flakt woods EQKA User manual

EQKA Cooling unit Contents Page

Safety Directions 2

Technical Data 2

lectric Connections 3

Installation and Commissioning 4

Operation and Care 5

Use 6

Maintenance 7

Troubleshooting 8

Refrigeration Flow Chart 9

Docking 10

EQKA Cooling unit

Fläkt Woods 8643 B 2012.11 1 We reserve the right to alter specifications

Installation and Maintenance Instructions

Safety Directions Compulsory declaration and recurring

inspection

Declaration of possession of cooling equipment must

be submitted to the local inspection authorities, in

most cases the Public Health and nvironment

Authority in your municipality, if including this

cooling unit the total amount of refrigerant charged in

your operations amounts to more than 10 kg.

Recurring inspection

Recurring inspection, i.e. leakage searching of the refri-

gerant system that must be done at least once annually

by an accredited inspectorate (normally a refrigeration

service company), See under “Maintenance”.

EQKA Cooling unit

Fläkt Woods 8643 B 2012.11 2 We reserve the right to alter specifications

Installation and Maintenance Instructions

Important!

– The unit must NOT be used for pur-

poses other than as a cooling unit.

– The cooling unit’s Operating & Main-

tenance Instructions must be studied

carefully before starting/ operating/

servicing/maintaining/scrapping

the unit.

Keep these instructions in a safe place

for future reference!

– All service and maintenance must be

carried out by a professional!

Service/maintenance of the cooling

system must only be carried out by an

accredited company and qualified

personnel wearing required protective

equipment (gloves and protective eye-

glasses).

– Automatic start! Open and lock the

main switch of the cooling unit before

beginning any work on the unit!

– Do NOT stand on the cooling unit!

– Use only genuine spare parts for

maintenance!

Neglect to comply with any of the

above terms can involve a serious

safety risk and nullify the guarantee/

product liability!

Size Capacity Nom. Cooling Max. Max.

(a) Variant Capacity Current Current Circuit Circuit Circuit Circuit Total

(c) (kW) (A) (A) 1234

008 1 13 9,3 18,5 1,4 2,1 3,5

008 2 15,5 11,2 22 1,6 2,4 4

011 1 15,5 11,2 22 1,6 2,4 4

011 2 24,5 17,3 36,1 2,6 3,9 6,5

018 1 28 20 40,6 3,0 4,5 7,5

018 2 37,5 25,9 50,3 4,0 6,0 10

023 1 44 27,8 58,6 4,8 7,2 12

023 2 56 35,3 71,6 6,0 9,0 15

032 1 58,5 37,3 69,8 6,0 9,0 15

032 2 73,5 49,9 104,8 7,6 11,4 19

041 1 69 49 88 8,0 12,0 20

041 2 98,5 58,8 117,3 8,6 8,6 8,6 26

050 1 98,5 58,8 117,3 8,6 8,6 8,6 26

050 2 125,5 81 10,9 10,9 10,9 33

072 1 125,5 81 10,9 10,9 10,9 33

072 2 151 89,2 10,0 10,0 10,0 10,0 40

The fuse protection should be sized by a qualified electrician.

3 x 400 V

Technical Data - EQKA

3 x 230 V

Fläkt Woods 8643 B 2012.11 3 We reserve the right to alter specifications

Installation and Maintenance Instructions

EQKA Cooling unit

Electric Connections

Check that the cooling unit has been switched off with

the main switch. The electric connections are wired on

the main switch.

The direction of rotation of the compressorsdepends on

the sequence of the phases. The cooling unit must be

wired with the correct phase sequence; otherwise an

alarm will be initiated. The alarm chain of the cooling

unit can also transmit a group alarm signal to an external

monitoring unit. ( Q air handling unit or another unit

across a monitoring unit).

This alarm group can be obtained as potential-free

contacts at pins 57 and 58 on wiring terminals.

To prevent unnecessary stops and alarm from the

cooling unit, it should be interlocked across the extract

air fan, FF.

Connect the cooling unit as illustrated in the wiring

diagram below.

Incoming

3x400V supply

To be connected

to main switch in

cooling unit.

