Flaming River FR1058 User manual

Table of contents

Popular Industrial Electrical manuals by other brands

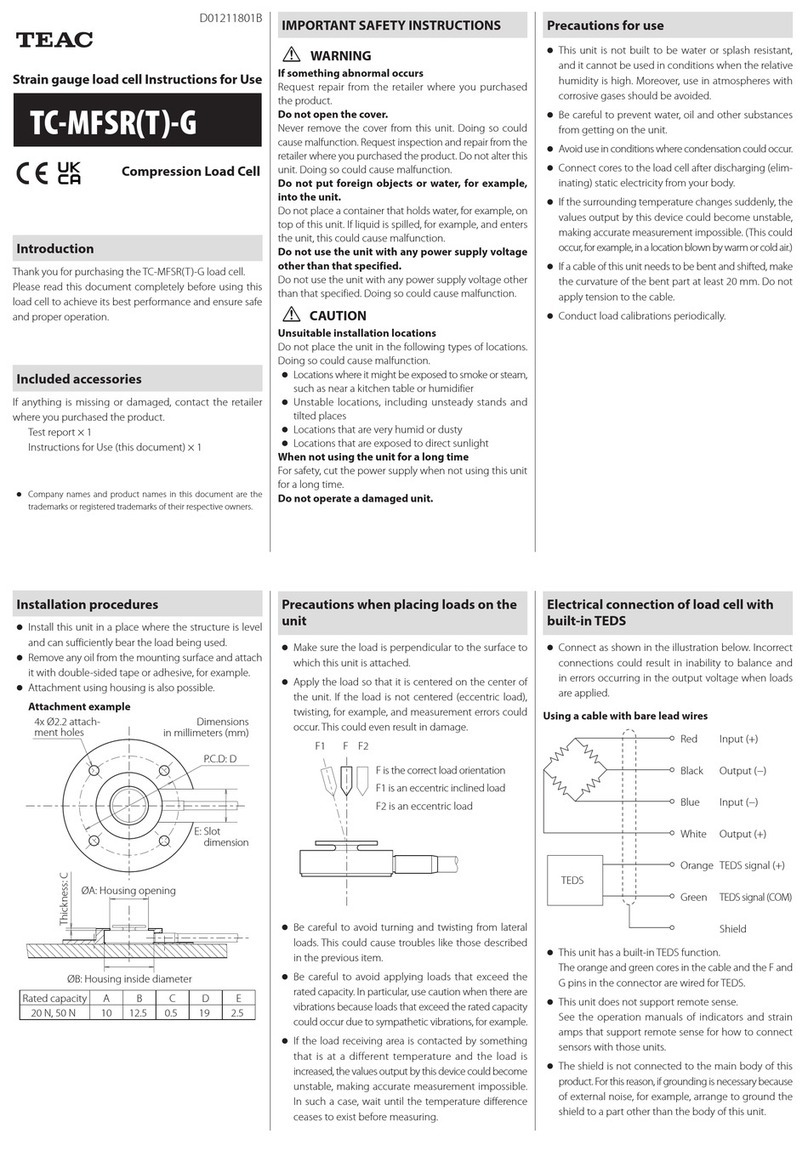

Teac

Teac TC-MFSR-G Instructions for use

Murata

