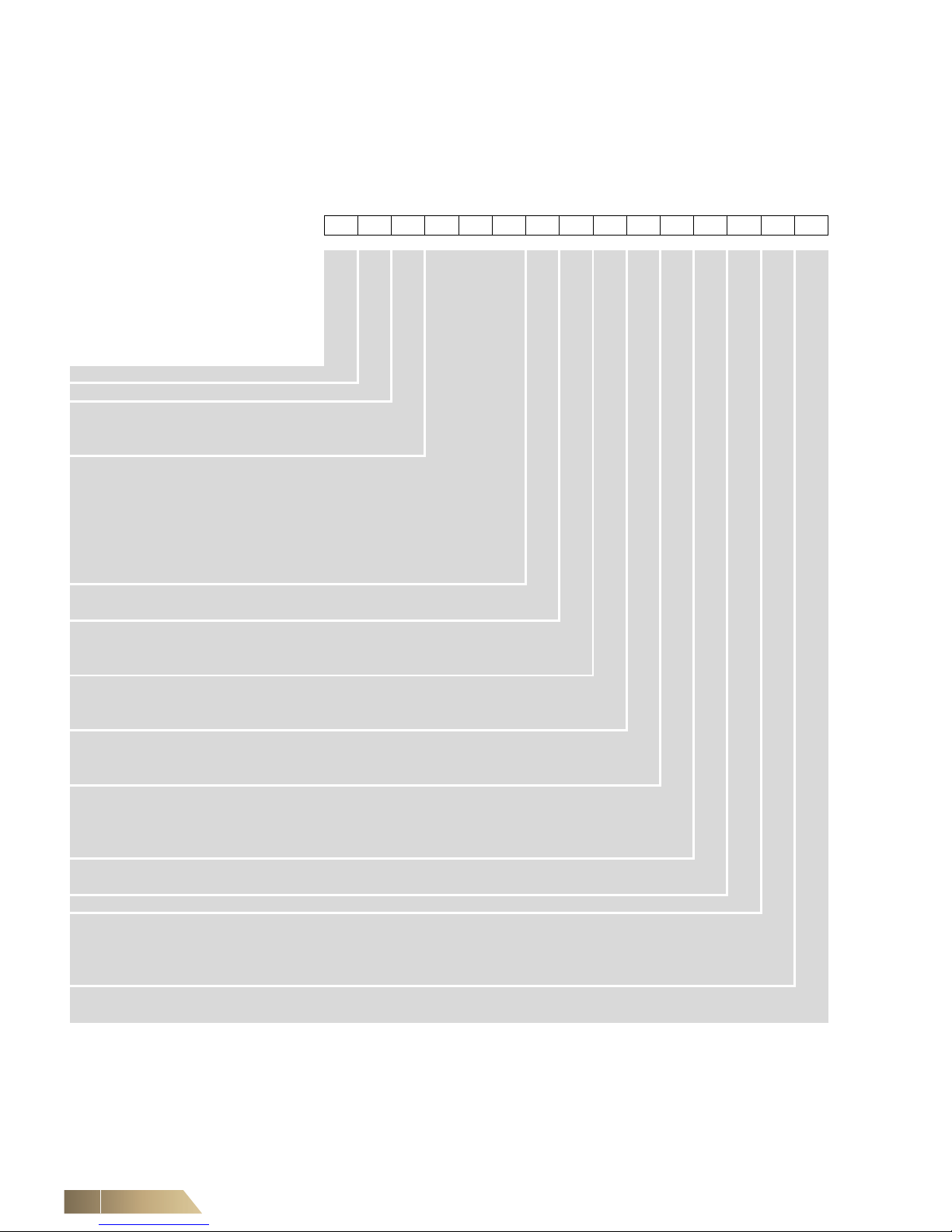

Table of Contents Multi-DENCO

2FläktGroup DC-2013-0101-GB • Subject to modifications • R4-05/2018

1 Overview of Units and Scope of Supply ................................. 13

1.1 Introduction .............................................................................................. 13

1.2 Model number explained .......................................................................... 13

1.3 Product series overview ........................................................................... 14

1.4 DENCO-OfficeCool .................................................................................. 15

1.5 Scope of supply ....................................................................................... 15

1.6 Accessories and special equipment ......................................................... 15

1.7 Directives and regulations ........................................................................ 15

1.8 References within manual ........................................................................ 16

2 Safety and User Information .................................................... 17

2.1 Availability of the operation manual ......................................................... 17

2.2 Scope of the operation manual ................................................................ 17

2.3 Document format ..................................................................................... 18

2.4 Signs used within this manual .................................................................. 19

2.5 Labelling of safety information ................................................................. 21

2.6 Safety-conscious working ........................................................................ 23

2.7 Proper use ............................................................................................... 25

2.8 Modifications and changes ...................................................................... 25

2.9 Spare parts .............................................................................................. 25

2.10 Disposal ................................................................................................... 26

2.11 Personnel selection and qualification ....................................................... 26

2.12 Noise ........................................................................................................ 26

2.13 Environmental considerations .................................................................. 26

3 Technical Description ............................................................... 27

3.1 Unit description ........................................................................................ 27

3.2 Operating limits ........................................................................................ 28

3.3 Operating modes ..................................................................................... 28

3.4 Operating strategies ................................................................................. 29

3.5 Components ............................................................................................. 31

3.6 Heat rejection systems ............................................................................. 33

4 Shipping and Storage ............................................................... 35

4.1 Delivery .................................................................................................... 35

4.2 Handling ................................................................................................... 35

4.3 Storage .................................................................................................... 36

5 Installation ................................................................................. 37

5.1 Requirements and considerations ........................................................... 37

5.2 Substructures ........................................................................................... 39

5.3 Unit placement ......................................................................................... 41

5.4 Clearance and Access ............................................................................. 42

5.5 Installing enclosed accessories ............................................................... 44

5.6 Installation of outdoor units ...................................................................... 47

5.7 Fan touch protection ................................................................................ 50

5.8 EC Declaration of Conformity .................................................................. 50

6 Medium Connections ................................................................ 52

6.1 Requirements ........................................................................................... 52

6.2 Connecting refrigeration pipework ........................................................... 52

6.3 Refrigerant pipework testing procedures ................................................. 60

6.4 Humidifier water connections (optional) ................................................... 62

6.5 Connecting condensate drain .................................................................. 64