L1

L2

L3

N

PE PE

PE

N

QO1.6

QO1.4

QO1.2

Outgoing

group alarm

(closes on an alarm)

58 NO

57 C

2

1

2

PE PE

1

2

3

PE

1

2

3

44

PE

1

PE

54

53

2

1

2

PE PE

1

C

NC

PE

56

55

2

1

2

PE PE

1

C

NO

52

51

2

1

20-10V

1

+

–

Interlock across possible

outdoor thermostat, GT

(otherwise fit with jumper)

Interlock across

extract air fan

0-10V DC control signal

External wiring diagram

Fläkt Woods 8643 B 2012.11 4 We reserve the right to alter specifications

Installation and Maintenance Instructions

EQKA Cooling unit

Installation and Commissioning

Connection of the water-cooled condenser

Cooling units equipped with a KD-W water-cooled

condenser (see unit specification) must be connected to

a mains water supply having a minimum pressure of 0.5

bar and a maximum pressure of 10 bar. Use an appropri-

ate coupling for connecting the mains water supply (see

pipe connection instructions on the cooling unit).

Follow the arrows carefully. If heat is recovered, the

drain water must be connected to an accumulator tank.

Important!

Check list

– Always study the safety directions

on page 2 before beginning all work!

– The air handling unit must not be

commissioned until the installation

had been inspected according to the

check list below!

Before commissioning check the

following:

– Condition on delivery - no transport

damage, installation site, (adequate

lighting, supporting surface etc.)

– No leakage of compressor oil

– Follow-up tightening of the Rotalock

connection

– Phase sequence and retightening of

the power supply connection

– Cooling control signal from the air

handling unit

– Cooling energy recovery not enabled

– Crankcase heater is operating

– Condensate drainage, cooling instal-

lation report submitted

– There are no loss cables

After commissioning check the

following:

– outdoor-/suppllyair temperature

– condensation-/evaporating

– hot gas temperature/

subcooling/overheating

– operating currents

– information to staff-performed.

In a cooling unit with KD-W water-cooled condenser,

the mains water supply must not be shut off.

To start the cooling unit

If the cooling unit is commissioned in cold weather, i.e.

when the temperature is below +15 °C, the compressors

mustbepre-heated:Settheprotectivemotorswitchofthe

compressors to position 0 (Off). Set the main switch insi-

de the cooling unit to position 1 (On) and activate the

control circuit fuse. The crank case heater now heats up

the compressor. If the ambient temperature is below +15

°C, wait for 4-8 hours until the compressor has become

warm, before you start up the compressors.

To set the setpoint for cooling

When cooling is required, the controller in the air

handling unit transmits a control signal (0 – 10V) to the

cooling unit which switches in the capacity steps in

proportion to the signal.

Performance check

The performance of the cooling unit can be tested by

temporarily lowering the cooling setpoint to the point

that the cooling unit starts up.

Inspection

For a description of the control unit, see page 9. The

control function of the air handling unit should include

a minimum temperature sensor in the supply air located

as far as possible from the air handling unit, and a room

or extract air sensor. The cooling unit should be inter-

locked across the extract air fan (and also an outdoor

thermostat). It is important that the compressors stop if

the extract air fan stops. Due to the location of the con-

denser coil, so-called cooling energy recovery cannot be

utilizedatthesametimeasthecoolingunitisinoperation.

High pressure condenser, KD

If condenser heat cannot be emitted into the extract air,

KM1 (“Capac.Control”) will first be automatically swit-

ched off, however if this is insufficient, the high pressure

switch will open and must be manually reset, (see page 9).

Alarm

All the alarms are indicated on the display of the

control unit (see page 10). Potential-free closure is on

the wiring terminal for group alarm transmission, if

required.

Important!

If the unit is installed outdoors, the

heat carrier must contain an appro-

priate mixture of anti-freeze agent to

suit the climate.

Important!

If anti-freeze agent is used, the unit

must have a closed system for the heat

carrier.

Fläkt Woods 8643 B 2012.11 5 We reserve the right to alter specifications

Installation and Maintenance Instructions

Operating and Care

Description

The cooling unit is a part of the air handling unit and

should be installed as a module in the U air handling

unit.

The cooling unit operates independently and has its

own cubicle; however cooling capacity must be swit-

ched in according to signals from the air handling unit.

The cooling unit is designed for cooling the supply air in

the temperature range of between +20 – +32 °C. It is

possible to lower the supply air temperature by 9 – 16 °C

depending on the selected capacity variant, air tempe-

ratures and air volume ratio: supply air/extract air.

Use

An electric equipment cubicle is installed in the service

section of the cooling unit. The cubicle contains mainly

the following items of equipment:

– Main switch

– Control circuit fuse

– Protective motor switch

– Control unit with display

Refrigerant tank

Component description

Control unit (RC1)

The control unit is located in the door of the cubicle.

See the description on page 9.

Control circuit fuse

To reset the miniature circuit breaker, pull the black

actuator button upward.