Murata GRT31CR61A106ME01 Series Reference sheet

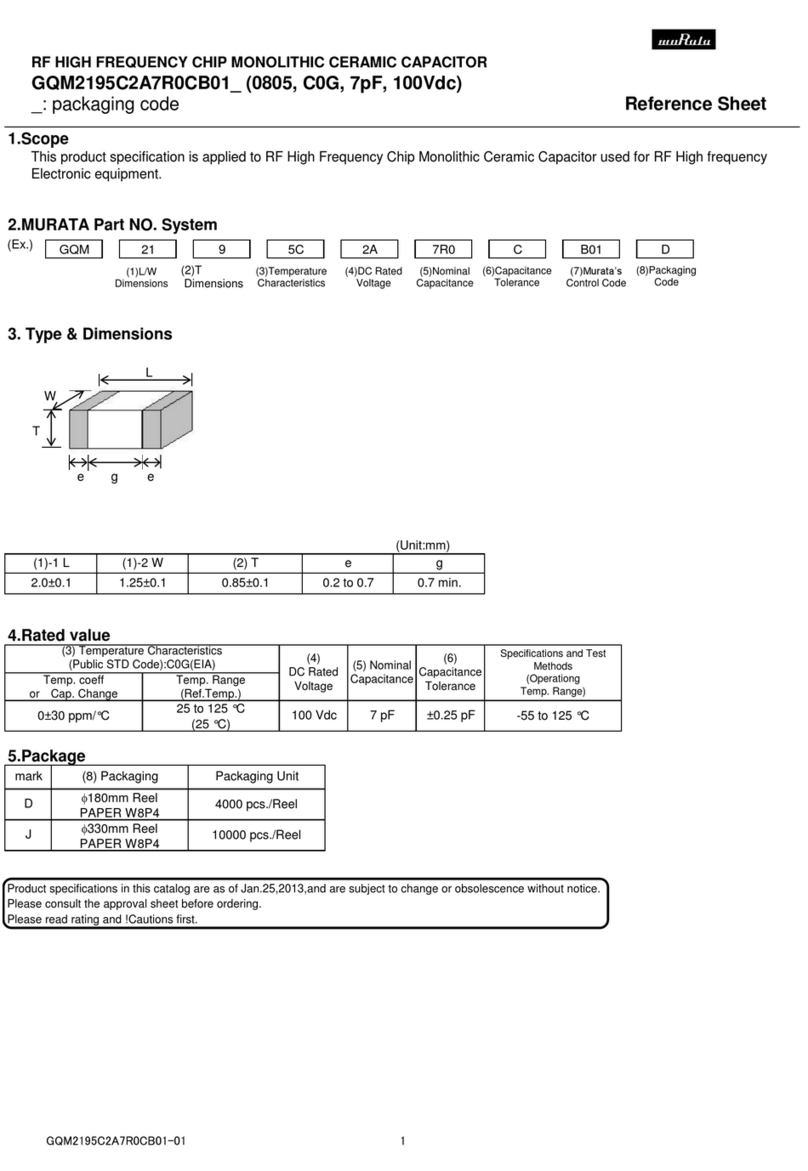

Murata

Murata GQM2195C2A7R0CB01 Series Reference sheet

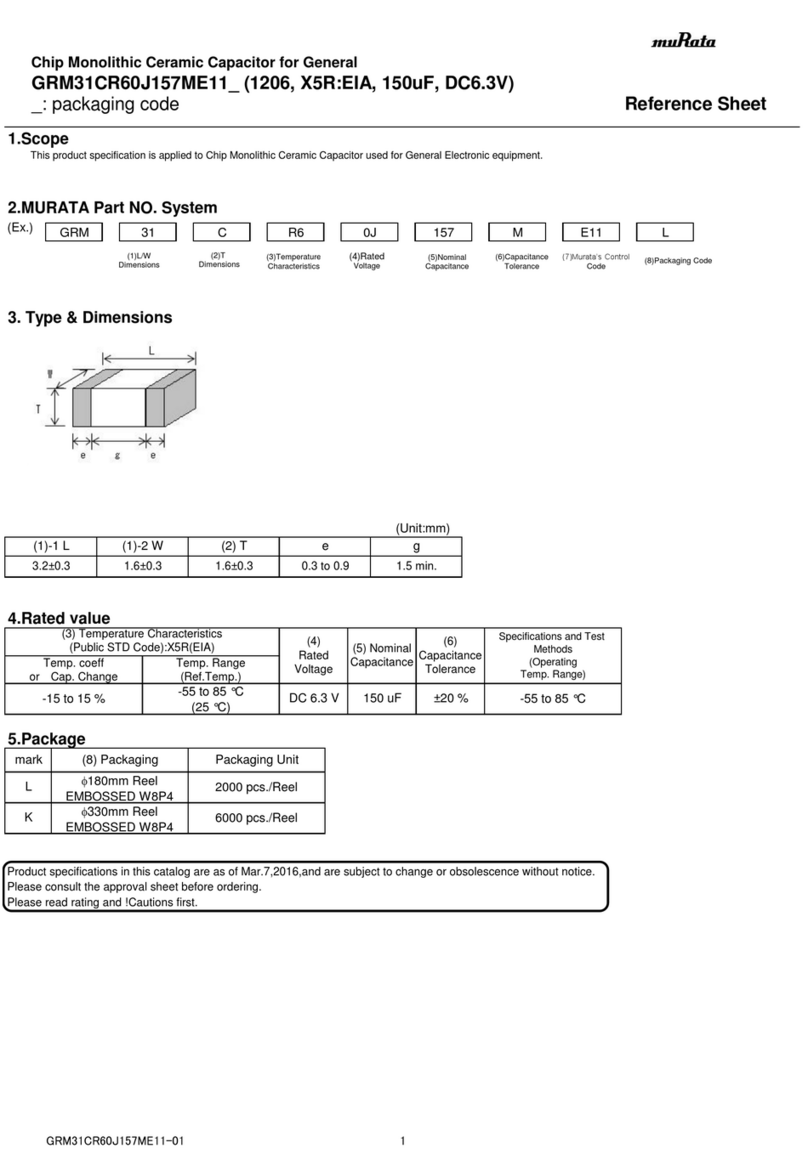

Murata

Murata GRM31CR60J157ME11 Series Reference sheet