Main switch

Use the main switch for switching the cooling unit

on/off. Always switch off the main switch on the

cooling unit and lock it in position before beginning

work! Certain wiring terminals can be energized despi-

te the fact that the switch is switched off, for example

terminals for group alarm outputs.

EQKA Cooling unit

Warning!

The refrigerant tank is intended for

use as a ”passive” container only, i.e.

it must NOT be connected while the

unit is normally operating. (Applies

to units with refrigerant tank).

Important!

Always study the safety directions on

page 2 before beginning all work!

Warning!

The control circuit fuse does NOT

switch off the voltage to the entire

cooling unit! Always open the main

switch on the cooling unit and lock it

in position!

Fläkt Woods 8643 B 2012.11 6 We reserve the right to alter specifications

Installation and Maintenance Instructions

EQKA Cooling unit

Functions, eneral

The compressor’s capacity is controlled by an external

control signal of 0 – 10V. Its operation is interlocked via

the extract air fan contactor and possibly an outdoor

thermostat as well as via a phase rotation relay.After the

fan starts, the compressors are interlocked for 2 minutes

– delayed start of the compressors (“Startwait 2 min.” is

shown in the display”).

Delayed restart

The compressors cannot start again until after a

300/305/310/315 second idle time (KM1/KM2/KM3/

KM4). During this time “ Startwait 2 min.” flashes in the

display if the relevant compressor needs to be started.

Capacity control (Capac. control)

Compressor 1 has a special high pressure switch for

capacity control.

If the condenser pressure is high, compressor 1 is stopp-

ped and is then allowed to restart after 300 sec.

The text "Capac." alt ”1= capacity control” is shown in

the display while capacity control is in progress.

Compressor protection

ach compressor is protected by a high pressure switch

and motor protection. The compressors are protected

fromincorrectphasesequenceviaaphase-sequencerelay.

The oil heater is switched in while the compressors are

not in operation.

Stepping levels

The various compressor steps are switched in at the

following signal levels:

Cooling unit with hot gas bypass

On a 20% control signal, the ICM2 with hot gas valve

starts in the fully open position. The hot gas valve

closes linearly between 2 and 8 V. The KMI starts at 8 V

and the valve opens 40%.

Between 8 and 10 V the valve closes again.

Stepping levels

Stepping out of each step occurs 20%(2.0V) during

stepping level for 2 or 3 compressors and 10% (1.0v)

During the stepping level for 4 compressors.

roup alarm

For all alarms, the group alarm relay is energized for

possible external alarm indication.

Display texts

Line 1 shows the type of Cooler

Cooler KM1-2, Cooler KM1-2 bin.

Cooler KM1-3, Cooler KM1-4 bin.

Signifies that the steps are switched in binary mode.

Lines 2 and 3

Show the in-service status of compressors 1-4

Start, (flashes in the event of time-delayed start of KM)

Run, (operation of KM)

Capac. or capacity control

AlarmH, or AlarmHigh pres

AlarmL, or AlarmLowpres

AlarmQ, or AlarmQ1/term.

(Q=motor protection and term= thermistor.

Line 2 can also show

* 3-Phase alarm *

Line 3 can also show

* Fan stop *

* Startwait 2 min *

Line 4

Shows input control signal as 0 – 100%:

Signal %058.

PressAto see the compressor running time and possible

control signal to SV1 (valve for hot gas bypass).

Program

The control unit is programmed on delivery and its

settings cannot be changed.

Cooler KM – 4

1= Capac. 3 = Run

2= Start 4 = Alarm H

Signal % 082

A B ESC – + OK

KM1–4 Run time (h)

1= 00242 3= 00154

2= 00228 4 = 00125

Signal SV1 % 098

ABESC– + OK

Compressor 34Compressor 2

1 30 % 20 % 1 30 %

2 60 % 40 % 1 60 %

3 90 % 60 % 1 + 2 90 %

4 80 %

Straight-line stepping

Number of compressors

Binary stepping

Number of compressors

Fläkt Woods 8643 B 2012.11 7 We reserve the right to alter specifications

Installation and Maintenance Instructions

EQKA Cooling unit

Maintenance

Inspection/maintenance

The unit is designed for fully-automatic operation;

however it does require a some regular inspection and

maintenance.

Moreover in accordance with legislation in force,

”Recurring Inspection” must be carried out by an accre-

dited refrigeration service company.

Inspection

To be carried out by the owner/user once a week.

Check (see/listen to) the following:

1. Indicated alarms

2. Abnormal noise/vibrations

3. Leakage of medium (oil, water)

4. Corrosion, wear

5. Suspension, fixation items

6. The interior of the unit, light fittings

Maintenance

To be carried out by a refrigeration service company or

equivalent at least once each year.

Check the following:

1. vaporation/condensation temperature.

2. Hot gas temperature.

3. xpansion valve (overheating of suction gas).

4. Safety equipment (tripping function on the pressure

switches).

5. Cooling capacity

6. Control/feedback control equipment (Performance

check)

7. lectric equipment (retightening of power supply

connections)

8. Cleaning (Coils, drip tray, drainage)

9. Air filter

Recurring checks

Mustonlybecarried out byarefrigerationservicecompany.

Inspect the system at least once every 12 months and main-

tainajournal. Check thefollowingwhereverapplicable:

1. Piping

2. Inspection to detect leakage from the refrigerant

system

3. Check for abnormal vibration

4. Check to detect possible corrosion

5. Whether filling with additional refrigerant is needed

6. Check to detect possible oil leakage

7. Safety equipment

8. Connection joints/Seals

Dismantling

When dismantling (scrapping) this type of unit, the

refrigerant and compressor oil must unconditionally be

collected and contained for destruction/recycling.

Spare parts

Spare parts can be bought via local cooling suppliers.

Contact your local Fläkt Woods office for information

regarding components that need to be replaced.

Important!

Always study the safety directions

on page 2 before beginning work!

Fläkt Woods 8643 B 2012.11 8 We reserve the right to alter specifications

Installation and Maintenance Instructions

EQKA Cooling unit

Troubleshooting

To reset the pressure switch

A pressure switch is mounted on each compressor

To reset the protective motor switch:

The protective motor switches are mounted in the control

equipment cubicle.

Remedial measures

Check that there is voltage on all

phases and that the phase sequ-

ence is correct.

Startthefans ortestbyfitting a jumper

betweenwiringterminals55and 56.

Wait 2 minutes for the dampers to

open before starting the cooling unit.

High pressure switch has tripped.

Reset button is on the pressure

switch. The load is too great or

there is too little air. Check that

filter and coils are not clogged.

Low pressure switch has tripped.

Ingoing air temperature is too low or

there’s a shortage of refrigerant.

Tripped motor protection or ther-

mistor. Press motor protection

button to reset it or let the com-

pressor motor cool off.

Check after resetting the motor

protection that the compressor

operates without abnormal noise.

High pressure switch with automatic

reset has tripped and compressor 1

is switched off for 5 min.

Check that filter and coils are not

clogged.

Check that the control signal is at

least 30% for start of first com-

pressor.

To start all the compressors, the

signal should be at least 90%

Current compressor will start after

a delay of approx. 5 min. Wait!

Current compressor should now

have started. If not, check that

voltage is coming from the com-

pressor contactor. If there is vol-

tage, the compressor is probably

defective.

Display text:

*3-phase alarm *

*fan Stop *

* Start wait 2 min *

’Alarm H’ alt.

’Alarm High pres.’

’Alarm L’ alt.

’Alarm low pres.’

Alarm Q alt.

Alarm Q1 / Term

1= Capac. alt.

1= Capac. Control

Signal % <030

1/2/3/4 = start

1/2/3/4 = run

Ca tion!

Faults should always be cleared without

delay!

All service and maintenance should be

performed by professionals!

Service/maintenance of the cooling sys-

tem must only be performed by accre-

dited company with authorized per-

sonnel wearing protective equipment!

Press here

Fläkt Woods 8643 B 2012.11 9 We reserve the right to alter specifications

Installation and Maintenance Instructions

EQKA Cooling unit

Description of the Functions, example with two compressors

Operation

The cooling unit is started and stopped by an external

control signal of 0–10 V.

The step-by-step opening and closing operation is

described on page 7.

Note: The water-cooled condenser is mounted on circuit

no. 3 or 4 on the sizes that have 3 or 4 compressors.

Description of the Functions

Designation

EV:1, EV:2, EV:3 = Evaporator

FT:1, FT:2, FT3 = Drying filter

P1:1, P1:2, P1:3 = Protective pressure switch – high pressure

P1a:1 = In-service pressure switch – high pressure

P2:1, P2:2, P2:3 = Protective pressure switch – low pressure

KD:1, KD:2, KD:3 = Condenser

KD-W = Water-cooled condenser (optional)

KM:1, KM:2, KM:3 = Compressor

MU1:1, MU1:2, MU1:3 = Measurement tapping – high pressure

MU2:1, MU2:2, MU2:3 = Measurement tapping – low pressure

S :1, S :2, S :3 = Sight glass

SÄV = Safety valve

VS:1, VS:2, VS:3 = Expansion valve

VW = Pressure-controlled water-saving valve

(optional)

Fan section

Design pressure: 29.3 bar (e) = effective

Test pressure: 33.0 bar (e) effective

Water-cooled

condenser

Direction

of flow

Fan section

VW

KD-W

Cold

water

inlet

1) Optional: code suffix –d

Water-cooled condenser

Refrigeration flow chart for unit sizes

with 2 compressors

These units with 3 compressors have a

third circuit which is similar to circuit no 2.