Siemens

Siemens SIVACON 8PS BD2 Series installation instructions

nvent

nvent ERICO SRF N Series Installation and operating instructions

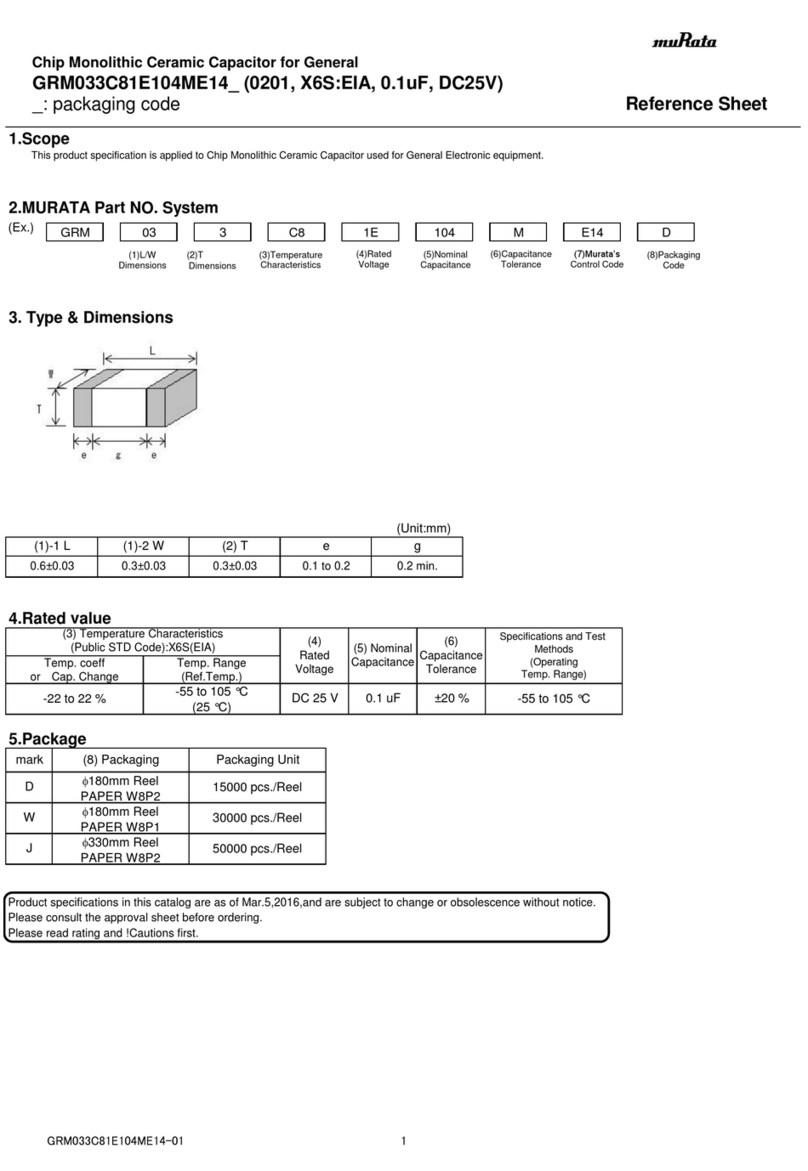

Murata

Murata GRM033C81E104ME14 Series Reference sheet