Fläkt Woods 8643 B 2012.11 10 We reserve the right to alter specifications

Installation and Maintenance Instructions

EQKA Cooling unit

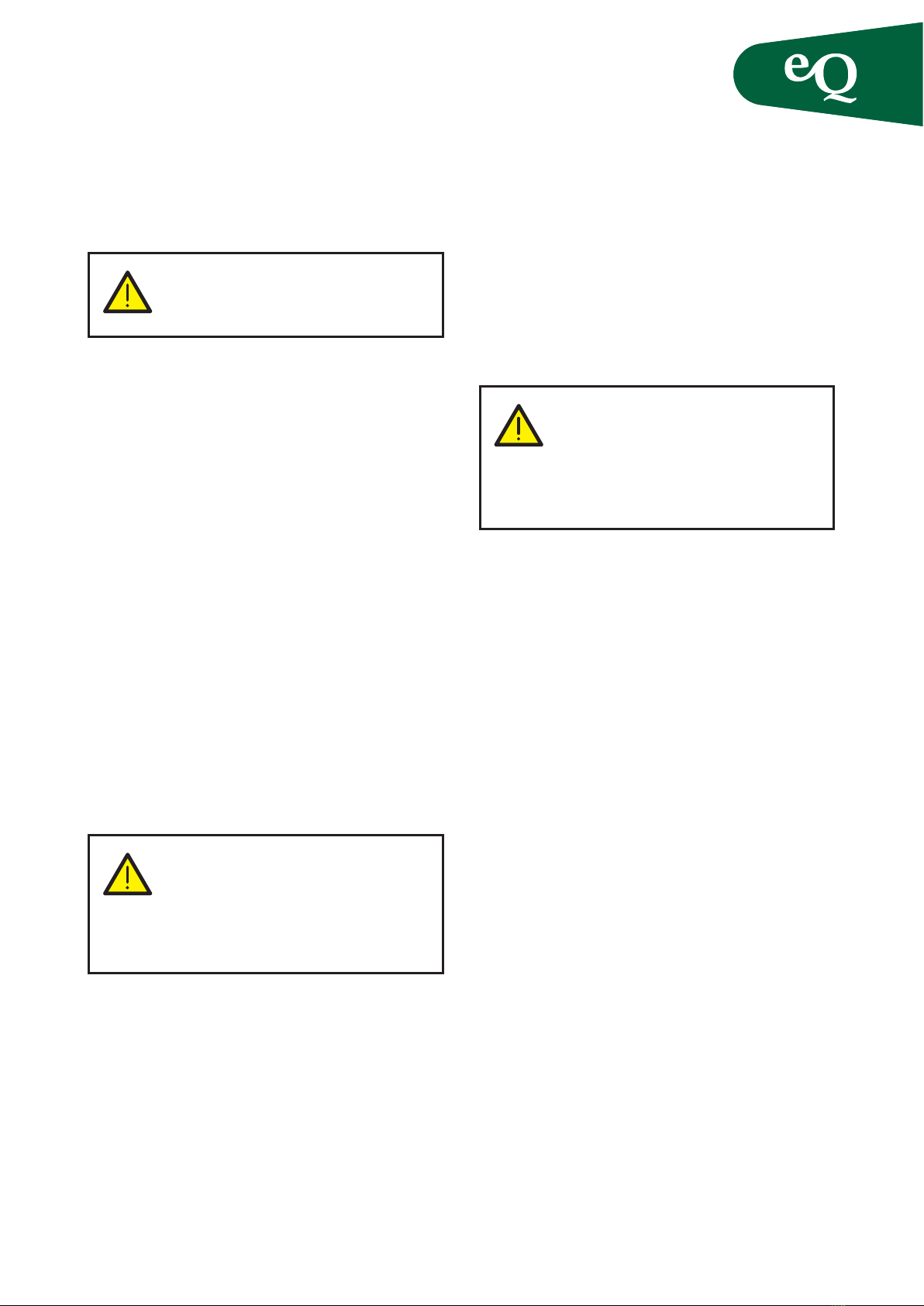

Jointing - Externally

Jointing - Internally

AC

B

D

A

B, D

C

Table of contents

Other flakt woods Cooling Box manuals