ADC

ADC ETU-911A Quick installation

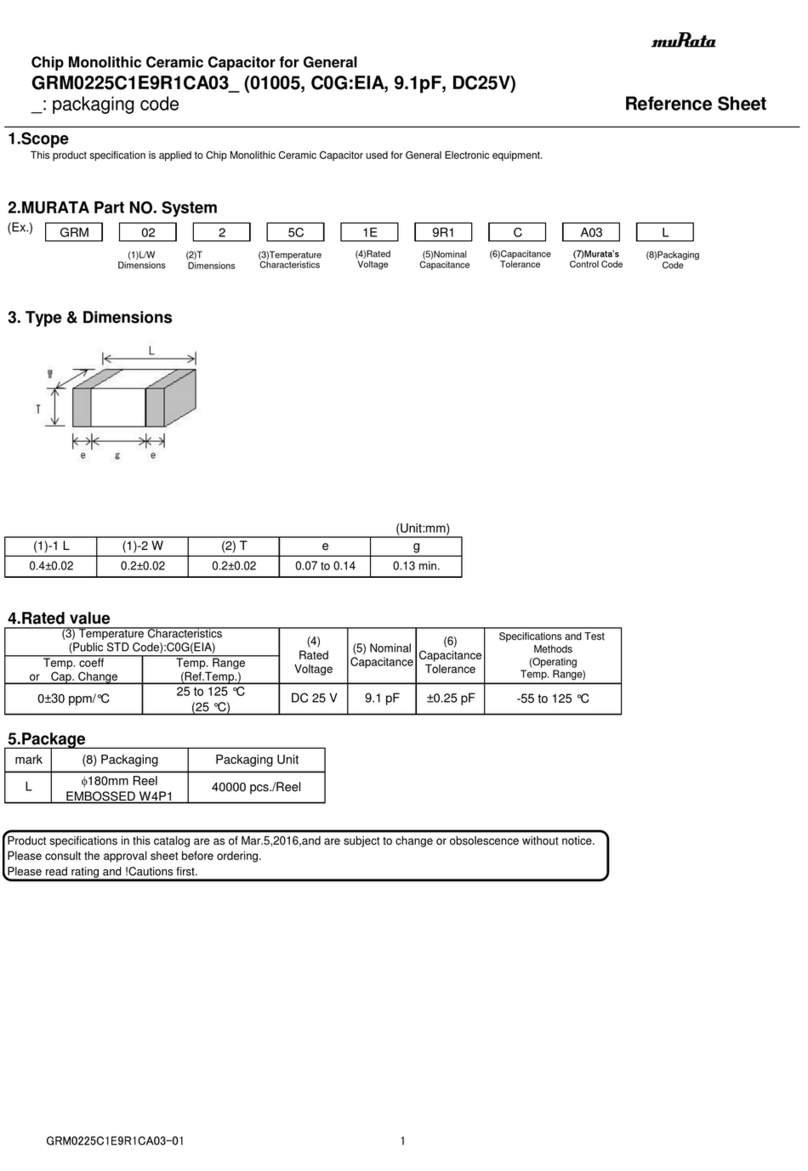

Murata

Murata GRM0225C1E9R1CA03 Series Reference sheet

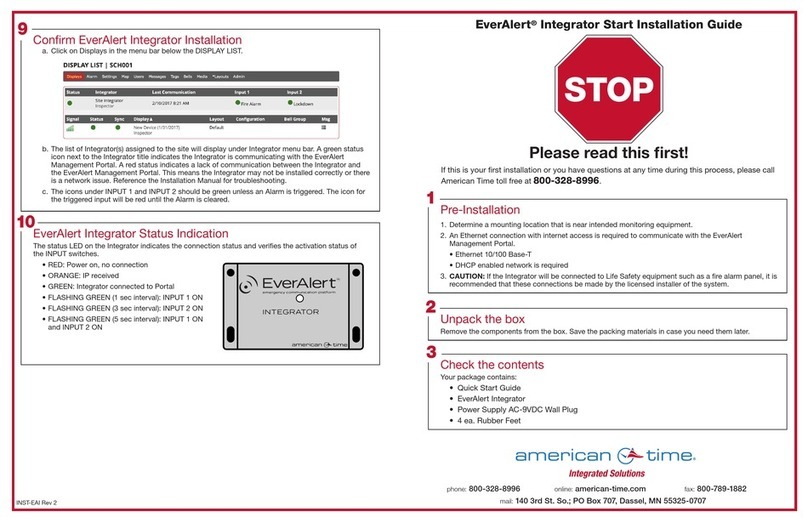

American Time

American Time EverAlert Integrator installation guide

Moeller

Moeller MSC-R series installation instructions

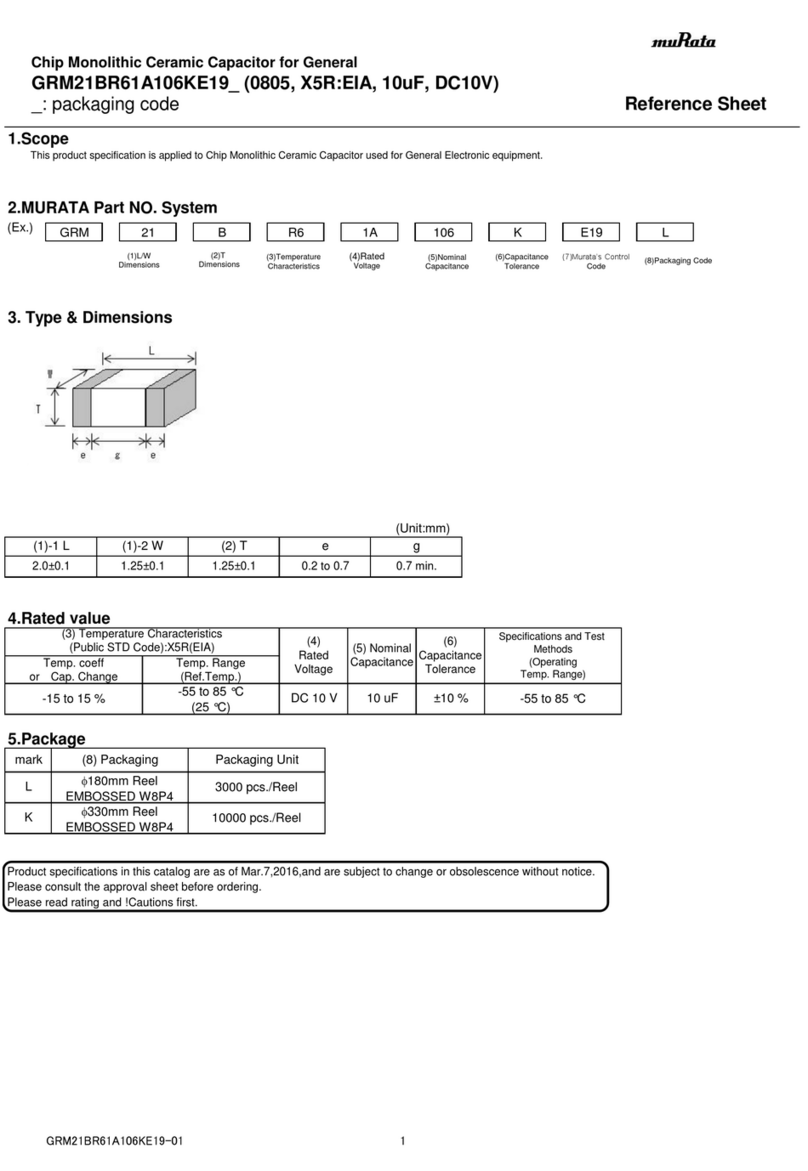

Murata

Murata GRM21BR61A106KE19 Series Reference sheet

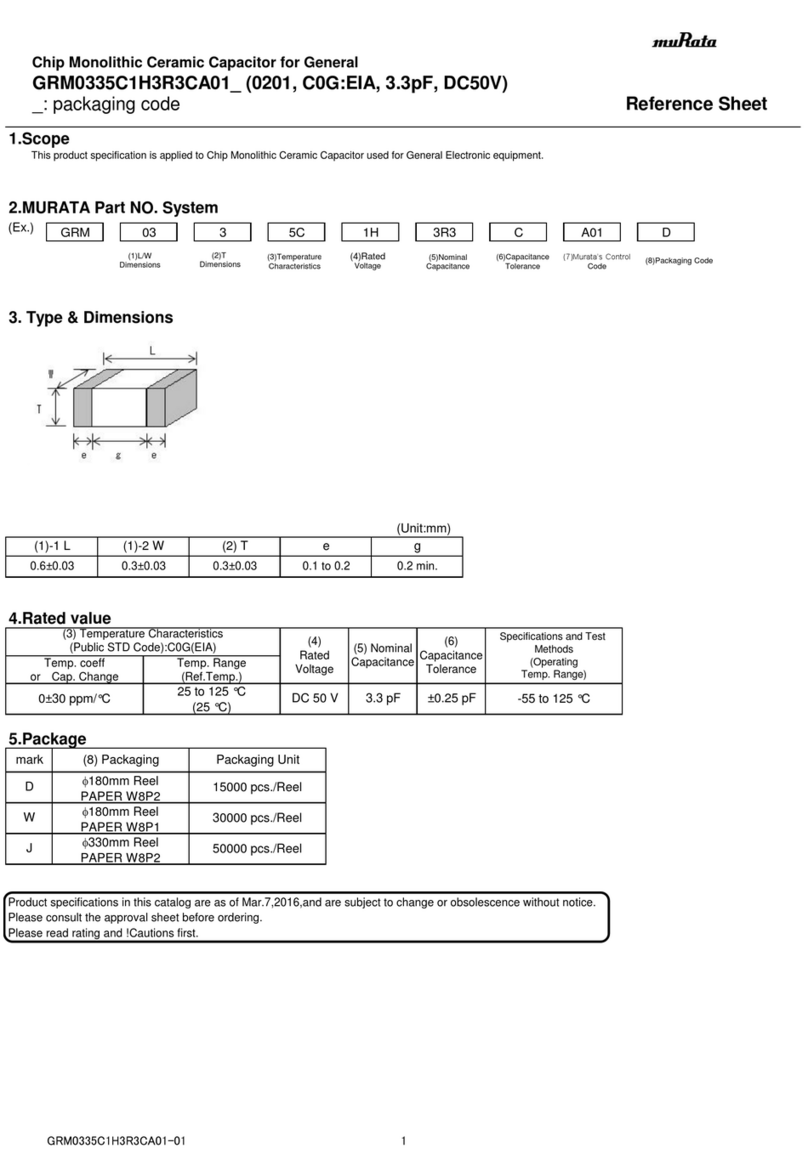

Murata

Murata GRM0335C1H3R3CA01 Series Reference sheet

Synergy

Synergy SwitchPak SPAK 4S/2D installation instructions

EUCHNER

EUCHNER ESM-F Series System manual

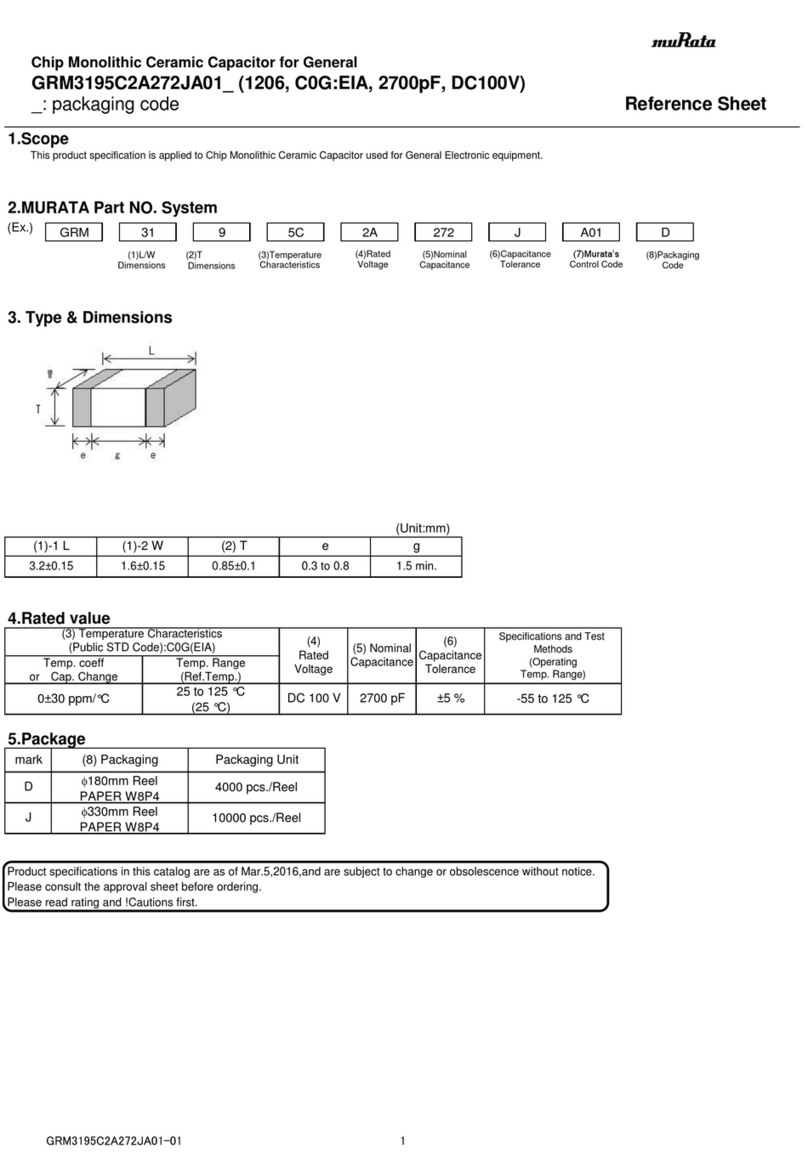

Murata

Murata GRM3195C2A272JA01 Series Reference sheet

MR

MR VACUTAP VM-Ex Installation and commissioning instructions

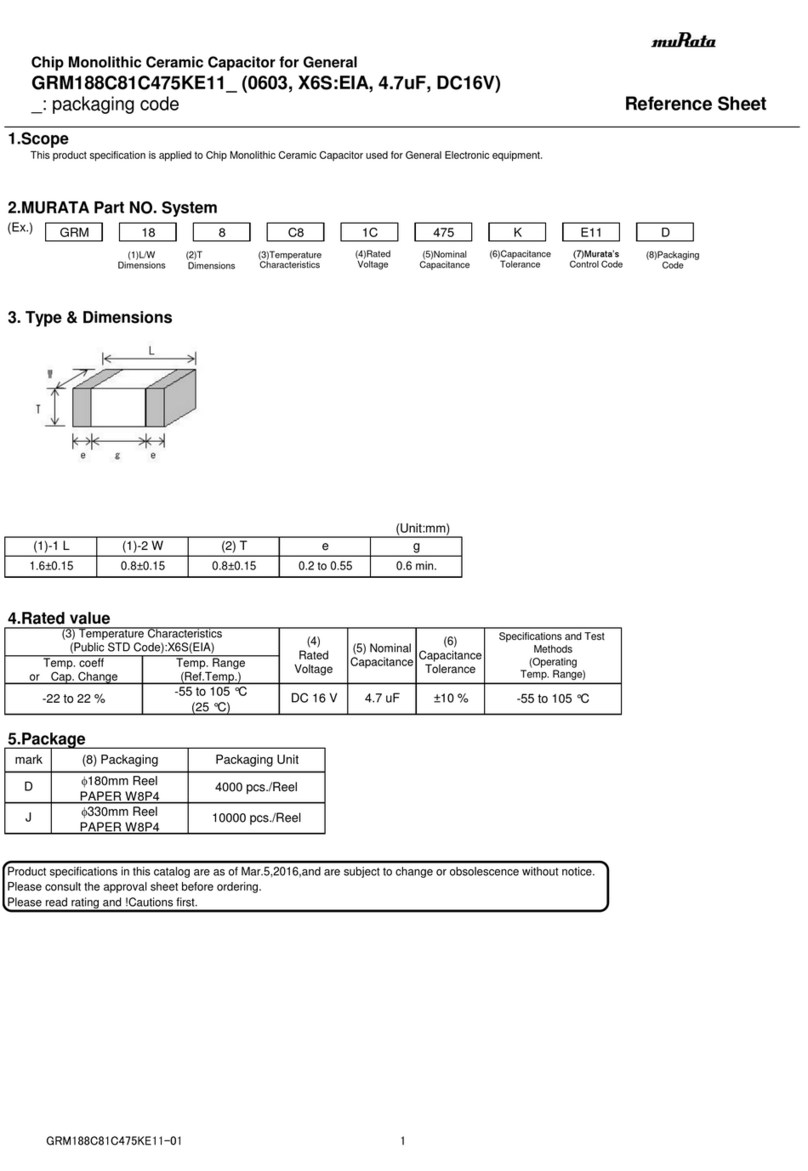

Murata

Murata GRM188C81C475KE11 Series Reference sheet